10 The Interface Solution Experts

SPA2

Programmable Current/Voltage

Limit Alarm Trips

SPA2Configuration:

Front Panel Pushbuttons

The SPA2 (HLPRG) operating parameters may be set

using front panel pushbuttons and/or Moore

Industries’ PC Configuration Software. This section

describes configuration via the front panel

pushbuttons.

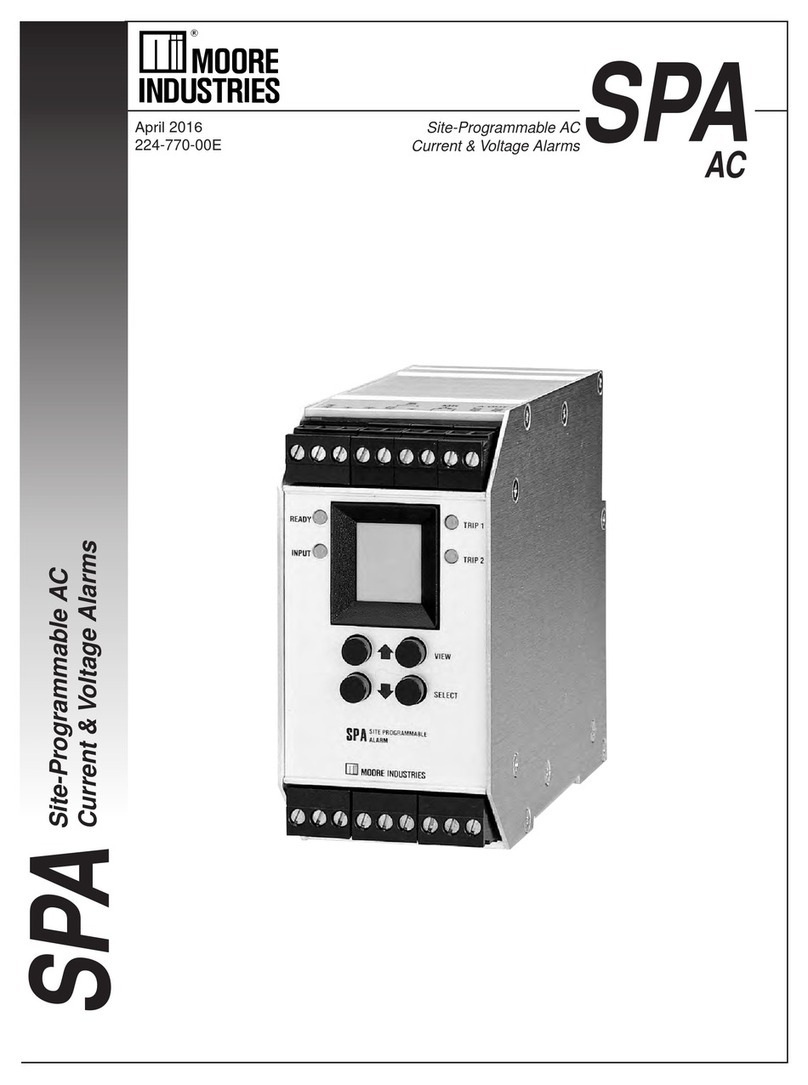

There are three pushbuttons on the unit’s front

panel;

UP

,

DOWN

and

SELECT

. Together with the

prompting messages displayed on the LCD, these

are used to access menus, and to view and change

the settings.

Use

SELECT

as your “Enter” button, to make your

selections.

Use the

UP

and

DOWN

buttons to navigate within

the menus.

Note:

All parameters, except the Custom Curve feature,

can be configured using the front panel pushbuttons.

The Custom Curve table can only be configured

using the PC Configuration Software Program.

Main Menu/View Settings

Figure 4 gives an overview of the Main menu; the

View menu is shown in Figure 5.

Upon power-up, the SPA2defaults to a display of the

measured value. Pressing the

DOWN

button ac-

cesses a series of displays that show, in succession,

the settings currently stored in unit memory.

Depending upon whether or not the Security Jumper

has been installed (Figure 2), pressing

SELECT

will

access either the first screen in the main configuration

menu, “CONFG INPUT”, or the password code query

screen, “ENTER PASS”.

Once the Main Menu has been accessed, the

DOWN

button is used to move through all of the sub-menus in

a loop. Pressing the

SELECT

button accesses the

first screen of the sub-menu shown on the LCD.

Password

This menu is bypassed if the Password Security

Jumper is not installed. If the jumper is installed, the

menu comes up when

SELECT

is pressed from the

display of the process variable input. To access the

security jumpers, you must remove the top cover

(refer to Figure 2). The menu is shown as part of

Figure 4. Refer to the

Password Configuration

section

of this manual for a more detailed description of the

password feature.

1. If the jumper is installed, pressing

SELECT

from the display of the process variable input

will bring up the “ENTER PASS” screen.

2. Press

SELECT

again to enter the “PASS”

screen. Use the

UP

and

DOWN

buttons to

enter “55”, the default screen for this point in

the menu.

3. If a password has been set (four characters,

maximum), use the

UP

or

DOWN

buttons to

display the correct password.

When the correct password number is

displayed, press

SELECT

.

Note:

If the correct password is not known, the unit

settings can be viewed, but not changed.

4. If you have entered the correct password, the

input configuration menu, “CONFG INPUT”, will

be accessed. If not, the display will show a

“VIEW ONLY” message.

5. From “VIEW ONLY”, press

SELECT

to go back

to the process variable input. Use the

UP

and

DOWN

buttons to view the settings in the

various menus. The “VIEW ONLY” mode locks

out any attempt to make changes to the

settings.

Note:

The menu to set or change the password stored in

SPA

2

memory is presented in the Password

Configuration section of the manual.