4 The Interface Solution Experts

Site-Programmable Volt &

Milliamp Limit Alarm Trips

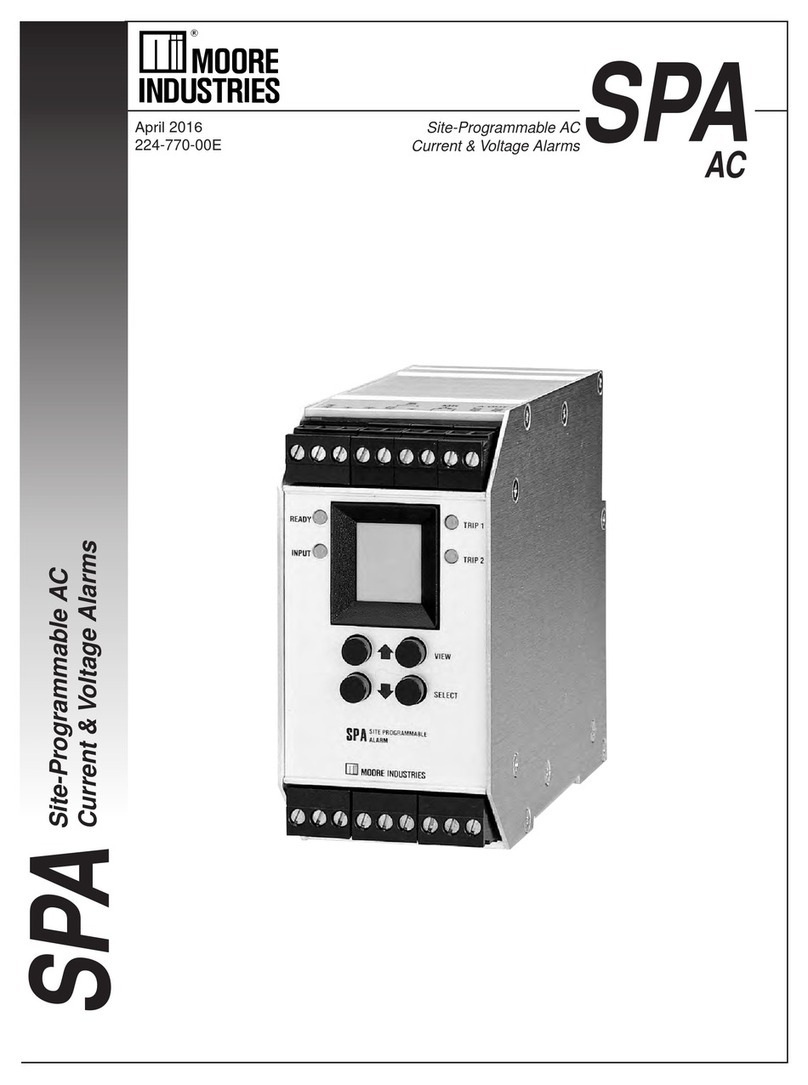

SPAVolt/Milliamp AlarmTrips

This is the users’manual for theVolt/Milliamp Input

model of the Moore Industries’ Site-Programmable

process Alarms (SPA). The SPA monitors a process

variable and provides up to four, fully configurable,

contact closure outputs whenever that input falls

outside a user-set, high or low trip point. SPAs are

typically used to activate a warning light, bell, or

buzzer; or to initiate a system shutdown, thus acting as

simple, but highly reliable and effective means of safe-

guarding a process.

Programmable Inputs

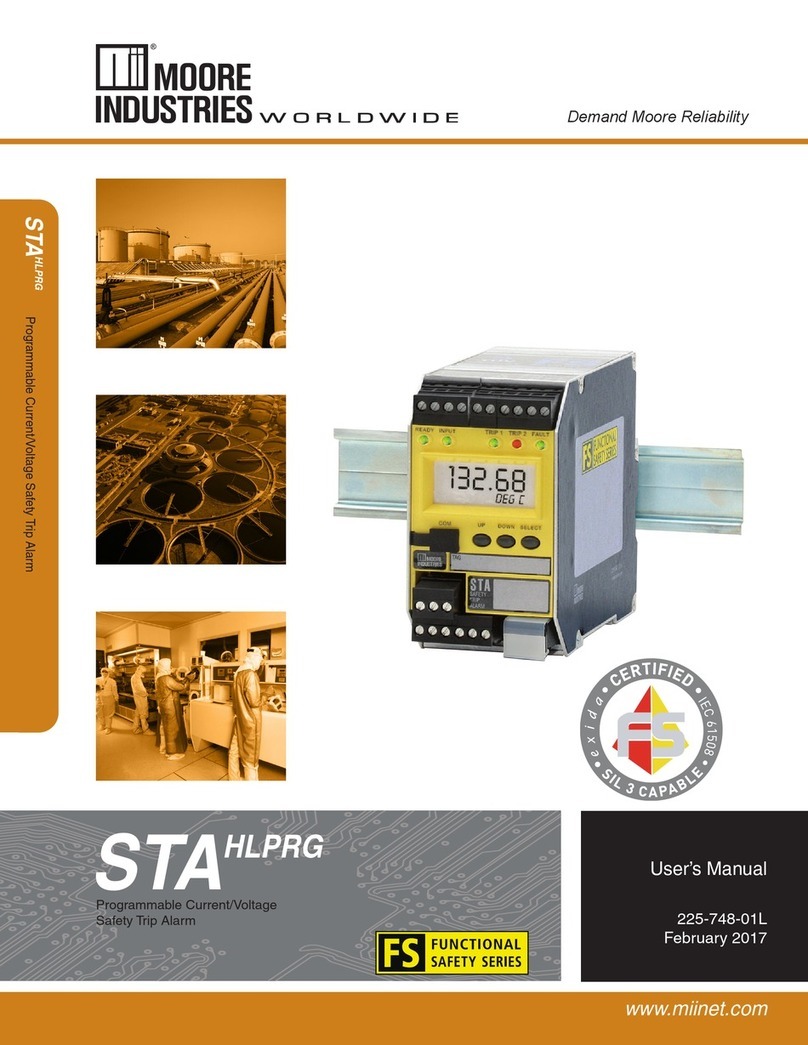

The Programmable Current/Voltage unit, or HLPRG

SPA (for “High Level” Programmable input), handles

either current or voltage inputs in any user-set span

in a 0-50mA or 0-10V range. The HLPRG comes

standard with transmitter excitation capability for use

with 2-wire loop transmitters.

Programmable Outputs

The SPA HLPRG can be equipped with a fully

scaleable analog output (-AO) option with the capacity

of being switched by the user to either 0-20mA (source

or sink), or 0-5V.

The source/sink setting for the optional analog output

is controlled by DIP switches that are located behind

an easy-to-remove access panel inside the unit’s

housing.

Programmable Display

With the Volt/Milliamp Input SPA, the user can choose

between the Linear function mode and the Custom

function mode.

In the Linear Mode, the SPA HLPRG behaves much

like a simple input meter. The display is set by the

user to show the input in either mA or volts. Its scaling

is tied to any input scaling performed. (If equipped

with the –AO option, the SPA’s output can be scaled

independent of the input.)

The SPA HLPRG’s Custom Mode sets the unit up for

independent programming of input scaling, display

scaling, and, if equipped with the –AO option, output

scaling. In Custom Mode, the user selects °C, °F, % of

scale, Blank (for raw display), or a pre-specified

4-place custom engineering unit label.

Programmable Input Failure Alarms

The SPA can be ordered with 1, 2, 3, or 4 contact

closure alarms. Each alarm can be individually

programmed for a different trip point, deadband, delay,

high or low alarming, latching or non-latching, and

failsafe or non-failsafe operation.

The SPA also provides two ways to set the alarm

trip point. If an input source is either unavailable or

inconvenient, the unit’s front panel push buttons and

integral liquid crystal display (LCD) can be used to

enter the desired trip point.

When a source is available, the SPA can capture

trip points by setting the input to the desired trip and

pressing the appropriate button.

Failsafe or Non-failsafe alarm functioning is controlled

by DIP switches that are located behind an easy-to-

remove access panel inside the unit’s housing.

Universal Mounting

The SPA is housed in a “universal” DIN case that can

be mounted on both 32mm G-type (EN50035) and

35mm Top-Hat (EN50022) DIN-rail. The Installation

section of this manual gives the dimensions of the

housings for the various SPA configurations.