Page 5

SYSTEM

Section 12

Section 13

Section 14

Section 15

Section 16

Section 17

Section 18

Section 19

Section 20

Section 21

Section 22

…….Gathering Station Electrics….…………………………….......……PAGE

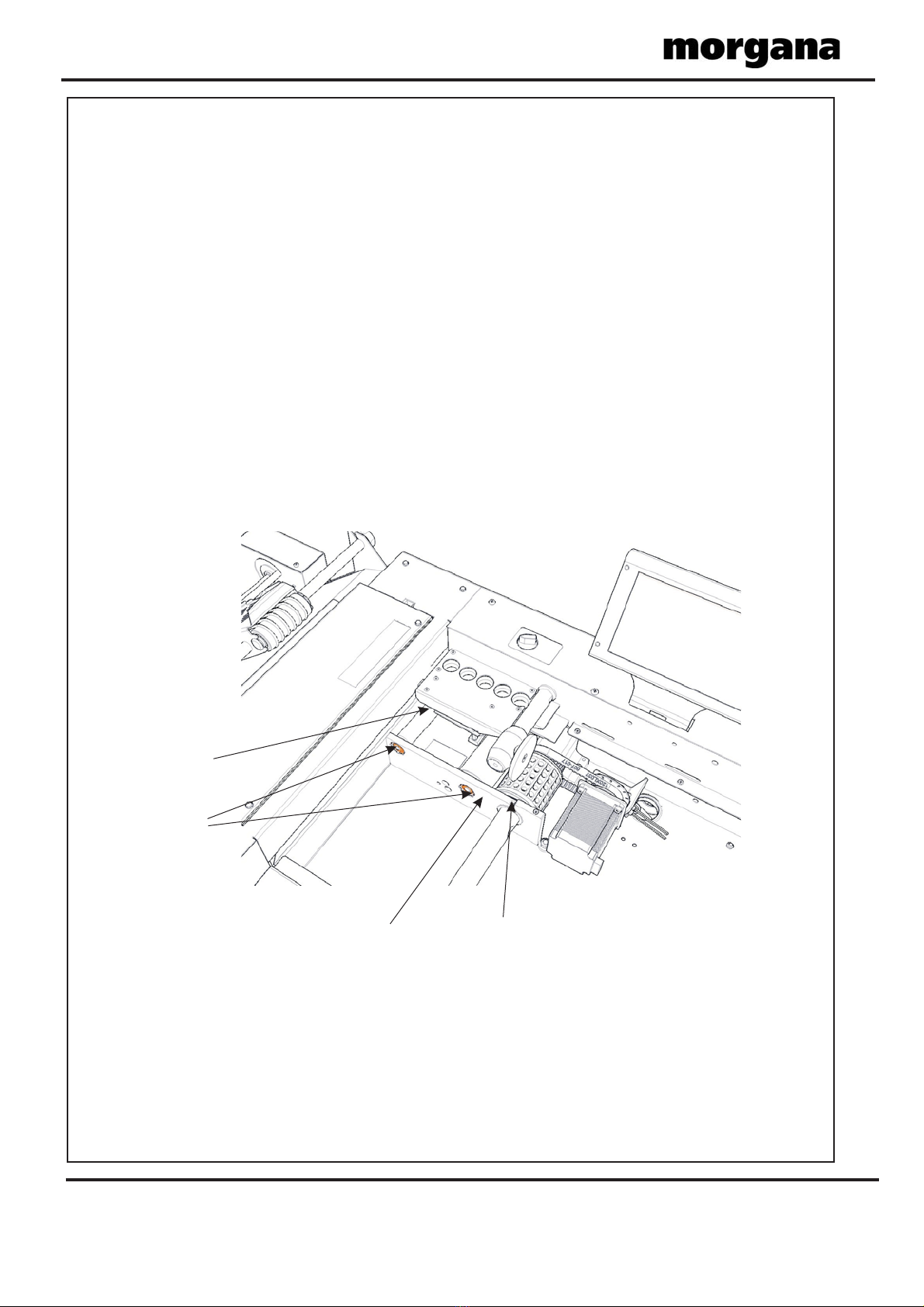

Removal/Refitting PCBs. .....................................................28

Replacement Interface PCB....................................................28

Removal/Replacement Stepper Drive PCB ............................28

Removal/Replacement Small Stepper Drive PCBs ................28

…..Optical Sensors…….…………………………………………................

Creaser - Cleaning and Setting....................................... 29

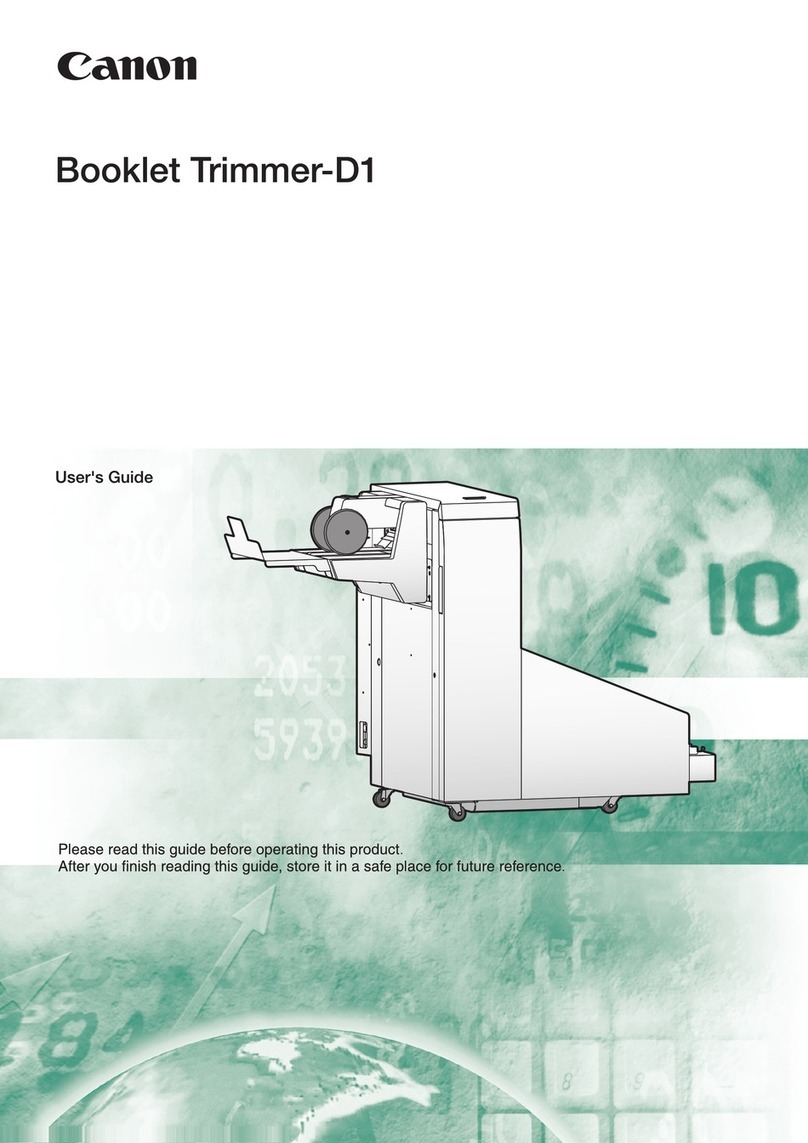

….Machine Installation............................................................................

Machine Installation....................................................31

Software upgrade Watkiss bookletmaker....................31

….Machine Set-up Prior to Calibration..................................................32

….Replacing Touch Screen Assembly…………………………..............33

…Calibration…….…………………………………………...............

Calibration of crease position ......................................34

Width Trim ...................................................................34

Calibration of Gathering Station paper guides............35

Switching from Watkiss to Nagel.................................36

Setting the Measurement System METRIC to INCH...36

Zero Total Count .........................................................36

….Trouble Shooting…………………………………………………

Error Messages.........................................................37

Camera and Double Detect.......................................37

Creasing Unit........................................................38/41

Machine Width Positioning.......................................41

Gathering Station..................................................47/48

…Creaser Circuit Diagrams………..………….……………….......…

UK - Wiring Diagram................................................49

Control PCB Connection Diagram............................50

…Gathering Station Circuit Diagrams………..………….…………

UK - Wiring Diagram...............................................51

Control PCB Connection Diagram...........................52

….Fuse Positions & Ratings ............…………………………..............53

…Image Recognition Camera………..……………….......…

Camera Replacement...........................................54/56

....

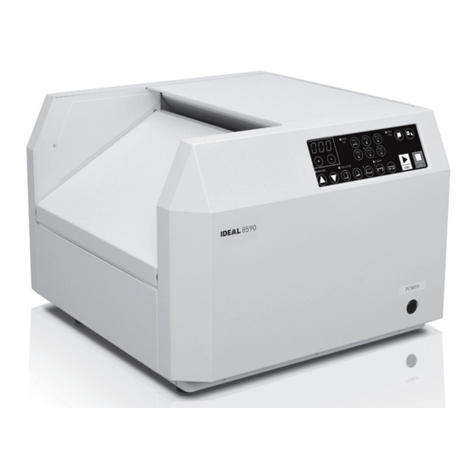

DocuMaster Pro