SYSTEM

AutoCreaser Pro 33

Page 7

SECTION 2

VACUUM DRUM REMOVAL / REPLACEMENT.

1.Remove the Compressor cover below the feed bed.

2.Remove the top stainless steel feed bed.

3.Remove the moving side guide.

4.From the underside of the fed table loosen the valve assembly by unscrewing

the two M5 posi pan head screws, allow the assembly to hang on its two pipes.

5.Inside the feed table to the rear, locate the two M4 soc cap head screws that 'position’

the black delrin housing in place, this is the support block for the drum and the choke.

6.Using a 4mmA/F ball ended allen key loosen the two screws until they are flush with

the underside of the mounting block, this will enable the delrin block to slide to the rear

of the machine.

7.Locate the M4 soc set screw in the bearing plate that is used to lock the choke tube to

the choke and using a 3mmA/F allen key unscrew until clear of the plate.

8.Twist the vacuum drum towards the motor to clear the bearing plate location hole and

withdraw the drum assembly clear of the machine.

Replacing the Vacuum Drum assembly.

Replacement is the reverse procedure.

1.Place the delrin block loosely in position .

2.Ensuring the end plug is correctly located in the end of choke tube the vacuum drum

can be manoeuvred into position, ensure the wavey washer is correctly positioned

between the drum and the bearing plate.

3.Ensure the drive belt is in place and thew 'O'ring is in the lock, slide the delrin bloc

k over the choke tube end. Using the 4mmA/F ball ended allen key tighten the two

locating screws into the feed table clearance holes.

4.Refit the vlave assembly beneath the feed table ensuring the 'O' ring is correctly

located and the two M5 posi pan head screws are tight.

5.The feed bed and compressor cover can then be refitted.

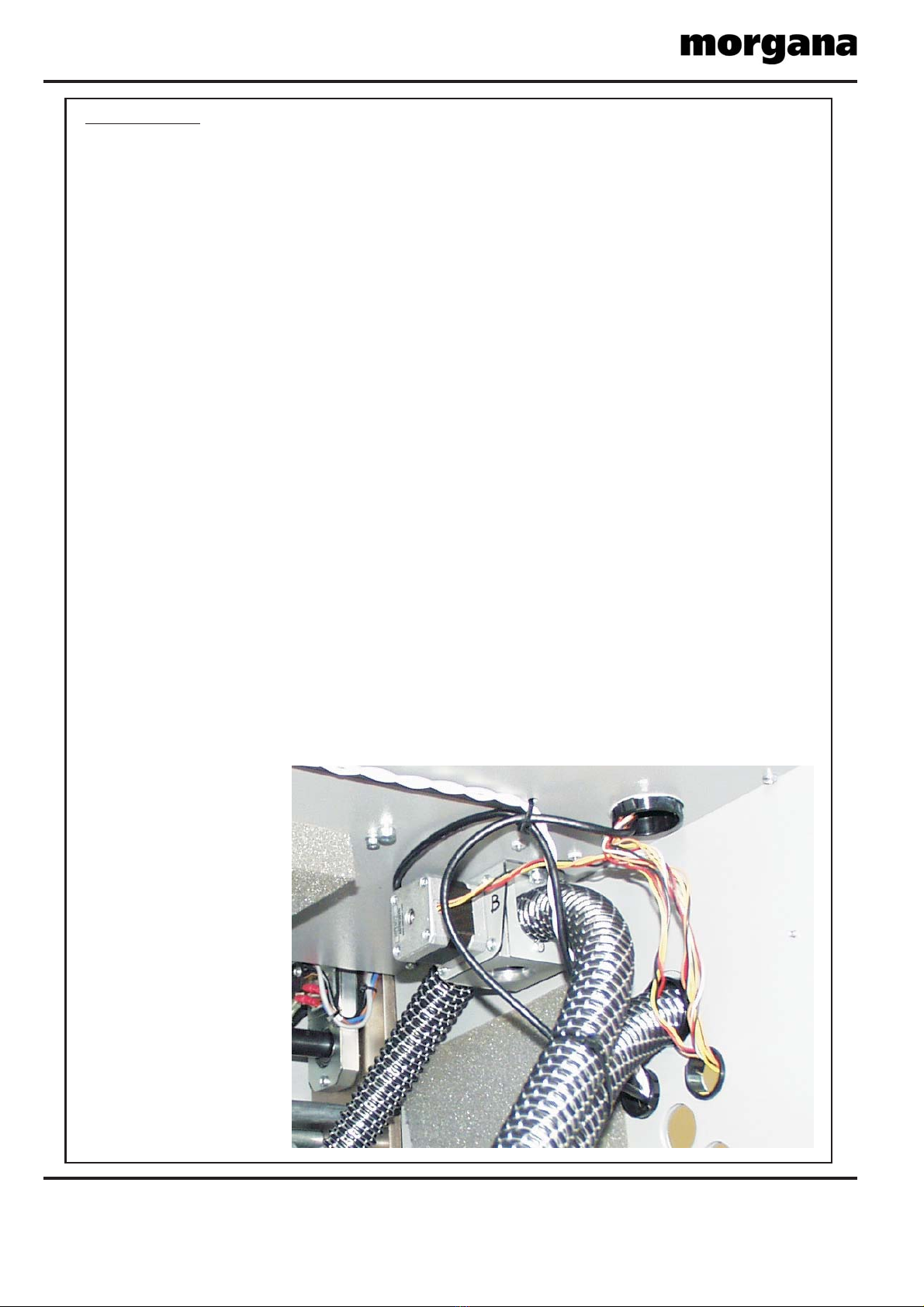

Vacuum Drum

Mounting Block

Papergate

Assembly

Sensor

Vacuum

Drum

Timing

Belt

FIG.2.1