Delivery....................................................................................................................................... 47

Lower Paper Tray ....................................................................................................................... 47

Running Test Sheets................................................................................................................... 48

Action Buttons............................................................................................................................. 48

Creating and Saving Jobs........................................................................................................... 48

Expert User Options ................................................................................................................... 49

Home .......................................................................................................................................... 49

Job completed ............................................................................................................................ 50

Check Paper Size ....................................................................................................................... 50

Job Preparation ................................................................................................................ 52

Loading Paper ............................................................................................................................ 52

Crease Pressure......................................................................................................................... 52

Setting Crease Pressure............................................................................................................. 53

3. Expert User Options........................................................................ 55

Accessing Expert User Options...................................................................................... 55

Expert User Main Menu .............................................................................................................. 55

DSD switch button ...................................................................................................................... 55

Conversion button....................................................................................................................... 56

Service menu.............................................................................................................................. 56

Plint............................................................................................................................................. 56

Settings in production ................................................................................................................. 57

Tools menu ................................................................................................................................. 57

4. Troubleshooting - General.............................................................. 59

Misfeeds/Jams.................................................................................................................. 59

Misfeed/Jam in Feeder Area....................................................................................................... 59

Jam between Units or Jam in Creaser/Folder ............................................................................ 60

Recommended Settings Adjustments............................................................................ 61

5. Troubleshooting - Fault Codes....................................................... 63

Pro 385 Fault codes.......................................................................................................... 63

General ....................................................................................................................................... 63

Pro 385 Jam Codes .................................................................................................................... 64

Pro 385 Error Codes .................................................................................................................. 69

6. Remarks ........................................................................................... 73

Do’s And Don’ts................................................................................................................ 73

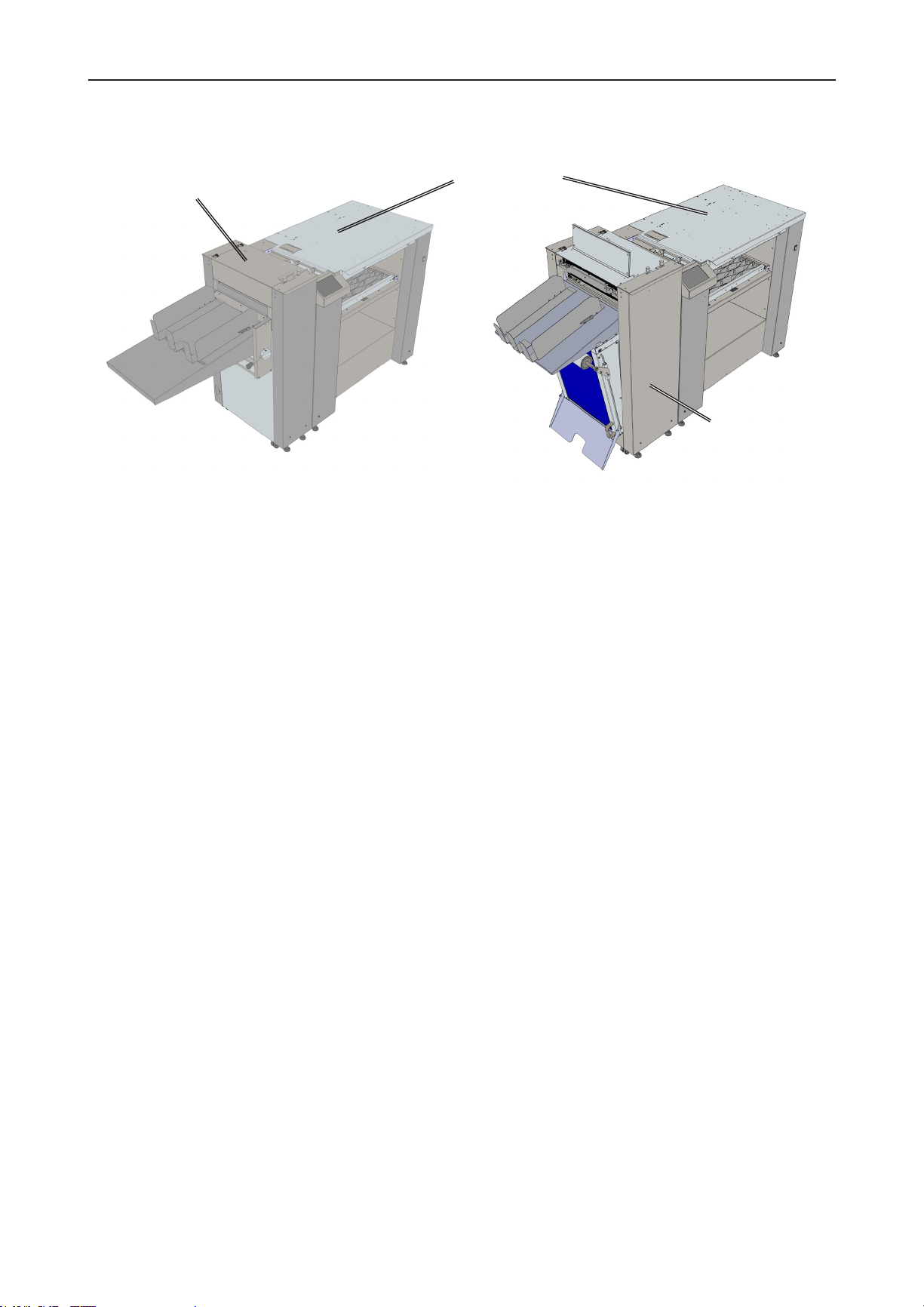

Where to Put Your Machine ............................................................................................. 74

Machine Environment ................................................................................................................. 74

Power Connection ...................................................................................................................... 74

Access to Machine...................................................................................................................... 75

Maintaining Your Machines ............................................................................................. 76

Pro 385 Maintenance.................................................................................................................. 76

Limitations of the Pro 385................................................................................................ 77

7. Specications ................................................................................. 79

Machine Specications - Feeder Pro385 ................................................................................... 79

Machine Specications - Creaser Pro385 .................................................................................. 79

Machine Specications - Folder Pro385 ..................................................................................... 79

EU Declaration Of Conformity .................................................................................................... 82

MyBinding.com

5500 NE Moore Court

Hillsboro, OR 97124

Toll Free: 1-800-944-4573

Local: 503-640-5920