5

2. SAFETY INSTRUCTIONS

General Instructions :

This pH Indicating Controller Transmitter was carefully calibrated at the factory before

shipment. When pH Indicating Controller Transmitter is delivered, visually check that no

damage has occurred during transportation.

Read this Manual carefully and understand instructions provided herein.

In general, instruments from the manufacturer may only be installed, commissioned,

operated and maintained by properly trained and authorized personnel.

Look at the ordering detail to ensure that the device is delivered according to your order.

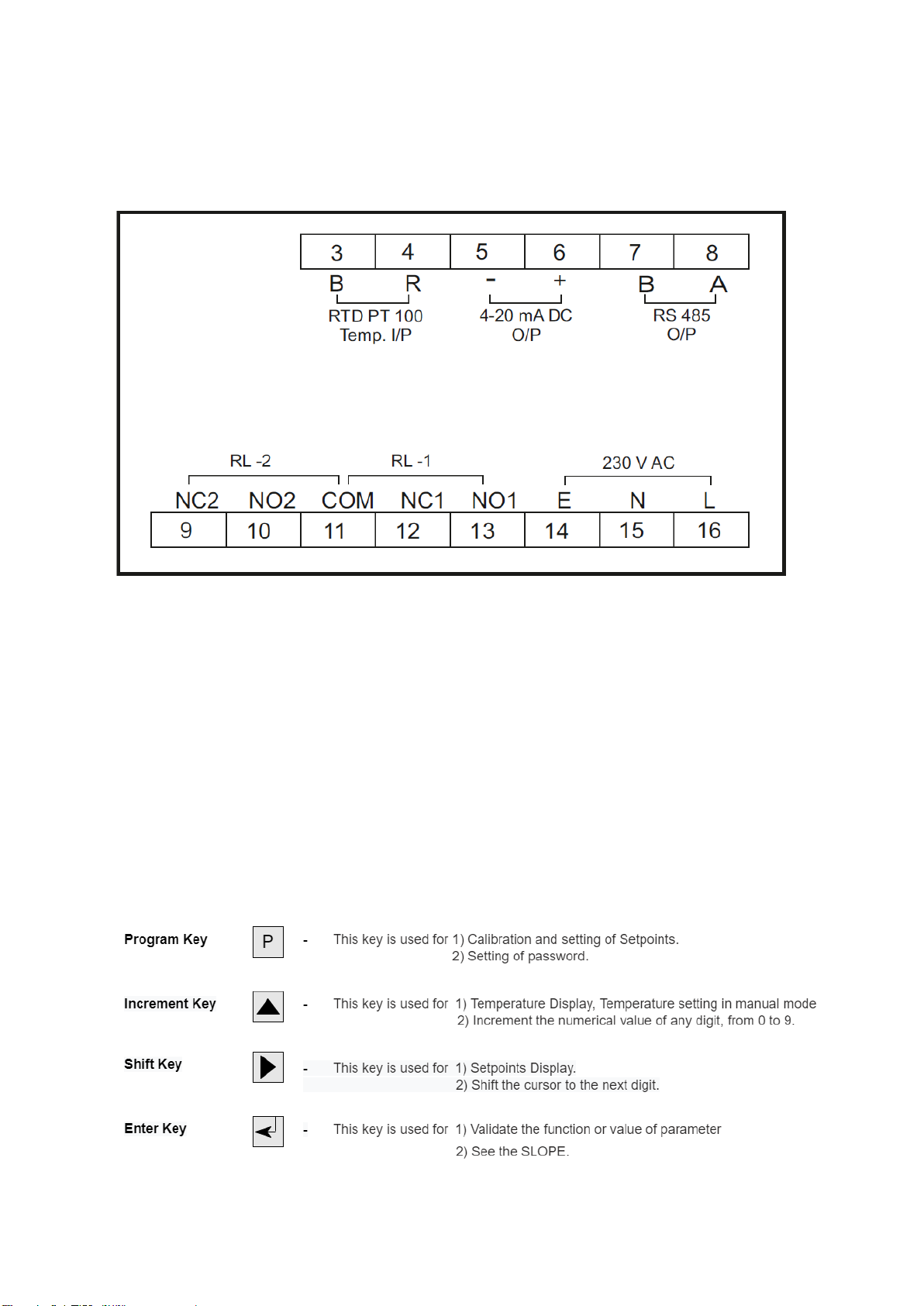

Check for the correct supply voltage printed on the back plate.

Before powering up the instrument, consider the following:

1. Check if the supply voltage is correct.

2. Do not give power supply to any other terminal.

Storage Precautions :

Store the device in a dry, dust-free location.

Avoid continuous direct sunlight.

Store the device in its original packing.

Storage temperature: 0 to 55°C.