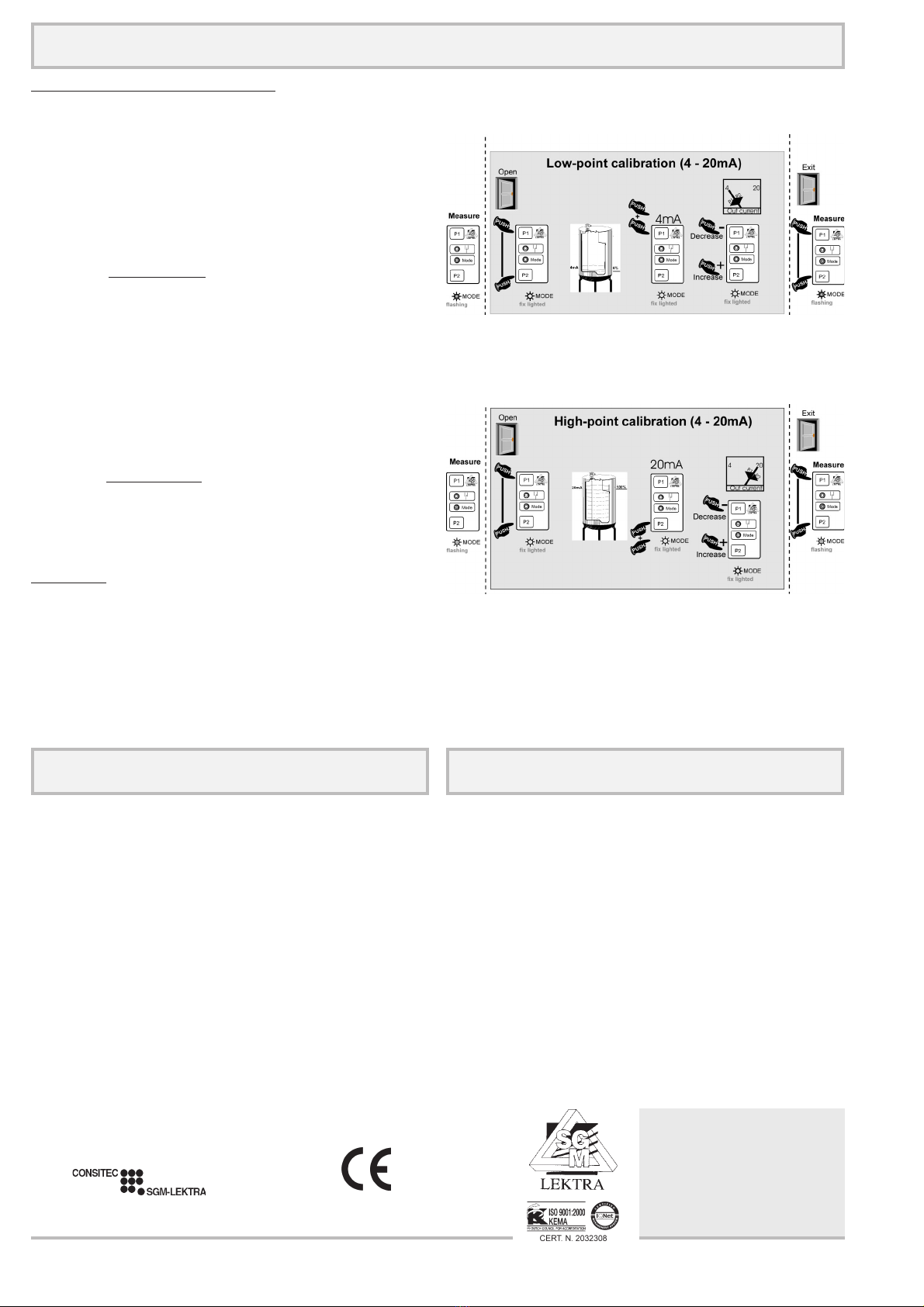

TC26-9 4-20mA Calibration (intermediate High-point , Low-point)

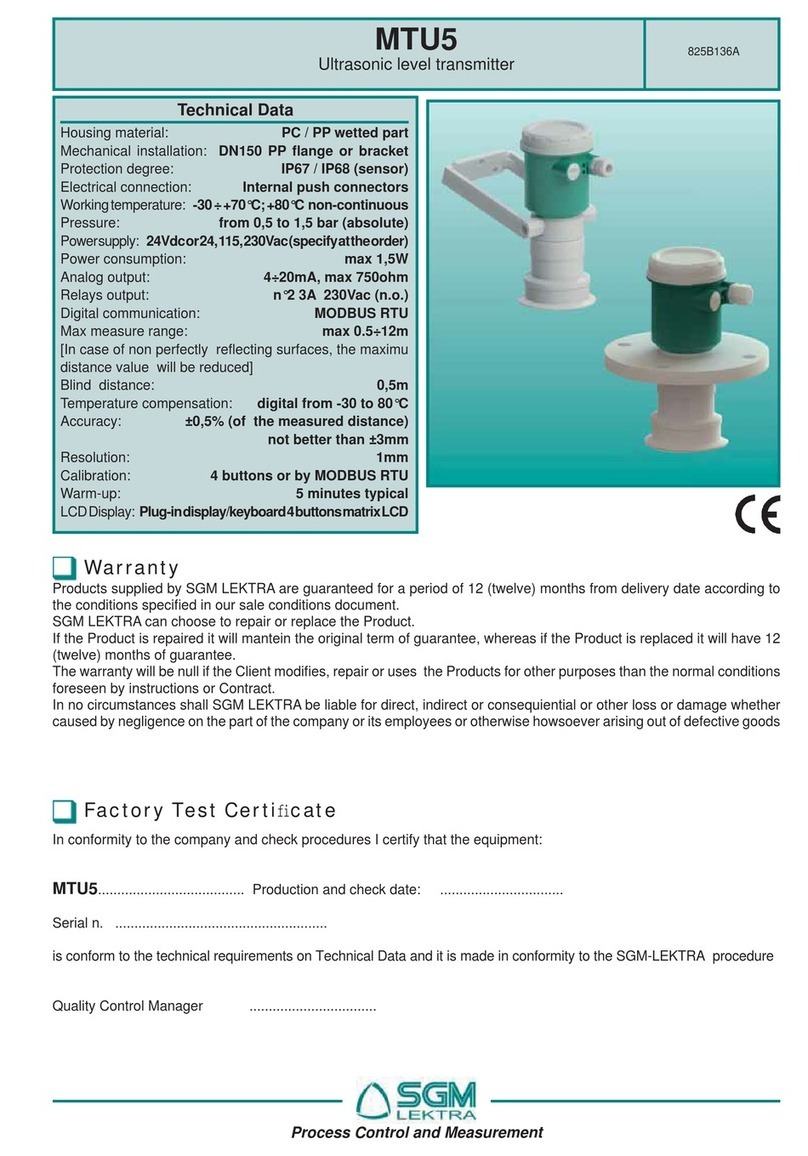

TC26-9 Factory test certificate TC26-9 Warranty

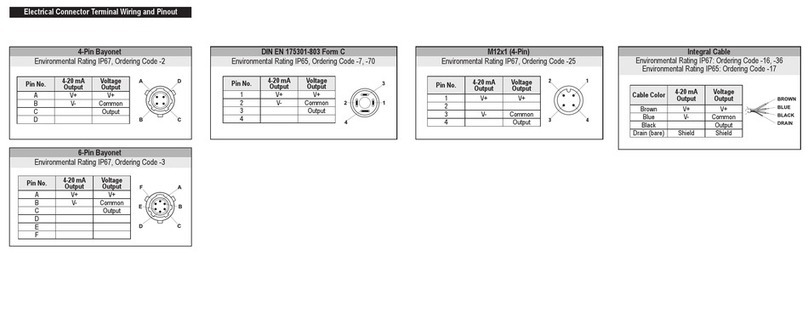

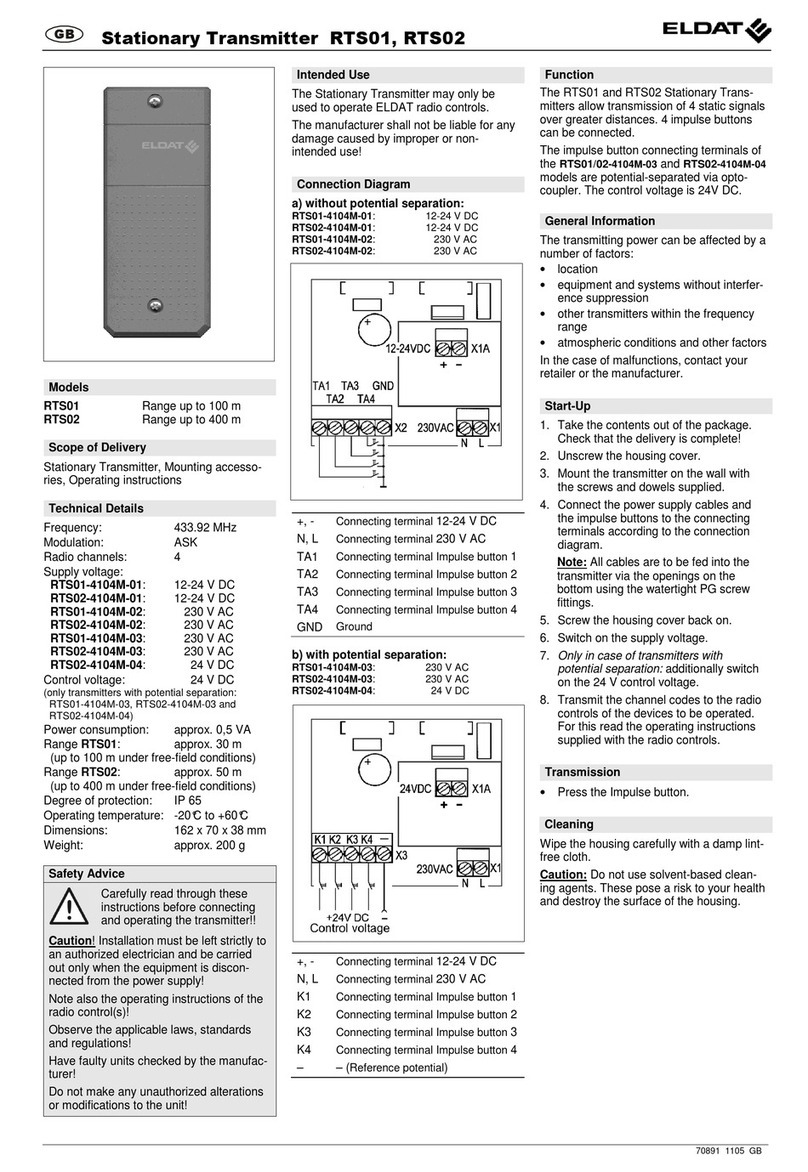

fig.11

.

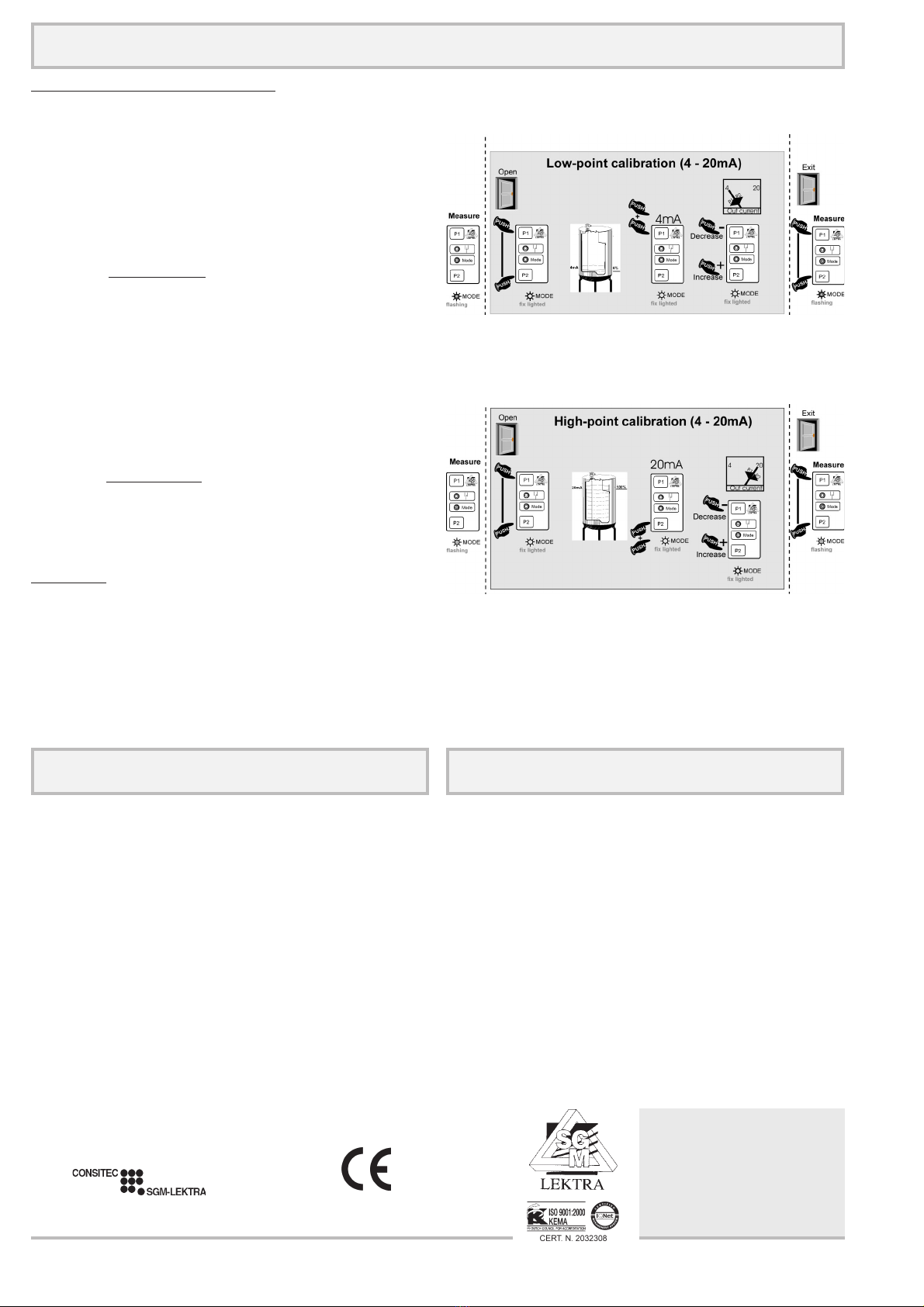

fig.10

In conformity to the company and ceck procedure I certify

that the equipment:

TC2 ............. Serial n. ......................

is conform to the technical requirements on Technical Data

and it is made in conformity to the SGM-LEKTRA procedu-

re

Quality Control Manager

.............................................................................................

Production and ceck date

.............................................................................................

The warranty expires when damages they have provoked from

the use not quite or from not correct installations. The

warranty is valid for a period of 12 months from the sell behind

presentation of this manual. All the reparations in warranty will

have realized in our workshop in Rodano (MI), the costs of

dismuonting and reinstalling of the device and the costs of the

transport will be paid by the customer.

High-point, Low-point Calibration

If only a limitate level variation is possible, the calibration of

the TC26-9 is still possible.

Need to connect a current-meter on the TC26-9 output current

and verify the present level point at which make the calibration.

Supposely you are on the Low-point calibration, and the

relevant level is 26%(8,16mA) than;

Press simultaneously P1 and P2, release them and verify

that “Mode led” will stay fix lightened, Open the calibration

mode. Press two times P1. The measured capacity has been

associated at the moment to 4mA output. Now, pushing few

times the P2 key, increase the output current from 4mA to

8,16mA, (P1 decrease the value). Once the correct current-

output is displayed in to the current meter; press

simultaneously P1 and P2 again to Exit from calibration going

in measure mode (Mode led flashing).

Increase the level of your product as much as possible, for

instance up to 58%(13,28mA) than;

Press simultaneously P1 and P2, release them and verify

that “Mode led” will stay fix lightened, Open the calibration

mode. Press two times P2. The measured capacity has been

associated at the moment to 20mA output. Now, pushing few

times the P1 key, decrease the output current from 20mA to

13,28mA, (P2 increase the value) ; press simultaneously P1

and P2 again to Exit from calibration going in measure mode

(Mode led flashing).

Important!

The calibration can be done first with low-point and than with

high-point (as the above procedure) or first with high-point and

than with low-point as well.

documentation subject to technical change with no prior warning

SGM LEKTRA s.r.l.

Via Papa Giovanni XXIII, 49

20090 Rodano (Milano)

tel. ++39 0295328257 r.a.

fax ++39 0295328321

web: www.sgm-lektra.com