CONTENTS:

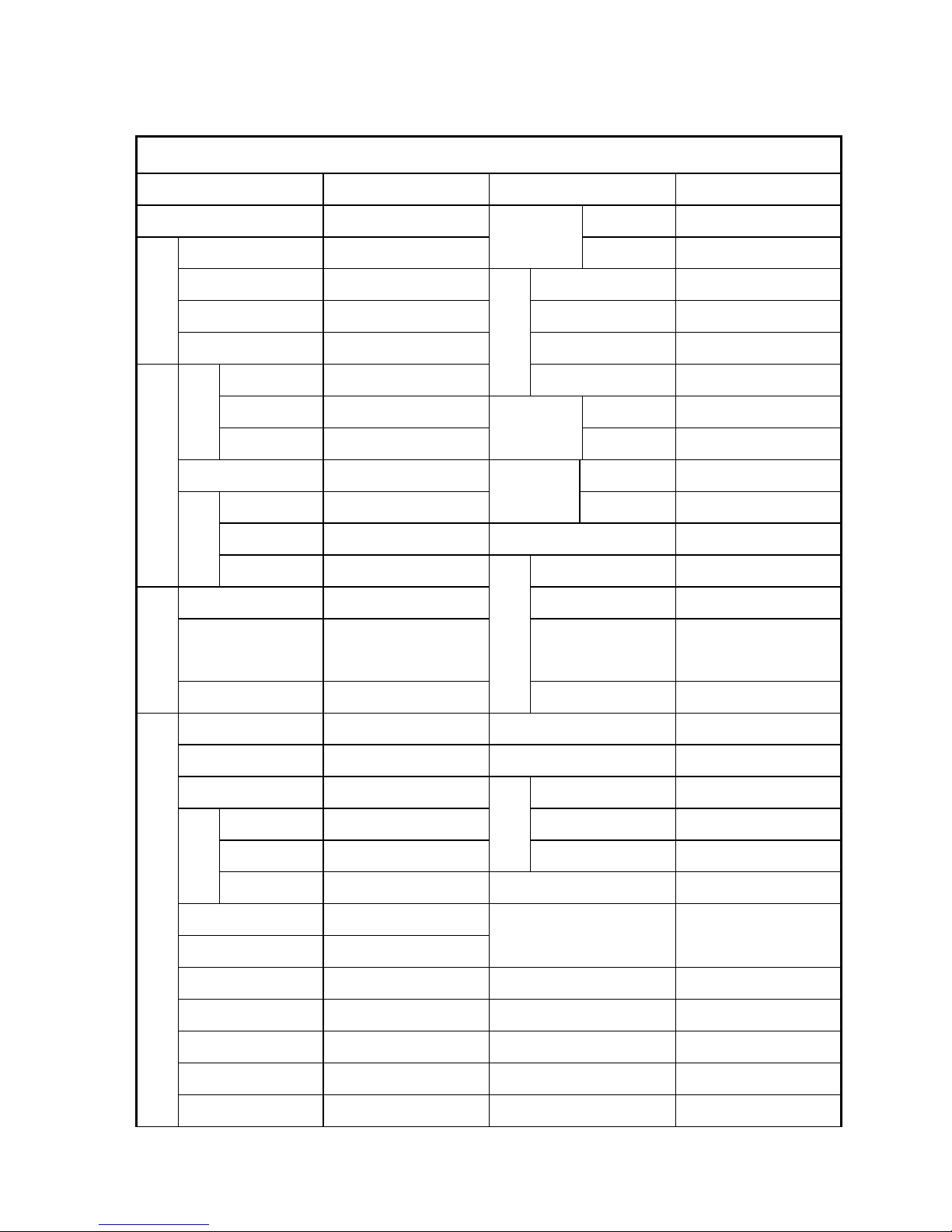

1.The specification of BLUR (ALLORO) ……………………………………………….. 1

2.Service information ………………………………………………. 3

(1)The operation notice ………………………………………………. 4

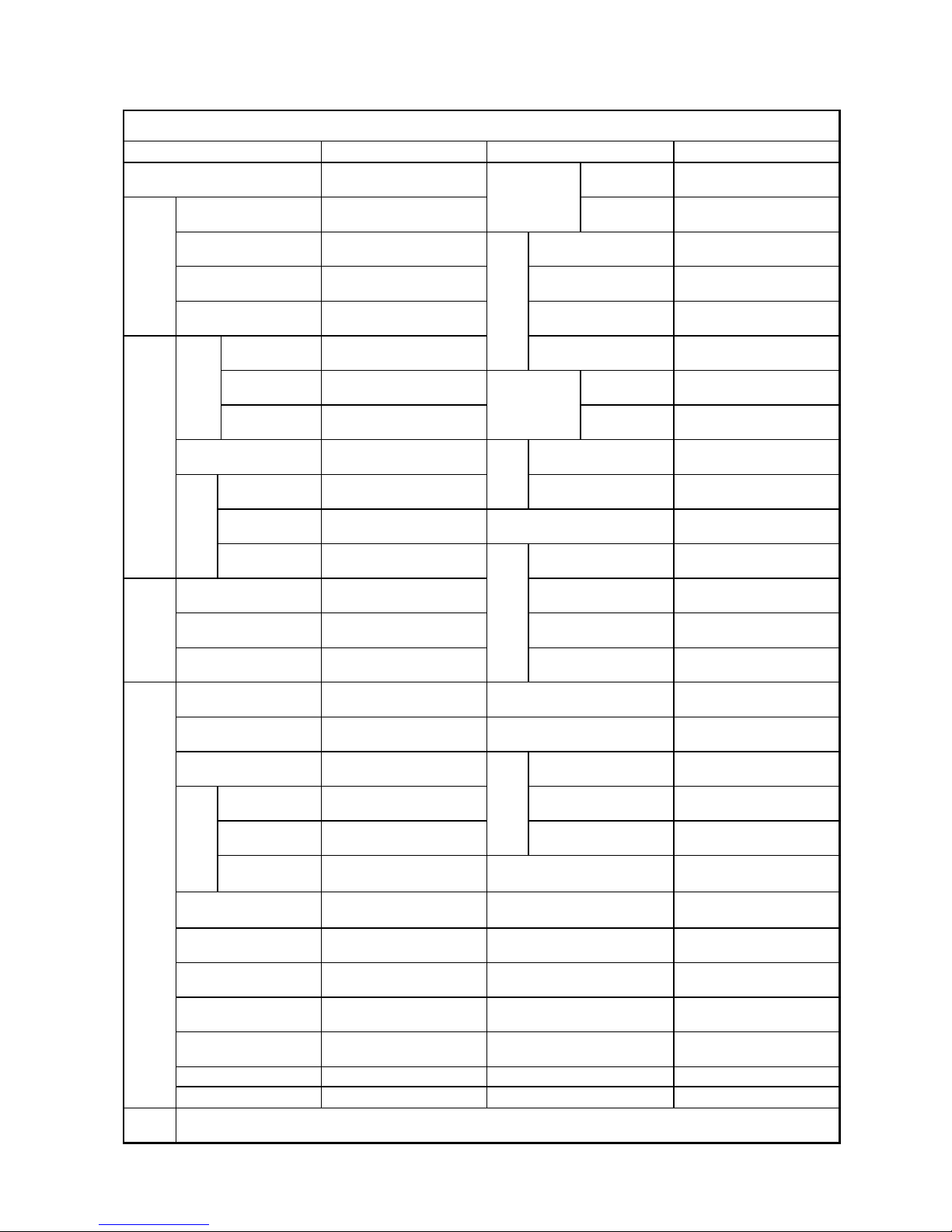

(2)Locking torque value .……………………………………………… 5

(3)Lubrication instruction ……………………………………………….. 7

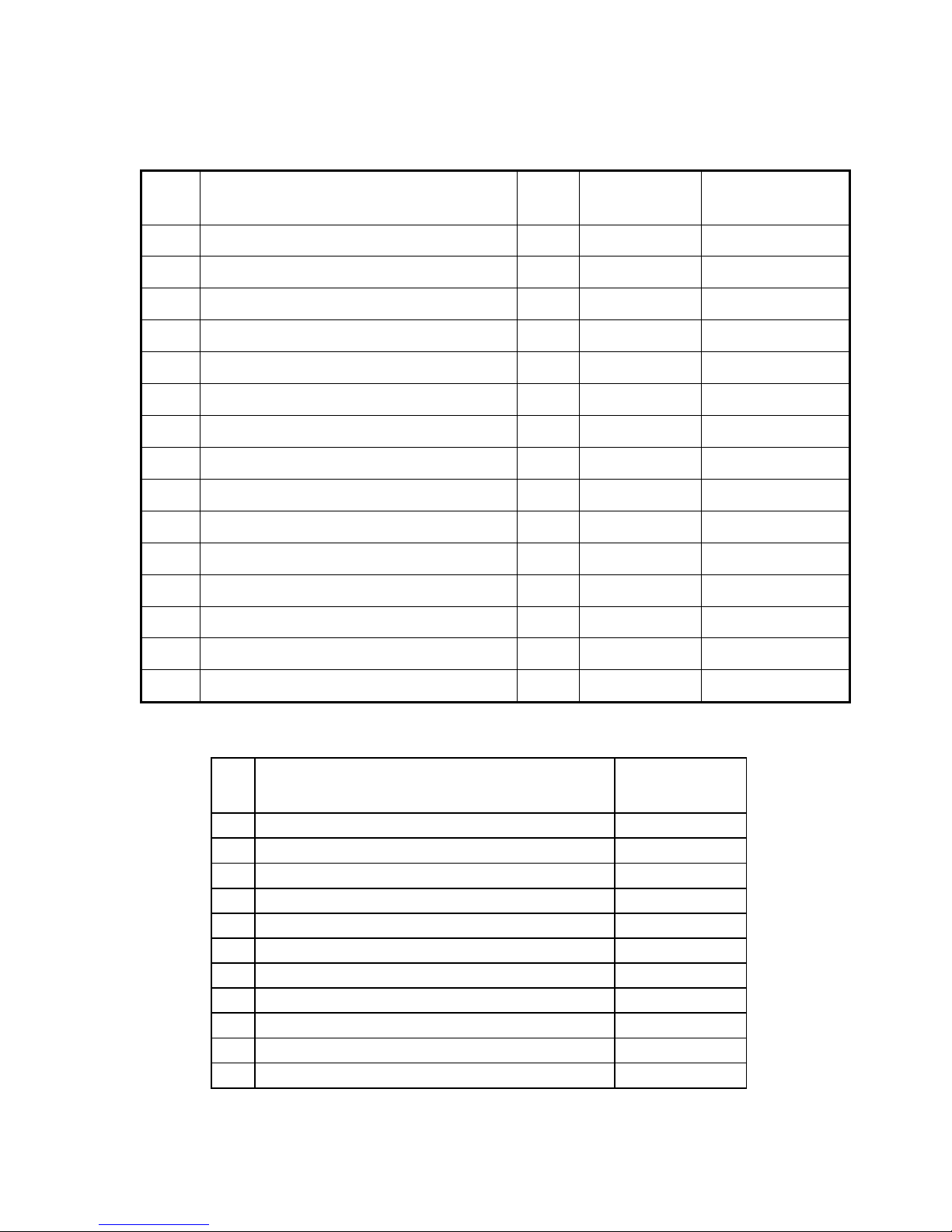

(4)Periodical maintenance table ………………………………………………. 10

(5)Troubleshooting ………………………………………………. 12

3.Checkingandadjustment ….……………………………………………..39

(1)Regular checking table …………………………………..……………40

(2)Battery …………..……………………………………44

(3)Cleaning air cleaner ………………………………………………..45

(4)The final reduction mechanism oil ……………………………………………….46

(5)Spark plug ……………………………………………….46

(6)Compression pressure measurement ……………………………………………….47

(7)Ignition timing ……………………………………………....48

(8)Throttle cables adjustment ………………………………………………48

(9)Idle adjustment ……………………………………………….49

(10)Front/Rear brake adjustment ………………………………………………49

(11) Tire ………………………………………………50

4.Dismantling, maintaining, repairing and assembling operation … ………………………51

(A). Plastic parts ……………………..………………………51

(B). BLUR 150 Engine dismantling ……………………………………………...58

(1) Lubrication system ……………………………………………..59

(2) Engine dismantling ……………………………………………..63

(3) Install Engine ……………….…………………………….63

(4) Drive pulley, starter, clutch, driven pulley …………………………………………….64

(5) Cylinder head and valve . ……………………………………………73

(6) Cylinder and piston ……………………………………………..78

(7) AC generator ………………………………...……………83

(8) Final transmission mechanism ……………………………………………..86

(9) Crankcase, crank shaft ……………………………………………..90

(10) Carburetor …………………………………………….94

(C)Steering column, front wheel, front brake comp, front fork ……………………………...107

(D)Rear wheel, rear brake, rear damper ……………………………………………115