Thank you for purchasing the MotoAlliance’s Lawn Tractor Plow System by MotoAlliance! Fully

engineered in the USA.

Warning And User Caution

- Never allow passengers to ride on the blade while plowing

- Stay clear of bystanders while plowing

- Do not exceed 10 MPH with blade installed

- Always wear safety gear (helmet, glasses, etc) when plowing

- Always put your vehicle in Park before changing the angle of the plow blade

- Use extreme caution when plowing and riding on sloped surfaces

- Avoid all fixed objects and always wear a seatbelt

- Be cautious of the blade when lowering it from an upright position

- Always store your blade resting on the ground

Maintenance:

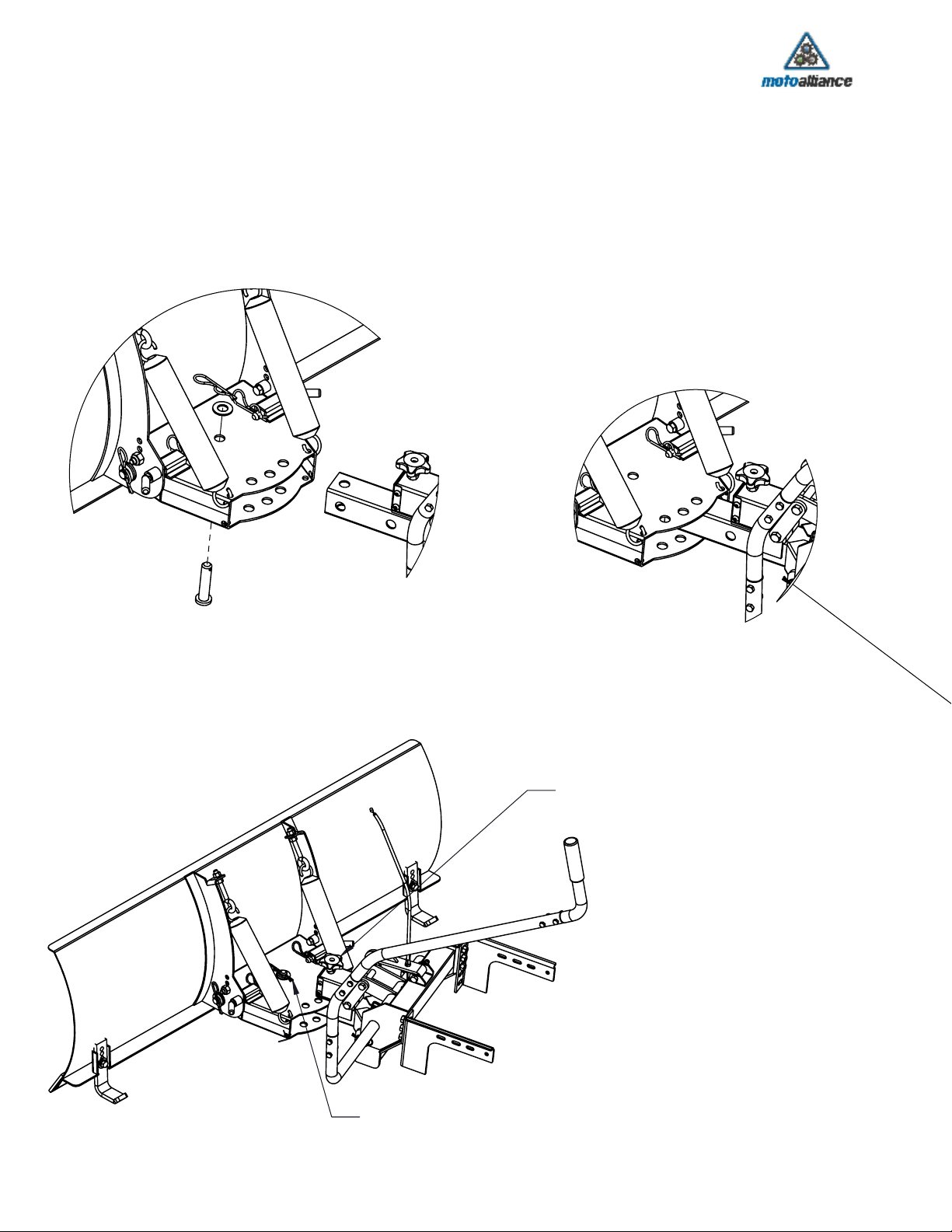

It is recommended to check all hardware on the Lift System from time to tim. Loose or worn

hardware could cause severe damage to the lift and plow system, or injury to the operator in

the event of component failure.

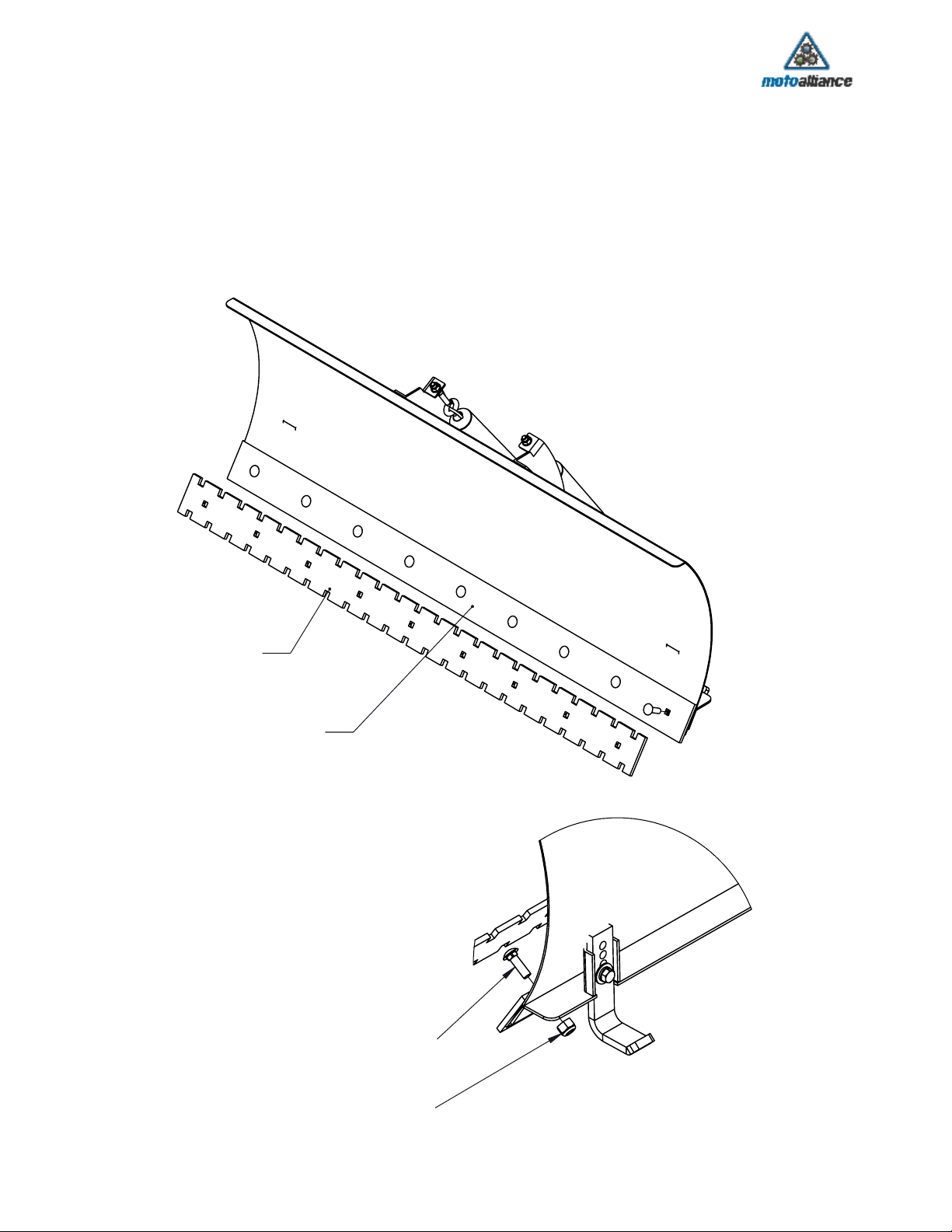

Some degree of paint scratching or chipping is inevitable during the plowing season. We recommend

purchasing a rust preventing paint at the end of the season to be applied per the manufacturer's

recomendation on areas of exposed metal.

Long Distance Travel:

When transporting long distances (1/4 mile or more) it is receommended to secure the plow blade to

the lawn mower with a rachet strap to prevent the plow blade from bouncing and causing potential

damage to the lawn mower or lift system.

23001 Industrial Blvd, Rogers, MN 55374

1-866-527-7637 (toll free)

1

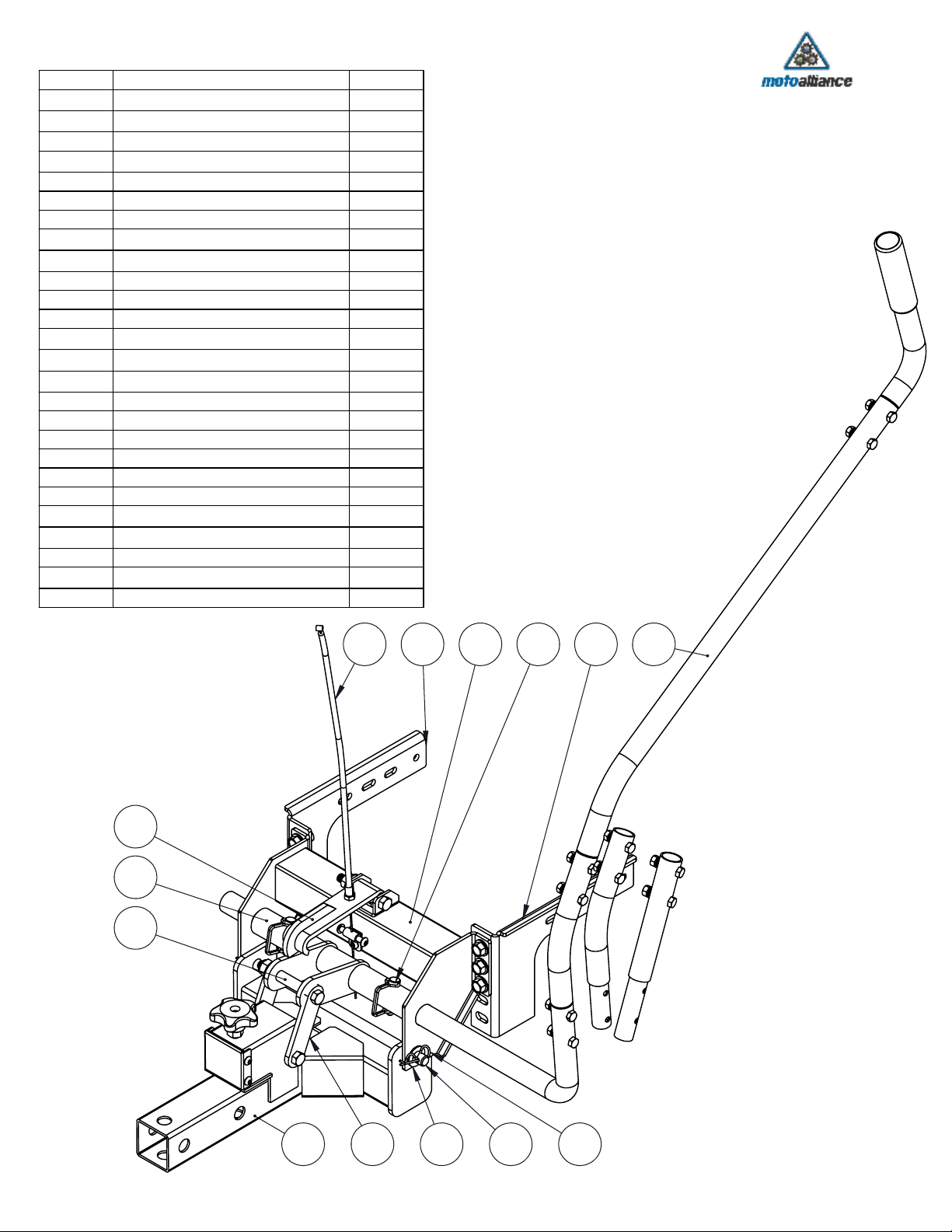

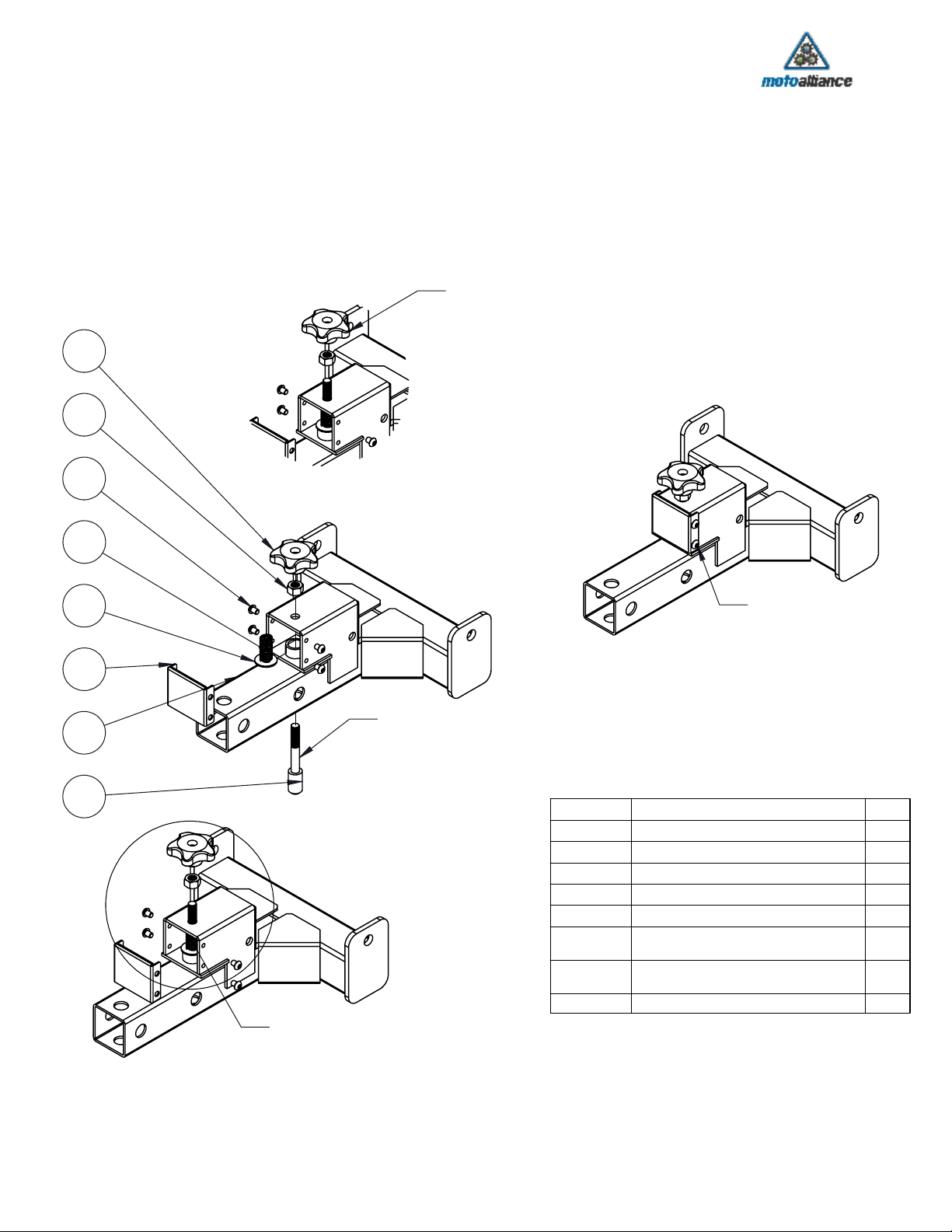

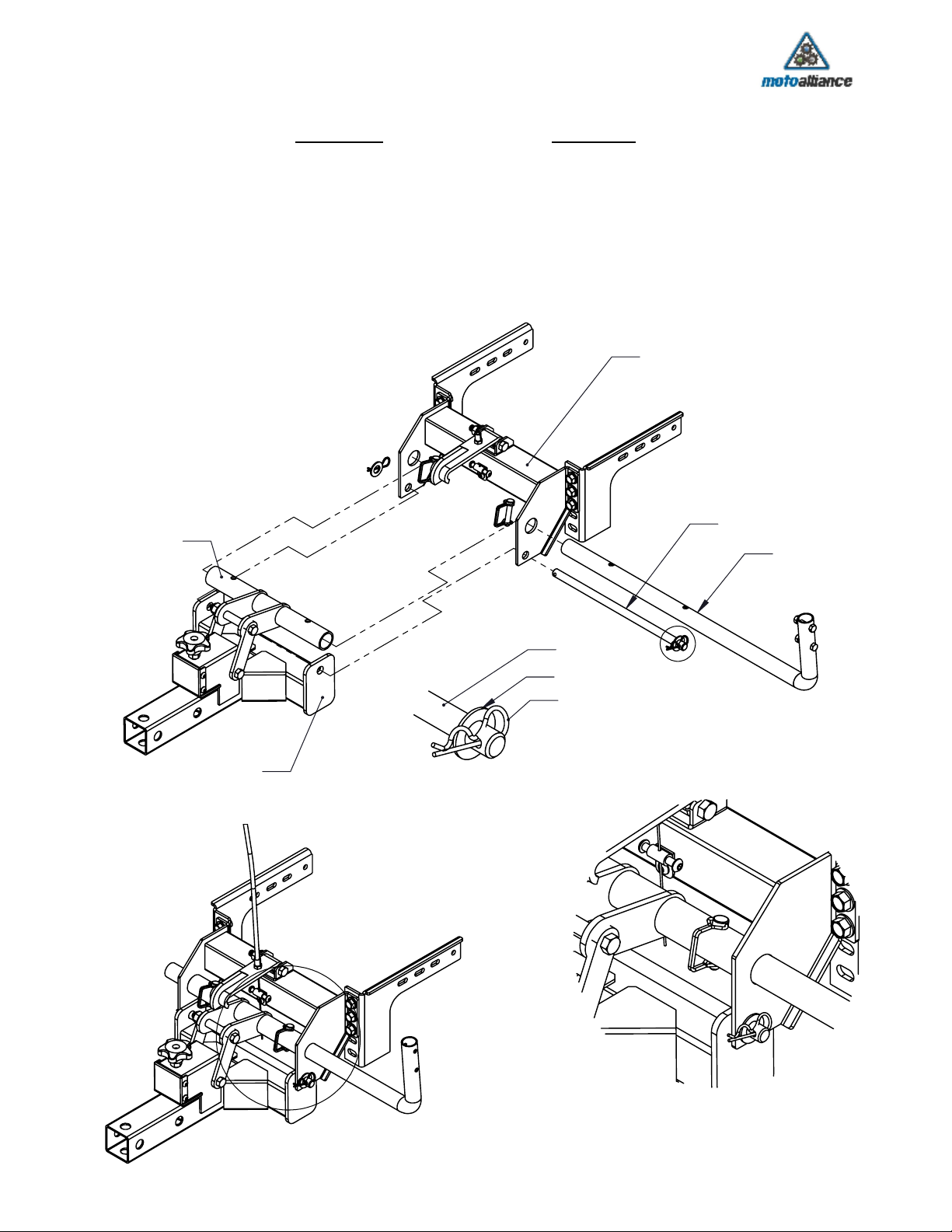

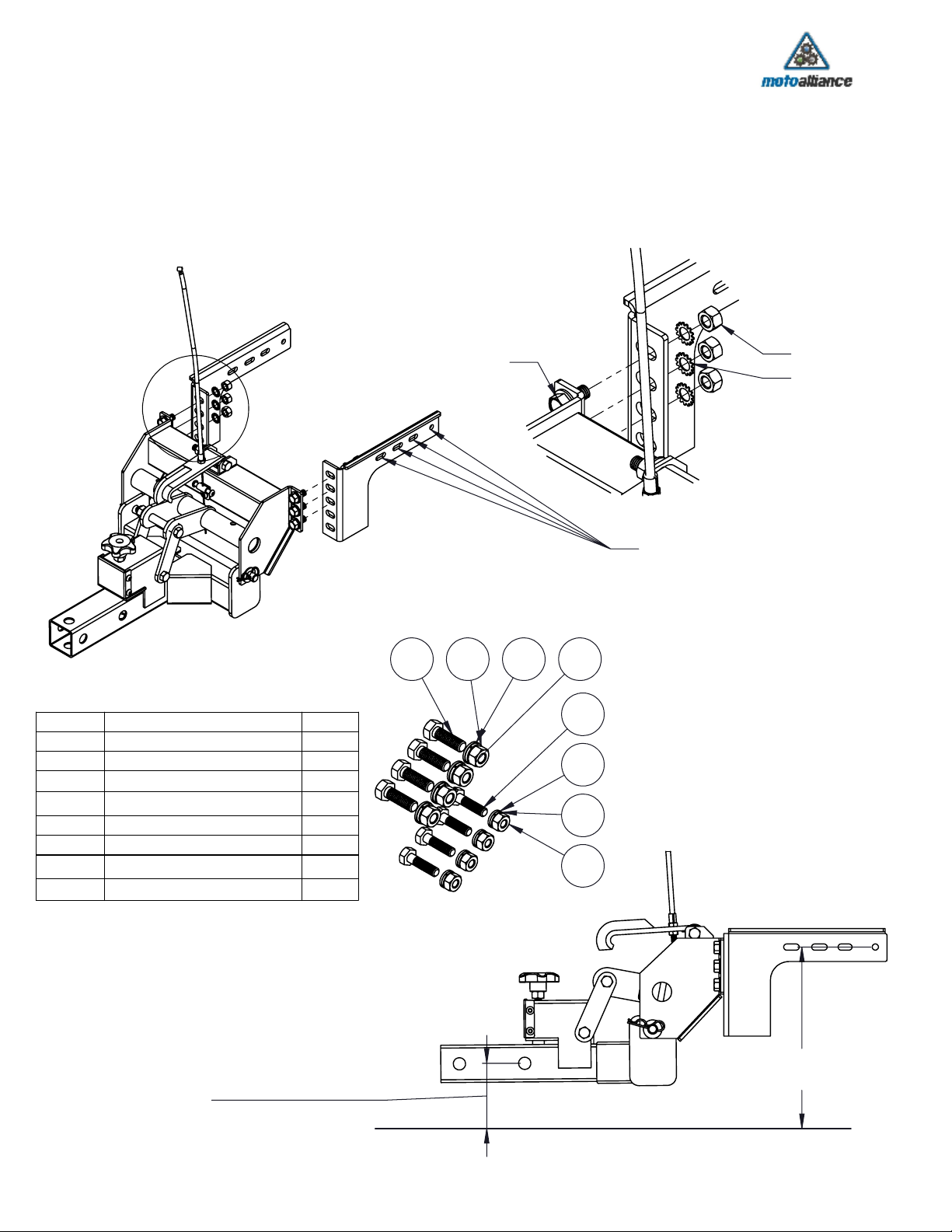

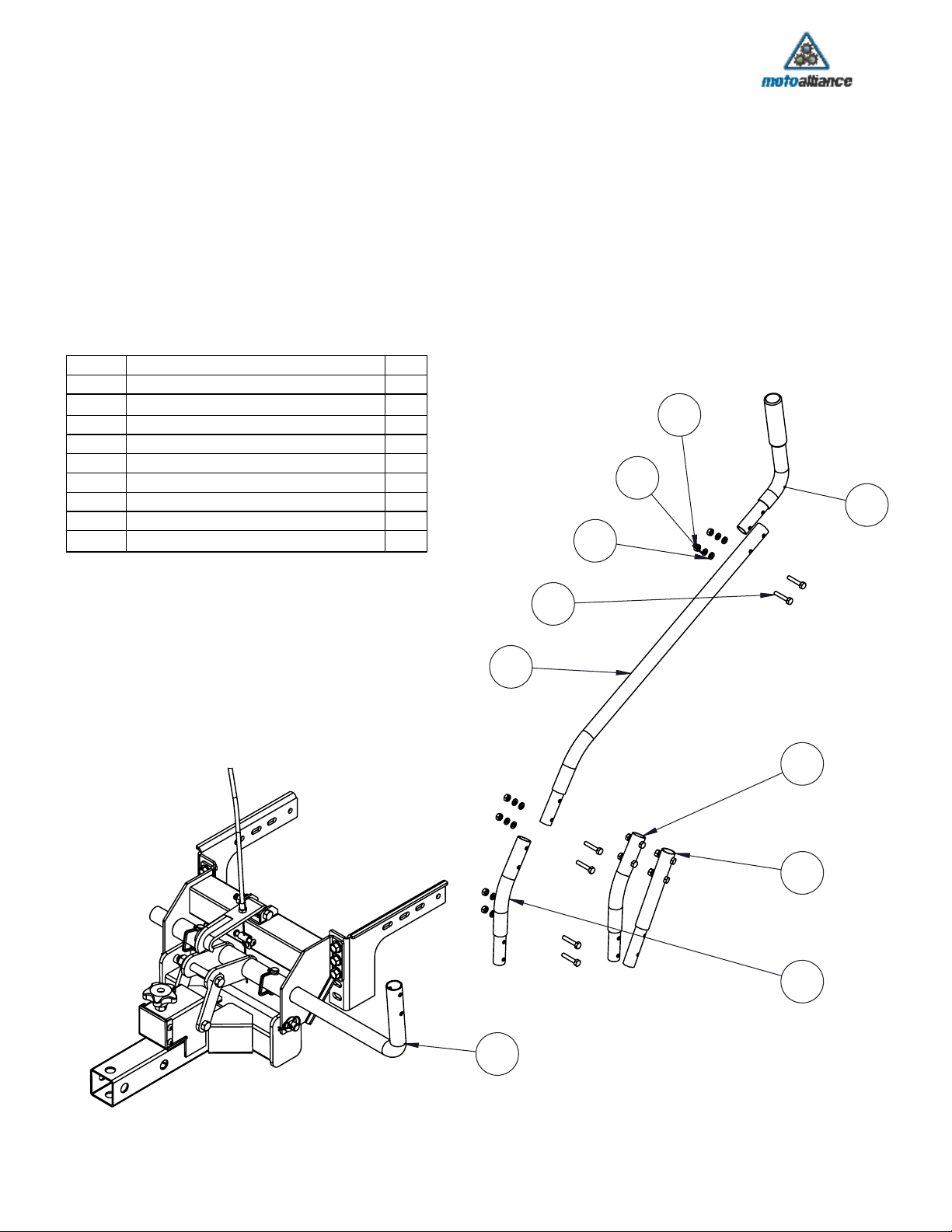

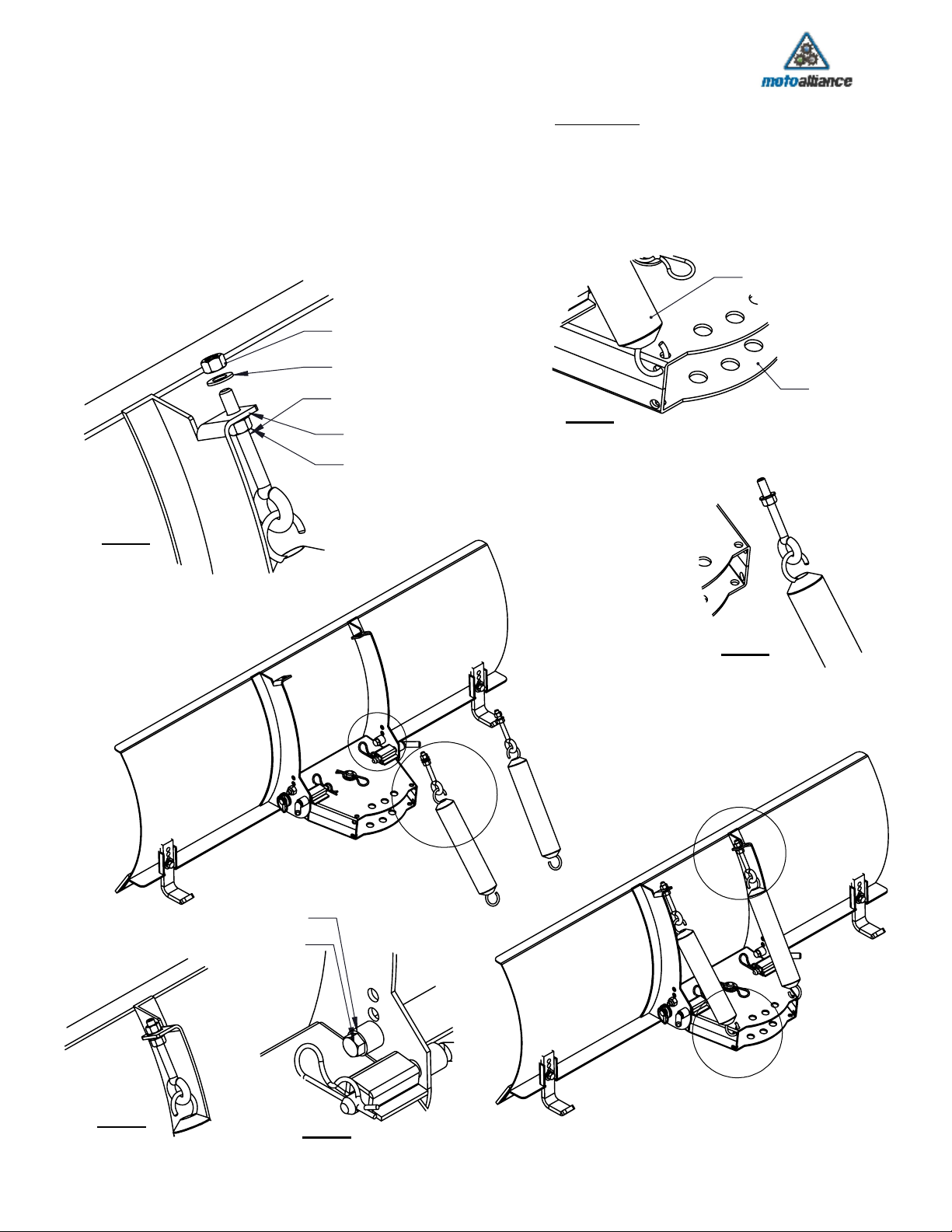

46" Garden Tractor Plow System