A BA B

ENEN

05. CONFIGURATION 05. CONFIGURATION

TRANSMITTERS CONFIGURATION

WORKING TIME PROGRAMMING

PAUSE TIME PROGRAMMING

WORKING TIME PROGRAMMING

01 • Press the SEL button once and the LED CODE will flash slowly.

02 • Press the SEL button again and the LED CODE will flash quickly.

03 • Press the ↑ button of transmitter to configure.

04 • The LED CODE will stop flashing and stay on, which means the success of the configuration.

The transmitter is this programmed with one button opening and one button closing.

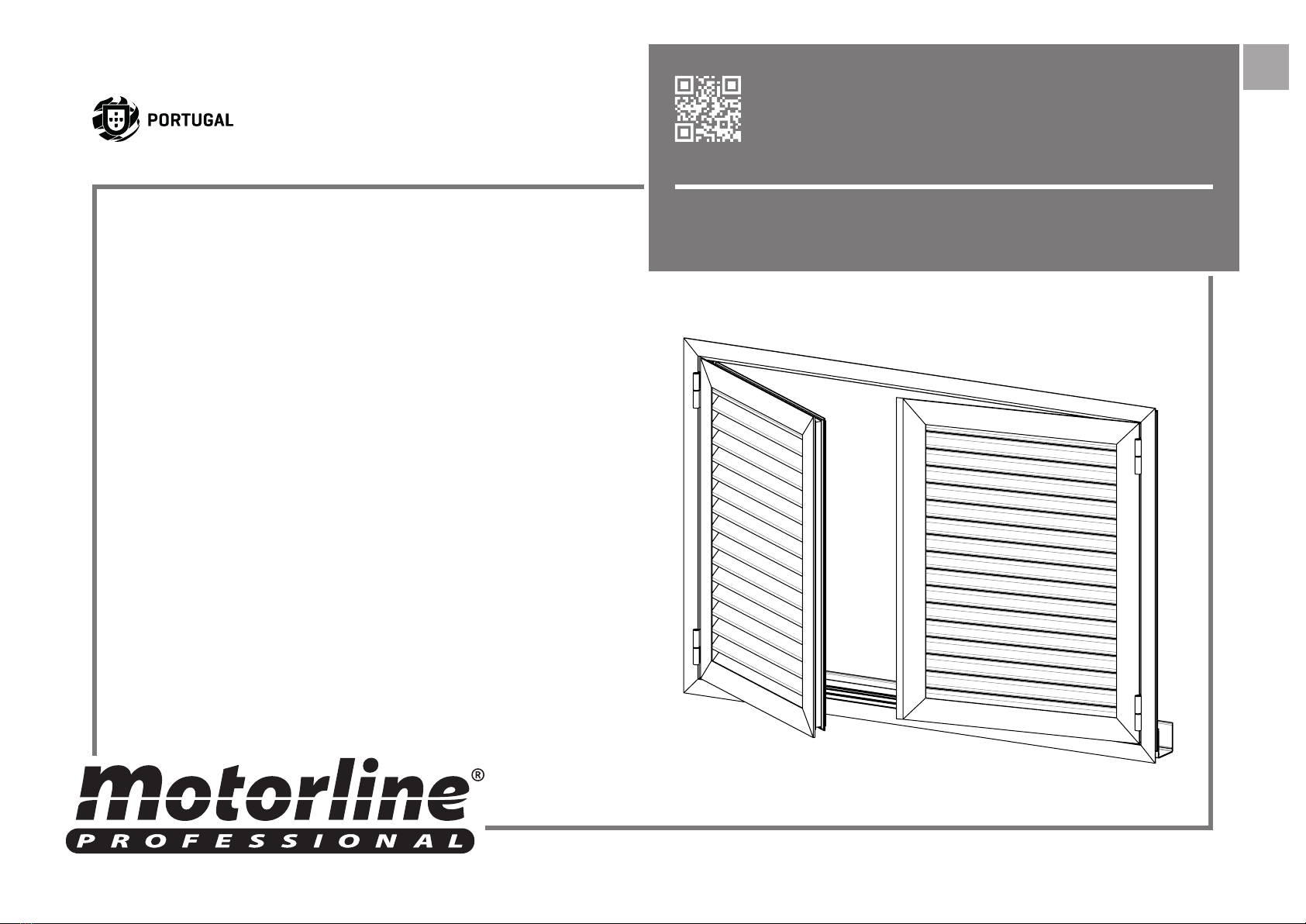

Working time without soft stop (starting with closed shutters):

01 • Put shutters in the closed position.

02 • Press the SEL button the necessary times until the LED T. MOT start flashing.

03 • Press the SET button once, and leaf nº1 will begin to open.

04 • When the leaf nº1 get to the open position, press SET once to save that position. The leaf nº2

will start to open immediately.

05 • When the leaf nº2 get to the open position, press SET once to save that position. This same leaf

will start closing immediately.

06 • When the leaf nº2 get to the closed position, press SET once to save that position. The leaf nº1

will start closing immediately.

07 • When the leaf nº1 get to the closed position, press SET once to save that position.

The configuration of the time work was finished successfully.

Working time with soft stop (starting with closed shutters):

01 • Put shutters in the closed position.

02 • Press the SEL button the necessary times until the LED T. MOT start flashing.

03 • Press the SET button once, and the leaf nº1 will begin to open. Press the SET button again when

you want that the leaf nº1 start slowdown.

04 • When the leaf nº1 get to the open position, press SET once to save that position. The leaf nº2

will start to open immediately. Press again the SET button when you want the leaf nº1 to start the

slowdown.

05 • When the leaf nº2 get to the open position, press SET once to save that position. This same leaf

•The settings should be made with the control board connected to a 20V transformer (IN:

230 OUT: 20V), supplied in kit.

• Whenever you end a configuration - T.MOT / T. PAUSE / etc, you must wait 10 seconds or

press the SEL button the necessary times until all LEDs remain fixed (on or off).

While some flashing LED, the control board is in programming mode.

LED LED OFF LED ON

• CODE No code Insert code

• T.MOT The time of motor 30 sec. Programmed time

• T. PA U S A Without automatic closure With automatic closure

• T. R.AP Without delay in opening Programmed time

• T. R. CH Without delay in closing Programmed time

will start closing immediately. Press the SET button again when you want the leaf nº2 to start the

slowdown.

06 • When the leaf nº2 get to the closed position, press SET once to save that position. The leaf nº1

will start closing again immediately. Press the SET button when you want the leaf nº1 to start the

slowdown.

07 • When the leaf nº1 get to the closed position, press SET once to save that position.

The configuration of the time work was finished successfully.

NOTE • To put the shutters in the closed position, you have two options:

Option 1 •

Disconnect the cables from the motors and the motors connect directly to a battery of 12 /24V

until the doors are in closed position. Turn on again the wires to the motor, the same way they were.

Option 2 • Programming a false work time, to cause the motors to return to the closed position. At the

end of this false programming, you can start over and make the correct programming.

DELAY TIME PROGRAMMING

Opening delay time programming:

01 • Press the SEL button the necessary times until the LED T.R.AP start flashing.

02 • Press the SET button once, wait the desired time for delay and press the SET button once to finish.

The time that waited between the two times that you pressed the SET button, is the time the control

board will wait from the start of the opening of the leaf 1 until the start of opening of the leaf 2.

This function is especially useful when it is required that leaf 1 to start opening before the leaf 2 (see

page 01.A to know how to identify leaves 1 and 2).

Closing delay time programming:

01 • Press the SEL button the necessary times until the LED T.R.AP start flashing.

02 • Press the SET button once, wait the desired time for delay and press the SET button once to finish.

The time that waited between the two times when you pressed the SET button, is the time the control

board will wait from the start of the closing of the leaf 1 until the start of closing of the leaf 2.

This function is especially useful when it is required that leaf 2 to start closing before the leaf 1 (see

page 01.A to know how to identify leaves 1 and 2).

The pause time is the time that the shutter is paused since the full opening operation to begin to close

automatically.

01 • Press the SEL button the necessary times until the LED T.PAUSA start flashing.

02 • Press the SET button once, wait the required time to pause and press the SET button once more, giving

as complete programming of pause time.

The time waited between the two times you pressed the SET button, is the time the control board will wait

since it ends the opening maneuver to automatically start closing the shutters.