EN - English - Instruction manual

2 MNLKUEBP4_2330_EN

5.1 Unpacking

When the product is delivered, make sure that the

package is intact and that there are no signs that it

has been dropped or scratched.

If there are obvious signs of damage, contact the

supplier immediately.

When returning a faulty product we recommend

using the original packaging for shipping.

Keep the packaging in case you need to send the

product for repairs.

5.2 Safely disposing of packaging

material

The packaging material can all be recycled. The

installer technician will be responsible for separating

the material for disposal, and in any case for

compliance with the legislation in force where the

device is to be used.

5.3 Contents

Check the contents to make sure they correspond

with the list of materials as below:

• Fastening support

• Bolts and screws

• O-ring

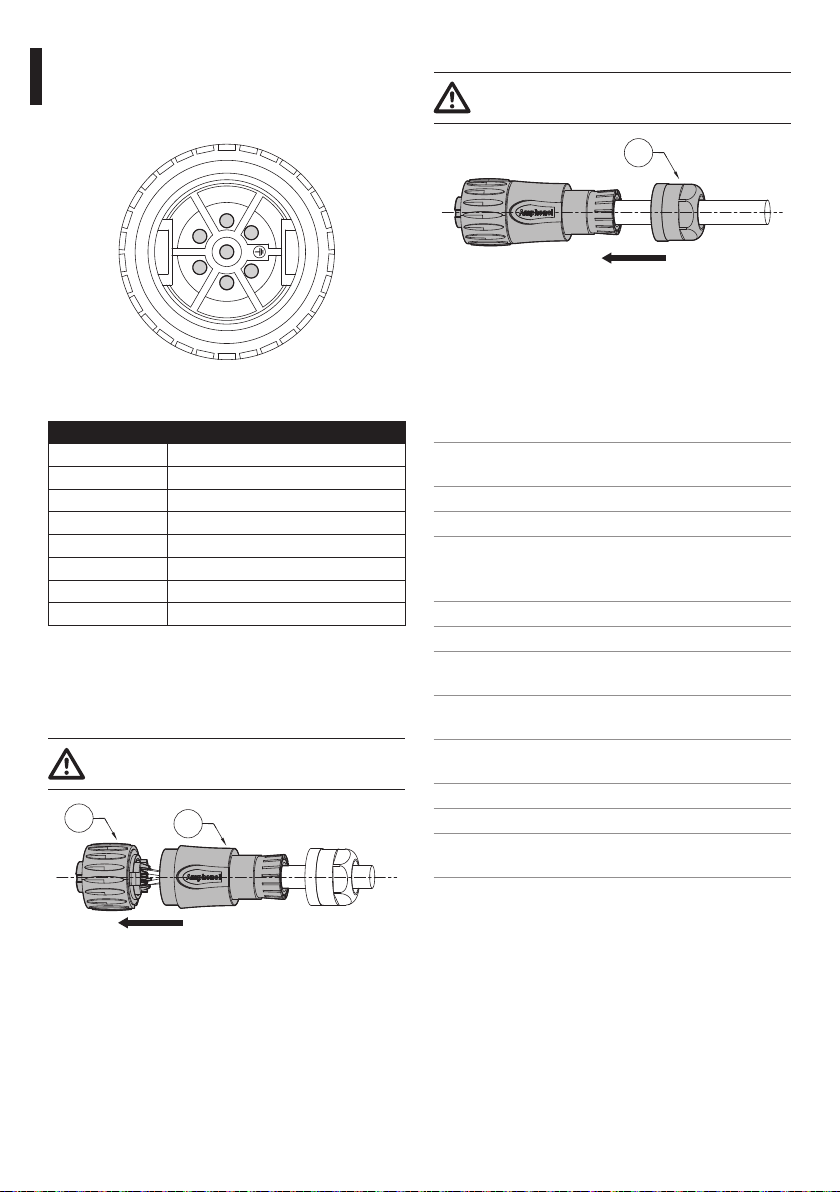

• Ethernet cable

• Mobile connector for ethernet, with quick

connector

• Mobile connector for power supply and I/O, with

quick connector

• Perforation masking

• Instruction manual

6 Installation

6.1 Mounting the bracket

Take special care when attaching and

fastening down the apparatus. If it is to

be attached to a concrete surface you

must use dowel pins with a traction

torque rating of at least 300dN each. For a

metal surface use screws with a diameter

of at least 8mm and of an appropriate

length. The fastening system must be

capable of supporting at least 4 times the

weight of the entire equipment (product,

accessories, supports and adapters).

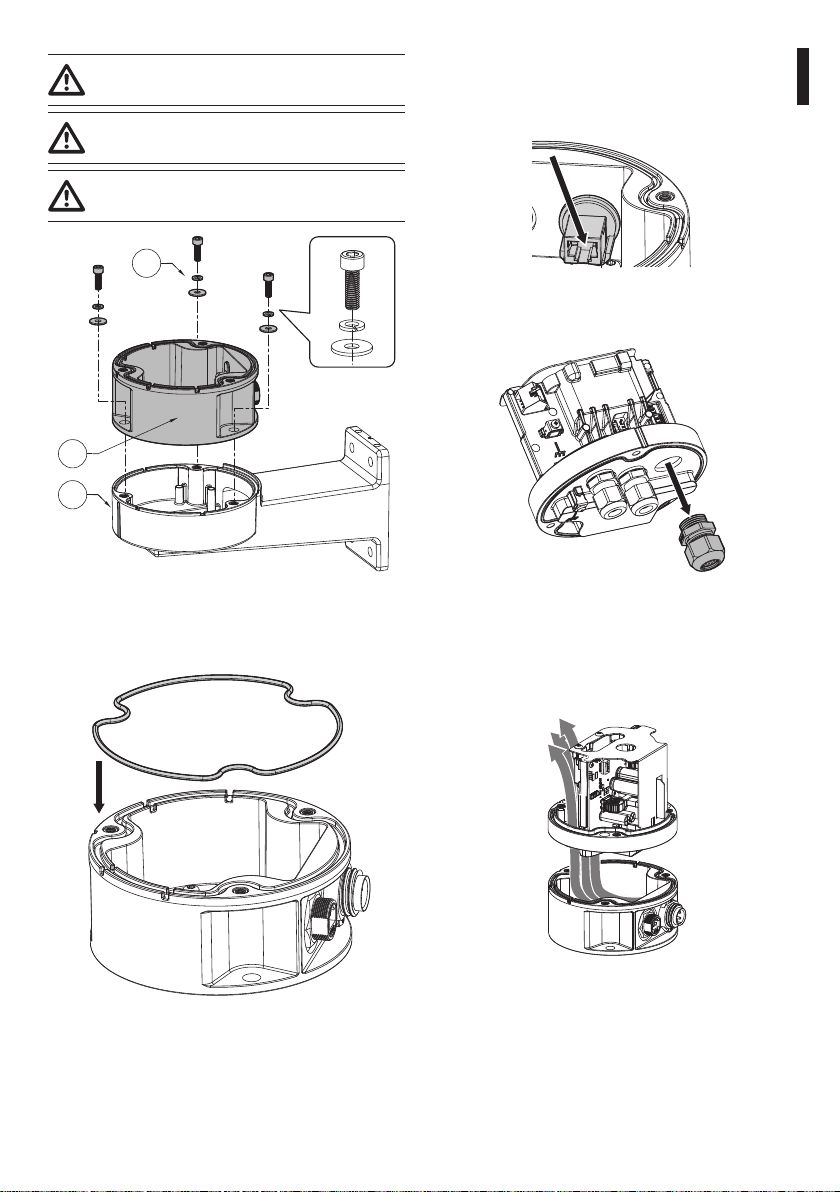

The support can be combined with other dierent

types of supports (UEAW, UEBW) or it can be directly

fastened to the chosen surface.

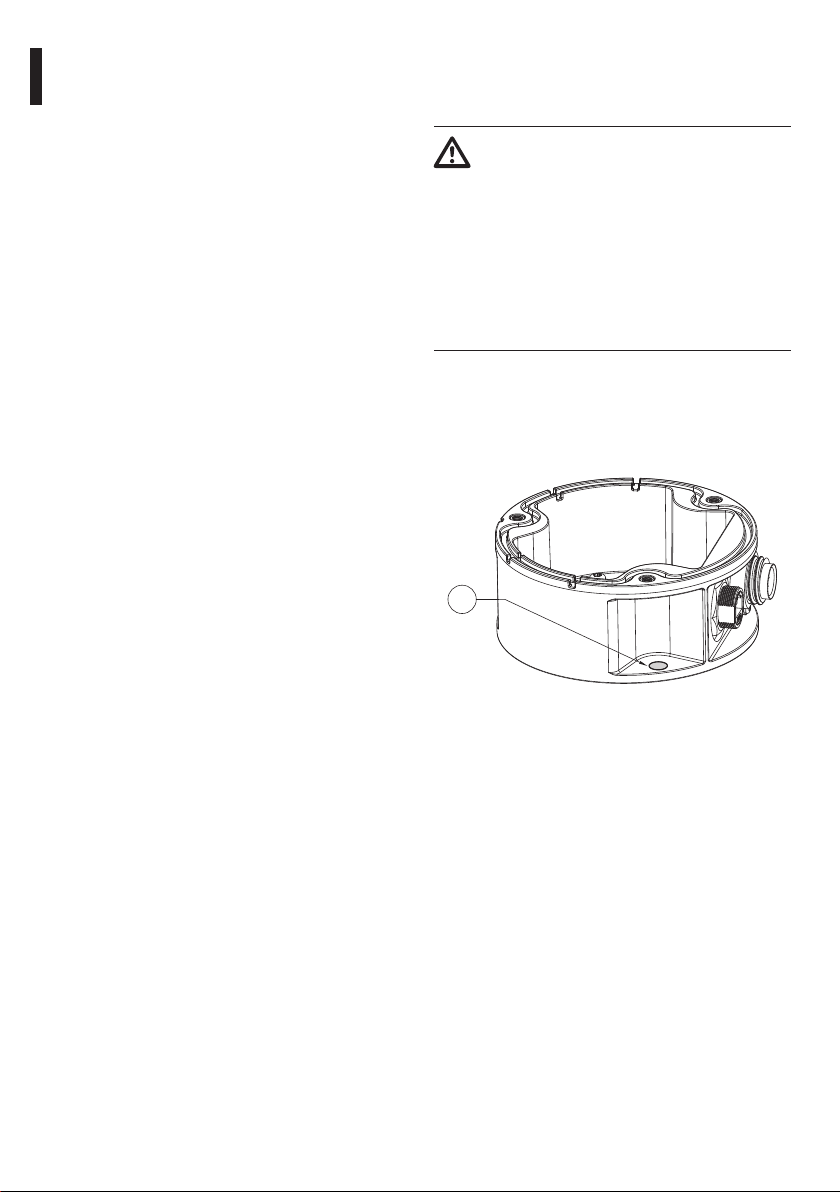

Fasten the support using the 3 holes (01). Use the

screws with a diameter equal to 8mm.

01

Fig. 1

For correct perforation of the fastening surface, use

the perforation masking supplied.

For installation combined with the UEBW support,

fasten the support with quick connectors (02) to the

wall support (03) using the screws and the washer

(04) supplied, paying attention to alignment of the

two supports (Fig. 2, page3).