STARLINE®

SG4-DRT-2X

Installation Sheet 509978-001

The Motorola®Digital Return Transmitter (SG4-DRT-2X) implements Time Division

Multiplexing (TDM) to convert two, independent 5 to 65 MHz analog RF return-path signals,

into one digital optical signal within SG4000 optical nodes. This digital optical signal with 10-bit

resolution and 3.125 Gbps rate is suitable for optical transmission on the International

Telecommunications Union (ITU) grid to the GX2-DRR-2X Digital Return Receiver (DRR) where

the original analog return-path signals are recreated.

The transmitter is configured with an 8 dBm digital Distributed Feedback (DFBT) laser that is

thermally stabilized to minimize wavelength drift. Multiple ITU wavelengths are available

depending on specific link requirements. The specific ITU channel and frequency are stamped

on the label on each transmitter and are identified in the subsection SG4-DRT-2X Models at the

end of this document.

The SG4-DRT-2X transmitter features high-speed digital technology to achieve reliable return

path communications at greater distances. The system is completely scalable and can be

expanded from a single transmitter/receiver to groups of 4, 8, 16, 32, or 40 wavelengths over a

single fiber with the use of muxing and demuxing equipment. The system is compatible with

Motorola low-noise optical amplifiers (EDFAs), enabling network designs that cover large

geographical areas. Without amplification, the SG4-DRT-2X Dense Wave Division Multiplexing

(DWDM) digital return system is capable of achieving a link loss budget of 26 dB.

The system achieves superior noise power ratio (NPR) and dynamic range (DR) performance in

return path communications. The SG4-DRT-2X system is HMS compliant and features an

enable/fault LED to report local status information. The SG4-DRT-2X comes standard with

SC/APC optical connectors; E2000 adapters are optional.

To facilitate easy upgrades, the double-wide SG4-DRT-2X module has the same set-up levels as

the analog return transmitters and can accomplish any two-transmitter configuration using

only a single fiber.

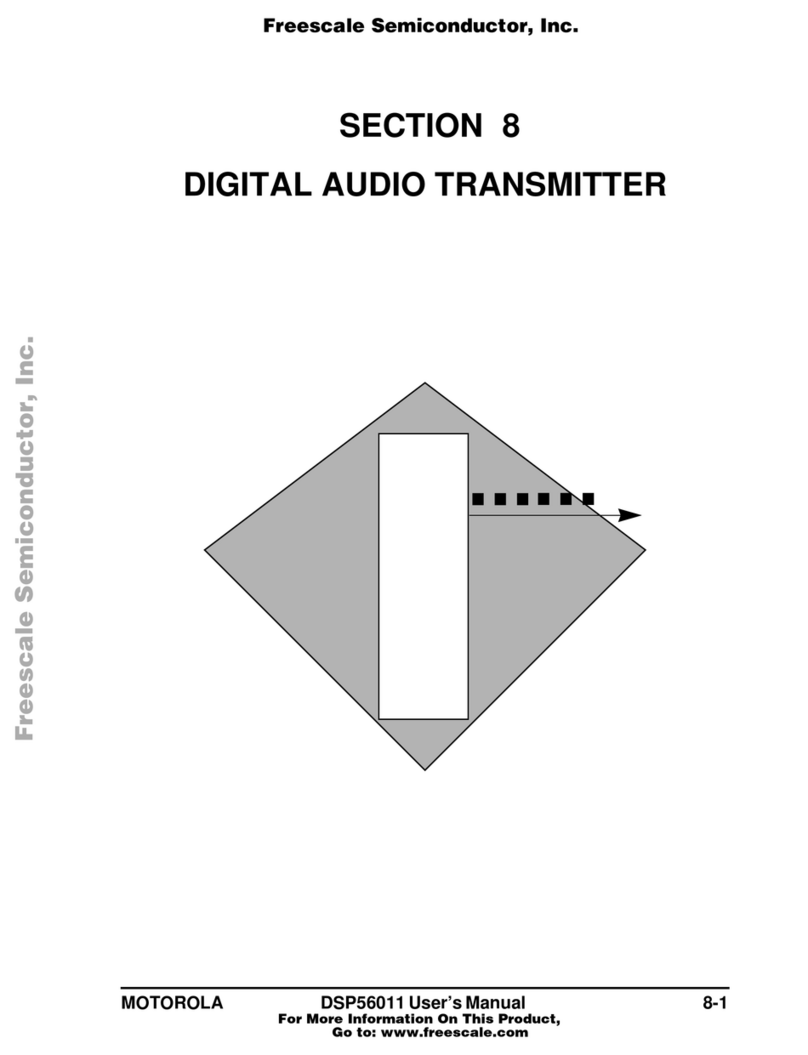

Figure 1 illustrates a block diagram of the SG4-DRT-2X:

Figure 1

SG4-DRT-2X block diagram

Return

Channel

Input B

5-65 MHz

Te s t

Input B

-20 dB

Te s t

Input B

-20 d

Return

Channel

Input B

5-65 MHz

Optical

Output

-3 Gbps

Laser

driver

Laser

Te s t P oi n t

Laser

TEC

JXP Coupler EQ Fiber A/D

Mux

A/D

TXF

MR

Transmit

Signal

Processing

TXF

MR

FiberEQ

Coupler

JXP

SG4-DRT-2X Installation Sheet