NOVUS AUTOMATION 1/2

400

RELATIVE PRESSURE TRANSMITTER

– INSTRUCTIONS MANUAL – V1.0x A

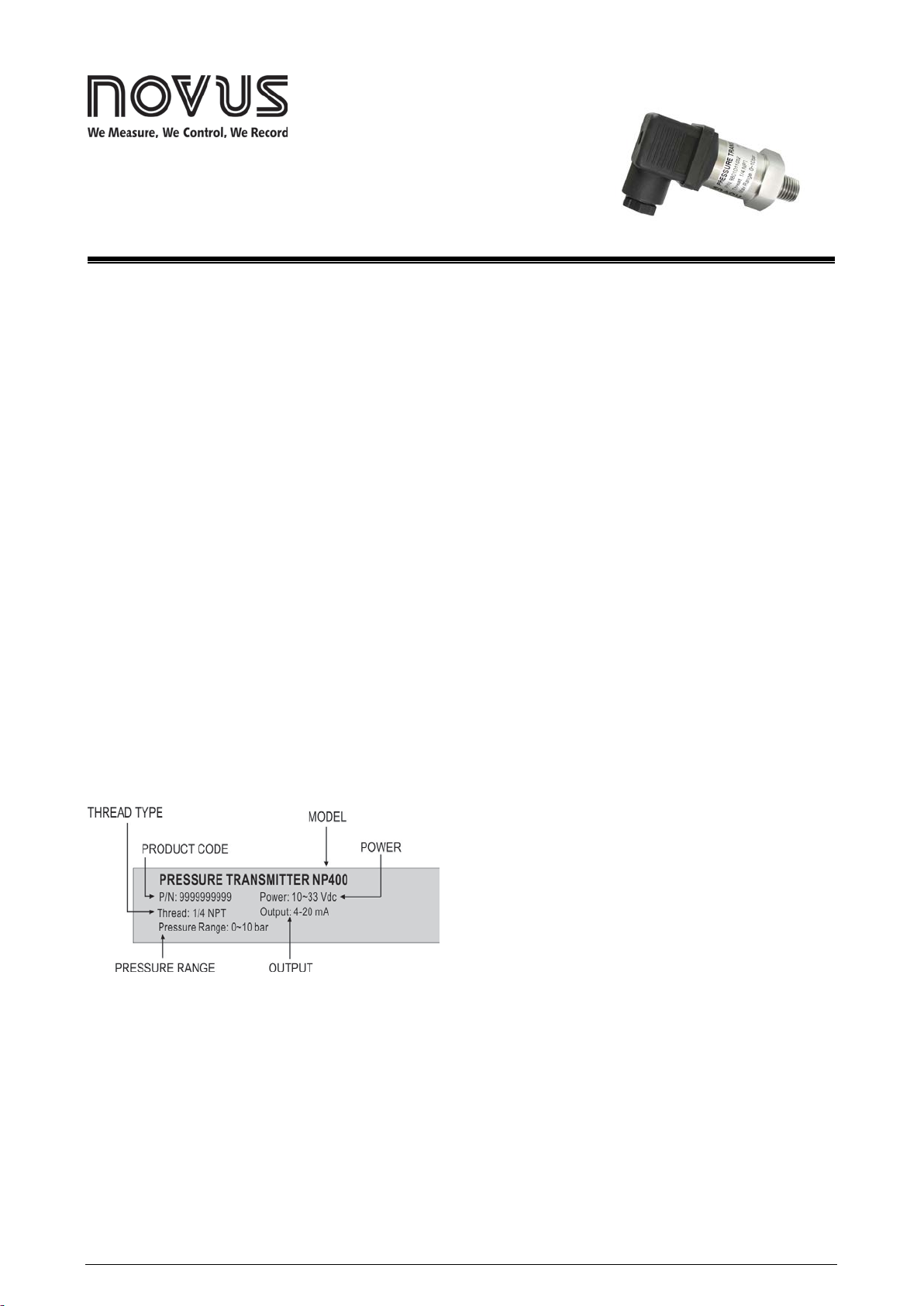

INTRODUCTION

The NP400 relative pressure transmitters are robust and reliable

equipment suitable for general industrial applications. They are

available in several measuring ranges and process connection

threads.

PRECAUTION

Before operating the transmitter, carefully read its specifications and

operating instructions. In case of damage caused by incorrect

operation or inappropriate usage, and its consequences, warranty

becomes ineffective and null.

A specialized professional shall perform the installation.

A specific electrical power supply network should be provided for

instruments use only.

UNPACKING

After unpacking the product, besides the transmitter it must be

available:

•A quick guide to installation and operation.

•A sealed electrical connector.

•A screw to fix the connector to the transmitter.

IDENTIFICATION

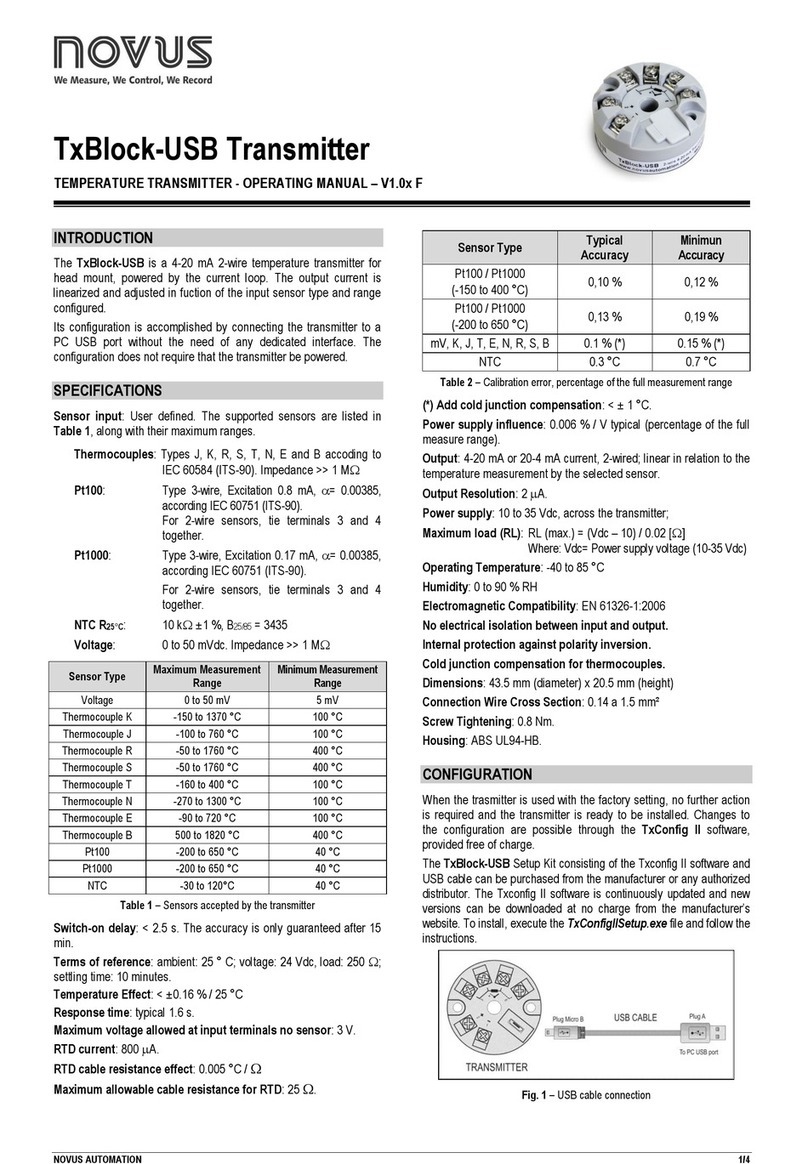

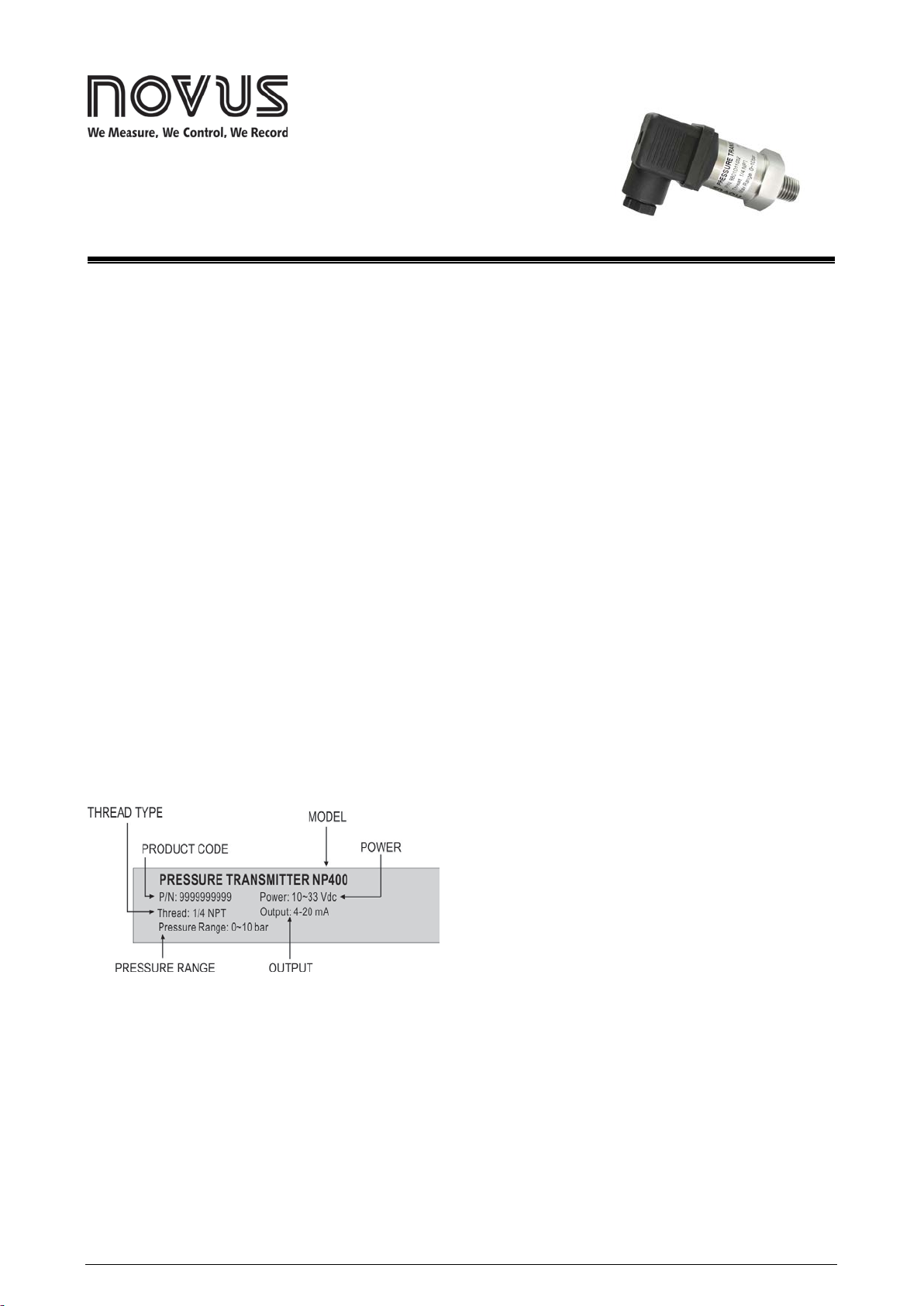

An identification label is attached to the equipment housing. On this

label, you can found detailed information about the transmitter.

Fig. 1 shows the identification label.

Fig. 1 – Transmitter identification

SPECIFICATIONS

Pressure Range:

0-2 / 0-5 / 0-10 / 0-20 / 0-50 / 0-100 bar (*)

Measurement Accuracy:

< ±0.5 % pressure range

< ±1.0 % pressure range for 0~100 bar model

Including linearity, hysteresis and repeatability, in 25 °C

Thermal Deviation Maximum:

< ± 0.06 % the span / °C

Overpressure Range:

Twice the pressure range upper value.

Rupture Pressure:

Three times the pressure range upper value.

Output Signal (Output):

Electric current, 4-20 mA, 2 wires.

Power Supply (Power):

10 to 33 Vdc

Maximum Load (RL):

RL= (Vdc - 10) / 0.02 (Ω)

Where: Vdc= Power supply voltage

Electrical Connection:

Connector for Type A valves (DIN EN 175301-803), IP65.

Conductor 1.5 mm² (max.) and cables between 6 and 8 mm in

diameter.

Operating Temperature:

-20 to 70 °C

Medium Temperature:

-20 to 100 °C

Dynamic Response:

< 30 ms

Process Connection (Thread):

¼ NPT; ½ NPT; ½ BSP (*)

Materials:

Metal housing of the transmitter:............................Stainless steel 316

Sensor:...............................................................Ceramic (Al2O396 %)

Sealing ring:...................................................................................FKM

Wetted parts:

Sensor (Ceramic), sealing ring (FKM) and metal connection

(stainless steel 316).

Compatibility:Any gas or liquid compatible with the constituent

materials of the wetted parts.

(*) Information available on the product identification label.