Mouvex SLS4 i User manual

SLS4 i - SLS8 i

PUMPS

INSTALLATION

OPERATION

MAINTENANCE

INSTRUCTIONS 1004-E00 e

Section 1004

Effective February 2018

Replaces December 2016

Original instructions

Your distributor :

Z.I. La Plaine des Isles - F 89000 AUXERRE - FRANCE

Tel. : +33 (0)3.86.49.86.30 - Fax : +33 (0)3.86.49.87.17

WARRANTY :

SL Series pumps are covered 24 months by warranty within the limits mentioned in our General Sales Conditions.

In case of a use other than that mentioned in the Instructions manual, and without preliminary agreement of MOUVEX,

warranty will be canceled.

2/31

NT 1004-E00 02 18 SLS4 i - SLS8 i e

ECCENTRIC PISTON PUMP

MOUVEX PRINCIPLE

SAFETY INSTRUCTIONS, STORAGE, INSTALLATION AND MAINTENANCE

SLS4 i - SLS8 i MODELS

TECHNICAL CHARACTERISTICS

- Maximum pump speed : 750 rpm

- Running temperatures :

• ambient ......................................................-15°C → .+ 40°C

• continuous pomped product.......................-15°C → .+100°C

• washing / rinsing / sterilisation product...... 0°C → .+121°C

• heating fluid (jacket)...................................-15°C → .+180°C

- Maximum suction pressure :

• In normal use, the suction pressure must be higher than the

required NPSH and less than 1,5 barg (21,75 psig).

• During CIP/SIP of the pump, the suction pressure must not

exceed 3 barg (43,5 psig).

• Pump stopped, the pressure must not exceed 6 barg

(87 psig).

- Acceptable maximal differential pressure :

• SLS4 i ..........................10 bar (145 psi)

• SLS8 i .......................... 6 bar (87 psi)

- Maximum pressure jacket : 5 barg (72,50 psig)

- Cylinder capacity :

• SLS4 i ..........................0,108 litre

• SLS8 i ..........................0,178 litre

1. CODIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2. OVERALL DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . .4

3. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.1 Installation design . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.2 Orientation of the pump ports . . . . . . . . . . . . . . . . . . .10

3.3 Direction of rotation . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.4 Protection of the pump installation . . . . . . . . . . . . . . .11

3.5 Hoisting devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.6 Unit Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4. UTILISATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.1 Noise level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.2 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.3 Dry running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.4 Pump stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.5 Scrapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

5. CLEAN IN PLACE (CIP) & STERILISATION IN PLACE

(SIP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5.2 CIP circuit recommended . . . . . . . . . . . . . . . . . . . . . .15

5.3 Pumps arranged in series . . . . . . . . . . . . . . . . . . . . . .15

5.4 Pumps arranged in parallel . . . . . . . . . . . . . . . . . . . . .16

5.5 Successive cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5.6 Sterilisation In Place (SIP) . . . . . . . . . . . . . . . . . . . . .17

6. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

6.1 Necessary tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

7. OPENING OF THE PUMP . . . . . . . . . . . . . . . . . . . . . . . .18

7.1 Assembly / Dismantling . . . . . . . . . . . . . . . . . . . . . . . .18

7.2 Checking of parts . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

8. ASSEMBLY OF CYLINDER/PISTON . . . . . . . . . . . . . . . .20

9. PROTECTION OF THE BELLOWS . . . . . . . . . . . . . . . . . .22

10. DISMANTLING OF THE BELLOWS . . . . . . . . . . . . . . . .23

11. CHANGING THE ORIENTATION OF THE PORTS . . . . .26

11.1 Discharge port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

11.2 Suction port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

12. DRAINING OF BEARING . . . . . . . . . . . . . . . . . . . . . . . .27

13. STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

13.1 Short duration (≤ 1 month) . . . . . . . . . . . . . . . . . . . .28

13.2 Long duration (> 1 month) . . . . . . . . . . . . . . . . . . . .28

13.3 Restarting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

14. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . .29

15. CERTIFICATE OF CONFORMITY . . . . . . . . . . . . . . . . .31

TABLE OF CONTENTS Page

USED PRESSURE UNITS

Unit without suffix :

Differential pressure, for example, pressure difference between

equipment suction and discharge.

Unit with suffix "a" :

Absolute pressure.

Unit with suffix "g" :

Gauge pressure, given regarding to atmospheric pressure

(~101325 Pa, taken at 1 bar / 14,5 psi in this IOM).

Pompe

P

asp

P

re

f

Psuc Pdis

Pump

Example :

Psuc = -0,2 barg = 0,8 bara

Pdis = 8,8 barg = 9,8 bara

∆P = Pdis - Psuc = 9 bar

Definition of safety symbols

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the product, or in the manual,

look for one of the following signal words and be alert to the

potential for personal injury, death or major property damage.

Warns of hazards that WILL cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause personal injury or property

damage.

NOTICE

Indicates special instructions which are very important and

must be followed.

DANGER

WARNING

CAUTION

3/31

NT 1004-E00 02 18 SLS4 i - SLS8 i e

SLS

4- 4 m3/h

8- 8 m3/h

I Standard

ST- Standard

EV- Heating jacket

VT- FKM

CVT- FKM encapsulated FEP

AF50- Flanges DIN11864-BF-A D50

CLAS51- Connections CLAMP ASME BPE-2009 D51

SMS51- Connections SMS1145 D51

DIN50- Connections DIN11851 D50

- Without

BMS- Bellows Monitoring System

BMSA- ATEX Bellows Monitoring System

Transmission security

Connections-Flanges

Seals

Conception

Flowrate

Temperature

4- I ST- VT- AF50- -

1. CODIFICATION

4/31

NT 1004-E00 02 18 SLS4 i - SLS8 i e

2. OVERALL DIMENSIONS

Pump plate

Filling / Breather

Draining

Oil level

P

R

V

N

SLS4 i - SLS8 i

with connections

DN A B C D E F

499 177 26728749

51 [19.646][6.969][10.512][11.299]109 129 51 x1,25 [109]

[2.008]516 194 284 304 [4.291][5.079][2.008 x0.049]51

[20.315] [7.638][11.181][11.969][113]

499 177 26728749

51 [19.646][6.969][10.512][11.299]109 129 52 x2[109]

[2.008]516 194 284 304 [4.291][5.079][2.047x0.079]51

[20.315] [7.638][11.181][11.969][113]

499 177 26728749

50 [19.646][6.969][10.512][11.299]109 129 55 x2,5[109]

[1.969]516 194 284 304 [4.291][5.079][2.165 x0.098]51

[20.315] [7.638][11.181][11.969][113]

DIN 11851

SLS4

SLS8

ODx T

SMS 1145

SLS4

SLS8

Clamp

ASME BPE

2009

SLS4

SLS8

Connections

Weight

kg [lb]

CAUTION : When welding the connections, the bellows should be protected.

SECTION A-A

5/31

NT 1004-E00 02 18 SLS4 i - SLS8 i e

2. OVERALL DIMENSIONS (continued)

Pump plate

Filling / Breather

Draining

Oil level

P

R

V

N

SLS4 i - SLS8 i

with flanges

DN A B C D E F ØG ØLØK

499 177 26728749,5

50 [19.646][6.969][10.512][11.299]109 129 53 x1,594 9 77 [110]

[1.969]516 194 284 304 [4.291][5.079][2.087x0.059][3.701][0.354][3.031]51,5

[20.315] [7.638][11.181][11.969][114]

ODxT

DIN11864

BFͲA

SLS4

SLS8

Flanges

Weight

kg [lb]

CAUTION : When welding the connections, the bellows should be protected.

SECTION A-A

4 x Ø L on Ø K

6/31

NT 1004-E00 02 18 SLS4 i - SLS8 i e

2. OVERALL DIMENSIONS (continued)

SLS4 i - SLS8 i

with heating jacket

JACKET CONNECTION

The entry connection may be connected to one or two points. NOTICE :

For the other sides, see the specific overall dimension plan for the connection.

Maximum jacket temperature : FKM and FEP encapsulated FKM seals : 180°C

Maximum pressure jacket : see TECHNICAL CHARACTERISTICS.

CAUTION :

The pumped product must not exceed the temperature of 100°C.

On jacketed pumps, suction port can only be in position 2 (top).

Positions 1 and 3 (sides) are not possible.

FOR ATEX PUMPS, SEE INSTRUCTIONS NR 1071.

STEAM

LIQUID

The outlet connection may be connected to one or two points.

If it is done at 1 point, purge the air at the second point.

OR

OR

7/31

NT 1004-E00 02 18 SLS4 i - SLS8 i e

2. OVERALL DIMENSIONS (continued)

NOTA :

The monitoring system is mounted on the right in standard version but can be mounted on the left if the suction port

of the pump is on the same side.

Setting of detection levels is done in factory and do not have to be modified.

For other dimensions, report to pump dimensional drawing.

The dismantling of the transmission could be done only in factory.

Transmission SL 4 i - SL 8 i

with BMS (Bellows Monitoring System)

Connector M15

5 pins

BMS right mounted BMS left mounted

8/31

NT 1004-E00 02 18 SLS4 i - SLS8 i e

2. OVERALL DIMENSIONS (continued)

NOTA :

The monitoring system is mounted on the right in standard version but can be mounted on the left if the suction port

of the pump is on the same side.

Setting of detection levels is done in factory and do not have to be modified.

For other dimensions, report to pump dimensional drawing.

The dismantling of the transmission could be done only in factory.

Connector M15

5 pins

Transmission SL 4 i - SL 8 i

with ATEX BMS (Bellows Monitoring System)

BMS right mounted BMS left mounted

9/31

NT 1004-E00 02 18 SLS4 i - SLS8 i e

3.1 Installation design

3.1.1 Pump

To obtain the service expected from a MOUVEX pump,

regarding both performance and longevity, it is vital that

the type of pump, its speed and the materials used for its

construction are determined as a function of the pump

output, its installation and operating conditions.

You can contact our Technical Services at any time to

ask for the information you require.

3.1.2 Pipe

Suction pipe length

Length should be as short as possible.

Suction pipe diameter

Diameter must be at least equal to pump port diameter

and even more if required by pumping conditions.

Suction pipe configuration

Check tightness to avoid accidental air intake.

--------------------------------------------------------------------

Pipe alignment and supporting

Pump must not support piping nor endure stress resul-

ting from piping weight or dilatation effects. For latters,

expansion loops should be included.

L=10xDminimum

R=3xDminimum

Not recommended

To be avoided if possible

Recommended

3. INSTALLATION

10/31

NT 1004-E00 02 18 SLS4 i - SLS8 i e

Pipe equipment

• Place valves close to the pump to avoid draining pipe

during maintenance operations. Preferably select full

bore ball or butterfly valves.

Pressure connections on pump suction and discharge

are recommended for settings and controls.

Make sure piping, vessels valves and other installation

devices are carefully cleaned before mounting.

• MOUVEX pumps are self priming. However, if line

emptying should be avoided and/or if suction lift is high,

a foot valve can be added.

• If pumped liquid presents a risk of in pipe solidification

and potential dilatation, low points on the pipe should

be avoided or equipped with drain valve.

• If installation is heated, it must be designed so that fluid

dilatation can evacuate through piping. Therefore fluid

contained in piping must be heated before fluid contained

in the pump. Also check that a heated pump is not iso-

lated by closed valves.

The SL Series pump is a selfpriming volumetric PD

pump. Therefore, the pump must not run on a circuit with

a closed valve. This is valid both for the suction circuit

and for the discharge circuit.

3.2 Orientation of the pump ports

The suction and discharge ports may be oriented in

various positions.

If the ports positions needs to be changed at any time,

see the corresponding paragraph.

3.3 Direction of rotation

When looking at the shaft, the rotation will be clockwise.

When looking at the front cover, the direction of rotation

will be anti-clockwise. An arrow situated on the bearing

housing indicates the correct direction of rotation.

NOTICE

SL Series pumps remains drainable whatever

position is chosen for the inlet port, but the

outlet port must be at the bottom (position 4) to

keep the self-draining capability.

3. INSTALLATION (continued)

POSSIBLE POSITIONS

Pumps with heating jacket : see § OVERALL DIMENSIONS - Heating jacket

SUCTION

1 2 STANDARD 3 4

DISCHARGE

1234STANDARD

11/31

NT 1004-E00 02 18 SLS4 i - SLS8 i e

Verification of the correct rotation direction :

• Run motor briefly to ensure proper direction of rotation.

This verification can be performed without presence of

liquid in the pump.

When checking with presence of liquid in the pump,

make sure discharge and suction pressure do not

exceed authorized limits.

3.4 Protection of the pump installation

• Before any start-up, during operation or complete stop-

ping of the pump, make sure the valves are open.

• During stop periods, with the pump full of product,

either the suction or discharge circuit must be left open

to enable expansion or contraction of the pumped pro-

duct through reheating or cooling. If this instruction is

not complied with, the bellows may be damaged and

lead to premate failure.

• The stop time may lead to cooling of the product in the

pump and therefore to an increase in viscosity. If this is

the case, we recommend re-starting the pump at a

speed adapted to this new viscosity (starting pump).

Once the product arrives in the pump at the installation

definition temperature, the pump may run at the speed

specified for this application.

• Protection against excess pressure :

The pump must be protected against excess pressure.

It can be delivered with a pressure switch to carry out

this function.

If protection is provided by a control valve, check that

the system does not generate excess pressure at the

bellows (particularly if there are water hammers).

Operating in this way would damage the bellows and

shorten their lifetime.

• Protection against foreign bodies :

The pump and the installation must also be protected

against any risk of damage through the passage of

foreign bodies by mounting a pre-filter at the pump suc-

tion.

In the case of foreseeable clogging of the pre-filter, we

recommend using a vacuum switch to inform the user

of pre-filter clogging. Prolonged running under cavita-

tion may damage the pump.

The largest dimensions of the allowable particles in the

pump are :

• Soft particles : .............6,5 mm

• Hard particles : ............2,0 mm

3.5 Hoisting devices

Hoisting points :

Take care of possible additionnal equipments mounted on

the pump.

3.6 Unit Assembly

The following instructions apply to pumps delivered with

a bare shaft or for MOUVEX motor-driven pump units (if

the latter have no specific instruction notice).

WARNING

WARNING

INCORRECT SETTINGS OF THE PRES-

SURE RELIEF VALVE CAN CAUSE PUMP

COMPONENT FAILURE, PERSONAL INJURY,

AND PROPERTY DAMAGE.

Hazardous pressure

can cause

personal injury

or property damage.

WARNING

FAILURE TO INSTALL ADEQUATELY SIZED

PRESSURE RELIEF VALVE(S) CAN CAUSE

PROPERTY DAMAGE, PERSONAL INJURY

OR DEATH.

Hazardous pressure

can cause

personal injury

or property damage.

WARNING

PUMPS OPERATING AGAINST A CLOSED

VALVE CAN CAUSE SYSTEM FAILURE,

PERSONAL INJURY AND PROPERTY

DAMAGE.

Hazardous pressure

can cause

personal injury

or property damage.

3. INSTALLATION (continued)

12/31

NT 1004-E00 02 18 SLS4 i - SLS8 i e

3.6.1 INSTALLATION OF UNITS

The base on which the unit is mounted is fundamental to

ensure correct operation and long service life.

The unit base must be flat, level and sufficiently resistant

to absorb the stresses caused by the motor-driven pump

unit without deformation (if it is made of concrete, it must

comply with the BAEL 91 standard).

If the unit is fastened using securing lugs or bolts, it must

be carefully wedged to avoid deforming the frame while

the bolts are tightened. A deformed frame would apply

damaging stresses on the pump and the drive mecha-

nism and misalign the coupling, causing vibrations,

noise and premature wear. Ensure that the frame is well

above the floor, except from the support plates.

If the unit is to be used in a food environment, support

plates that allow the unit to be lifted for easier cleaning

are recommended.

Allow, if possible, a clear space of approximately 50 cm

on each side of the motor-driven pump unit (overall

dimensions) to facilitate cleaning and give access if

necessary to the pump, reduction gear and motor faste-

ning nuts. In all cases, the dimensions around the motor-

driven pump unit must be designed to give the space

required for dismantling the pump (if the need arises,

use the values given on the overall dimension drawing).

For staff and equipment protection, the frame includes a

ground connection point that should be used.

3.6.2 ALIGNMENT OF THE MOTOR/PUMP OR

REDUCTION GEAR/PUMP SHAFTS

NEVER START A UNIT IF THE COUPLING ALIGNMENT IS

INCORRECT. THIS IS A CONDITION OF OUR GUARANTEE.

REMINDER :

Coupling must never be used to compensate for a misa-

lignment.

To control the alignment between the coupling and the

shaft, use a straight-edge for concentricity and thickness

gauges for angular misalignment (see instructions of the

coupling for authorised values).

The 3 figures below show in detail the operation and the

possible defects :

WARNING

BE CAREFUL WITH THE WEIGHT OF THE

PARTS WHEN THEY ARE BEING

REMOVED.

The weight ot the parts

can be dangerous and

may provoke bodily inju-

ries or material damages.

WARNING

DISCONNECT THE ELECTRICITY SUPPLY

BEFORE ANY MAINTENANCE OPERATION.

Dangerous voltage.

Can cause

injury and death.

WARNING

IF OPERATED WITHOUT THE SHAFT

GUARD, THERE IS CONSIDERABLE RISK

OF SEVERE PERSONAL INJURY, SIGNIFI-

CANT PROPERTY DAMAGE OR EVEN

DEATH.

Do not operate

without guard

in place.

WARNING

DISCONNECT THE ELECTRICITY SUPPLY

BEFORE ANY MAINTENANCE OPERATION.

Dangerous voltage.

Can cause

injury and death.

Carry out the control at four points :

at the top ‐ at the bottom ‐ left ‐ right

Correct

Bad alignment

Angular fault

3. INSTALLATION (continued)

13/31

NT 1004-E00 02 18 SLS4 i - SLS8 i e

Controlling the alignment at each stage of the installa-

tion is important to be sure that none of these stages

have generated stresses on the unit or the pump :

• after fastening on the foundations.

• after fastening the pipes.

• after the pump has been operated at the normal

operating temperature.

Where the pumps are supplied assembled as a unit, the

motor and pump shafts have been perfectly aligned in

the factory before delivery, but they must be systemati-

cally controlled on acceptance at the site and realigned

if necessary.

To do this, do not modify the wedging of the various

parts, but check the flatness of the support surface and

use the adjustable foot to clear the frame of stresses that

could affect it.

3.6.3 ELECTIC MOTORS

Check the compatibility of the instructions on the motor

with the supply voltage.

Follow the wiring diagram, use wiring that is appropriate

for the power and be particularly careful about the

contacts which must be well tightened.

The motors should be protected with circuit breakers

and suitable fuses. Connect the regulatory electrical

grounding.

3.6.4 THERMIC MOTORS

Do not forget that these motors are not reversible. It is

absolutely necessary to carefully control the suction and

discharge sides of the pump before connecting the

group to the piping.

Using electric motors is very common now; however, we

strongly advise careful reading of the accompanying ins-

truction manual.

3.6.5 CONTROL OF THE SENSE OF ROTATION

This control needs to be done with no liquid pumped

through the pump, and both the suction and discharge

circuits venting to avoid generating unexpected pressure

(at the suction side, for example). This will ensure that

the control will not damage either the pump or the instal-

lation.

Start the pump empty to check that the connections are

good and that the direction of rotation corresponds to the

suction and discharge direction on the installation. If it is

necessary to reverse the direction of rotation, follow the

instructions below :

Three-phase motor : switch any 2 current input wires.

Bi-phase motor : switch two same phase wires.

Single-phase motor : follow the instructions on the notice

supplied with the motor.

WARNING

DISCONNECT THE ELECTRICITY SUPPLY

BEFORE ANY MAINTENANCE OPERATION.

Dangerous voltage.

Can cause

injury and death.

CAUTION

THE SURFACES CAN BE AT A TEMPERA-

TURE LIABLE TO CAUSE INJURY OR

SEVERE DAMAGE.

Excessive temperature

can cause injury or

severe damage.

WARNING

TAKE ALL NECESSARY MEASURES TO

RENDER ANY START-UP, EVEN ACCI-

DENTAL, OF THE PUMP DURING THE

WORK IMPOSSIBLE.

Any unforeseen start-

up

can cause serious

injuries or important

WARNING

IT IS IMPERATIVE THAT THE HYDRAU-

LIC PRESSURE IS RELEASED BEFORE

EACH MAINTENANCE OPERATION

TO AVOID PERSONAL INJURY OR

MATERIAL DAMAGE

Hazardous pressure

can cause

personal injury

or property damage.

WARNING

IF OPERATED WITHOUT THE SHAFT

GUARD, THERE IS CONSIDERABLE RISK

OF SEVERE PERSONAL INJURY, SIGNIFI-

CANT PROPERTY DAMAGE OR EVEN

DEATH.

Do not operate

without guard

in place.

3. INSTALLATION (continued)

14/31

NT 1004-E00 02 18 SLS4 i - SLS8 i e

4.1 Noise level

The sound level of a pump is greatly influenced by its

conditions of use. Cavitation and pumping products with

high gas contents generally increases the sound level.

Under the following pumping conditions :

• excluding cavitation

• discharge pressure :

• SLS4 i . . . . . 10 bar (145 psi)

• SLS8 i . . . . . 6 bar (87 psi)

• speed of rotation 750 rpm

• product viscosity of 10 cSt

The sound level reached for the SLS4 i / SLS8 i pump in

good conditions without the drive is less than 79 dB(A).

4.2 Commissioning

Make sure that the circuit valves are open before star-

ting the pump.

To avoid any risk of polluting the product to be pumped,

rinse the whole installation before starting-up so as to

eliminate any contaminants that may remain in the

piping, tanks etc. at the time of installation.

4.3 Dry running

The SL Series pump is self priming and is capable of

emptying the pipes. To do this, it can run dry for a maxi-

mum duration of 5 minutes.

4.4 Pump stop

So as not to damage the pump, make sure that the

pump is completely stopped before closing the valves.

4.5 Scrapping

The pump must be scrapped in compliance with the

regulations in force.

During this operation, particular care must be paid to the

drainage stages of the pump (pumped product) and of

its transmission (lubricant).

For any pure water pumping during process or

cleaning operations, consult MOUVEX imperatively.

4. UTILISATION

15/31

NT 1004-E00 02 18 SLS4 i - SLS8 i e

5. CLEAN IN PLACE (CIP) &

STERILISATION IN PLACE (SIP)

5.1 General

On-site cleaning (CIP) of an installation is undertaken by

circulating various cleaning solutions through the equip-

ment parts.

An automated CIP system enables :

• Preparation of the appropriate concentrations for the

different cleaning solutions.

• Re-heating of certain cleaning solutions at the opti-

mum temperature.

• Circulation of the different solutions through the equip-

ment parts to be cleaned.

• Rinsing and drying of the equipment parts.

For the most part, automated CIP systems are an inte-

gral part of process equipments.

Before starting CIP and if the process has not been fol-

lowed by a water flush, care must be taken that a mini-

mum of residual products remains in the piping and in

the pump. The SL Series pumps, thanks to their excellent

suction and compression capabilities, enable reducing

the quantities of residual products. This minimises loss

of products, eases cleaning and reduces cycle times.

The SL Series pumps are perfectly adapted to all pro-

cesses necessitating CIP. SL Series pumps are 3-A mar-

ked units and have been successfully tested for in-place

cleanability according to EHEDG document n°2. By

complying with the installation rules described above,

these pumps will give you entire satisfaction for a long time.

The start of CIP must immediately follow the end of the

process to avoid any clogging or untimely drying.

Non-compliance with this instruction may lead to rapid

wear of cylinder and piston.

5.2 CIP circuit recommended

In all cases, the pressure at the pump inlet during clea-

ning must not exceed 3 barg (43,50 psig).

The flow through the pump required for optimal cleaning

is 10 m3/h.

This flow corresponds to difficult cleaning (sticky and vis-

cous products). It can be reduced for easier types of

cleaning.

The pressure required to raise the piston is 0,7 bar

(10,40 psi). This pressure difference is accounted for by

the pressure losses.

5.3 Pumps arranged in series

This type of assembly is preferred in all cases. It

ensures optimal cleaning for the pump and makes use of

the special design of the SL Series, i.e. the possibility of

lifting the piston with the cleaning product.

As the pressure at the pump inlet is higher than that at

its outlet, the piston lifts from the cylinder and permits

the passage of all the cleaning liquid through the SL

Series pump.

• A pump (centrifuge for example) is used for CIP cycles.

This pump is placed upstream of the SL Series pump.

The pump must be installed in series with the SL Series

pump.

It is preferable not to run the SL Series pump during CIP

although low speed (< 100 rpm) is acceptable by alter-

nating start/stop operation.

• In certain cases, the flow of the cleaning liquid requi-

red for the installation is higher than that recommen-

ded for cleaning the pump. In this case, a bypass must

be used.

The bypass valve is adjusted to divide the flow bet-

ween the circuit flowing through the SL Series pump

and the bypass circuit.

SL SERIES PUMPS MUST NEVER BE USED AS CIP

PUMPS.

SLS pump

Max pressure 3 barg (43,5 psig)

16/31

NT 1004-E00 02 18 SLS4 i - SLS8 i e

5. CLEAN IN PLACE (CIP) &

STERILISATION IN PLACE (SIP) (continued)

It is preferable not to run the SL Series pump during CIP,

although low speed (< 100 rpm) is acceptable by alter-

nating start/stop operation.

• In certain cases, the cleaning pressure required for the

installation is higher than 3 barg (43,5 psig). In this

case, the use of a bypass is required and cleaning is

done in 2 steps.

Cleaning the pump :

The cleaning flow should be limited during the cleaning

of the C pump to ensure a maximum pressure of 3 barg

(43,5 psig) at the C pump inlet.

It is preferable not to run the SL Series pump during CIP

although low speed (< 100 rpm) is acceptable by alter-

nating start/stop operation.

Cleaning the installation :

During this operation, the valve system used must ensu-

re that no flow can pass through the pump so that the SL

Series pump does not rotate. Under these conditions,

with the pump completely stopped, the pressure of the

washing circuit can rise up to 6 barg (87 psig).

The pump must not run during this operation.

5.4 Pumps arranged in parallel

For applications where cleaning is easy and the differen-

tial pressure of, the SL Series pump is lower than 2 bar

(29 psi) during this operation, assembly in parallel is

authorised. It should be noted that during cleaning, the

SL Series pump will be acting on a product with generally

few lubricating properties. This will contribute towards

wear of the pump.

The CIP centrifuge pump must never be installed in

parallel with a SL Series pump without taking special

precautions.

Indeed, in this case, the pressure at the inlet of the SL

Series pump is lower than the pressure at the discharge

and the piston remains forced against the cylinder.

Therefore, there the SL Series pump no longer provides a

passage. Its efficient cleaning can no longer be ensured

and the cylinder/piston pair will become prematurely worn.

Authorised assembly :

As mentioned previously for applications where cleaning

is easy, assembly in parallel is authorised when the

valves are installed so that the cleaning pressure of the

circuit does not come into contact with the SL Series

pump.

In this case, the SL Series pump cleans itself.

Cleaning the pump :

We recommend limiting the rotation speed of the SL

Series pump.

Cleaning the installation :

The SL Series pump is stopped when cleaning the ins-

tallation.

SLS pump

Max pressure

3 barg (43,5 psig)

SLS pump

Max pressure 3 barg

(43,5 psig)

SLS pump

Max pressure 6 barg

(87 psig)

CIP pump

SLS pump

SLS pump

Max pressure

1,5 barg (21,7 psig)

SLS pump

17/31

NT 1004-E00 02 18 SLS4 i - SLS8 i e

5.5 Successive cycles

Generally, the most efficient CIPs comprise 5 stages :

1. Pre-washing with clean water

Water at room temperature. 10 to 15 minute cycle. This

pre-wash enables evacuation of the remaining residues.

2. Washing with an alkaline detergent

Typically this is soda at 2,5% at a temperature of 80°C.

20 to 30 minute cycle. This wash particularly enables

dissolving and evacuating grease and proteins.

3. Rinsing with clean water

Water at room temperature. 10 minute cycle. This rinse

enables avoiding the mixture of 2 cleaning solutions.

4. Washing with an acid solution

Typically this is nitric acid at 2,5% at room temperature.

10 to 15 minute cycle. This wash particularly enables

dissolving and evacuating proteins and inorganic salts.

5. Rinsing with clean water

Water at room temperature. Several 1 to 2 minute

cycles. These rinses enable evacuating all traces of

acid solution.

During all these CIP stages, the average speeds of the

cleaning liquids in the pipes must be between 1,5 and 3 m/s.

5.6 Sterilisation In Place (SIP)

The SL Series pumps are perfectly adapted to all pro-

cesses using SIP (Sterilisation In Place) : pump stopped

/ maximum 20 mn per cycle / 1 or 2 cycles per day.

5. CLEAN IN PLACE (CIP) &

STERILISATION IN PLACE (SIP) (continued)

6.1 Necessary tools

• 50 Open-end spanner or Monkey wrench

• Torque wrenches 18 - 24 - 30

• Extractor

• Mallet

Tightened torques :

• M10 : 30 Nm

• M12 : 50 Nm

• M18 : 120 Nm

6. MAINTENANCE

18/31

NT 1004-E00 02 18 SLS4 i - SLS8 i e

7.1 Assembly / Dismantling

• Disconnect the pump from the discharge pipe.

• Unscrew the 4 nuts 106 and remove the 4 washers 406.

• Remove the front cover 401 and its seal 205.

• Hold the piston 301 with a 50 Open-end spanner or a

monkey wrench and unscrew the piston screw 304 and

its seal 305.

Before any dismantling, make sure that the

pump has been drained and take the neces-

sary measures to avoid starting-up. No start-up,

even accidental, must be allowed. It is important to keep a good grip on the pis-

ton, its rotation could lead to deterioration of

the bellows.

106

406

205

107

401

301

305

304

7. OPENING OF THE PUMP

CAUTION

THE PUMP LUBRICANT IS VERY SLIPPERY

AND MAY CAUSE SERIOUS INJURY. ANY

SPILLS MUST BE CLEANED UP.

Slippery lubricant.

Spills should be

cleaned up.

WARNING

BE CAREFUL WITH THE WEIGHT OF THE

PARTS WHEN THEYARE BEING REMOVED.

The weight ot the parts

can be dangerous and

may provoke bodily

injuries or material

damages.

WARNING

TAKE ALL NECESSARY MEASURES TO

RENDER ANY START-UP, EVEN ACCI-

DENTAL, OF THE PUMP DURING THE

WORK IMPOSSIBLE.

Any unforeseen start-up

can cause serious

injuries or important

material damages.

WARNING

FAILURE TO RELIEVE THE SYSTEM

PRESSURE PRIOR TO PERFORMING

ANY WORK ON THE PUMP OR THE

INSTALLATION CAN CAUSE PERSONAL

INJURY OR PROPERTY DAMAGE.

Hazardous pressure

can cause

personal injury

or property damage.

WARNING

DISCONNECTING THE FLUID OR PRES-

SURE CONTAINMENT COMPONENTS

DURING PUMP OPERATION CAN CAUSE

SERIOUS PERSONAL INJURY, DEATH OR

MAJOR PROPERTY DAMAGE.

Hazardous pressure

can cause

personal injury

or property damage.

WARNING

IF PUMPING HAZARDOUS OR TOXIC

FLUIDS, THE SYSTEM MUST BE

FLUSHED PRIOR TO PERFORMING ANY

SERVICE OPERATION.

Hazardous or toxic

fluids can cause

serious injury.

19/31

NT 1004-E00 02 18 SLS4 i - SLS8 i e

• Unscrew the piston screw 304 of 2 or 3 turns and hit it

with a mallet to take off the piston 301.

• If necessary, use a hub puller to extract the piston 301.

• Remove the cylinder 201 and the seals 113 and 306.

7.2 Checking of parts

The piston 301 and the cylinder 201 are active parts effi-

ciency directly depends. It is therefore advisable to regu-

larly check the pump's efficiency and replace the cylin-

der / piston if it decreases.

In addition, as using a cylinder / piston that is too worn

may damage the pump's transmission system, it is advi-

sable to replace the cylinder / piston if the maximum

acceptable wear dimensions defined in the table below

are reached.

As changes in the pump efficiency depend on the condi-

tions of use (pressure, rotation speed, liquid pumped, etc.),

MOUVEX recommends that users define the monitoring

ranges and the preventive maintenance schedule accor-

ding to their own experience.

NOTICE

When disassembling the piston screw 304,

if the enclosed thread surfaces have become

soiled, we recommend cleaning them as

follows : clean the inner thread by washing,

rinsing and sterilizing the whole part (i.e.

with a steam sterilization), then remove any

impurities from the external threads by

washing with a brush followed by rinsing with

a bactericide solution before reassembly.

Piston

301

mm (inch)

Cylinder

201

mm (inch)

SLS4

New dimension 7

(0,276)

31,5

(1,240)

Minimum wear dimension

acceptable

5

(0,197)

29,5

(1,161)

SLS8

New dimension 7

(0,276)

48,5

(1,909)

Minimum wear dimension

acceptable

5

(0,197)

46,5

(1,831)

305

304

301

201

113

301

306

7. OPENING OF THE PUMP (continued)

20/31

NT 1004-E00 02 18 SLS4 i - SLS8 i e

8. ASSEMBLY OF CYLINDER/PISTON

• Check the state of the seals 205, 305, 306, 113 and replace

them if necessary.

• Position the seal 113 on the large flange.

NOTICE

Seals material are intended for use in normal

conditions in food process. In order to ensure

a reliable sealing on SL Series pumps we

recommend to :

• do an inspection of the seals every three

months (this time could be shorter if using

the pump in hard conditions. Contact the

manufacturer for advice if necessary).

• replace the pump sealing every two years

(refer to the § PROTECTION OF THE BELLOWS

for the replacement of the second seal 113).

201

113

When controlling the piston and even if it has not reached

its minimum dimensions, it may show following aspects,

especially on abrasive liquid pumping or low viscosity :

• Triangular shape on top of piston wall (A),

• Small steps at piston wall base (B).

Before putting back the piston on the pump, eliminate

these asperities by filing and finishing with fine sandpaper

(No 320 grain or equivalent), taking care of not scratching

any other surface around. Piston must then look as follows :

Do not retouch any other surface of the piston by

any mean as it can degrade pump performance and

reliability. In particular, do not round or attenuate

disc wall edges.

Even if it shows wearing signs, do not retouch any

surface of the cylinder by any mean as it can degrade

pump performance and reliability.

7. OPENING OF THE PUMP (continued)

This manual suits for next models

1

Table of contents

Other Mouvex Water Pump manuals

Mouvex

Mouvex SLS24 i Owner's manual

Mouvex

Mouvex H-FLO 65 Owner's manual

Mouvex

Mouvex AS25 Owner's manual

Mouvex

Mouvex SLC1 Owner's manual

Mouvex

Mouvex SLC24 i Owner's manual

Mouvex

Mouvex AK Series Guide

Mouvex

Mouvex CC8-40 AP Owner's manual

Mouvex

Mouvex CC8-40 Owner's manual

Mouvex

Mouvex C24 i Owner's manual

Mouvex

Mouvex C12 A Owner's manual

Popular Water Pump manuals by other brands

Oase

Oase AquaMax Eco Twin 20000 operating instructions

KSB

KSB MEGAFLOW 50-160 Operating instructions manual

Silicon Solar

Silicon Solar AquaJet-Pro-PUMP1224 user manual

Walrus

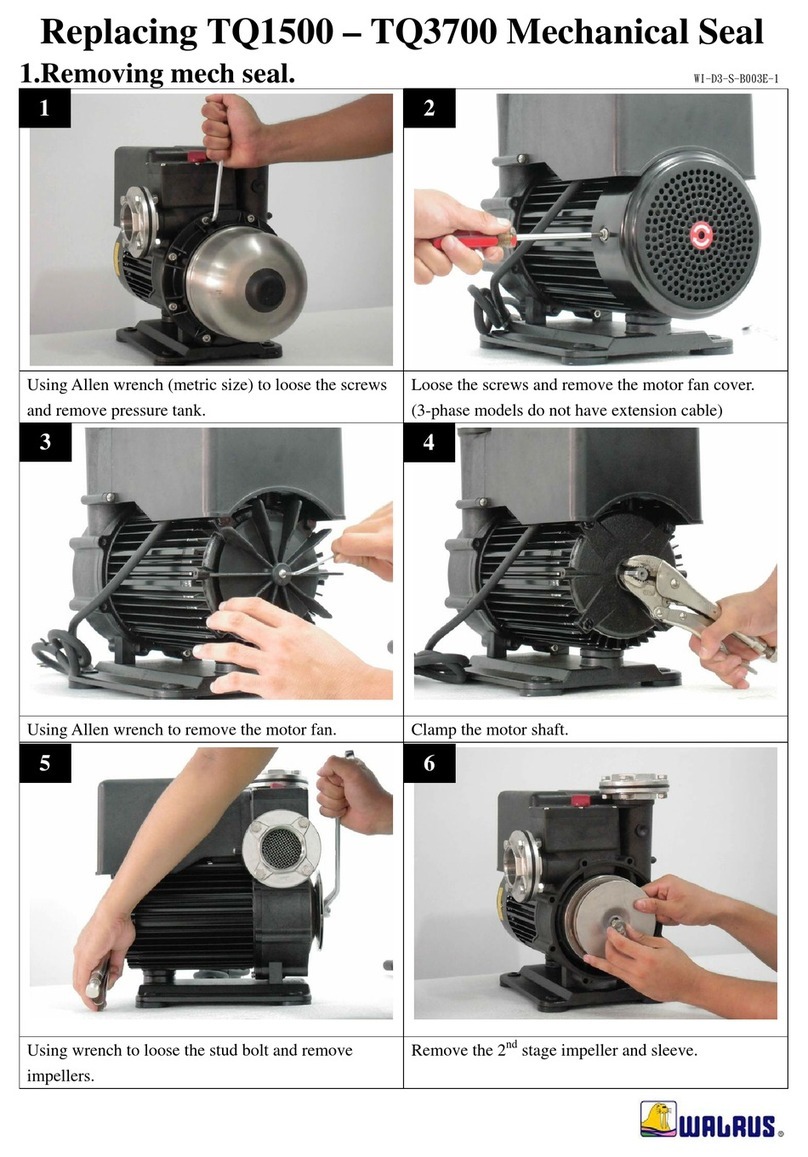

Walrus TQ1500 Replacing

ULTIMATE SPEED

ULTIMATE SPEED KH 4256 Original operating instructions

Garland

Garland GEISER 281 G instruction manual