Mouvex S4C Owner's manual

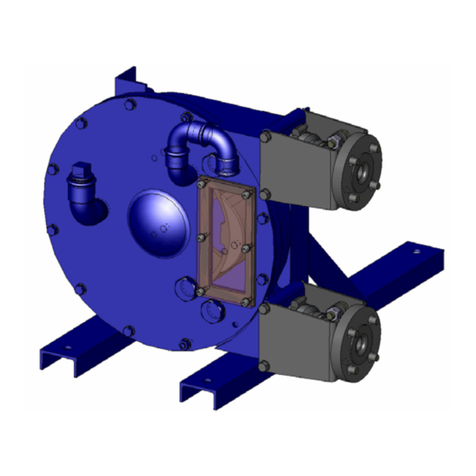

S4C PUMP

INSTALLATION

OPERATION

MAINTENANCE

INSTRUCTIONS 1002-B00 e

Section 1002

Effective July 2019

Replaces February 2018

Original instructions

Your distributor :

Z.I. La Plaine des Isles - F 89000 AUXERRE - FRANCE

Tel. : +33 (0)3.86.49.86.30 - Fax : +33 (0)3.86.49.87.17

contact.mouvex@psgdover.com - www.mouvex.com

WARRANTY :

S Series pumps are covered 24 months by warranty within the limits mentioned in our General Sales Conditions.

In case of a use other than that mentioned in the Instructions manual, and without preliminary agreement of MOUVEX,

warranty will be canceled.

2/15

NT 1002-B00 07 19 S4C Pump e

ECCENTRIC PISTON

MOUVEX PRINCIPLE

SAFETY, STORAGE, INSTALLATION AND MAINTENANCE INSTRUCTIONS

S4C MODEL

TECHNICAL CHARACTERISTICS

• Maximum speed : 750 rpm

• Range of acceptable temperature :

FKM :

* continuous.......................................0° C to 80°C

* washing / rinsing / sterilisation .....0° C to 121°C

• Acceptable pressure to the suction :

* minimum : - 0,4 barg (0,6 bara)

* maximum : 3,0 barg (4,0 bara)

• Acceptable maximal differential pressure : 6 bar*

• Cylinder capacity : 0,108 liter/rev.

* When the pump works with an inlet gauge pressure less than zero, the

maximum outlet pressure will be calculated as if the inlet pressure is

equal to zero.

1. OVERALL DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . .3

2. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.1 Installation design . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.2 Orientation of the pump ports . . . . . . . . . . . . . . . . . . . .5

2.3 Direction of rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.4 Protection of the installation . . . . . . . . . . . . . . . . . . . . .6

2.5 Unit assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3. USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.1 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.2 Dry running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.3 Scrapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4. CLEAN IN PLACE (CIP) & STERILISATION IN PLACE

(SIP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.1 Preamble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.2 Cleaning Out of Place . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.3 Cleaning In Place . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.4 Sterilisation In Place (SIP) . . . . . . . . . . . . . . . . . . . . .10

5. ASSEMBLY / DISMANTLING . . . . . . . . . . . . . . . . . . . . . .11

5.1 Necessary tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5.2 Opening the pump . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.3 Dismantling the transmission block . . . . . . . . . . . . . .12

5.4 Remounting the transmission block . . . . . . . . . . . . . .12

5.5 Remounting the pump . . . . . . . . . . . . . . . . . . . . . . . .12

6. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6.1 Checking of parts . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6.2 Checking of seals . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

7. STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

7.1 Short duration (≤ 1 month) . . . . . . . . . . . . . . . . . . . . .14

7.2 Long duration (> 1 month) . . . . . . . . . . . . . . . . . . . . .14

7.3 Restarting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

8. CERTIFICATE OF CONFORMITY . . . . . . . . . . . . . . . . . .15

TABLE OF CONTENTS Page

USED PRESSURE UNITS

Unit without suffix :

Differential pressure, for example, pressure difference between

equipment suction and discharge.

Unit with suffix "a" :

Absolute pressure.

Unit with suffix "g" :

Gauge pressure, given regarding to atmospheric pressure

(~101325 Pa, taken at 1 bar / 14,5 psi in this IOM).

Pompe

P

asp

P

re

f

Psuc Pdis

Pump

Example :

Psuc = -0,2 barg = 0,8 bara

Pdis = 8,8 barg = 9,8 bara

∆P = Pdis - Psuc = 9 bar

Definition of safety symbols

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the product, or in the manual,

look for one of the following signal words and be alert to the

potential for personal injury, death or major property damage.

Warns of hazards that WILL cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause personal injury or property

damage.

NOTICE

Indicates special instructions which are very important and

must be followed.

DANGER

WARNING

CAUTION

3/15

NT 1002-B00 07 19 S4C Pump e

1. OVERALL DIMENSIONS

Pump plate

POSITION OF THE ORIFICES

Dimensions in millimetres

Weight : 23,5 kg

Orifices Connection Standards

Suction 1 - 2 - 3 - 4 1

Discharge 1 - 2 - 3 - 4 2

This position of the mounting bracket does not permit

orientation of the discharge in position 4.

4/15

NT 1002-B00 07 19 S4C Pump e

2.1 Installation design

2.1.1 Pump

To obtain the service expected from a MOUVEX pump,

regarding both performance and longevity, it is vital that

the type of pump, its speed and the materials used for its

construction are determined as a function of the pump

output, its installation and operating conditions.

You can contact our Technical Services at any time to

ask for the information you require.

2.1.2 Pipe

Suction pipe length

Length should be as short as possible.

Suction pipe diameter

Diameter must be at least equal to pump port diameter

and even more if required by pumping conditions.

Suction pipe configuration

Check tightness to avoid accidental air intake.

--------------------------------------------------------------------

Pipe alignment and supporting

Pump must not support piping nor endure stress resul-

ting from piping weight or dilatation effects. For latters,

expansion loops should be included.

Not recommended

To be avoided if possible

Recommended

L=10xDminimum

R=3xDminimum

2. INSTALLATION

Pipe equipment

• Place valves close to the pump to avoid draining pipe

during maintenance operations. Preferably select full

bore ball or butterfly valves.

Pressure connections on pump suction and discharge

are recommended for settings and controls.

Make sure piping, vessels valves and other installation

devices are carefully cleaned before mounting.

• MOUVEX pumps are self priming. However, if line

emptying should be avoided and/or if suction lift is high,

a foot valve can be added.

• If pumped liquid presents a risk of in pipe solidification

and potential dilatation, low points on the pipe should

be avoided or equipped with drain valve.

• If installation is heated, it must be designed so that fluid

dilatation can evacuate through piping. Therefore fluid

contained in piping must be heated before fluid contained

in the pump. Also check that a heated pump is not iso-

lated by closed valves.

The S Series pump is a selfpriming volumetric PD pump.

Therefore, the pump must not run on a circuit with a closed

valve. This is valid both for the suction circuit and for the

discharge circuit.

For hoses fitting on pump suction or discharge, a hose

whip restrain device must be installed to limit the whip or

travel of the pressurized hose at start up, or in case the

hose breaks free.

2.2 Orientation of the pump ports

The suction port and the discharge port may be oriented

in various positions (see overall dimensions plan).

If the port positions need to be changed at the time of

installation, see the corresponding §.

The suction port may be oriented the top, the right or the

left. Unless otherwise specified, the equipment is delive-

red with the suction port the right (for an observer facing

the back of the pump).

The discharge port may be oriented at any angle around

the pump's horizontal axis.

To orient the suction port

(cf. § DISMANTLING THE PUMP) :

Unscrew the 4 screws 002 at the back of the pump

mounting braket 001. Orient the pumps’ suction port

101 to the desired position. Screw back the 4 screws

002 at the back of the pump mounting braket 001.

To orient the discharge port :

Unscrew the 4 nuts 106 then remove the base 401.

Orient the base 401 to the desired position. Tighten the

nuts 106.

2.3 Direction of rotation

The S4C pump only has one rotation direction (the pump

not being reversible), clockwise (observer facing the

back of the pump).

When connecting the motor, make sure, by observing the

shaft, that the motor is turning in the correct direction.

An incorrect rotation direction will not damage the pump

but it will not allow the unit to pump product.

WARNING: SEVERE PERSONAL INJURY OR

PROPERTY DAMAGE CAN CAUSE FROM

WHIPPING HOSES.

2. INSTALLATION (continued)

5/15

NT 1002-B00 07 19 S4C Pump e

2.4 Protection of the installation

In the case where valves are placed on the suction and-

discharge pipes, make sure that they cannot be closed-

without prior stopping of the pump.

The pump must be protected against excess pressure. It can

be delivered with a pressure switch to ensure this function.

Also make sure that the pump and the installation are

protected against any risk of deterioration through the

passage of foreign bodies.

2.5 Unit assembly

The following instructions apply to pumps delivered with

a bare shaft or for MOUVEX motor-driven pump units (if

the latter have no specific instruction notice).

2.5.1 Fixing to the ground of non-mobile units

The base plate is equipped with 3 fixed legs (height

92 mm) + 1 screw jack leg, all fixed under the base plate.

These legs are made of an identical substance to that of

the base plate.

2.5.2 Installation of units

The base below the unit is fundamental to ensuring cor-

rect operation and long service life.

The unit’s base must be flat, level and sufficiently resis-

tant to absorb the stresses caused by the motor-driven

pump unit without deformation (if it is made of concrete,

it must comply with the BAEL 91 standard).

If the unit is fastened using securing lugs or bolts, it must

be carefully wedged to avoid deforming the frame while

the bolts are tightened. A deformed frame would apply

damaging stresses on the pump and the drive mecha-

nism and misalign the coupling, causing vibrations,

noise and premature wear. Ensure that the frame is well

above the floor, except from the support plates.

If the unit is to be used in a food environment, support

plates that allow the unit to be lifted for easier cleaning

are recommended.

Allow, if possible, a clear space of approximately 50 cm

on each side of the motor-driven pump unit (overall

dimensions) to facilitate cleaning and give access if

necessary to the pump, reduction gear and motor faste-

ning nuts. In all cases, the dimensions around the motor-

driven pump unit must be designed to give the space

required for dismantling the pump (if the need arises,

use the values given on the overall dimension drawing).

For staff and equipment protection, the frame includes a

ground connection point that should be used.

WARNING

FAILURE TO RELIEVE SYSTEM

PRESSURE PRIOR TO PERFORMING

PUMP SERVICE OR MAINTENANCE

CAN CAUSE PERSONAL INJURY OR

PROPERTY DAMAGE.

Hazardous pressure

can cause

personal injury

or property damage.

WARNING

FAILURE TO INSTALL ADEQUATELY

SIZED PRESSURE RELIEF VALVE(S)

CAN CAUSE PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

Hazardous pressure

can cause

personal injury

or property damage.

WARNING

BE CAREFUL WITH THE WEIGHT OF

THE PARTS WHEN THEY ARE BEING

REMOVED.

The weight ot the parts

can be dangerous and

may provoke bodily inju-

ries

or material damages.

WARNING

DISCONNECT THE ELECTRICITY

SUPPLY BEFORE ANY MAINTENAN-

CE OPERATION.

Dangerous voltage.

Can cause

injury and death.

WARNING

PUMPS OPERATING AGAINST A CLO-

SED VALVE CAN CAUSE SYSTEM

FAILURE, PERSONAL INJURY AND

PROPERTY DAMAGE.

Hazardous pressure

can cause

personal injury

or property damage.

2. INSTALLATION (continued)

6/15

NT 1002-B00 07 19 S4C Pump e

2.5.3 Alignment of the motor/pump or reduction

gear/pump shafts

NEVER START A UNIT IF THE COUPLING ALIGNMENT IS

INCORRECT. THIS IS A CONDITION OF OUR GUARANTEE.

REMINDER :

Coupling must never be used to compensate for a misa-

lignment.

To control the alignment between the coupling and the

shaft, use a straight-edge for concentricity and thickness

gauges for angular misalignment (see instructions of the

coupling for authorised values).

The 3 figures below show in detail the operation and the

possible defects :

Controlling the alignment at each stage of the installa-

tion is important to be sure that none of these stages

have generated stresses on the unit or the pump:

• after fastening on the foundations

• after fastening the pipes

• after the pump has been operated at the normal ope-

rating temperature

Where the pumps are supplied assembled as a unit, the

motor and pump shafts have been perfectly aligned in

the factory before delivery, but they must be systemati-

cally controlled on acceptance at the site and realigned

if necessary.

To do this, do not modify the wedging of the various

parts, but check the flatness of the support surface and

use the adjustable foot to clear the frame of stresses that

could affect it.

2.5.4 Electic motors

Check the compatibility of the instructions on the motor

with the supply voltage.

Follow the wiring diagram, use wiring that is appropriate

for the power and be particularly careful about the

contacts which must be well tightened.

The motors should be protected with circuit breakers

and suitable fuses. Connect the regulatory electrical

grounding.

2.5.5 Thermic motors

Do not forget that these motors are not reversible. It is

absolutely necessary to carefully control the suction and

discharge sides of the pump before connecting the

group to the piping.

Using electric motors is very common now; however, we

strongly advise careful reading of the accompanying ins-

truction manual.

WARNING

OPERATION WITHOUT THE SHAFT

PROTECTOR CAN CAUSE SERIOUS

PERSONAL INJURY, MAJOR PROPER-

TY DAMAGE OR DEATH.

Do not operate

without guard

in place.

WARNING

DISCONNECT THE ELECTRICITY

SUPPLY BEFORE ANY MAINTENAN-

CE OPERATION.

Dangerous voltage.

Can cause

injury and death.

Carry out the control at four points :

at the top ‐ at the bottom ‐ left ‐ right

Correct

Bad alignment

Angular fault

WARNING

DISCONNECT THE ELECTRICITY

SUPPLY BEFORE ANY MAINTENAN-

CE OPERATION.

Dangerous voltage.

Can cause

injury and death.

CAUTION

THE SURFACES CAN BE AT A TEMPE-

RATURE LIABLE TO CAUSE INJURY

OR SEVERE DAMAGE.

Excessive temperature-

can cause injury

or severe damage.

2. INSTALLATION (continued)

7/15

NT 1002-B00 07 19 S4C Pump e

2.5.6 Control of the sense of rotation This control needs to be done with no liquid pumped

through the pump, and both the suction and discharge

circuits venting to avoid generating unexpected pressure

(at the suction side, for example). This will ensure that the

control will not damage either the pump or the installation.

Start the pump empty to check that the connections are

good and that the direction of rotation corresponds to the

suction and discharge direction on the installation. If it is

necessary to reverse the direction of rotation, follow the

instructions below :

Three-phase motor : switch any 2 current input wires.

Bi-phase motor : switch two same phase wires.

Single-phase motor : follow the instructions on the notice

supplied with the motor.

WARNING

TAKE ALL NECESSARY MEASURES

TO RENDER ANY START-UP, EVEN

ACCIDENTAL, OF THE PUMP DURING

THE WORK IMPOSSIBLE.

Any unforeseen start-up

can cause serious

injuries or important

material damages.

WARNING

HYDRAULIC PRESSURE MUST BE FULLY

RELEASED BEFORE MAINTENANCE

OPERATIONS IN ORDER TO PREVENT

PERSONAL INJURY OR PROPERTY

DAMAGE.

Hazardous pressure

can cause

personal injury

or property damage.

WARNING

A DRIVE SHAFT GUARD BETWEEN THE

PTO AND PUMP MUST BE PROVIDED

TO PREVENT PERSONAL INJURY,

PROPERTY DAMAGE OR DEATH.

Do not operate

without guard

in place.

2. INSTALLATION (continued)

8/15

NT 1002-B00 07 19 S4C Pump e

3.1 Commissioning

Before starting-up the pump, rinse the whole installation

so as to eliminate any contaminants that may remain in

the pipes, tanks etc. at the time of installation, taking

care to bypass the pump.

3.2 Dry running

The pump may run dry for a maximum duration of 5 minutes.

At priming :

From a practical point of view, the time necessary for pri-

ming is much lower than this value.

If, after a period of 1 min., the product is still not in the-

body of the pump, we recommend reconsidering the ins-

tallation at the suction section.

Draining of pipes (suction & discharge) :

A compressor effect close to 3 bar is obtained for a period

of 3 minutes. After that, the value falls to 0.5 bar as the

lubrication ensured by the pumped product rapidly disap-

pears from between the piston and the cylinder.

3.3 Scrapping

The pump must be scrapped in compliance with the

regulations in force.

During this operation, particular care must be paid to the

drainage stages of the pump (pumped product) and of

its transmission (lubricant).

For any pure water pumping during process or

cleaning operations, consult Mouvex imperatively.

3. USE

9/15

NT 1002-B00 07 19 S4C Pump e

4.1 Preamble

S-Series pumps have been designed to permit an easy

cleaning with CIP procedure. However, this cleaning might

not be compliant with some high hygienic standards and

should then be replaced by a hand cleaning (also called

Cleaning Out Place or COP) when application require a

cleaning in compliance with the strictest hygienic standards.

4.2 Cleaning Out of Place

Please refer to the § ASSEMBLY / DISMANTLING of the

pump, while taking care to avoid any dropping or any

bumping of the parts as this could damage them.

4.3 Cleaning In Place

S-Series pumps are perfectly adapted to all processes

necessitating a CIP.

A centrifugal pump will be used for this purpose and must

be placed upstream of the S4C pump. The useful CIP

flow discharged by the centrifugal pump must be 10 m3/h.

The CIP pump must be installed in series with the S4C

pump (see fig. 1) or the couple piston/cylinder risks

being damaged.

Figure 1

It is preferable not to run the S Series pump during CIP

although low speed (< 100 rpm) is acceptable by alter-

nating start/stop operation.

During CIP, the S4C pump is flushed through. Indeed,

the pressure at entry to the pump is higher than the exit

pressure, the piston lifts off from the cylinder and

enables complete circulation of the cleaning liquid

through the S4C pump (see fig. 2).

Figure 2

CIP Pump

S4C Pump

NOTICE

Check that the chemical solutions making up

the cleaning solution are totally compatible

with the Elastomer of the S-series pump's

transmission (FKM).

NOTICE

Although a particular care was taken to clean-

liness when assembling the pump, we recom-

mend to carry out a cleaning of the pump before

any use.

WARNING

IF PUMPING HAZARDOUS OR TOXIC

FLUIDS, THE SYSTEM MUST BE FLU-

SHED PRIOR TO PERFORMING ANY

SERVICE OPERATION.

Hazardous or toxic

fluids can cause

serious injury.

WARNING

FAILURE TO RELIEVE SYSTEM

PRESSURE PRIOR TO PERFORMING

PUMP SERVICE OR MAINTENANCE

CAN CAUSE PERSONAL INJURY OR

PROPERTY DAMAGE.

Hazardous pressure

can cause

personal injury

or property damage.

S SERIES PUMPS MUST NEVER BE USED AS

CIP PUMPS.

4. CLEAN IN PLACE (CIP) &

STERILISATION IN PLACE (SIP)

The centrifugal pump delivering the washing solution is

generally calibrated to a higher troughput than 10 m3/h,

therefore a pump bypass circuit must be provided for

(see fig.3).

Figure 3

Figure 4

Indeed, in this case, the pressure at entry to the S4C pump is

lower than the exit pressure and the piston remains stuck

against the cylinder. The S4C pump is not flushed through. Its

good cleaning is therefore no longer ensured and the cylin-

der/piston couple will be prematurely worn.

In the case of assembly in "parallel" (discharge of the centri-

fuge pump to the discharge of the S4C pump), the 2 pumps

must never be run at the same time. In this case the S4C

pump cleans itself.

4.4 Sterilisation In Place (SIP)

The serie S pumps are perfectly adapted to all pro-

cesses using SIP (Sterilisation In Place): pump

stopped / maximum 20 mn per cycle / 1 or 2 cycles

per day.

Bypass circuit

CIP Pump

S4C Pump

S4C Pump

CIP Pump

THE CENTRIFUGAL PUMP DELIVERING THE

CLEANING SOLUTION MUST NEVER BE

INSTALLED IN PARALLEL TO THE S4 PUMP

(see fig. 4).

4. CLEAN IN PLACE (CIP) &

STERILISATION IN PLACE (SIP) (continued)

10/15

NT 1002-B00 07 19 S4C Pump e

11/15

NT 1002-B00 07 19 S4C Pump e

5.1 Necessary tools

- Wrench no. 13

- Wrench no. 16

- Plastic mallet

- Hexagonal socket wrench no. 6

Assembly torques :

- M8 : 23,7 Nm

- M10 : 30 Nm

Before any dismantling, make sure that the

pump has been drained and take all necessary

measures to avoid its start-up.

No start-up, even accidental, must be possible.

WARNING

IF PUMPING HAZARDOUS OR TOXIC

FLUIDS, THE SYSTEM MUST BE FLU-

SHED PRIOR TO PERFORMING ANY

SERVICE OPERATION.

Hazardous or toxic

fluids can cause

serious injury.

CAUTION

THE PUMP LUBRICANT IS VERY SLIPPE-

RY AND MAY CAUSE SERIOUS INJURY.

ANY SPILLS MUST BE CLEANED UP.

Slippery lubricant.

Spills should be

cleaned up.

WARNING

BE CAREFUL WITH THE WEIGHT OF

THE PARTS WHEN THEY ARE BEING

REMOVED.

The weight ot the parts

can be dangerous and may

provoke bodily injuries

or material damages.

WARNING

TAKE ALL NECESSARY MEASURES

TO RENDER ANY START-UP, EVEN

ACCIDENTAL, OF THE PUMP DURING

THE WORK IMPOSSIBLE.

Any unforeseen start-up

can cause serious

injuries or important

material damages.

WARNING

FAILURE TO RELIEVE SYSTEM

PRESSURE PRIOR TO PERFORMING

PUMP SERVICE OR MAINTENANCE

CAN CAUSE PERSONAL INJURY OR

PROPERTY DAMAGE.

Hazardous pressure

can cause

personal injury

or property damage.

WARNING

DISCONNECTING THE FLUID OR

PRESSURE CONTAINMENT COMPO-

NENTS DURING PUMP OPERATION

CAN CAUSE SERIOUS PERSONAL

INJURY, DEATH OR MAJOR PROPERTY

DAMAGE.

Hazardous pressure

can cause

personal injury

or property damage.

5. ASSEMBLY / DISMANTLING

12/15

NT 1002-B00 07 19 S4C Pump e

5.2 Opening the pump

Disconnect the pump from the discharge pipe.

Remove the base 401 : unscrew the 4 nuts 106.

Remove the pressure of the spring 311 by pushing it

towards the piston 301 and swivelling it to free it as well

as the spring support 310.

Pull the piston 301 out by holding it by its circumference.

In the case where the piston remains stuck after pumping

a viscous or sticky product, use of a hub puller is advised.

This operation can be eased by lightly tapping the exter-

nal surface of the piston with the help of a plastic mallet.

Remove the cylinder 201 and the seals 205.

At this stage of dismantling, a visual check of the state

of the transmission block 596 can be carried out. The

transmission block is a wearing part. In preventive main-

tenance, it can be changed every 5000 running hours

(see § MAINTENANCE).

5.3 Dismantling the transmission block

Disconnect the pump from the drive device, unscrew the

pump mounting bracket 001 from the base plate of the

pump then separate it from the pump by unscrewing the

4 screws 002.

Unscrew the 8 screws 750, separate the main body 101

from the transmission block by screwing 2 M8 screws in

the 2 diametrically opposed M8 internal threads in the

transmission block flange (so as to progressively eject

the main body 101).

5.4 Remounting the transmission block

Proceed in the reverse order from the preceding chapter

taking care to correctly orient the main body 101.

All screws must be degreased and mounted with a

medium thread locking adhesive (LOCTITE®243* for

example).

Caution : The assembly torque must be applied pro-

gressively in opposition.

Assembly torque: M8 : 23,7 Nm.

5.5 Remounting the pump

Replace the cylinder 201 and the seal 205 so that the

dowel 223 penetrates in the notch of the main body.

Engage the piston 301 on the transmission block, the

piston gap facing the cylinder partition.

Give a small push (contrary to the eccentricity of the

grooved hub of the transmission block) to the piston to

centre it and engage it in the cylinder. Then, push it tight

in taking care to correctly engage the female profile of

the piston splines on the male of the transmission

assembly.

Put the pressure spring at the back of the piston 310

then the hand nut 311.

Re-mount the base 401 and the seal 205 taking care to

give the discharge port the desired angular position.

CAUTION

Incorrect mounting of the cylinder may lead to

deterioration of the pump.

5. ASSEMBLY / DISMANTLING (continued)

* Loctite®is a registered trademark.

13/15

NT 1002-B00 07 19 S4C Pump e

During all dismantling and re-mounting operations, takecare

to protect the parts against any dropping or bumping that

might damage them.

6.1 Checking of parts

6.1.1 Cylinder and piston

The piston 301 and the cylinder 201 are active parts

(wear parts) on which the pump's efficiency directly

depends. It is therefore advisable to regularly check the

pump's efficiency and replace the cylinder / piston if it

decreases.

In addition, as using a cylinder / piston that is too worn

may damage the pump's transmission system, it is advi-

sable to replace the cylinder / piston if the maximum

acceptable wear dimensions defined in the table below

are reached.

As changes in the pump's efficiency depend on the

conditions of use (pressure, rotation speed, liquid pum-

ped, etc.), MOUVEX recommends that users define the

monitoring ranges and the preventive maintenance

schedule according to their own experience.

6.1.2 Checking of piston bushing wear

Proceed as follows :

The transmission block being held still, place the piston on

the piston hub, taking care that the front faces of splined

hub and piston are on the same level.

Rotate piston by hand from right to left and vice versa up to

the point where it is stopped by hub splines. Then mea-

sure the distance between the 2 most extreme positions.

This distance is proportional to the clearance between

the splines.

Replace the set cylindre/piston if the distance (d) (mea-

sured on the piston periphery) exceeds the maximal dis-

tance given in the table :

d : measured distance

6.2 Checking of seals

Seals material are intended for use in normal conditions

in food process. In order to ensure a reliable sealing on

S series pumps we recommend to :

- do an inspection of the seals every three months (this

time could be shorter if using the pump in hard condi-

tions. Contact the manufacturer for advice if necessary).

- replace the pump sealing every two years.

NOTICE

When disassembling the piston nut 304, if the

enclosed thread surfaces have become soiled,

we recommend cleaning them as follows : clean

the inner thread by washing, rinsing and sterili-

zing the whole part (i.e. with a steam sterilization),

then remove any impurities from the external

threads by washing with a brush followed by

rinsing with a bactericide solution before reas-

sembly.

Piston

301

mm (inch)

Cylinder

201

mm (inch)

S4

New dimension 7

(0,276)

32

(1,260)

Minimum wear dimension

acceptable

4

(0,157)

29

(1,142)

Pump S2 S4 S6

Max distance (mm) 2,5 2,5 4

d

d

6. MAINTENANCE

14/15

NT 1002-B00 07 19 S4C Pump e

If necessary, refer to § ASSEMBLY / DISMANTLING for pump

disassembly.

7.1 Short duration (≤ 1 month)

MOUVEX pumps and motor-driven pumps are well lubri-

cated when delivered to protect the internal parts during

brief storage in a building where :

• the temperature remains between 10°C and 50°C.

• the relative humidity does not exceed 60%.

• exposure to vibration is limited.

• pump is stored in an area sheltered from bad weather

and sun.

7.2 Long duration (> 1 month)

The recommendations from the manufacturer should be

followed if the pump is stored with its gear motor.

Pump ports should be filled with a non-corrosive liquid

that it compatible with the pump components in order to

prevent corrosion.

Unpainted external surfaces of the pump (e.g. shafts,

couplings, etc.) should be covered in some form of anti-

corrosion protection.

The best storage conditions are inside a building that

meets the conditions set out above.

If inside storage is not possible, the materials should be

covered to prevent direct exposure to sun and bad wea-

ther. This protection should also prevent condensation.

Rotate pump shaft manually a few revolutions every two

months.

7.3 Restarting

Follow the standard start-up procedure for the pump/

motor-driven pump, as well as the instructions below.

Turn the pump by hand to make sure the parts move

freely.

Control transmission sleeve which must not show any

visible damage :

• Cracks

• Vulcanization

• Deformation

• Discoloration

• Etc.

Do not attempt to remove the sleeve or to empty the oil

from it. This operation can only be done in the factory.

If in doubt, replace the complete transmission.

WARNING

IF PUMPING HAZARDOUS OR TOXIC

FLUIDS, THE SYSTEM MUST BE FLUSHED

PRIOR TO PERFORMING ANY SERVICE

OPERATION.

Toxic or hazardous

fluids can cause

serious injury.

7. STORAGE

15/15

NT 1002-B00 07 19 S4C Pump e

Est conforme aux dispositions suivantes :

Directive « MACHINES » 2006/42/CE et aux législations nationales la

transposant, portant sur les dispositifs de sécurité liés aux risques

mécaniques et électriques applicables aux machines tournantes.

NF EN 809:2009 NF EN 1672-2:2009 NF EN ISO 13857:2008

NF EN 12162:2009

Directive « ATEX » 2014/34/UE du26 février 2014 et aux législations

nationales la transposant, portant sur les appareils destinés à être utilisés

enatmosphères explosibles. Conformité obtenue par applicationdes

normes :

NF EN 1127-1:1997 NF EN 13463-1:2009 NF EN 13463-5:2009

CertificationATEX délivrée par INERIS*, Organisme Certificateur, et portant

le marquage suivant : (C)

L’équipement désigné ci-dessus doit impérativement respecter les

conditions d’utilisationATEX décrites dans nos notices d’instruction. Il doit

être employé conformément à l’utilisationqui ena été prévue de par sa

conceptionet sa fabrication, et conformément aux normes envigueur.

Nous, soussignés, déclarons que l’équipement concerné est conforme aux

Directives listées ci-dessus et aux normes applicables s’y rapportant.

Is in conformity with the provis

i

ons of the following D

i

rective:

« MACHINES » Directive 2006/42/EEC as transposed by the national

legislation, concerning safety equipments and arrangements relative to

mechanical and electric risks applicable to rotative machines.

NF EN 809:2009 NF EN 1672-2:2009 NF EN ISO 13857:2008

NF EN 12162:2009

« ATEX » Directive 2014/34/EU (26 Feb. 2014) as transposed by the

national legislation, concerning equipment intended to be used in explosive

atmospheres. Conformity obtained by application of the standards :

NF EN 1127-1:1997 NF EN 13463-1:2009 NF EN 13463-5:2009

ATEX Certification delivered by INERIS*, Notified Body, and with the

following marking: (C)

The equipment indicated above must imperatively comply with the ATEX

conditions of use described in our Instruction book. It must be used

according to the foreseen use by its design and its manufacturing, and

according to the current standards.

We, undersigned, declare that the concerned equipment is in conformity

with the Directives listed above and in the applicable standards in force.

den Bestimmungen der nachstehenden Richtlinien en

t

spricht:

„Maschinen-Richtlinie“ 2006/42/EEC wie umgesetzt im nationalen Recht

hinsichtlich der Ausrüstungssicherheit und Sicherheitsvorkehrungen bezogen

auf mechanische und elektrische Risiken, die für rotierende Maschinen

gelten.

NF EN 809:2009 NF EN 1672-2:2009 NF EN ISO 13857:2008

NF EN 12162:2009

„ATEX“ Richtlinie 2014/34/EU (26. Feb. 2014) wie umgesetzt im

nationalen Recht in Bezug auf Ausrüstungen für den Einsatz in

explosionsgefährdeter Atmosphäre. Die Konformität hat Geltung durch

Anwendung folgender Normen:

NF EN 1127-1:1997 NF EN 13463-1:2009 NF EN 13463-5:2009

Die ATEX-Zertifizierung wurde von der benannten Stelle INERIS* erteilt, und

mit folgender Kennzeichnung: (C)

Oben stehend bezeichnete Ausrüstung muss unbedingt den in unseren

Betriebsanleitungen beschriebenen ATEX Anwendungs-bedingungen

entsprechen. Sie ist entsprechend dem durch Konstruktion und Fabrikation

vorgesehenen Verwendungszweck und entsprechend den geltenden Normen

einzusetzen.

Die Unterzeichner erklären, dass die bezeichnete Ausrüstung den oben

aufgeführten Richtlinien und den diesbezüglich geltenden Normen entspricht.

DECLARATION UE DE CONFORMITE

EU CERTIFICATE OF CONFORMITY – EU KONFORMITÄTSERKLÄRUNG

MOUVEX sas, ZI La Plaine des Isles – 2 Rue des Caillottes – 89000 Auxerre France, déclare que l’équipement suivant / declares the following equipment / erklärt, dass folgende Ausrüstung:

Modèle : N° de série : (A) Répondant aux spécifications indiquées dans l’ARC N° : (B)

Designation / Bezeichnung Serial N° / Serien Nr According to the specifications recorded in the acknowledgment of order N°:

Entsprechend den Spezifikationen aus AB-Nr :

Pour la Sté MOUVEX sas, fait à Auxerre le :

For Mouvex sas company – Date :

Fur die Fa Mouvex sas - Datum :

Responsable Qualité Clients

Customer

Q

ualit

y

Mana

g

er

/

Q

ualitätsbeau

f

tra

g

te

r

II __ G ____ II __ – T __ Temp Max produit pompé / Max Temp Flow / Max. T° Medium = _____ °C (X =voir notice / see IOM / siehe Handbuch)

Configuration : Pompe / Compresseur arbre nu Groupe de pompage / de compression

Konfiguration (Pump / Compressor « bare-shaft ») (Pumping Unit / Compressor Unit)

(Pumpe / Kompressor, freies Wellenende (Pumpen- / Kompressoraggregat)

Type / Geräteart :

Pompe à mvt excentré (Eccentric Disc Pump / Ringkolbenpumpe)Pompe à lobes (Lobes Pump / Drehkolbenpumpe)

Pompe péristaltique (Peristaltic Pump / Schlauchpumpe) Pompe à palettes (Vanes Pump / Flügelzellenpumpe)

Pompe centrifuge (Centrifugal Pump / Kreiselpumpe)Autre pompe (Other Pump / Andere Pumpe)

Compresseur à Vis (Screws compressor / Schraubenverdichter)

Compresseur à palettes (Vanes compressor / Flügelzellenverdichter)

Refroidisseur H

y

drauli

q

ue (H

y

draulic oil cooler / H

y

draulikkühler

)

CTRL.D025 – rév.04 du 25/05/2016 – Déclaration de conformité CE-Atex

* (INERIS

–

Parc Techno Atala

–

60550 Ver

n

eui

l

-

e

n

-

Halatte

–

France

)

.Pa

g

e 1/2

8. CERTIFICATE OF CONFORMITY

Table of contents

Other Mouvex Water Pump manuals

Mouvex

Mouvex C24 i Owner's manual

Mouvex

Mouvex SLS4 i User manual

Mouvex

Mouvex AS25 Owner's manual

Mouvex

Mouvex CC8-40 Owner's manual

Mouvex

Mouvex SLC24 i Owner's manual

Mouvex

Mouvex SLC1 Owner's manual

Mouvex

Mouvex H-FLO 65 Owner's manual

Mouvex

Mouvex C12 A Owner's manual

Mouvex

Mouvex SLS12 i Owner's manual

Mouvex

Mouvex SLS24 i Owner's manual

Popular Water Pump manuals by other brands

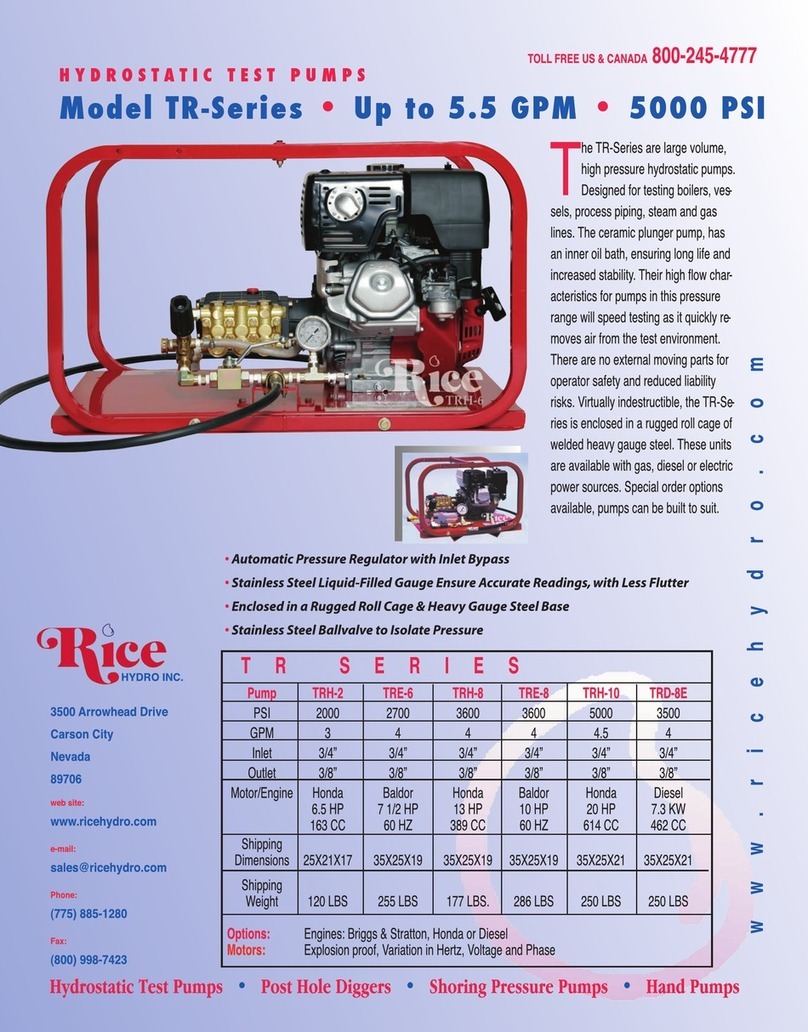

RICE HYDRO

RICE HYDRO TR Series quick start guide

Grundfos

Grundfos S Installation and operating instructions

Grundfos

Grundfos UNILIFT AP35B Installation and operating instructions

Black Knight

Black Knight HCPRO 12 CFM Operation manual

Hozelock

Hozelock 3000 K7 manual

EINHELL

EINHELL 41.709.64 Original operating instructions