Mouvex CC8-40 Owner's manual

CC8-40 - CC8-50 - CC8-65

pumps

Constructions A & C

INSTRUCTIONS 1010-D00 e

Section 1010

Effective May 2020

Replaces March 2018

INSTALLATION

OPERATION

MAINTENANCE

Original instructions

Your distributor :

Z.I. La Plaine des Isles - F 89000 AUXERRE - FRANCE

Tel. : +33 (0)3.86.49.86.30 - Fax : +33 (0)3.86.49.87.17

contact.mouvex@psgdover.com - www.mouvex.com

WARRANTY :

CC8 Series pumps are covered 24 months by warranty within the limits mentioned in our General Sales Conditions.

In case of a use other than that mentioned in the Instructions manual, and without preliminary agreement of MOUVEX,

warranty will be canceled.

2/20

NT 1010-D00 05 20 CC8-40 - CC8-50 - CC8-65 A & C pumps e

NOTE :

The numbers after part names correspond to items in the

spare parts lists.

REMARKS :

CC8 pumps MUST be installed in systems designed by qualified

personnel. The installation MUST be in compliance with local stan-

dards, national regulations and rules of safety.

This manual is designed to permit installation and commis-

sioning of CC8 pumps and MUST accompany the pump.

Maintenance of CC8 pumps must ONLY be carried out by qualified

technicians. This maintenance must meet local and national stan-

dards as well as all safety regulations. Read this manual, including

all instructions and warnings, in full BEFORE any use of CC8

pumps.

Do not remove the warning and use label stickers that are found

on the CC8 pumps.

Definition of safety symbols

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the product, or in the manual,

look for one of the following signal words and be alert to the

potential for personal injury, death or major property damage.

Warns of hazards that WILL cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause personal injury or property

damage.

NOTICE

Indicates special instructions which are very important and

must be followed.

DANGER

WARNING

CAUTION

1. OPERATING LIMITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2. OVERALL DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . .4

3. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.1 Choice of pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.2 Direction of rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.3 Pump protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.4 Pipe diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.5 Piping assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.6 Bypass setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4. DIRECT DRIVE BY MOTOR . . . . . . . . . . . . . . . . . . . . . . .10

4.1 Installation of units . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4.2 Alignment of motor/pump and reduction gearbox/pump

shafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4.3 Electric motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4.4 Diesel engines drive . . . . . . . . . . . . . . . . . . . . . . . . . .11

5. DRIVE BY POWER TAKE OFF . . . . . . . . . . . . . . . . . . . . .11

6. USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

6.1 Pumping hot liquids . . . . . . . . . . . . . . . . . . . . . . . . . .12

6.2 Pump full of liquid when stopped . . . . . . . . . . . . . . . .12

6.3 Starting-up the pump . . . . . . . . . . . . . . . . . . . . . . . . .12

6.4 Running without liquid in the pump . . . . . . . . . . . . . . .12

6.5 Using of the pump with a valve closed on the

discharge line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

6.6 Shutting down the pump . . . . . . . . . . . . . . . . . . . . . . .12

6.7 Protection from frost . . . . . . . . . . . . . . . . . . . . . . . . . .13

6.8 Restarting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

7. NECESSARY TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

8. DISMANTLING - REASSEMBLY . . . . . . . . . . . . . . . . . . .14

8.1 Dismantling on side opposite to drive system . . . . . .15

8.2 Dismantling on drive side . . . . . . . . . . . . . . . . . . . . . .15

8.3 Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

8.4 Assembly of flange for hydraulic trunk . . . . . . . . . . . .15

9. CHANGING THE VANES . . . . . . . . . . . . . . . . . . . . . . . . .16

10. CHANGING MONOBLOC SHAFT SEAL . . . . . . . . . . . . .16

11. BYPASS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

12. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

12.1 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

12.2 Inspection of the vanes . . . . . . . . . . . . . . . . . . . . . . .17

12.3 Cleaning the filter . . . . . . . . . . . . . . . . . . . . . . . . . . .17

13. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . .18

13.1 Abnormal noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

13.2 Leaking seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

13.3 Inadequate output . . . . . . . . . . . . . . . . . . . . . . . . . . .18

14. STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

14.1 Short duration (≤ 1 month) . . . . . . . . . . . . . . . . . . . .19

14.2 Long duration (> 1 month) . . . . . . . . . . . . . . . . . . . .19

15. SCRAPPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

16. CERTIFICATE OF CONFORMITY . . . . . . . . . . . . . . . . .20

TABLE OF CONTENTS Page

TANK TRUCK PUMP

SAFETY, STORAGE, INSTALLATION AND MAINTENANCE INSTRUCTIONS

MODELS : CC8-40 - CC8-50 - CC8-65 A & C

3/20

NT 1010-D00 05 20 CC8-40 - CC8-50 - CC8-65 A & C pumps e

1. OPERATING LIMITS

The pumps CC8 are delivered with spring (4 or 8 bar) adjusted at 4 bar.

When requested, they can be delivered with a 8 bar spring adjusted at the maximum pressure of use.

Temperature range allowed : Construction A ..........-20°C to +80°C

Construction C..........-20°C to +170°C

Products authorised : Clean petroleum product

Other products: Contact us

Construction Speed range

(rpm)

Flow rate pression

(m3/h) Max

pressure

(bar)

Required power

(Kw)

CC8-40 CC8-50 CC8-65 CC8-40 CC8-50 CC8-65

Construction A

Viscosity < 40 cSt 450 ► 1200 48 - - 4 7,6 - -

450 ►750 28 35 44 8 7,8 10 13

450 ► 1000 40 50 65 4 6 6,5 8,5

Construction C

Viscosity < 400 cSt 450 ►750 31 36 44 8 9,7 11 13

Viscosity < 900 cSt 450 ►600 - - 35 6 - - 7,7

4/20

NT 1010-D00 05 20 CC8-40 - CC8-50 - CC8-65 A & C pumps e

2. OVERALL DIMENSIONS

Weight : 48 kg

CC8-40

CC8-50

EBypass adjustment

JEnd plate dismounting

V1 Drain/vacuum plug

V2 Drain/pressure plug

PPump plate

PA ATEX plate

SInserting M6 sensor - Thread size : 8 mm

5/20

NT 1010-D00 05 20 CC8-40 - CC8-50 - CC8-65 A & C pumps e

2. OVERALL DIMENSIONS (continued)

Weight : 57 kg

CC8-65

EBypass adjustment

JEnd plate dismounting

V1 Drain/vacuum plug

V2 Drain/pressure plug

PPump plate

PA ATEX plate

SInserting M6 sensor - Thread size : 8 mm

6/20

NT 1010-D00 05 20 CC8-40 - CC8-50 - CC8-65 A & C pumps e

2. OVERALL DIMENSIONS (continued)

$

[0

3

(

9

0

9

0

6

3$

[0

[0

VXU

[0

VXU

[0

Weight : 56 kg

CC8-40 - CC8-50

with SAE-A hydraulic motor

Hydraulic motor

Coupling hub provided

for hydraulic motor shaft Ø 25

(for other Ø consult us)

DETAIL A

DETAIL B

DETAIL B : Motor fixation

EBypass adjustment

V1 Drain/vacuum plug

V2 Drain/pressure plug

PPump plate

PA ATEX plate

SInserting M6 sensor - Thread size : 8 mm

7/20

NT 1010-D00 05 20 CC8-40 - CC8-50 - CC8-65 A & C pumps e

2. OVERALL DIMENSIONS (continued)

!>'

!>'

<

<

Weight : 67 kg

CC8-65

with SAE-A hydraulic motor

Hydraulic motor

Coupling hub provided

for hydraulic motor shaft Ø 25

(for other Ø consult us)

DETAIL A

DETAIL B

DETAIL B : Motor fixation

EBypass adjustment

V1 Drain/vacuum plug

V2 Drain/pressure plug

PPump plate

PA ATEX plate

SInserting M6 sensor - Thread size : 8 mm

8/20

NT 1010-D00 05 20 CC8-40 - CC8-50 - CC8-65 A & C pumps e

3.1 Choice of pump

To obtain the service expected from a MOUVEX pump,

regarding both performance and longevity, it is vital that

the type of pump, its speed and the materials used for its

construction are determined as a function of the pump

output, its installation and operating conditions.

You can contact our Technical Services at any time to

ask for the information you require.

3.2 Direction of rotation

The pump rotates in one direction only. This is indicated by

an arrow on the pump housing. However, the pump has

both of shaft-ends led out and must be driven through

one the other depending on the direction of rotation of the

power take-off.

Because the pump rotates in one direction only, the

positions of the suction and discharge ports are not be

reversed (see arrows on housing). The safety bypass

has not to be reversed.

3.3 Pump protection

It is essential to protect the pump against possible

foreign matter by connecting a filter to the suction pipe

(see Instructions 1011-G00 Filters PF).

3.4 Pipe diameter

In order to achieve the best usage conditions, it is impor-

tant to take the following recommendations into account

when it comes to pipe dimensions :

• The pipe diameter should be chosen as a function of

pipe length and the flow rate and viscosity of the pum-

ped liquid, so that any head loss remains within the per-

missible limits for the motor/pump unit. Therefore it is

difficult to give general and precise directions. However,

it is never a disadvantage to over-dimension pipe dia-

meters, especially for the section on the inlet side.

• In the case of thin liquids and the piping on the dischar-

ge side, one can generally allow a diameter equal to

that of the ports on the pump and a larger diameter for

the piping on the inlet side, if the value for the inlet

power of the pump is negative or especially high.

• In the case of viscous liquids, special care should be

given to choosing pipe diameters. In fact, the variation

in head loss is proportional to viscosity and inversely

proportional to the diameter as power of 3. A slight

reduction in the pipe diameter could have serious

consequences for the operating conditions of the pump.

Our Technical Services are always available to provide

you with precise data if you give them accurate informa-

tion or, better still, the installation plans.

3.5 Piping assembly

In order to achieve the best usage conditions, it is impor-

tant to take the following recommendations into account

when it comes to fitting pipes :

• The location of the pump in the transfer or recycling cir-

cuit should always be determined so as to reduce the

height and length of the piping as much as possible.

• Wherever possible, siphons and reverse slopes should

be avoided in the inlet piping.

• Particular care needs to be taken with the sealing on

the inlet side to prevent air entering.

• Pipe elbows must always have a large radius (more

than 3 times the diameter of the pipes) and must not be

mounted too close to the pump flanges (min. recom-

mended distance : 10 times the diameter of the pipes),

on both the inlet and discharge sides.

• The pipes are supported and aligned with the pump in

such a way as to avoid putting stress on the pump flan-

ges. Non-compliance with this instruction can lead to

deformation of pump parts, misalignment of bearings

and accelerated material wear, even causing parts to

break.

• For ease of adjustment and checking, it is recommen-

ded that pressure tapping ports for pressure

gauges/vacuum gauges be provided as close as pos-

sible to the pump’s inlet ports (preferably, at a distance

of less than 5 times the diameter of the piping).

• If the suction head is especially high or if you want to

prevent the pipes emptying at shutdown, you can

install a foot valve. It should have a large diameter so

as not to generate additional head loss.

• We recommend placing valves as close as possible to

the pump ports to avoid having to drain the entire sys-

tem each time maintenance is carried out. These val-

ves should have the same diameter as the pipes and

preferably by full bore models.

• All these steps should be taken to prevent foreign

bodies entering the pump (the use of a filter in the

pump inlet pipe is strongly recommended).

• Before installing new pipes or tanks, be sure to clean

them very carefully to remove any solder, rust, etc.

which could be carried along with the water and cause

excessive pump wear.

• The pipes should be designed to allow for thermal

expansion/contraction (the use of flexible hoses or

expansion loops is recommended).

• If the liquid may freeze or solidify, prepare for draining

the piping by installing drain taps at the low points and

air vents at the high points.

3. INSTALLATION

3.6 Bypass setting

The bypass must be set depending on the needs and

the limitations of the installation.

A preset can be operated for mechanical bypass, please

refer to the information below, but it has to be followed up

by a check-up on the installation.

Process :

• Loose the nut.

• Unscrew completely the pressure screw.

• Screw it clockwise depending on the values given below.

Please consider te accuracy is +/- 0,3 bar on the given

values.

• Tight the nut.

• Check on the installation the pump gives the right pres-

sure (using a manometer) with a closed valve on the

discharge line.

Pressure got (bar) :

CC8-40 - CC8-50

CC8-65

(1) Pressure limited to 8 bar, prohibited zone

Pressure screw

Pressure screw rotation Mechanical bypass

4 bar 8 bar

0 2,1 3,5

1 2,4 4,0

2 2,6 4,5

3 2,9 5,0

4 3,2 5,5

5 3,4 6,0

6 3,6 6,5

7 3,9 7,5

8 4,2 8,0

9 4,4 -

Pressure screw rotation Mechanical bypass

4 bar 8 bar

0 2,3 4,0

1 2,6 4,5

2 2,7 5,0

3 2,8 5,5

4 3,3 6,0

5 3,6 7,0

6 3,9 7,5

7 4,2 8,0

8 4,4 8,5 (1)

9 4,6 9,5 (1)

9/20

NT 1010-D00 05 20 CC8-40 - CC8-50 - CC8-65 A & C pumps e

3. INSTALLATION (continued)

4.1 Installation of units

The correct seating of the pump is vital for its efficient ope-

ration and its longevity. The base must be flat, level and

sufficiently resistant to absorb the stresses caused by the

motor-driven pump without deformation (if it is made of

concrete, it must comply with standard BAEL 91).

In the case where the unit is fastened by anchor lugs or

bolts, it must be carefully wedged to prevent any defor-

mation of the chassis when tightening the bolts.

Deformation of the chassis will cause stress prejudicial

to the pump and the drive device and put the coupling

out of true alignment, thereby causing vibrations, noise

and premature wear. Care must be taken so that the

chassis is clear of the ground, apart from the base pla-

tes.

If the chassis is a one-piece unit in doubled plate, it is

recommended that a horizontal clearance of about 50

cm be left between one section of the chassis and the

other to allow access for fastening the nuts on the pump,

reduction gearbox and motor. In all cases, the clearance

around the motor-driven pump should all room for

demounting the pump (for distances, refer to the dimen-

sion drawing at the start of the notice).

The chassis is equipped with a ground connection that

must be used to protect people and equipment.

4.2 Alignment of motor/pump and reduction

gearbox/pump shafts

The motor and pump shafts are accurately aligned at the

factory before dispatch, but they should be checked

carefully when received at the site and realigned if

necessary. To align the coupling and the shaft, use a

straight-edge to check the concentricity and thickness

gauges for the angular misalignment.

The 3 figures below show the procedure in detail and the

admissible deviations :

Controlling the alignment at each stage of the installation

is important to be sure that none of the following procedu-

res has generated stresses on the unit or the pump :

• after fastening on the foundations.

• after fastening the pipes.

• after the pump has been operated at the normal

operating temperature.

REMINDER :

You cannot rely on the coupling to compensate for mis-

alignment.

NEVER START A UNIT IF THE COUPLING ALIGNMENT IS

INCORRECT. THIS WILL RENDER OUR WARRANTY INVALID.

WARNING

OPERATION WITHOUT THE SHAFT

PROTECTOR CAN CAUSE SERIOUS

PERSONAL INJURY, MAJOR PROPER-

TY DAMAGE OR DEATH.

Do not operate

without guard

in place.

WARNING

DISCONNECT THE ELECTRICITY

SUPPLY BEFORE ANY MAINTENAN-

CE OPERATION.

Dangerous voltage.

Can cause

injury and death.

WARNING

BE CAREFUL WITH THE WEIGHT OF

THE PARTS WHEN THEY ARE BEING

REMOVED.

The weight ot the parts

can be dangerous and may

provoke bodily injuries

or material damages.

Carry out the control at four points :

at the top ‐ at the bottom ‐ left ‐ right

Correct

Bad alignment

Angular fault

(maximum : 1°)

10/20

NT 1010-D00 05 20 CC8-40 - CC8-50 - CC8-65 A & C pumps e

4. DIRECT DRIVE BY MOTOR

4.3 Electric motors

Check that the supply voltage matches the indications

on the motor rating plate.

Comply with the wiring diagram, make sure the wires are

rated for the power and take care with the contacts,

which must be thoroughly tightened. The motors must

be protected by appropriate circuit breakers and fuses.

Connect the regulatory ground connections.

Check the direction of rotation.

This check should be done with no liquid being pumped,

and both the inlet and discharge circuits vented to avoid

generating unexpected pressure (on the inlet side, for

example). This will avoid damaging either the pump or

the system.

Start the pump empty to check that the connections are

good and that the direction of rotation corresponds to the

system intake and discharge directions. If it is necessary

to reverse the direction of rotation, follow the instructions

below :

Three-phase motor : switch any 2 current input wires.

Bi-phase motor : switch two same phase wires.

Single-phase motor : follow the instructions on the notice

supplied with the motor.

4.4 Diesel engines drive

Do not forget that these engines are not reversible. It is

therefore vital to carefully check the inlet and outlet sides

of the pump before connecting the pump unit to the piping.

The use of diesel engines drive is now well known.

Nevertheless, we strongly recommend that you carefully

read the technical manuals concerning them.

WARNING

OPERATION WITHOUT THE SHAFT

PROTECTOR CAN CAUSE SERIOUS

PERSONAL INJURY, MAJOR PROPER-

TY DAMAGE OR DEATH.

Do not operate

without guard

in place.

WARNING

DISCONNECT THE ELECTRICITY

SUPPLY BEFORE ANY MAINTENAN-

CE OPERATION.

Dangerous voltage.

Can cause

injury and death.

WARNING

TAKE ALL NECESSARY MEASURES

TO RENDER ANY START-UP, EVEN

ACCIDENTAL, OF THE PUMP DURING

THE WORK IMPOSSIBLE.

Any unforeseen start-up

can cause serious

injuries or important

material damages.

WARNING

PUMPS OPERATING AGAINST A CLO-

SED VALVE CAN CAUSE SYSTEM

FAILURE, PERSONAL INJURY AND

PROPERTY DAMAGE.

Hazardous pressure

can cause

personal injury

or property damage.

CAUTION

THE SURFACES OF THE PUMP CAN

BE AT A TEMPERATURE LIABLE TO

CAUSE INJURY OR SEVERE DAMAGE.

Excessive temperature-

can cause injury

or severe damage.

11/20

NT 1010-D00 05 20 CC8-40 - CC8-50 - CC8-65 A & C pumps e

4. DIRECT DRIVE BY MOTOR (continued)

Refer to Instructions NT 1010-B00 CC8 CC10 CC20 PUMPS

DRIVEN BY POWER TAKE OFF.

5. DRIVE BY POWER TAKE OFF

12/20

NT 1010-D00 05 20 CC8-40 - CC8-50 - CC8-65 A & C pumps e

6. USE

The operator should remain nearby the equipment through-

out the use to ensure the proper functioning of the system.

6.1 Pumping hot liquids

When pumping hot liquids, make your you retighten

screws and bolts after starting for the first time in order

to compensate for contraction.

6.2 Pump full of liquid when stopped

If the pump circuit is to be located between valves and/or

a non-return valve, you need to take account of the

variations in temperature that can lead to contraction of

the liquid in the circuit. In this case, you need to provide

some means of compensating for the contraction. A dis-

charge valve may be sufficient. The opening pressure

for this valve should be compatible with the permitted

pressure for the other components in the circuit.

It is also advisable to fit a discharge device to allow the

circuit to be completely emptied for any maintenance work.

In the case of liquids containing particles settling on

shut-down, it is necessary to make sure the consistency

of the deposit will not impede restarting the pump.

6.3 Starting-up the pump

Before starting the pump, make sure that the following

conditions are met :

• The circuit should be in one of its pumping configu-

rations, with the appropriate valves open, especially

on the intake side.

• For products requiring heating, they must be brought

to their pumping temperature before starting the

pump.

6.4 Running without liquid in the pump

MOUVEX CC8 pumps can run without liquid in the pump

for 5 minutes without causing damage, in particular during

pump priming.

6.5 Using of the pump with a valve closed on

the discharge line

The using of the pump with a valve closed on the dis-

charge line implies the liquid is not renewed which gene-

rates a heating up. In consequence, that operating way

must not exceed 3 minutes.

6.6 Shutting down the pump

When shutting down the pump, we recommend waiting

for it to stop completely before closing the valves, espe-

cially the inlet valve.

WARNING

FAILURE TO INSTALL ADEQUATELY

SIZED PRESSURE RELIEF VALVE(S)

CAN CAUSE PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

Hazardous pressure

can cause

personal injury

or property damage.

CAUTION

THE SURFACES OF THE PUMP CAN

BE AT A TEMPERATURE LIABLE TO

CAUSE INJURY OR SEVERE DAMAGE.

Excessive temperature-

can cause injury

or severe damage.

WARNING

IF PUMPING HAZARDOUS OR TOXIC

FLUIDS, THE SYSTEM MUST BE FLUS-

HED PRIOR TO PERFORMING ANY

SERVICE OPERATION.

Toxic or hazardous

fluids can cause

serious injury.

WARNING

FAILURE TO RELIEVE SYSTEM

PRESSURE PRIOR TO PERFORMING

PUMP SERVICE OR MAINTENANCE

CAN CAUSE PERSONAL INJURY OR

PROPERTY DAMAGE.

Hazardous pressure

can cause

personal injury

or property damage.

WARNING

OPERATION WITHOUT THE SHAFT

PROTECTOR CAN CAUSE SERIOUS

PERSONAL INJURY, MAJOR PROPER-

TY DAMAGE OR DEATH.

Do not operate

without guard

in place.

13/20

NT 1010-D00 05 20 CC8-40 - CC8-50 - CC8-65 A & C pumps e

6.7 Protection from frost

If there is a risk of frost with the product contained in

the pump, it is necessary to drain the body after each

use as follows :

Step 1 :

• Check there is no valve closed on the discharge side

as well potential counter pressure due to a check

valve or liquid remaining inside a vertical pipe.

• Rotate the pump.

• Create an air entering on the suction side during 30

seconds.

• Stop the pump and make sure no liquid is coming

back > pump has to be closed.

Step 2 :

• Defect or in complement, drain by the bottom plug.

6.8 Restarting

Follow the standard start-up procedure for the pump/

motor-driven pump, as well as the instructions below.

Turn the pump by hand to make sure the parts move

freely.

Remove the bypass and inspect the parts and make

sure they move freely.

Drain plug

6. USE (continued)

14/20

NT 1010-D00 05 20 CC8-40 - CC8-50 - CC8-65 A & C pumps e

• Flat wrenches 13 - 17 - 22

• Tube wrench 17

• Circlip opening pliers

• Screwdriver

Makeup torques :

• M10 ...........47 Nm

• M 8 ............23 Nm

• M 6 ............10 Nm

7. NECESSARY TOOLS

Before any dismantling, make sure that the pump has been drained and take all the necessary precautions to prevent it from star-

ting up. The pump must not start up, even accidentally.

WARNING

DISCONNECTING THE FLUID OR

PRESSURE CONTAINMENT COMPO-

NENTS DURING PUMP OPERATION

CAN CAUSE SERIOUS PERSONAL

INJURY, DEATH OR MAJOR PROPERTY

DAMAGE.

Hazardous pressure

can cause

personal injury

or property damage.

WARNING

IF PUMPING HAZARDOUS OR TOXIC

FLUIDS, THE SYSTEM MUST BE FLUS-

HED PRIOR TO PERFORMING ANY

SERVICE OPERATION.

Hazardous or toxic

fluids can cause

serious injury.

CAUTION

THE PUMP LUBRICANT IS VERY SLIPPE-

RY AND MAY CAUSE SERIOUS INJURY.

ANY SPILLS MUST BE CLEANED UP.

Slippery lubricant.

Spills should be

cleaned up.

WARNING

FAILURE TO RELEASE ALL SYSTEM AIR

AND WHEN EQUIPPED, HYDRAULIC

PRESSURE, CAN CAUSE PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

Hazardous pressure

can cause

personal injury

or property damage.

WARNING

DISCONNECT THE ELECTRICITY

SUPPLY BEFORE ANY MAINTENAN-

CE OPERATION.

Dangerous voltage.

Can cause

injury and death.

CAUTION

THE SURFACES OF THE PUMP CAN

BE AT A TEMPERATURE LIABLE TO

CAUSE INJURY OR SEVERE DAMAGE.

Excessive temperature-

can cause injury

or severe damage.

WARNING

BE CAREFUL WITH THE WEIGHT OF

THE PARTS WHEN THEY ARE BEING

REMOVED.

The weight ot the parts

can be dangerous and may

provoke bodily injuries

or material damages.

WARNING

TAKE ALL NECESSARY MEASURES

TO RENDER ANY START-UP, EVEN

ACCIDENTAL, OF THE PUMP DURING

THE WORK IMPOSSIBLE.

Any unforeseen start-up

can cause serious

injuries or important

material damages.

8. DISMANTLING - REASSEMBLY

15/20

NT 1010-D00 05 20 CC8-40 - CC8-50 - CC8-65 A & C pumps e

8. DISMANTLING - REASSEMBLY (continued)

8.1 Dismantling on side opposite to drive system

Unscrew the screws 723, and remove the cover 712 and

the seal 714.

Remove circlip 537.

Carefully clean the shaft end (remove any trace of paint,

oxidation, burrs...).

Unscrew the 4 screws 410.

Unscrew the 4 screws 411 fitted with their nut 412 and

place them in the 2 tapped holes T.

Screw up the 2 screws at the same time so that the end-

plate is gradually released along the centre line.

When the end-plate is free on the shaft, hold it by hand

supporting it.

8.2 Dismantling on drive side

Uncouple the pump by removing the coupling.

Remove the key 508 and clean the end shaft. Then pro-

ceed in the same way as when dismounting on the other

side. On CC8-40 and CC8-50 pumps, it is necessary to

push cover 705 slightly a side to avoid damaging O-ring

707 on key.

Unscrew the screws 723, remove the cover 705 with its

seal 714 taking care not damaging seal 707.

Remove the circlip 537.

Operate then in a identical way in § DISMANTLING ON

SIDE OPPOSITE TO DRIVE SYSTEM.

8.3 Reassembly

When putting the end-plate back into place, take care to

have the shaft seal drive lugs facing the notches on

rotor.

Replace the cover 712 or 705 on the end plate 401 with

screws 723.

Lubricate the shaft 501 slightly.

Make sure that the end-plate seal 403 is correctly posi-

tioned, check it and change it if necessary.

Position the end plate 401 on the shaft and approach it

as far as possible by hand.

Finish fitting the end-plate, screwing the 2 nuts 412 gra-

dually on to the 2 screws 411.

Make sure that end-plate is centred while screwing.

When the end-plate is in place, remove the screws 411

and their nuts 412 and screw them up in the 2 bosses

taking care to position one of the drainage port L pointing

down.

Replace the screws 410.

Remove the cover 712 or 705.

Replace the circlip 537.

Replace the cover 705 with its seal 707 after check

condition of seal.

Free the shaft line by a light blow of mallet on its extremity

and make sure that the pump rotates freely when turned

by hand.

8.4 Assembly of flange for hydraulic trunk

Refer to Instructions NT 1010-K00 ASSEMBLY OF FLANGE

FOR HYDRAULIC TRUNK ON PUMP CC8 CC10.

16/20

NT 1010-D00 05 20 CC8-40 - CC8-50 - CC8-65 A & C pumps e

9. CHANGING THE VANES

Dismantling

Open the pump and remove the end-plate on its machined

side taking care not to damage the shaft seal drive lugs.

Remove parts.

Remove shaft seal by inserting fingers in shaft seal

center hole.

Reassembly

IMPORTANT

Lubricate the bore which takes the roller bea-

rings.

Make sure that the seals 605, 613 and the shaft seal

are in good condition. Change them if necessary.

Place the seal 605 in the end plate 401.

Make sure that the seal 613 is correctly positioned in

the shaft seal 630.

Refit the shaft seal 630 (a new one if necessary), in the

end plate 401, supported on the seal 605.

Place the protection ring 733 so as to be supported on

the shaft seal 630.

Place a bearing 703 supported on the protection ring 733.

Position the spacer 734 with its aperture opposite a

grease nipple 708 (if present).

Place the second bearing 703 so it is supported on the

spacer 734.

Refit the end plate (see § REASSEMBLY OF THE PUMP).

10. CHANGING MONOBLOC SHAFT SEAL

Open the pump on one side or the other.

Remove the vanes 317.

Check for wear (see § MAINTENANCE).

If vane wear is abnormal, check surface condition of body

and of end-plate faces.

Refit the vanes (new if necessary) respecting the direction of

assembly.

Reassemble the pump and check that it rotates freely when

turned by hand.

17/20

NT 1010-D00 05 20 CC8-40 - CC8-50 - CC8-65 A & C pumps e

Dismantling

Set bypass at minimal pressure by unscrewing the

lock-nut 835 taking care to count the number of rota-

tions so as to be able to reset bypass at initial pressure

setting.

Unscrew the 3 screws 856 of the bypass cap.

Remove spring 824.

Remove the valve 823 by pulling its cylindrical section

with the fingers.

Check condition of bypass.

Reassembly

Clean all parts before reassembly.

Reassemble in reverse order of dismantling.

Set bypass at initial pressure setting by tightening nut

with the same number of rotations as counted during

dismounting.

11. BYPASS

12.1 Lubrication

Pumps CC8-40A ; CC8-50A ; CC8-65C :

• Grease to use : good quality ball bearing grease.

In case of pumps operated higher than 100°C, a high

point of drop grease has to be selected.

• Fréquency : every 500 hours or one time per year.

• Injected volume : the usage of a pneumatic grease pump

is forbidden because of the risk to damage the mecha-

nical seals. The grease has to be added with a manual

pump, 2 blows on an only one grease nipple of every

pump end.

Pump CC8-65A :

Ball bearing are lubricated for life and don’t require any

grease adding.

12.2 Inspection of the vanes

12.3 Cleaning the filter

The pump should always be protected against possible

foreign matter by means of a filter connected into the

suction pipe.

Check the cleanliness of the filter mesh from time to time

as a.partly clogged filter could starve the pump and reduce

its output.

To clean the filter, remove the meshes and clean them

carefully. Before refitting them, drain the filter by removing

the drain plug, then rinse it thoroughly.

Pump CC8-40 CC8-50 CC8-65

Original height h 35 35 38

Change when h < to 30,5 32,5 35,5

12. MAINTENANCE

18/20

NT 1010-D00 05 20 CC8-40 - CC8-50 - CC8-65 A & C pumps e

13. TROUBLESHOOTING

13.1 Abnormal noise

Main causes :

• Excessive suction vacuum, due to :

- a pipe, accessories (valves, filter...) which are either

clogged or of insufficient diameter,

- excessive suction head (e.g. during liquid transfer

operations),

- a viscosity or vapour tension too high for the system

to cope with (e.g. when changing the product to be

pumped).

• Overly high rotation speed for the liquid being pumped.

• Pump damaged

- as a result of binding due to :

• an excessively high rotation speed,

• failure to release the drive when pumping is ended,

• sudden engagement of the drive,

• an unduly high pulling force on the shaft, leading to

a damaged ball-bearing and shaft.

- as a result of foreign matter, due to :

• the absence of a filter or inefficient cleaning,

• the absence of a basket (faîlure to replace it after

cleaning),

• solder or rust particles remaining in the pipe bet-

ween the filter and the pump.

• Bypass valve hammer on its seat due to incorrect

adjustment of the spring’s tension.

13.2 Leaking seal

Main causes :

- Abnormal pulling force on the shaft, leading to a dama-

ged bearing and seal,

- Displacement of the shaft when mounting an unduly

tight coupling making the seal unserviceable,

- Seal damage caused by pumping an agressive product,

- Ball-bearing lubricated excessively or at unduly high

pressure.

13.3 Inadequate output

Main causes :

- Excessive suction vacuum (see § Abnormal noise -

Excessive suction vacuum),

- Bypass setting too low,

- Air leaking in at suction end,

- Discharge pipe diameter too small,

- Speed of rotation too low,

- Bypass valve not closing properly due to foreign mat-

ters on valve seat or because the valve lifting wheel (in

the case of pumps fitted with one) has not been retur-

ned to its initial position after use,

- Pump damaged (see § Abnormal noise - Pump damaged

due to passage of foreign matter).

CAUTION :

OBSERVE ALL SAFETY WARNINGS CONTAINED IN THIS MANUAL.

19/20

NT 1010-D00 05 20 CC8-40 - CC8-50 - CC8-65 A & C pumps e

14.1 Short duration (≤ 1 month)

MOUVEX pumps and motor-driven pumps are well lubri-

cated when delivered to protect the internal parts during

brief storage in a building where :

• the temperature remains between 10°C and 50°C.

• the relative humidity does not exceed 60%.

• exposure to vibration is limited (maximum movement :

0,05 mm).

• pump is stored in an area sheltered from bad weather

and sun.

14.2 Long duration (> 1 month)

We recommend the following procedure for longer periods

of storage :

The recommendations from the manufacturer should be

followed if the pump is stored with its gear motor.

Pump ports should be filled with a non-corrosive liquid

that it compatible with the pump components in order to

prevent corrosion.

Unpainted external surfaces of the pump (e.g. shafts,

couplings, etc.) should be covered in some form of anti-

corrosion protection.

The bearing should be greased. If the pump is to be stored

for more than three years, the grease should be replaced

every three years to prevent it degrading.

The best storage conditions are inside a building that

meets the conditions set out above.

If inside storage is not possible, the materials should be

covered to prevent direct exposure to sun and bad wea-

ther. This protection should also prevent condensation.

It is recommended to turn the pump by hand every two

months to distribute the lubricant around the interior.

Items should then be placed where there is no risk of

damage if they are moved slightly by vibrations.

WARNING

IF PUMPING HAZARDOUS OR TOXIC

FLUIDS, THE SYSTEM MUST BE FLUS-

HED PRIOR TO PERFORMING ANY

SERVICE OPERATION.

Toxic or hazardous

fluids can cause

serious injury.

14. STORAGE

The pump must be scrapped in compliance with the regulations

in force.

During this operation, particular care must be paid to the drai-

nage stages of the pump (pumped product).

15. SCRAPPING

20/20

NT 1010-D00 05 20 CC8-40 - CC8-50 - CC8-65 A & C pumps e

Est conforme aux dispositions suivantes :

Directive « MACHINES » 2006/42/CE et aux législations nationales la

transposant, portant sur les dispositifs de sécurité liés aux risques

mécaniques et électriques applicables aux machines tournantes.

NF EN 809:2009 NF EN 1672-2:2009 NF EN ISO 13857:2008

NF EN 12162:2009

Directive « ATEX » 2014/34/UE du 26 février 2014 et aux législations

nationales la transposant, portant sur les appareils destinés à être utilisés

en atmosphères explosibles. Conformité obtenue par application des

normes :

NF EN 1127-1:1997 NF EN 13463-1:2009 NF EN 13463-5:2009

Certification ATEX délivrée par INERIS*, Organisme Certificateur, et portant

le marquage suivant : (C)

L’équipement désigné ci-dessus doit impérativement respecter les

conditions d’utilisation ATEX décrites dans nos notices d’instruction. Il doit

être employé conformément à l’utilisation qui en a été prévue de par sa

conception et sa fabrication, et conformément aux normes en vigueur.

Nous, soussignés, déclarons que l’équipement concerné est conforme aux

Directives listées ci-dessus et aux normes applicables s’y rapportant.

Is in conformity with the provis

i

ons of the following D

i

rective:

« MACHINES » Directive 2006/42/EEC as transposed by the national

legislation, concerning safety equipments and arrangements relative to

mechanical and electric risks applicable to rotative machines.

NF EN 809:2009 NF EN 1672-2:2009 NF EN ISO 13857:2008

NF EN 12162:2009

« ATEX » Directive 2014/34/EU (26 Feb. 2014) as transposed by the

national legislation, concerning equipment intended to be used in explosive

atmospheres. Conformity obtained by application of the standards :

NF EN 1127-1:1997 NF EN 13463-1:2009 NF EN 13463-5:2009

ATEX Certification delivered by INERIS*, Notified Body, and with the

following marking: (C)

The equipment indicated above must imperatively comply with the ATEX

conditions of use described in our Instruction book. It must be used

according to the foreseen use by its design and its manufacturing, and

according to the current standards.

We, undersigned, declare that the concerned equipment is in conformity

with the Directives listed above and in the applicable standards in force.

den Bestimmungen der nachstehenden Richtlinien en

t

spricht:

„Maschinen-Richtlinie“ 2006/42/EEC wie umgesetzt im nationalen Recht

hinsichtlich der Ausrüstungssicherheit und Sicherheitsvorkehrungen bezogen

auf mechanische und elektrische Risiken, die für rotierende Maschinen

gelten.

NF EN 809:2009 NF EN 1672-2:2009 NF EN ISO 13857:2008

NF EN 12162:2009

„ATEX“ Richtlinie 2014/34/EU (26. Feb. 2014) wie umgesetzt im

nationalen Recht in Bezug auf Ausrüstungen für den Einsatz in

explosionsgefährdeter Atmosphäre. Die Konformität hat Geltung durch

Anwendung folgender Normen:

NF EN 1127-1:1997 NF EN 13463-1:2009 NF EN 13463-5:2009

Die ATEX-Zertifizierung wurde von der benannten Stelle INERIS* erteilt, und

mit folgender Kennzeichnung: (C)

Oben stehend bezeichnete Ausrüstung muss unbedingt den in unseren

Betriebsanleitungen beschriebenen ATEX Anwendungs-bedingungen

entsprechen. Sie ist entsprechend dem durch Konstruktion und Fabrikation

vorgesehenen Verwendungszweck und entsprechend den geltenden Normen

einzusetzen.

Die Unterzeichner erklären, dass die bezeichnete Ausrüstung den oben

aufgeführten Richtlinien und den diesbezüglich geltenden Normen entspricht.

DECLARATION UE DE CONFORMITE

EU CERTIFICATE OF CONFORMITY – EU KONFORMITÄTSERKLÄRUNG

MOUVEX sas, ZI La Plaine des Isles – 2 Rue des Caillottes – 89000 Auxerre France, déclare que l’équipement suivant / declares the following equipment / erklärt, dass folgende Ausrüstung:

Modèle : N° de série : (A) Répondant aux spécifications indiquées dans l’ARC N° : (B)

Designation / Bezeichnung Serial N° / Serien Nr According to the specifications recorded in the acknowledgment of order N°:

Entsprechend den Spezifikationen aus AB-Nr :

Pour la Sté MOUVEX sas, fait à Auxerre le :

For Mouvex sas company – Date :

Fur die Fa Mouvex sas - Datum :

Responsable Qualité Clients

Customer

Q

ualit

y

Mana

g

er

/

Q

ualitätsbeau

f

tra

g

te

r

II __ G ____ II __ – T __ Temp Max produit pompé / Max Temp Flow / Max. T° Medium = _____ °C (X = voir notice / see IOM / siehe Handbuch)

Configuration : Pompe / Compresseur arbre nu Groupe de pompage / de compression

Konfiguration (Pump / Compressor « bare-shaft ») (Pumping Unit / Compressor Unit)

(Pumpe / Kompressor, freies Wellenende (Pumpen- / Kompressoraggregat)

Type / Geräteart :

Pompe à mvt excentré (Eccentric Disc Pump / Ringkolbenpumpe)Pompe à lobes (Lobes Pump / Drehkolbenpumpe)

Pompe péristaltique (Peristaltic Pump / Schlauchpumpe) Pompe à palettes (Vanes Pump / Flügelzellenpumpe)

Pompe centrifuge (Centrifugal Pump / Kreiselpumpe)Autre pompe (Other Pump / Andere Pumpe)

Compresseur à Vis (Screws compressor / Schraubenverdichter)

Compresseur à palettes (Vanes compressor / Flügelzellenverdichter)

Refroidisseur H

y

drauli

q

ue (H

y

draulic oil cooler / H

y

draulikkühler

)

CTRL.D025 – rév.04 du 25/05/2016 – Déclaration de conformité CE-Atex

* (INERIS

–

Parc Techno Atala

–

60550 Ver

n

eui

l

-

e

n

-

Halatte

–

France

)

.Pa

g

e 1/2

16. CERTIFICATE OF CONFORMITY

This manual suits for next models

2

Table of contents

Other Mouvex Water Pump manuals

Mouvex

Mouvex C24 i Owner's manual

Mouvex

Mouvex AK Series Guide

Mouvex

Mouvex SLS24 i Owner's manual

Mouvex

Mouvex SLC24 i Owner's manual

Mouvex

Mouvex SLP25 i Series User manual

Mouvex

Mouvex SLC1 Owner's manual

Mouvex

Mouvex SLS12 i Owner's manual

Mouvex

Mouvex SLS4 i User manual

Mouvex

Mouvex CC8-80 F Owner's manual

Mouvex

Mouvex C12 A Owner's manual

Popular Water Pump manuals by other brands

Oase

Oase AquaMax Eco Twin 20000 operating instructions

KSB

KSB MEGAFLOW 50-160 Operating instructions manual

Silicon Solar

Silicon Solar AquaJet-Pro-PUMP1224 user manual

Walrus

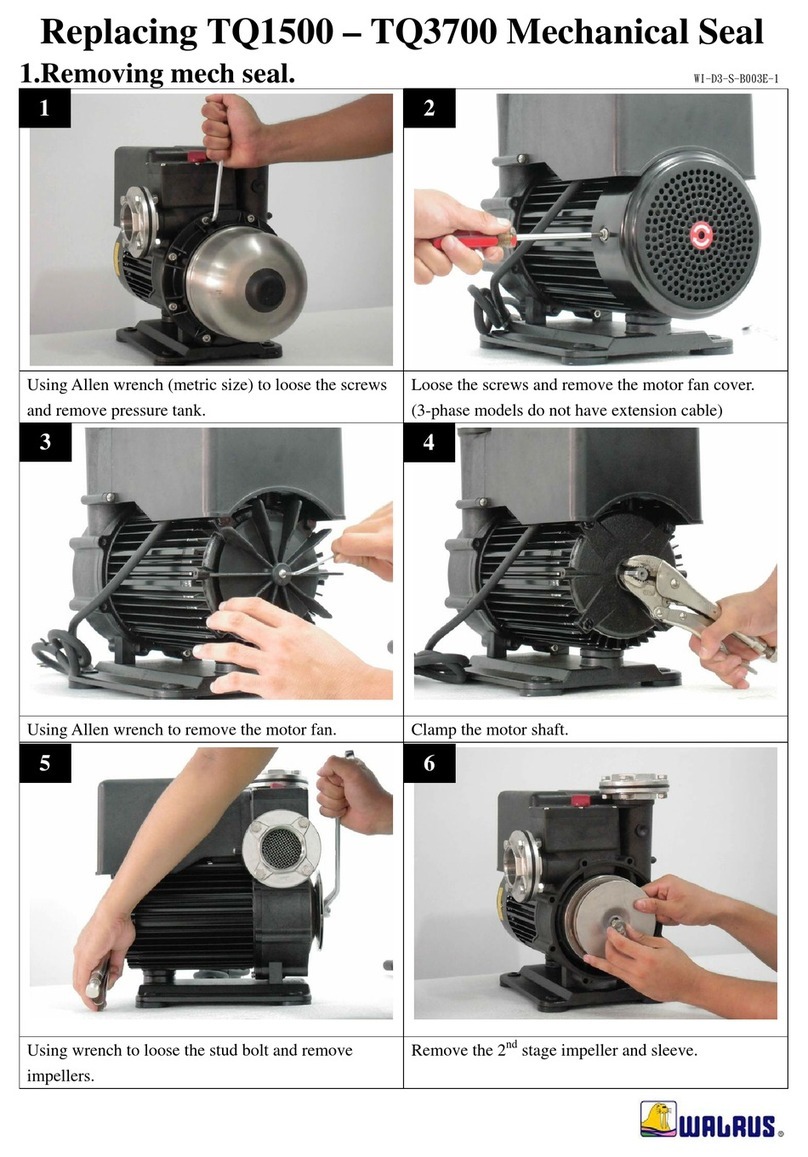

Walrus TQ1500 Replacing

ULTIMATE SPEED

ULTIMATE SPEED KH 4256 Original operating instructions

Garland

Garland GEISER 281 G instruction manual