Movex 553 FLEXTOP Installation and operation manual

2

© Copyright Movex® S.p.A. 2021

The contents of this manual are the copyright of the publisher and may not be

reproduced (even extracts) unless permission is granted. Every care has been taken

to ensure the accuracy of the information contained in this publication, but no

liability can be accepted for any error or omission.

APPLICATION CONSIDERATIONS.

The proper selection and application of Movex® products and components, including the related area of product safety, is the

responsibility of the customer. Operating and performance requirements and potential associated issues will vary appreciably

depending upon the use and application of such products and components. The scope of the technical and application

information included in this publication is necessarily limited. Unusual operating environments and conditions, lubrication

requirements, loading supports, and other factors can materially affect the application and operating results of the products

and components and the customer should carefully review its requirements. Users of our products should make their own tests

to determine the suitability of any product for their particular purposes.

Any technical advice or review furnished by Movex® with respect to the use of products and components is given in good faith

and without charge, and Movex® assumes no obligation or liability for the advice given, or results obtained, all such advice and

review being given and accepted at customer’s risk.

For a copy of our Standard Terms and Conditions of Sale, Disclaimers of Warranty, Limitation of Liability and Remedy, please see

our web site www.movexii.com or contact our Customer Service.

These terms and conditions of sale, disclaimers and limitations of liability apply to any person who may buy, acquire, or use

any Movex® product referred to herein, including any person who buys from a licensed distributor of these branded products.

The applicable Movex® product catalogs and installation/maintenance bulletins must be used only by qualied individuals

familiar with Movex® products; these documents contain important precautions and other information intended to reduce the

risk of bodily injury. Refer to these documents before specifying, installing, operating, or servicing equipment.

Incorrect and/or incomplete data could cause the selection of improper components,

potentially resulting in bodily injury. Movex® makes no warranties, express or implied,

of merchantability or tness for a particular purpose. Movex® will not be liable for

direct or indirect incidental, consequential, or punitive damages arising from the

use or inability to use this any of the information made available, including but not

limited to product literature, selection programs and interchange guides. Movex®

reserves the right to correct, modify, update and/or enhance these documents at

any time without notice or penalty, including but not limited to pricing, technical

data, etc.

Most updated documents can always be found on the website.

Manual N° M999579

The digital version of this manual is available on www.movexii.com

EMPLOYEES

AROUND THE WORLD

23.000+200+

DIFFERENT

PRODUCTS AVAILABLE

REFERENCE YEAR 2018

16.500 Mq2

OF PRODUCTION SPACE

PRODUCTION

CAPACITY

+40%

+35%

WAREHOUSE

CAPACITY

+40%

+35%

MISSION

Creating value through innovative development of

ideas, supporting our partners with professionalism,

exibility and effectiveness.

VISION

Reaching market leadership as a reliable and precise

supplier. Planning the future without losing sight of

our history and the values that allow our growth.

Logistics Center Headquarter

FACTS

Movex around the world

Movex S.p.A. | Headquarter

Via lndustria, 22 - 24060 Castelli Calepio (BG)

P +39 035 8359711 | F +39 035 4420873

Movex S.p.A. | Logistics Center

Via Repubblica, 25

24060 Castelli Calepio (BG)

Movex UK Ltd.

P +44-77-20678442

Movex Nederland

P +31-630-994850

Movex Russia

P +7 (495) 925-88-56

Movex CIS countries

P +380-667507756

Movex AG India

P +91-120-4159660-62

Movex France

P +39-335-8085980

Movex GmbH

P +49-6204-9375-0

Movex USA Inc.

P +1-919-274-5477

Movex Brasil Ltda

P +55-15-3141-2550

Movex SA de CV

P +52-1-3318458187

A top service level is the goal of a qualied Engineering and Sales team

with the objective of presenting

Movex

as a supplier of excellence to

all clients.

Through a distribution/network which spans the globe,

Movex

offers

technical support and a careful after-sales service, always at your disposal.

WE SUPPORT YOU

Customer service Dept.

The rich experience that

Movex

has acquired over the years shows

that care and innovation of products are essential to guarantee costant

quality.

Thanks to the investments as well as developing strategic departments

Movex

has created new space where research and innovation become

concrete tools to satisfy customers’ requirements.

RESEARCH & DEVELOPMENT

Research & development meeting

In the new headquarters

Movex

designs and manufactures high quality

components for the food, beverage, packaging, automotive and automation

industries.

Movex

meets your needs for standard and custom products in a dynamic

and responsive way ensuring the best performance product with an attractive

market price.

WE CREATE SOLUTIONS

Engineering Dept.

is online!

Consult our catalogue from your

favorite device and request a free

quotation.

www.movexii.com

Always connected.

is App!

Discover more about us

and our products.

Stay updated

on our latest news.

553 FLEXTOP

Multidirectional Modular Belt

12,7

152,4

25,4

25,4

152

12,5

0

-0.2

33,5

16,75

can improve

the performance of your job

Changing direction

TABLE OF CONTENTS

INTRODUCTION

Overview ..........................................................................................................................................................................................................................

Features ...........................................................................................................................................................................................................................

Suitable goods ...........................................................................................................................................................................................................

Application examples and Industries .....................................................................................................................................................

MAIN FUNCTIONALITIES

Belt and Sprockets specification ...................................................................................................................................................................

Basic controls ...............................................................................................................................................................................................................

Goods dimensioning ...............................................................................................................................................................................................

MOVEMENTS

Divert ..................................................................................................................................................................................................................................

Static Rotation................................................................................................................................................................................................................

Dynamic Rotation .......................................................................................................................................................................................................

Accumulation .................................................................................................................................................................................................................

Acceleration/Deceleration ....................................................................................................................................................................................

ADVANCED CONTROLS

Divider – Merger .........................................................................................................................................................................................................

Sorter ..................................................................................................................................................................................................................................

Divider - Merger - Sorter - Complete dimensioning solution and Example .................................................................

Static Rotation - Complete dimensioning solution and Example .......................................................................................

Dynamic Rotation - Complete dimensioning solution and Example ................................................................................

CONVEYOR CONSTRUCTION & MAINTENANCE

Sprockets position ....................................................................................................................................................................................................

Wear Strips and Machined Plates ................................................................................................................................................................

Return rollers ................................................................................................................................................................................................................

Maintenance .................................................................................................................................................................................................................

NOTES

....................................................................................................................................................................................................................................................

10

11

12

13-14

15

16

17

18

18

19

19

19

20

21

22-23

24-25

26-27

28

29

30

31

32

A page for your notes

ENGINEERING MANUAL

553 FLEXTOP

Multidirectional Modular Belt

The new Movex® 553 FlexTop modular belt

with self-locking spheres is specifically

designed for high-precision material

handling, suitable for several applications

like logistic centers, packaging stations (food

and beverage) and corrugated industries,

easily to be integrated into existing systems.

The 360° movement possibility makes

the belt suitable for diverting, rotating,

accumulation and acceleration applications

and minimize required maintenance and

downtimes.

The small pitch between the spheres

(diameter 12,7 mm and pitch 25,4 mm) allows

every type of good transfer and is ideal for

small and light packages, unlike traditional

roller conveyors.

Density: 1.600 spheres/m2.

The complete closed sliding belt surface

is the perfect solution to carry carton

boxes, crates, cans and bottles shrink-wrap

packaging and any kind of polybag with Top-

Accuracy package control.

ENGINEERING MANUAL

10

Overview

11

With a directional belt underneath the FlexTop belt you

can control the direction and more precisely the speed

of the spheres, making this belt 100% versatile.

This function is very useful when goods must be separated

from each other but also to transfer your package laterally

without external guides and pushers. This scenario is ideal

for several applications requiring rapid 90° transfer of

the conveyed items.

Using two parallel running belts positioned

underneath 553 Flextop belt, and running in opposite

directions, goods in the middle of the belt will rotate

quickly without interrupting the main transport movement

(rotation with good moving).

553 FlexTop belt can also be used in combination with

a rotating plate to have an optimum control of the

rotation of the good (rotation with item stopped).

In this manual, you will find more details for each option.

The small pitch between the spheres allows for a great

goods control.

A complete closed sliding surface , in combination with

self-locking spheres, makes the belt design flexible and

robust.

Design and features of 553 FlexTop make it ideal for

the transport of several type of goods

(e.g. polybags,

shrink-wrap packaging).

High

strength

Perfect

good

control

Self

cleaning Great

versatility Long

durability Reduced

downtimes

Features

ENGINEERING MANUAL

553 FlexTop belt can be used over a xed support area

to accelerate transport speed or with additional belts

and rotating plates to fully express its potential.

The main advantage of the Movex® 553 FlexTop

modular belt is its maximum flexibility to

meet your needs.

Ideal to transport cardboard boxes and

small packages, the 553 FlexTop belt is also

the right solution when you have to transport

polybags, papers, plastic cases, containers,

rubber parts (tires), shrink packs of bottles

and cans, etc…

What’s important is understanding if the

good sliding surface is suitable with the 553

FlexTop surface, because that will determine

the success of the application.

To do this, the goods bottom surface must

have flat parts able to run completely on at

least one sphere with a minimum of 6 spheres

per good.

Another important aspect is the total weight

of the good: most of the times is suitable with

the max working load of the belt, especially

of the spheres. Anyway, we always suggest

to double check that the total weight of the

good does not exceed the max load of the

spheres, 15N/ea.

We have several machines in our showroom

that can be used for testing your goods with

all the type of movements available with 553

FlexTop belt (sorting and rotation).

ENGINEERING MANUAL

12

VERSATILITY

Suitable goods

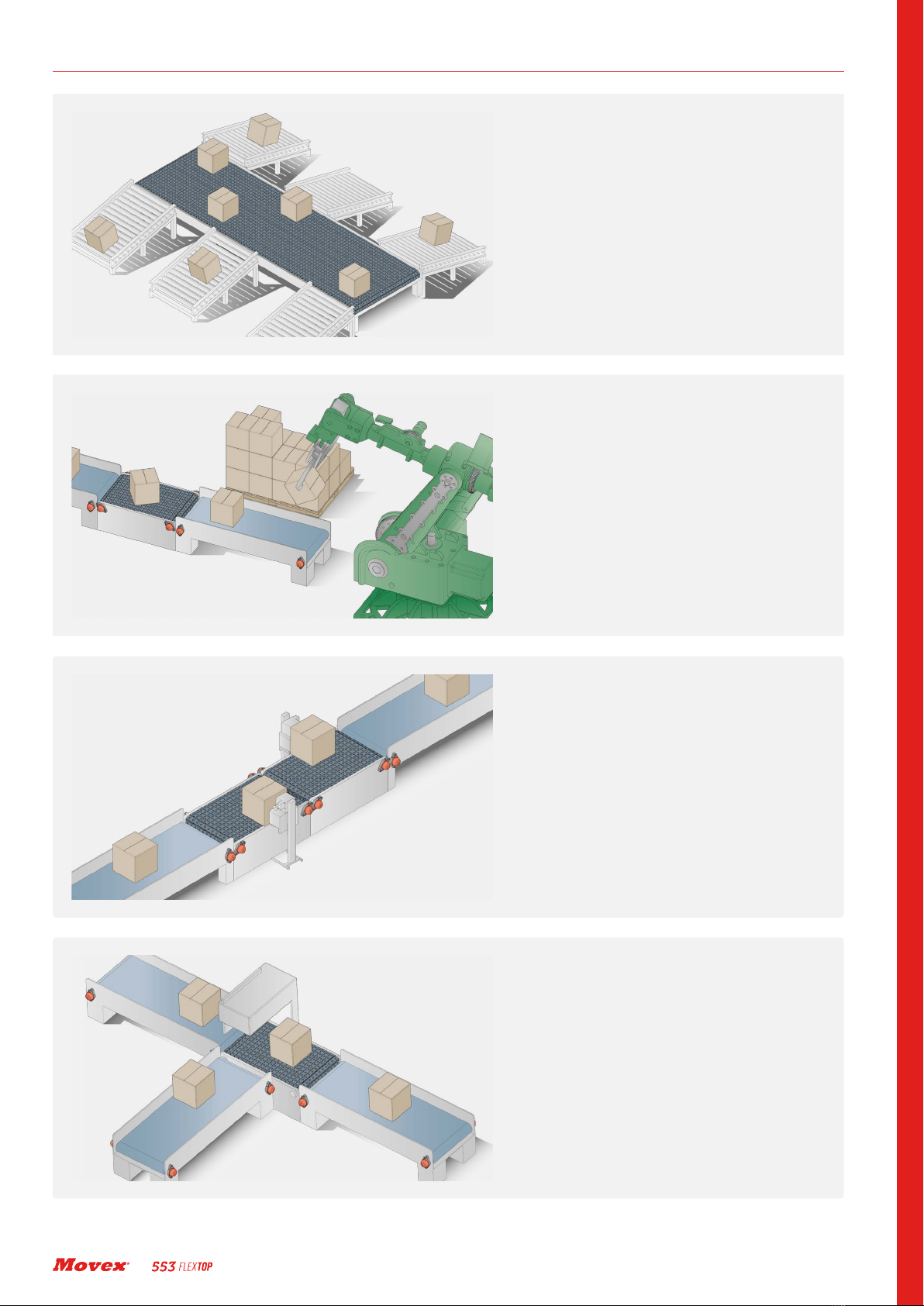

ENGINEERING MANUAL

13

GOOD ORIENTATION

• Casing machines

• Palletizers

REJECT STATION

• Inspection equipment

• Measuring devices

The goods can be oriented on the right

side. This can be done by static rotation or

dynamic rotation, based on the required

quality output and the process speed.

AUTOMATIC STORAGE SYSTEM

• Distribution system

• Sorting

• Lane divider

The goods can be guided over the 553

Flextop in 3 dierent directions: straight,

left or right, bases on the correct exit to be

taken.

GOOD POSITIONING

• Labelling

• Printing

• Barcodes Reading

The goods can be rejected on its left/right.

Application examples and Industries

The goods needs to be guided first on the

right and then on the left. This can be done

by using two separate modules or one single

solution.

The 553 FlexTop modular belt is ideal for all those applications where a dedicated movement

is required.

Its versatility with dierent movements oer great use in dierent application areas.

The most used are logistic and distribution centers, food and beverage and corrugated.

At the same time, whevener a dedicated movement is required and the good sliding surface is

suitable to the 553 FlexTop belt, it can be used as well.

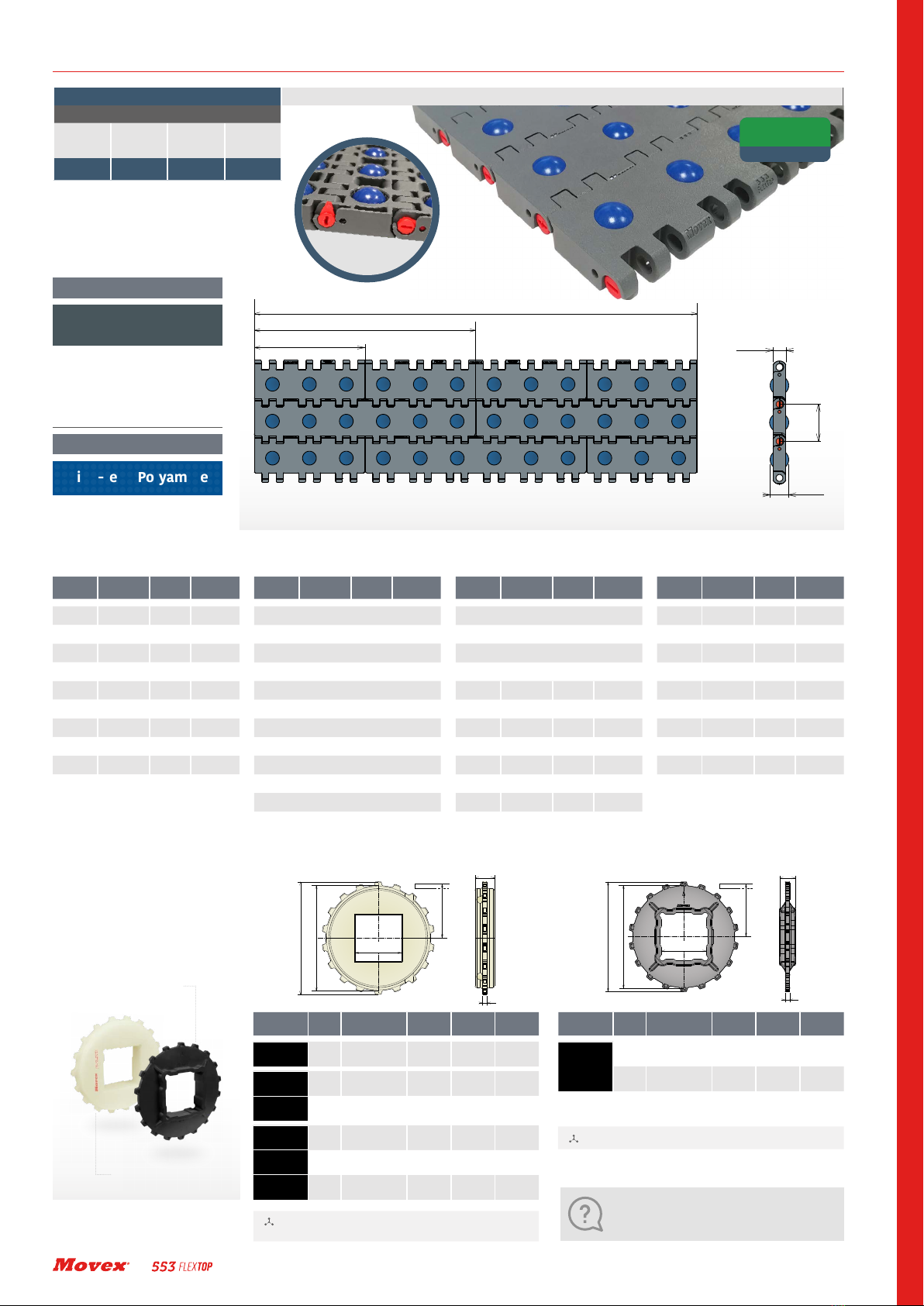

Logistic and distribution centers

With more and more consumers buying from

the web, logistics and distribution centers

are becoming more ecient. The 553 FlexTop

modular belt is ideal when dierent product

sizes and sliding surface are running over,

keeping the eciency at the maximum value

and avoiding machines and robots which may

result very expensive.

Safe design, very high speed, low noise.

Food and beverage

In the packaging area of the food and

beverage industries, the 553 FlexTop modular

belt can help creating dierent actions with

one machine only: orientate the package to

the right side, align with the group, reject in

case of non-conformity, move side to side,

everything done by keeping always one eye

on safety aspect.

Safe design, high speed, high working load.

Corrugated

The corrugated industry is the most traditional

system where the 553 FlexTop can be used.

With this belt all type of stack of cardboards

can be easily handled and with only one

machine the good can have 3 dierent exit

directions: straight, left or right, without the

needs of having dierent conveyors, head to

tail transfers and the risk of downtimes.

Safe design, low speed, very high working load.

ENGINEERING MANUAL

14

Application examples and Industries

15

ENGINEERING MANUAL

Supplied coil length: Width ≤ 30” : 1.524 m (60 pitches) - Width > 30” : 1.016 m (40 pitches)

On request wider belts are available with 3” increments.

25,4

1.00

8,7

0.34

6”

W (inch)

M=3”

12,7

0.5

25,4

1.00

8,7

0.34

6”

W (inch)

M=3”

12,7

0.5

Material

LFG - Code 27

Low friction Acetal

Sphere material

High-tech Polyamide

Max working load:

Weight:

Temp. range dry:

Temp. range wet:

Pin material:

Belt available also in RAL 5005 (Blue)

Max working load:

Sphere Diameter:

27500 N/m (1850 lbs/ft)

10 Kg/m² (2.04 lbs/ft²)

-40÷80 °C (-40÷176°F)

-0÷65 °C (+32÷149°F)

PBT white

15 N (3.37” lbs)

12,7 mm (0.50”)

Belt and Sprockets specification

Backflex radius min.: 25 mm

25.4mm

PITCH

Version A - Standard

Continue >>

Series Material Width Version

5530 27 0003 A

5530 27 0006 A

5530 27 0009 A

5530 27 0012 A

5530 27 0015 A

5530 27 0018 A

5530 27 0021 A

5530 27 0024 A

5530 27 0027 A

5530 27 0030 A

5530 27 0033 A

Continue >> Continue >>

Series Material Width Version

5530 27 0069 A

5530 27 0072 A

5530 27 0075 A

5530 27 0078 A

5530 27 0081 A

5530 27 0084 A

5530 27 0087 A

5530 27 0090 A

5530 27 0093 A

5530 27 0096 A

5530 27 0099 A

Series Material Width Version

5530 27 0102 A

5530 27 0105 A

5530 27 0108 A

5530 27 0111 A

5530 27 0114 A

5530 27 0117 A

5530 27 0108 A

5530 27 0111 A

5530 27 0114 A

5530 27 0117 A

CODE STRUCTURE GUIDE

(Example)

5530 27 0042 A

Series *Material Width Version

Art-Nr. Z- Bore

(mm-in) PD

(mm-in) OD

(mm-in) S

(mm-in)

166108 12 40x40

1.57x1.57

98,1

3.86

97,6

3.84

44,5

1.75

166208 15 40x40

1.57x1.57

122,2

4.81

121,9

4.80

56,5

2.22

166210 60x60

2.36x2.36

166308 18 40x40

1.57x1.57

146,3

5.76

146,0

5.75

68,5

2.70

166310 60x60

2.36x2.36

166311 65x65

2.56x2.56

Material: Reinforced polyamide

Material: Polyamide

Screws: Stainless steel Nuts: Zinc plated steel

S

OD

PD

B

6

24

S

OD

PD

B

6

21

• Optimized hygenic

• Quick replacement

• Easy clean and installation

• Heavy duty design

Drive split sprockets - Machined and molded

Series Material Width Version

5530 27 0036 A

5530 27 0039 A

5530 27 0042 A

5530 27 0045 A

5530 27 0048 A

5530 27 0051 A

5530 27 0054 A

5530 27 0057 A

5530 27 0060 A

5530 27 0063 A

5530 27 0066 A

Machined sprockets with round

bore are available on request.

Art-Nr. Z- Bore

(mm-in) PD

(mm-in) OD

(mm-in) S

(mm-in)

166511 18 40x40

1.57x1.57

146,3

5.76

146,0

5.75

68,5

2.70

166510 60x60

2.36x2.36

Basic controls

When the 553 FlexTop modular belt is running over a static

support, directional belt or rotating plate, its spheres start

changing direction and speed. It is very important to give

enough friction to the spheres to better control them.

In case of acceleration, 553 FlexTop belt spheres can run

on a Polyethylene support plate (wear strips or machined

plate, min 15mm thickness). In case of lateral movements,

553 FlexTop belt spheres can run on a PVC or Polyurethane

coating belt with hardness of 60-70ShA.

To guarantee the same speed of the spheres (then of the

goods), it is always suggested to cover the support plate

with the same material of the directional belt (dierent

friction may cause dierent goods speeds).

Basic formulas to control goods speed/direction

553 FlexTop belt with directional belt mounted perpendicularly

The dierence in speed between the 553 FlexTop belt and the

directional belt determines the direction angle of the good.

Fixed strip or conveyor

553 FlexTop belt

Rotating sphere

Good

553 FlexTop belt

Directional Belt

553 FlexTop belt with a 360° rotating plate underneath

Useful option used to easily positioning the good.

Rotating plate

553 FlexTop belt

αY = αX

ENGINEERING MANUAL

16

553 FlexTop belt mounted over a

longitudinal conveyor running in

opposite direction.

Y= 2X + Z

Transport Speed

X

Z

X

Z

553 FlexTop belt mounted over a

longitudinal conveyor running in the

same direction.

Y= 2X - Z

Transport Speed

553 FlexTop belt running over fixed

surface.

X

Belt spheres run in the opposite direction of the directional belt (to go on the left the directional belt must run

on the right) and of the rotating plate (to go clockwise the rotating plate must turn counter clockwise).

!

Y=√2 2

(2X) + Z

For a better indication of possible directional belts,

their performances (maximum speed), as well as

minimum thickness of the coating, please enquire your

belting supplier.

Legend:

553 FlexTop belt direction

FlexTop belt

Directional belt or Rotating plate

Directional belt or Rotating plate direction

Transported good by 553 FlexTop belt

Belts speed and direction

Y= 2X

Transport Speed

Y

X

Z

Combine different movements to get the required direction for your business!

Goods dimensioning

Goods contact surface

ENGINEERING MANUAL

17

The type of the goods to be transported over the 553 FlexTop belt must be checked carefully.

In general, there are a few recommendations need to be followed to check if the good can be transported:

• Bottom surface of the goods – relatively flat

• Center of gravity of the goods – relatively distributed (+/-20% around the nominal one)

• Weight – suitable with spheres – maximum 15N per sphere

• Contact – goods running on at least 6 spheres

To guarantee sliding properties, it is very important to calculate the sliding contact surface of the good.

It must be bigger than 38cm2.

!

For more support or particular applications you can contact our engineering department.

Possible solutions to meet the requirements:

• Increase the dimension of the box to achieve 76,8 cm2 sliding surface (12 spheres x 6,4 cm2).

• Reduce the box weight to maximum 120N (8 spheres x 15N).

Contact with the spheres is a necessary condition

As a rule, there must be at least 6 spheres in contact with the good surface at the same time, so almost 6in2

(38cm2) 1in2per sphere (6,4cm2per sphere).

Good suitability assessment of a polystyrene box weight 18kg

with bottom surface – external contact.

• External Length

• Internal Length

• External width

• Internal width

Calculation:

Surface in contact: (10x16) - (8x13) = 56cm2> 38cm2OK

This can be transformed in N° of spheres in contact 56/6,4=8,75 8 spheres (would result 8 full sphere in contact)

Weight: 18Kg * 9,81= 176,6N 176,6/15=11,77 minimun 12 spheres required

Output:

This type of goods can’t be transported.

10cm

8cm

16cm

13cm

Example:

!

Because of the weight, this

box cannot be transported.

You have two options to

solve the problem:

!

Movements

ENGINEERING MANUAL

18

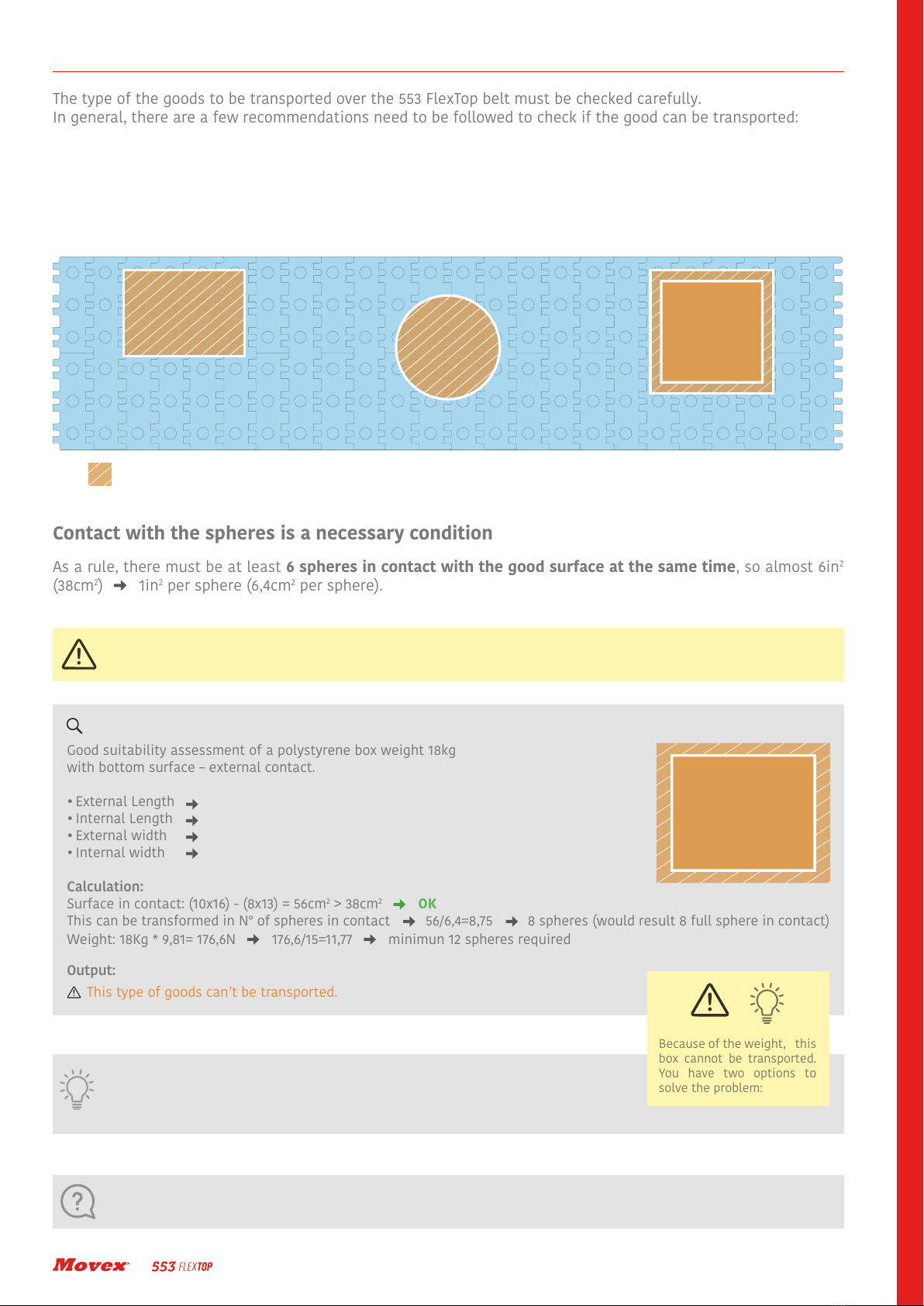

Divert – lateral movement

By using a directional belt underneath the 553 FlexTop

belt, running square to the travel direction, the goods

can be transferred left and right.

The combination of the speed of modular belt and

directional belt will determine the direction of the exit.

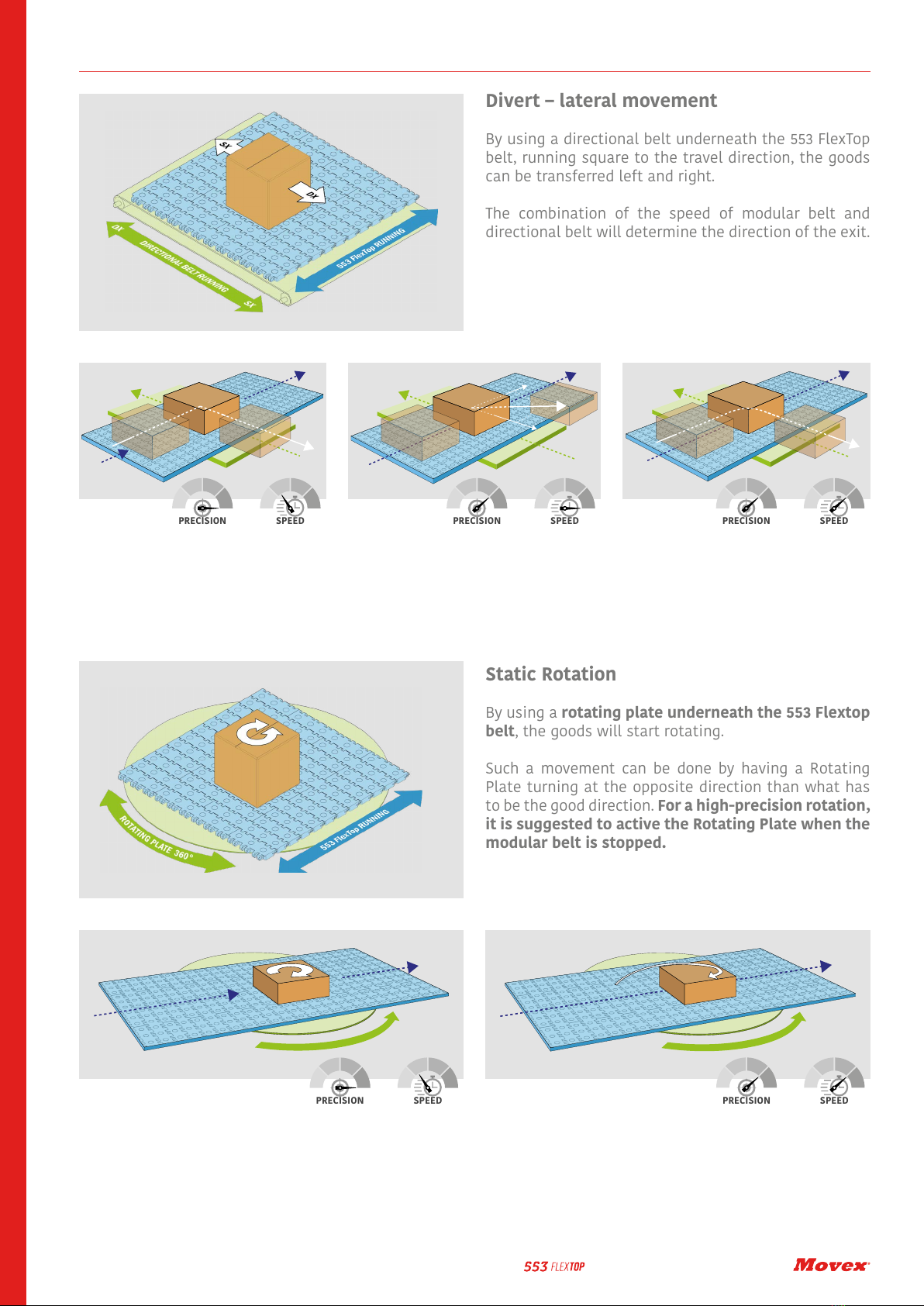

Static Rotation

By using a rotating plate underneath the 553 Flextop

belt, the goods will start rotating.

Such a movement can be done by having a Rotating

Plate turning at the opposite direction than what has

to be the good direction. For a high-precision rotation,

it is suggested to active the Rotating Plate when the

modular belt is stopped.

Controlled rotation

To get a controlled roation, the rotating plate must be activated when 553

FlexTop is not running.

Uncontrolled rotation

If the rotating plate get activated while the modular belt is running, the

good will rotate in more space.

Be sure the product is running over the plate till its rotation is completed.

Straight exit

To get a completely straight exit, the

directional belt must be activated when 553

FlexTop is not running.

Curved exit

To get a straight exit without loosing relatively

too much time, the directional belt can be

activated also when the 553 FlexTop is

running, while is reducing speed.

The combination of the two speeds will

determine the exit curve dimension.

Inclined exit

To get a 45° inclined direction, the speed of

the directional belt must be the same as

the speed of the 553 FlexTop and they have to

work contemporary.

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

1

2

3

4

5

6

7

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

1

2

3

4

5

6

7

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

1

2

3

4

5

6

7

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

1

2

3

4

5

6

7

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

1

2

3

4

5

6

7

Movements

Dynamic Rotation

By using two directional belts underneath the 553

Flextop belt, running at opposite direction, the good

will start rotating.

This option is ideal for high speed lines, while the

goods needs to be rotated to correct sides without

slowing down the production line. Based on the

combination of speeds between the 3 belts, the good

will rotate in a dierent distance. It is suggested to

keep the directional belts speed always the same.

Accumulation

For a limited time, in case of needs or special application

(e.g. rejected table), the 553 FlexTop belt can work as

accumulation.

In that case spheres must be free to run, so the belt

has to be supported by wear-strips positioned between

spheres (see page 29).

Maximum wear-strip width 8mm.

Acceleration/Deceleration

By using a static plate or a directional belt underneath

the 553 FlexTop belt, the good can accelerate or

decelerate.

Static plate

By using a static plate, the

good speed will result

double than the 553

FlexTop belt speed.

Directional belt

By using a directional belt,

the good speed can be

accelerated or decelerated

independently from the 553

FlexTop belt speed.

Counter clockwise direction:Clockwise direction:

To get a dynamic rotation to the right, the two directional belts must

run like the picture.

To get a dynamic rotation to the left, the two directional belts must run

like the picture.

ENGINEERING MANUAL

19

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

1

2

3

4

5

6

7

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

PRECISION

SPEED

1

2

3

4

5

6

7

Advanced Controls

ENGINEERING MANUAL

20

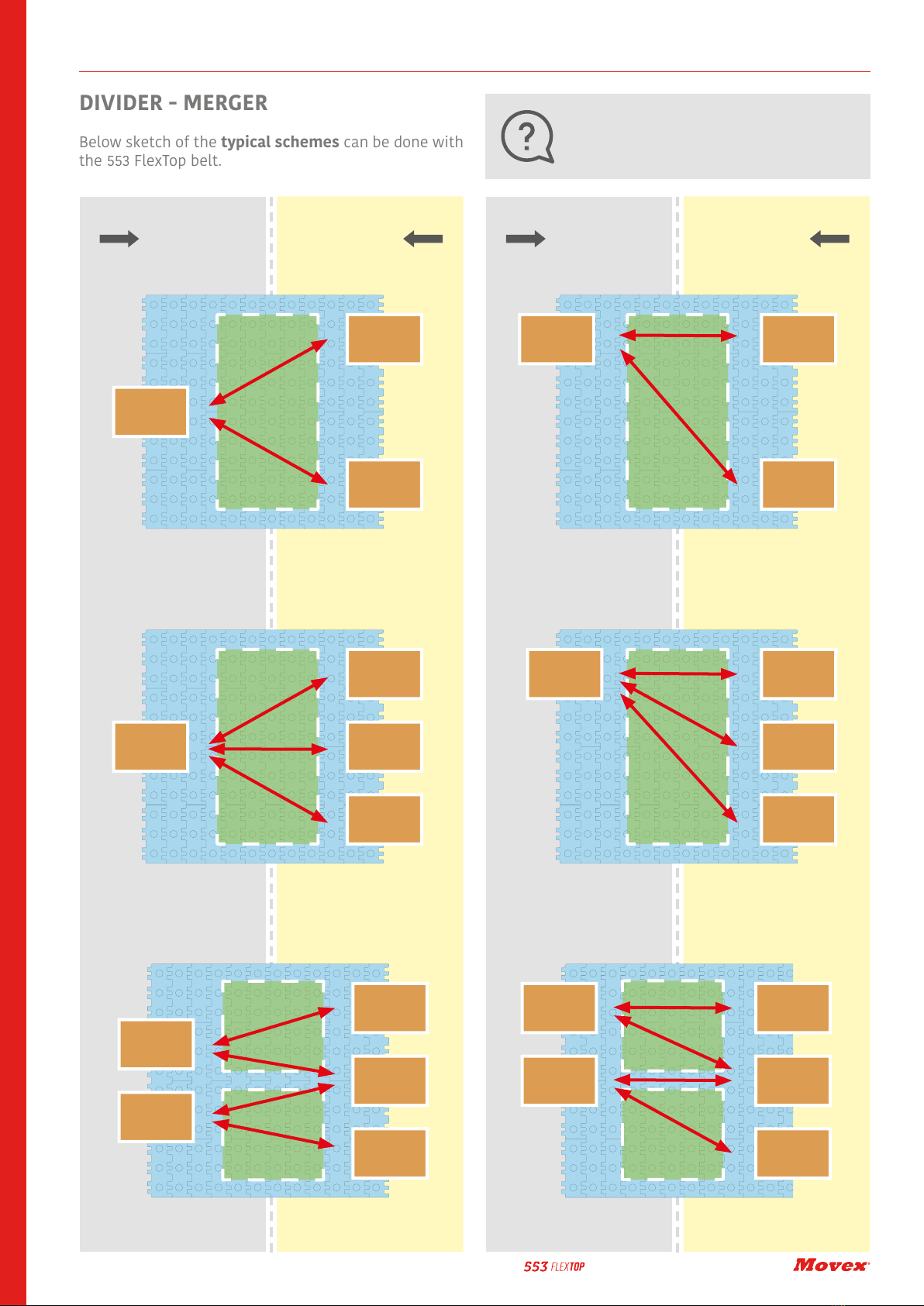

DIVIDER - MERGER

Below sketch of the typical schemes can be done with

the 553 FlexTop belt.

In case of dierent movement required, please

provide information to your sales representative

and you will receive required support.

1 to 3 - aside

1 to 3 - centered

1553 FlexTop belt - 1Directional belt1553 FlexTop belt - 1Directional belt

1 to 2 - centered 1 to 2 - aside

1553 FlexTop belt - 1Directional belt1553 FlexTop belt - 1Directional belt

1553 FlexTop belt - 2Directional belts1553 FlexTop belt - 2Directional belts

2 to 3 - centered 2 to 3 - aside

DIVIDER MERGER DIVIDER MERGER

Table of contents

Other Movex Industrial Equipment manuals