Movex Track-O CROSS-COUNTRY UTILITY User manual

Track-O

«CROSS-COUNTRY

UTILITY»

OPERATING MANUAL

READ CAREFULLY THIS

MANUAL BEFORE USING

THE TRACK-O

GENERAL SAFETY AND USE OF A TRACK-O

OPERATOR TRAINING REQUIRED

The employer must ensure that each operator of the TRACK-O has the skills to use

it safely, after receiving full training and assessment by a qualified person.

It is the employer’s responsibility to ensure that each operator has successfully

completed the required training.

Any user of a Track-O must know and master the basic principles of safety and use

of this device before using it.

GENERAL SAFETY RULES

Check the general condition of the Track-O, and if you see any anomaly, do share

them with your technical representative or anyone who can provide you technical

support (supplier or manufacturer).

The Track-o is very stable and highly reliable, please do not take any unnecessary

risk when operating this device.

Any reckless operation should be prohibited.

PRECAUTIONS BEFORE USE:

Make sure the route to take is free from objects and surfaces that are free from

grease and/or lubricants which may result in a reduced friction tracks. Also,

please make sure that the route to take do not require special protection if

restricted area.

Ensure that borrowing passages support the total load to be moved.

Never leave the unit where harmful.

The Track-O must not to be set in motion while the cable for recharging the

battery is still plugged in.

Ban all uses of the Track-O in an atmosphere containing a hazardous concentration

of acetylene, butadiene, ethylene oxide, hydrogen (or hazardous gases such as

manufactured gas), propylene oxide, of acetaldehyde, cyclopropane, diethyl

ether, ethylene, isoprene or unsymmetrical dimethylhydrazine (UDMH)

Ban all uses of the Track-o in a room where the atmosphere contains a harmful

concentration of metal dust including aluminum, magnesium and their commercial

alloys, other metals with similar hazardous properties, or in a room which

atmosphere contains carbon black, coal or coke dust.

The Track-O will function in temperatures between -25°C and + 40°C ( -13°F and

+ 104°F )

In case of failure or doubt concerning the use of the Track-O, please contact your

supplier. Do not take any risk to avoid any severe or fatal injury.

Never use the Track-O in water. It is not amphibious.

As part of the use of several Track-O at once in one place, operators must hold

approximately three lengths margin of safety equipment, and especially extra

careful in checking their gear perfectly.

BEFORE EACH HANDLING OPERATION WITH A TRACK-O:

Ensure that the load being moved is within the limits of weight recommended by

the manufacturer, depending on the model used, and this, as well as on flat

surface as inclined surface.

Ensure that the load is securely attached through the anchor eyelet.

Make sure the path does not have a bank angle greater than 15 degrees, and a

pitch or steeper than 40 degrees.

Never hesitate to do a dry run in order to best anticipate the space available to

maneuver.

DURING EACH HANDLING OPERATION WITH A TRACK-O:

Never use both remotes (wired and wireless) at the same time. One is enough and

may prefer the wireless remote (optional) for convenience.

Never stand downstream (below) the Track-O, but either side for wired remote

safe convoy, or outright upstream (above) of the convoy through the wireless

remote. This applies to both the operator and others in attendance in the scope of

the maneuver.

Never place hands near the track as the switch is turned OFF and the unit is not

completely still.

In all case, never stand below the Track-o and its load. If the load was to fall you

could be severely or mortally injured.

Before engaging the unit in an inclined, double check if the straps and anchor

points are in good condition and the unit responds well to the remote on the flat

surface.

AFTER EACH HANDLING OPERATION WITH A TRACK-O:

At the end of each use, power off the Track-O by pushing the emergency button on

the electrical panel. If you have a wireless remote, power off the remote by

pressing the emergency button on remote. Also, turn off the emergency stop on

the control panel.

Remember to keep the remote in the compartment.

Check the charge level of the Track-O, and if necessary, put in charge for the next

use.

TABLE OF CONTENTS

GETTING STARTED / CROSS-COUNTRY UTILITY

Putting breaker to “ON” position.................................... 7-8

Control panel.............................................................. 9

Wireless remote control ................................................. 9

Wired remote control................................................... 10

Moving the Track-O ..................................................... 11

Inclinometers ............................................................ 11

Working angles........................................................... 12

Configuration of the Track-O box ..................................... 13

Securing the transformer............................................... 14

Positioning the capstan................................................. 15

Retention mechanism................................................... 16

Installation to the pole ................................................. 16

Connecting the capstan to the Track-O .............................. 17

FEATURES ................................................................ 18-19

FOR SAFETY REASONS, BEFORE OPERATING THE TRACK-O, PLEASE

FAMILIARIZE YOURSELF WITH THE PRODUCT AND BE SURE TO

THOROUGHLY READ THE INSTRUCTIONS AND PRECAUTIONS CONTAINED

IN THIS MANUAL

OPERATING MANUAL

Page 7 of 19

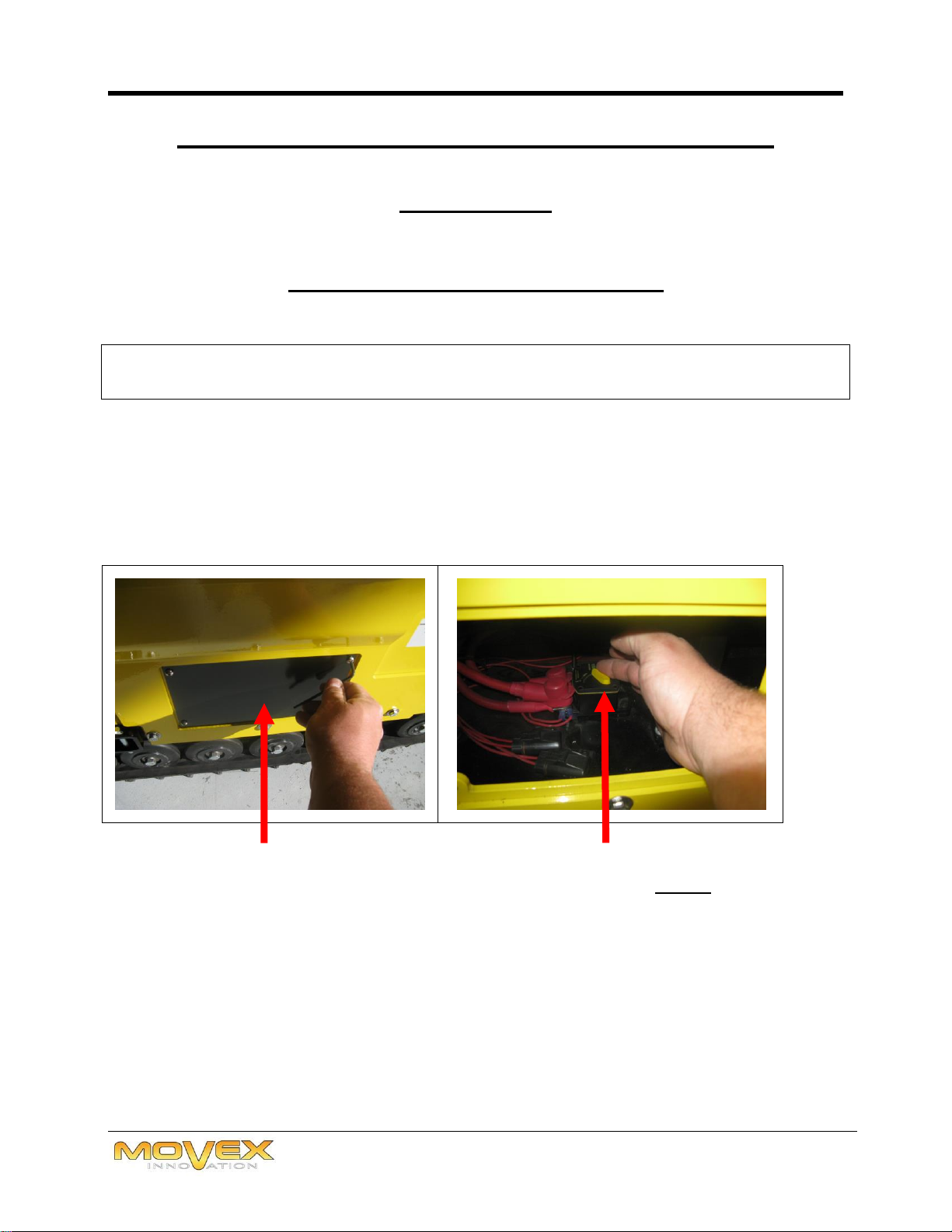

GETTING STARTED / CROSS-COUNTRY UTILITY

IMPORTANT

PUTTING BREAKER TO «ON» POSITION

DUE TO SHIPPING REGULATIONS, CIRCUIT BREAKERS ARE IN OFF

POSITION

BEFORE OPERATING THE TRACK-O, FOLLOW

INSTRUCTIONS BELOW

1) REMOVE THE ACCESS PANEL LOCATED ON THE LEFT SIDE OF THE

TRACK-O AND TURN YELLOW BREAKER SWITCH TO «ON» POSITION.

OPERATING MANUAL

Page 8 of 19

2) REPLACE THE ACCESS PANEL

3) UNSCREW THE SCREWS AND NUTS ON EACH SIDE OF THE BOX. TAKE

CARE TO REMOVE ONLY SCREWS AND NUTS AT THE TOP OF THE BOX.

4) TIP UP THE INNER PLATE AND TURN YELLOW BREAKER SWITCH TO

«ON» POSITION.

5) REPOSITION THE INNER PLATE AND TIGHTEN THE SCREWS AND NUTS.

OPERATING MANUAL

Page 9 of 19

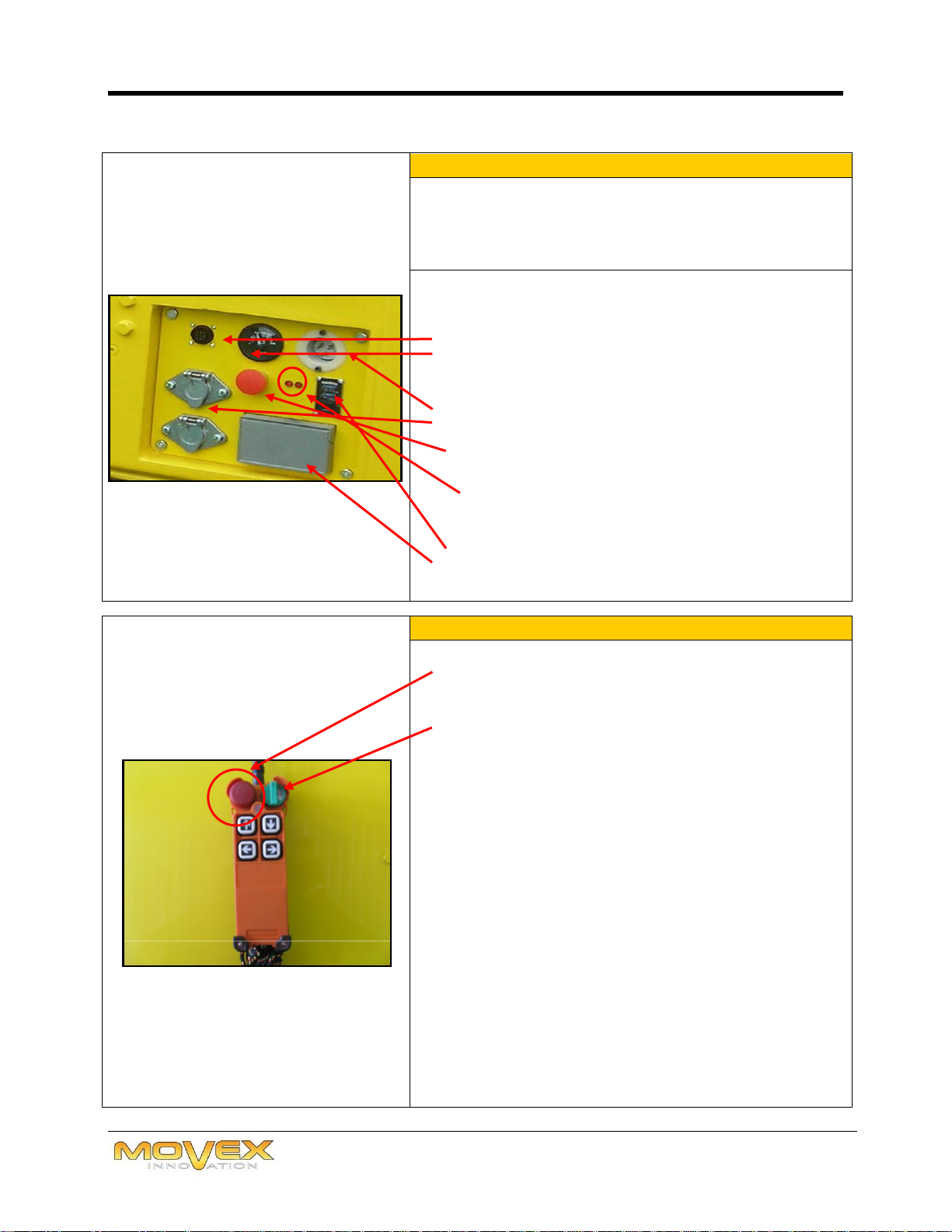

1 CONTROL PANEL

Note: Recharge when the needle shows 23 V.

A - Cable connector for the Track-O’s wired control

B - Voltmeter battery power display

Empty battery 22V

Full battery: between 24 and 28V

C - Charging socket

D - 24V outlet

E - Emergency stop.

F- Light signal indicating Track-O status

2 lights on = ok

Blinking light = problem (see wireless control) >

If the light flashes on the control panel of the

Track-O, it has to be reset.

G- Switch for the 120v inverter

H- 120V outlet

2 WIRELESS REMOTE CONTROL

The red emergency stop button on the remote

control should not be pressed.

Turn the green ignition key to activate the

remote green light.

The green light indicates that the wireless

connection has been established.

The red light indicates that the wireless connection

has not been established

The remote is powered by two AA batteries.

Note: Signal range can reach up to approximately

30 feet and self-deactivates after 10 minutes of

inactivity.

A

C

D

E

G

H

CAUTION:

The red emergency stop

button should not be

pressed!

F

B

OPERATING MANUAL

Page 10 of 19

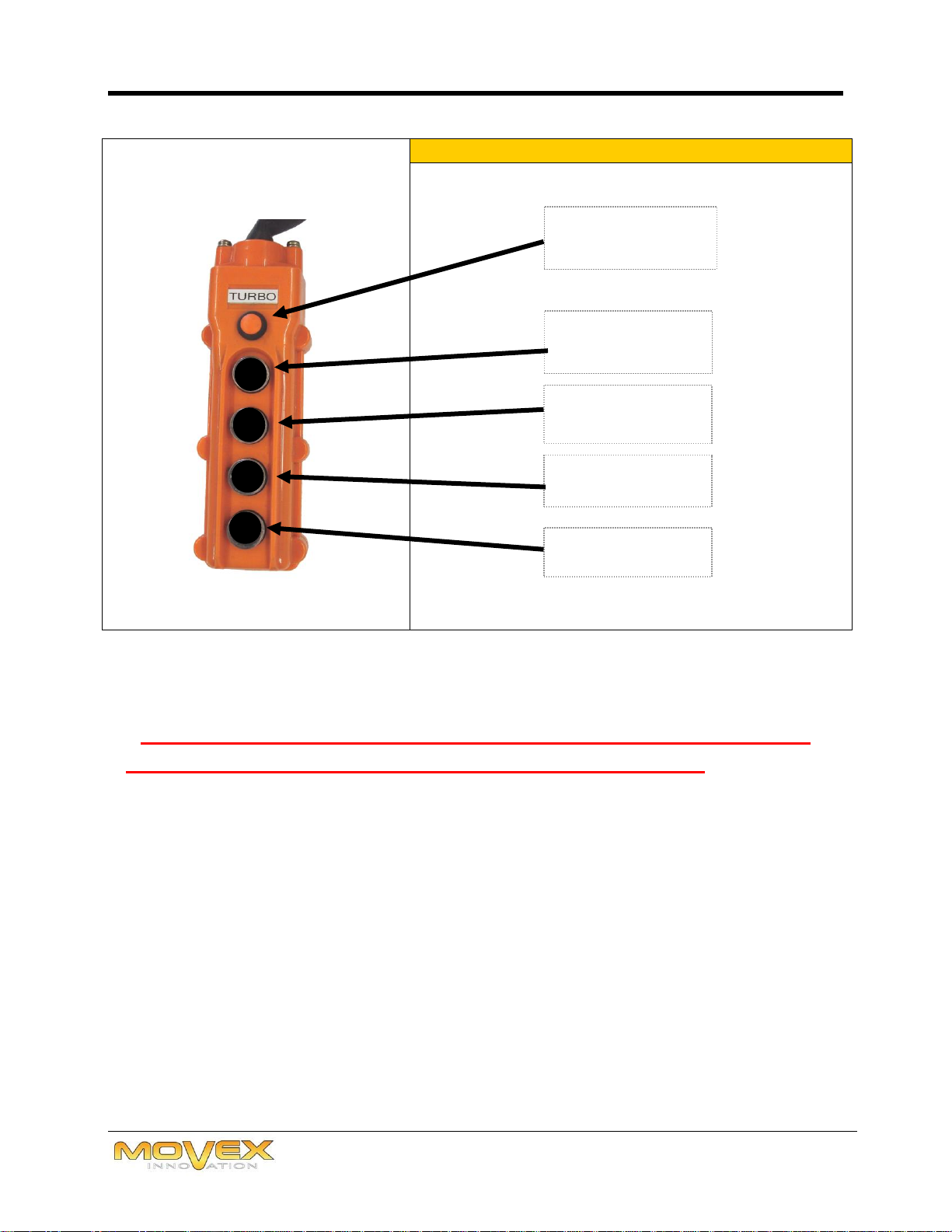

3 WIRED REMOTE CONTROL

FOR SAFETY REASONS IT IS STRONGLY RECOMMENDED THAT

WHEN THE TRACK-O IS NOT BEING USED TO MOVE A LOAD

THAT THE EMERGENCY STOP BUTTON BE PRESSED (EITHER ON

THE TRACK-O OR ON THE WIRELESS REMOTE CONTROL OR BOTH).

THIS WILL AVOID AN UNWANTED AND DANGEROUS MOVEMENT

OF THE TRACK-O CAUSED BY AN ACCIDENTAL PRESSING OF A

BUTTON ON THE WIRELESS REMOTE CONTROL.

FORWARD

REVERSE

TURN RIGHT

TURN LEFT

ACTIVATION

OF 2nd SPEED

OPERATING MANUAL

Page 11 of 19

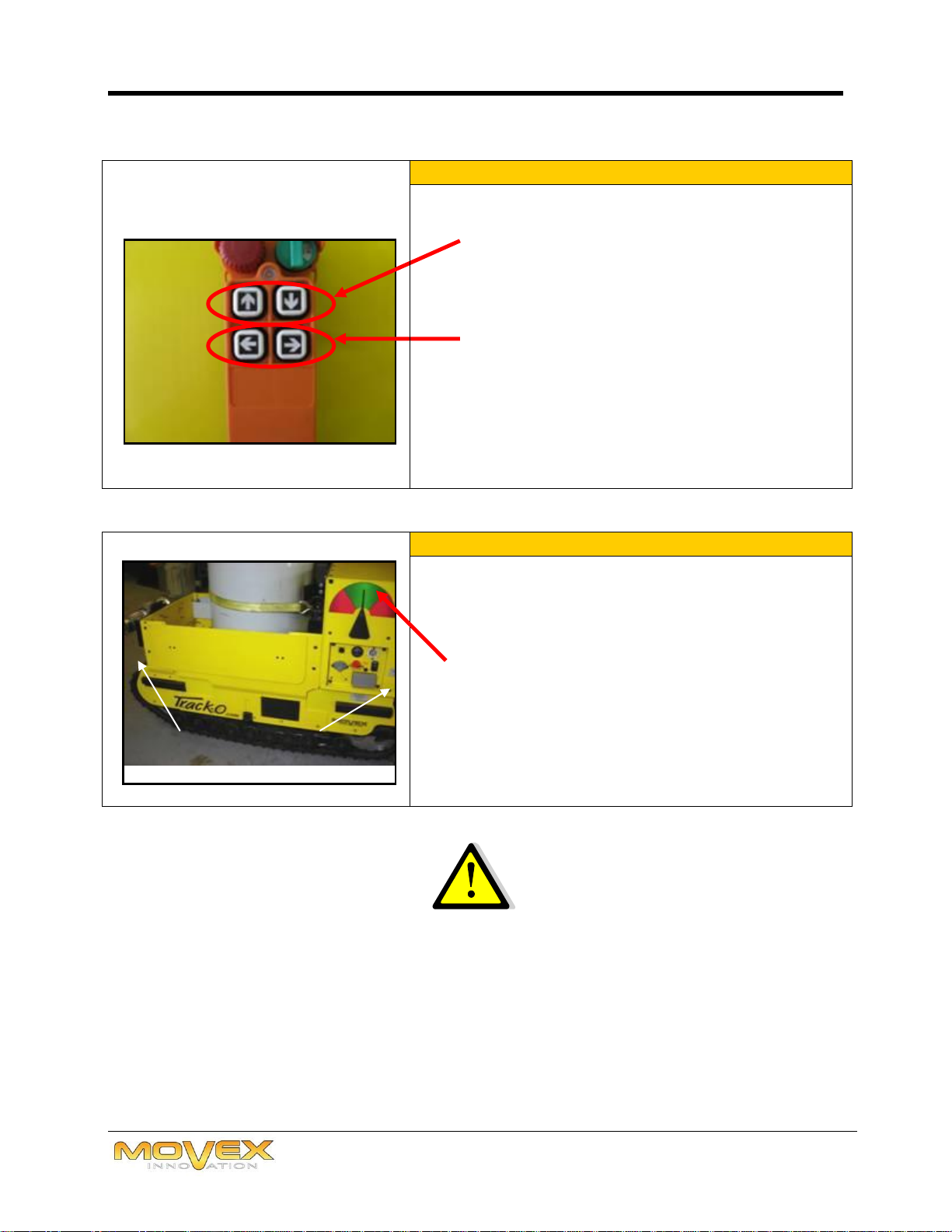

4 MOVING THE TRACK-O

By pressing gently the “Forward”or “Back”

buttons, you can move the Track-O slowly:

putting more pressure on the buttons will make

the Track-O accelerate the movement.

The direction buttons allow left or right

movements of the Track-O. Light pressure allows

for a simple curve, increased pressure for a

tighter curve.

Simultaneous pressure of both “Forward” and

“Back” buttons and direction button will create a

wide curve in the desired direction.

5 INCLINOMETERS

The degrees of tilt during movements are

represented by the Track-O’s integrated

inclinometers.

The green area indicates the comfort zone.

The red areas indicate a no-work zone.

Maximum longitudinal tilt: 40°

Maximum lateral tilt: 15°

WARNING

FRONT

BACK

Always put Front-end on the elevated part of an inclined

surface.

OPERATING MANUAL

Page 12 of 19

6 WORKING ANGLES

When the Track-O is used on rough terrain or

covered with vegetation, safety skates should

be installed.

The skates are kept in the storage

compartment.

These pads fit into the side cavity of the cab to

ensure the stability of the Track-O in case of

unexpected side tilt due to uneven terrain.

The skates can be removed to clear obstacles

such as stumps. However, this manoeuvre can

be performed only when the Track-O is

perfectly stable. The skates should be

reinstalled after obstacles are cleared.

Note: The skates have a print: they are

associated with the specific side (Right and

Left).

OPERATING MANUAL

Page 13 of 19

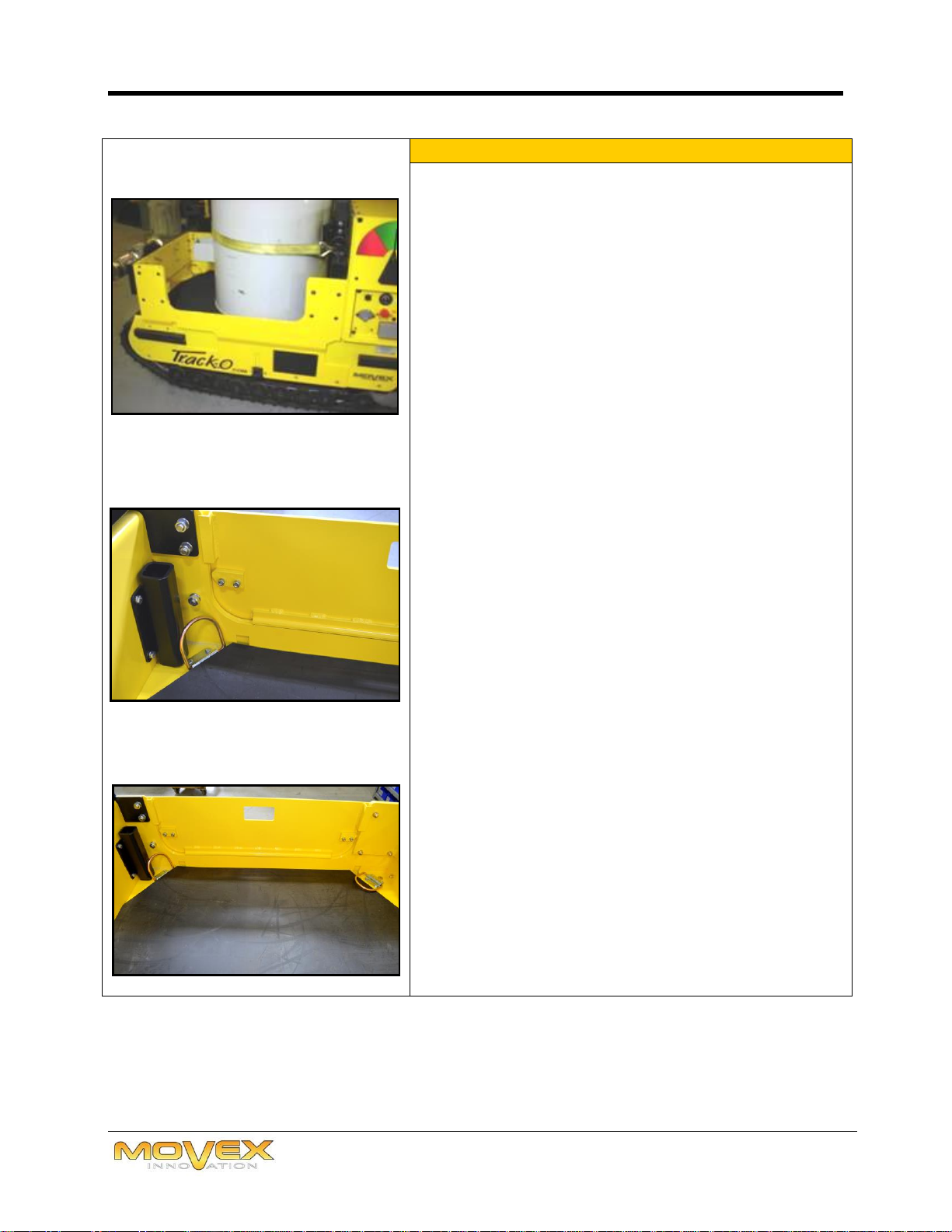

7 CONFIGURATION OF THE TRACK-O BOX

The Track-O box can be configured to carry

securely several types of transformers.

The sides can be removed if needed to allow the

cooling radiators to be loaded on the Track-O

box.

OPERATING MANUAL

Page 14 of 19

8 SECURING THE TRANSFORMER

Securely place the transformer against the

support.

Ensure that the adapter is required to properly

shoulder the transformer to the support. The

adapter is set on the existing support to allow a

better clearance for certain types of transformer.

Note: This adapter is generally used for

very old transformers.

Secure the transformer using with the ratchet

belt tensioners provided for this use.

OPERATING MANUAL

Page 15 of 19

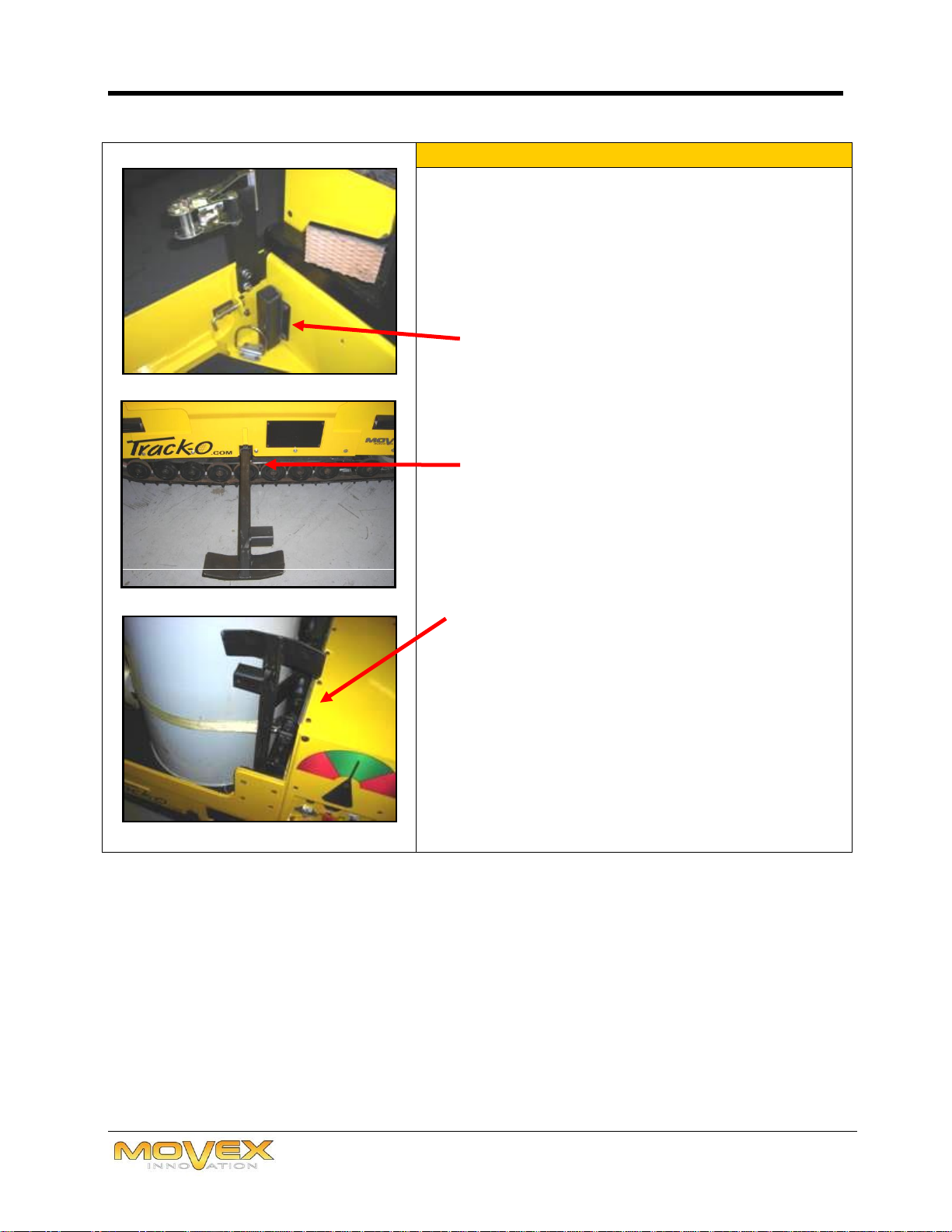

9 POSITIONING THE CAPSTAN - STORAGE MODE

The capstan has four positions: Two working

positions, one position for troubleshooting and

one position for storage.

Storage mode (used when carrying the Track-O to

a site).

10 POSITIONING THE CAPSTAN -

TROUBLESHOOTING MODE

The vertical position of the capstan can only be

used during repair/troubleshooting mode, i.e.:

To free the Track-O when bogged down or

whenever deemed necessary.

11 POSITIONING THE CAPSTAN -WORK MODE

Positioning the capstan-work mode :

1. Remove the retaining rod.

2. Slide the capstan sideway and tilt it

horizontally to the desired side.

3. Replace the retaining rod.

OPERATING MANUAL

Page 16 of 19

12 RETENTION MECHANISM FOR SLIPPERY GROUND

The retaining mechanism is used as needed to

stabilize the Track-O on slippery surfaces such as

ice, when using the capstan.

Retaining cylinders can be used in two ways,

directly on the chassis of the automotive Track-O

or on the safety skates

Lower the jacks so they lightly touch the ground,

without over lifting the Track-O.

13 INSTALLATION TO THE POLE

The capstan of the Track-O must be used at any

time with a pulley attached to the pole.

The capstan lever must be aligned as much as

possible with the cable axis.

IMPORTANT: DO NOT move the Track-O when the

winch is in use.

OPERATING MANUAL

Page 17 of 19

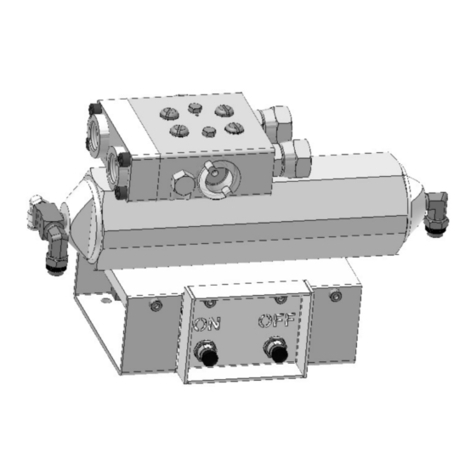

14 CONNNECTING THE CAPSTAN TO THE TRACK-O

Connecting the capstan to the Track-O :

1. Connect the pedal power cable to the capstan

2. Activate the inverter to power AC electrical

outlets The LED on the inverter will stay on for

4 hours. To reactivate it after this period, put

the switch to “OFF”and then switch back to

“ON”position.

3. Connect the other part of the cable (equipped

with a pedal) to the 120V outlet on the control

panel of the Track-O.

FEATURES

Page 18 of 19

CAPACITY of the Track-o

The automotive Track-O has been designed for rough terrain use. It is nonetheless

totally fit for back-lot access.

DESCRIPTION

DETAILS

Metric

Imperial

Width

76 cm

30 in.

Length

168 cm

66 in.

Weight

739.35 kg

1,630 lbs

Slow linear speed

6.7 m/min.

22 feet/min.

Fast line speed

13.4 m/min.

44 feet/min.

The Track-O is designed to work with an equivalent load of 2000 lbs / 907 kg. It can move

these loads over rough and sloped terrain. The Track-O’s integrated inclinometer

constantly indicates the degree of slope the Track-O can handle.

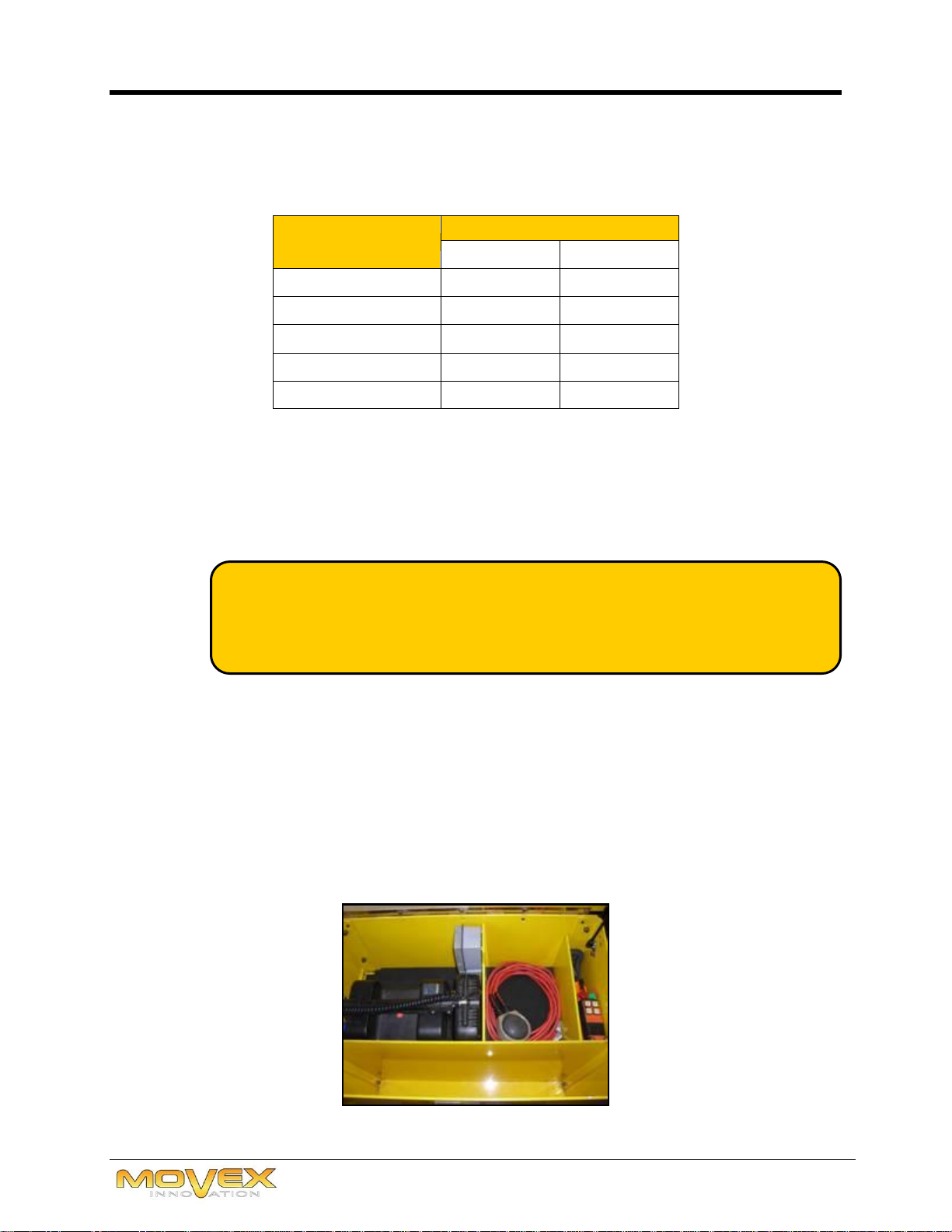

The storage comportment is ideal to put the Track-O’s accessories, such as the wireless

remote control, the wired control, the connection cable for the capstan and lighting

system.

Two 120 volts sockets are integrated in the trunk. The external socket is connected to

the inner socket which serves as protection and the other is independent and used to

charge the portable lamp.

Track-O’s charging time: 4 hours

Track-O’s continuous operating time: 4 hours

FEATURES CONT’D

Page 19 of 19

120 V Inverter

Capacity: Continuous 1000 W 15 A (3000 W peak)

Automatic shutdown conditions are:

The battery level reaches 21.2V;

The temperature of the inverter is too high;

There is a short-circuit on the 120VAC output;

Operation exceeds 4 hours;

Demand for power is too important;

The protection of 120V output inside the box has been triggered.

Track-O charging mode: Requires about 5A at 120V.

Recharge of the Track-O provides 25A to the accumulators.

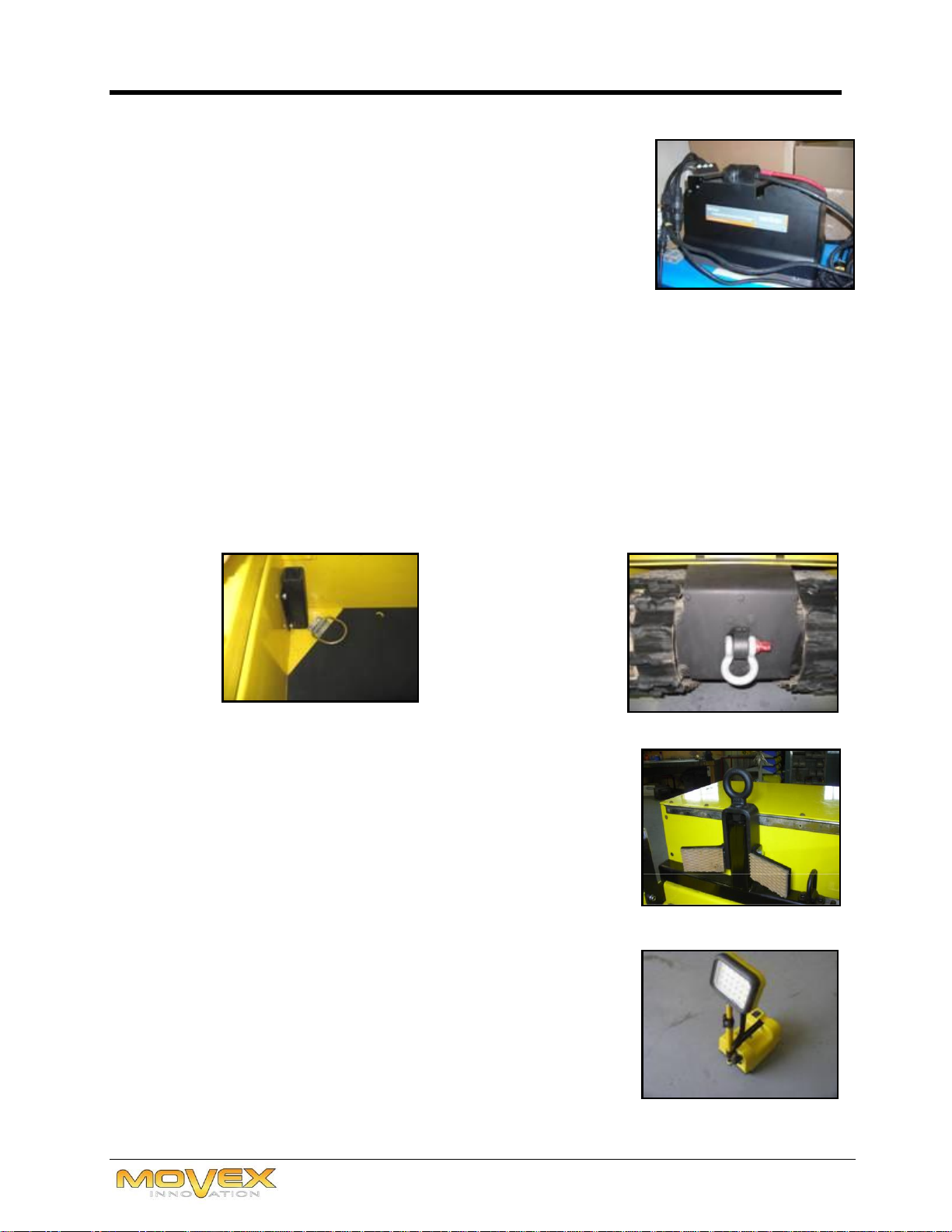

D-Ring and skate support

Capacity: 200 lbs

Lifting and transformer support

Transformer support

Lifting support

Capacity: 2000 lbs

Lighting for night use (Option)

Two (2) intensity lighting

8 hours autonomy

Charging time: 4 hours

Recharges when in storage compartment and connected

to the outlet. However, the inverter must be activated

to initiate charging.

Towing eye

Capacity: 3100 lbs

Table of contents

Other Movex Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

MVP

MVP HVDG-2000 Operation manual

Exmark

Exmark ULTRAVAC Setup instructions

FRIEDHELM LOH

FRIEDHELM LOH Rittal SK 3363 Series Assembly and operating instructions

Teknomotor

Teknomotor 3140-B-DBS-P-ER20 Use and Maintenance Instruction

Magnescale

Magnescale DT32N instruction manual

riverhawk

riverhawk IM-186 instruction manual