MOXTEK X-ray Sources User manual

MOXTEK

®TUB-MAN-1022 Rev A

Subject to technical change without notice

1

X-ray

Sources

Introduction

Moxtek manufactures low-power miniature X-ray sources for a variety

of applications including handheld XRF, Security, NDT and benchtop

instruments. Moxtek sources are small, lightweight and can be packaged

into customer enclosures. MOX140G is ideally congured for backscatter

and traditional imaging. MOX140G is capable of running up to 140kV

and 7W.

Figure 1: Fan Beam/Cone Beam

Table of Contents

• Introduction

• X-ray Source Characteristics

• Cooling

• Operating Conditions

• Mounting Information

• Initial Inspection

• Initial Setup

• Electrical Interface

• I2C Information

• Operating Precautions and Warnings

• Software and Setup

• Running the 140kV PC Controller Application

• Suggested Settings and Operation Parameters

1

2

2

2

2

3

3

3-4

3-4

5

6

7-9

10

MOX140G

Operation Manual

MOXTEK

®

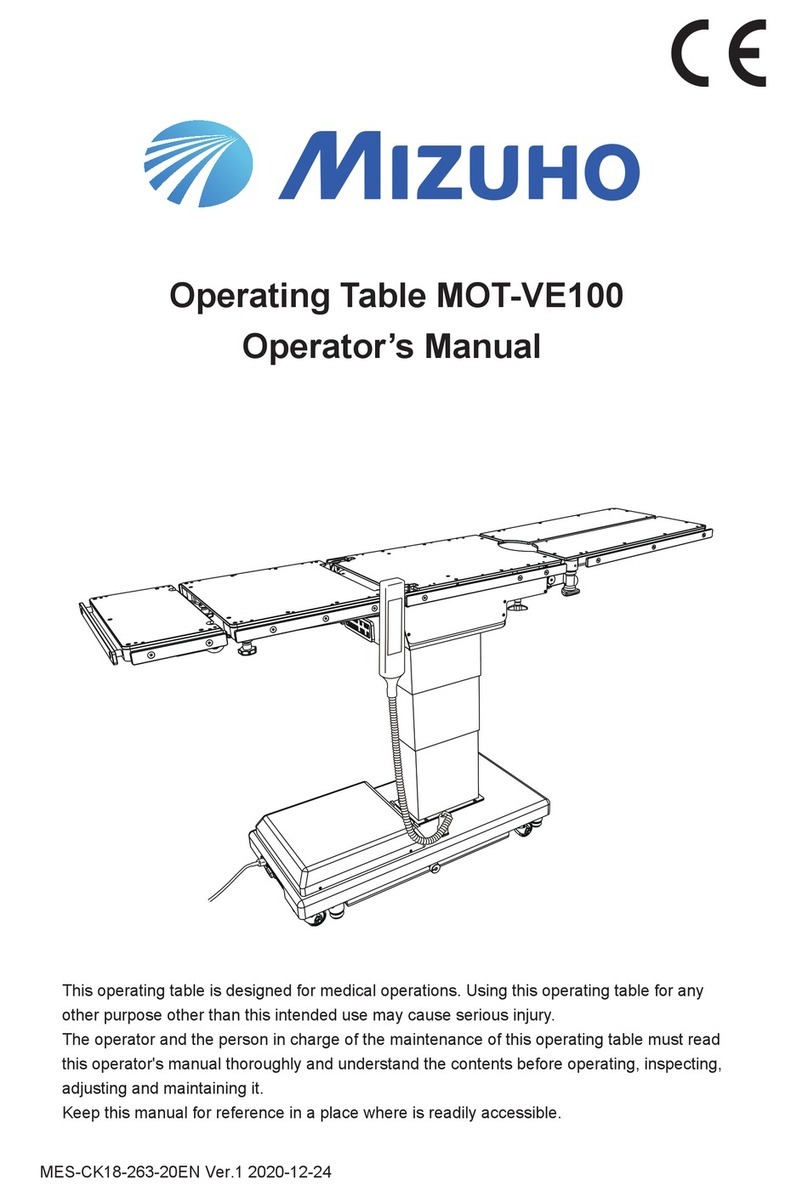

Figure 2: Mounting Points Diagram

TUB-MAN-1022 Rev A

Subject to technical change without notice

X-ray Source Characteristics

2

Mechanical Specications

Tube Type Metal-Ceramic

Window 0.001in Tungsten

Operating Temp -10º to +50º C

Storage Temp -30º to +65º C

Cooling Forced air (as needed)

Weight 1.9kg/ 4.2lbs

Available Targets: Tungsten

X-ray Tube Characteristics

HV Polarity Bi Polar

High Voltage 140kV (max)

Beam Current 25uA - 50uA

Maximum Power 7W (50% Duty Cycle)

Focal Spot Size 1.00mm max FWHM

Maximum Exposure 30sec

Standard Warranty 1 year with typical usage

Cooling

Operating Conditions

Active or passive cooling will be needed depending on the application. Adhering to the limits specied in the X-ray

Source Characteristics will prevent any damage. Internal memory records operating temperature to facilitate failure

analysis. Operation outside of the permitted limits will void the warranty.

140kV tube anodes are grounded to the sheet metal and the power supply. Damage to the tube and or power supply

may result if a ground wire is not provided from the case ground to an appropriate equipment ground. Note that the

sheet metal is potted directly to the HVPS and should never be removed.

When operating the 140kV x-ray tube, adhere to the maximum settings as shown in Table 1 and 2. Failure to adhere

to these limits may cause damage to the x-ray tube and/or high voltage power supply. Failure to adhere to this

parameter will void the tube warranty. Internal memory records operation outside established limits for failure.

Mounting Information

Side screws are M2.5-0.45 THD and can be put in at a depth of 2mm. The front has 4 studs with dimensions M2 X

8mm. Mox140G, has four dual purpose screws at the front of the device. The studs are used for mounting purposes,

and for grounding. Removal of more than two studs will void the warranty. Once removed, studs cannot be added

back due to a risk in puncturing potting and harming electronic components.

Table 1: Mechanical Specications Table 2: X-ray Tube Characteristics

Initial Inspection

Pin # Name Description

1 VDC Main power, 12V +/- .5V

2 VDC Main power, 12V +/- .5V

3 VDC Main power, 12V +/- .5V

4 SCL I2C clock line

5 SDA I2C data line

6 ENABLE +5V to enable x-rays

7 GND Ground return

8 GND Ground return

9 GND Ground return

10 GND Ground return

11 +5V Aux power

12 +3.3 OR +5V I2C power*

Ensure proper ground connection to the shell.

Ensure all pinouts are correct.

Conrm everything is powered o when connecting to source.

If using the adapter board, proceeed to software section.

Initial Setup

Electrical Interface

The Samtec 10-pin FLE-105-01-G-DV connector is not used. This is for Moxtek use only. See Figure 3 below.

The Moxtek uses a Molex Picoblade connector # 53398-1271 (12-pins) is used to interface with MOX140G.

MOXTEK

®

3

Table 4: Pins Dened

Components Quantity Required

TUB0020X-W08 1

Molex 12 pin Picoblade connector # 53398-1271* 1

Cable – USB Type A-B 2.0* 1

12V power supply* 1

TUB-MAN-1022 Rev A

Subject to technical change without notice

Please Inspect Contents

*Optional items to purchase

Table 3: Components, Quantities

*Pin 12 should be powered with the same voltage used on the host’s I2C pull-up. If +3.3V I2C bus, is used +3.3V

should be used for pin 12. If +5V I2C bus is used, +5V should be used for pin 12.

MOXTEK

®

Pin 1

X

TUB-MAN-1022 Rev A

Subject to technical change without notice

4

To interface with the Molex Picoblade connector, use a Molex 0510211200 connector housing and a Molex

28AWG jumper lead socket to socket wires. (Molex 0006660013 is a good example). Power on the cable should

be o when connecting or disconnecting to the source.

Table 5: Addresses amd Lengths of Various Data

I2C Information

The master I2C bus requires 1K ohm to close to blue ribbon resistors for the pull-up voltage because of the nature of

the level shifter used.

Name Type Size (bits) Address (hex) Description

ctrl_Interlock unsigned 8 0x00 Status of pin 6 above, the enable signal

ctrl_Enable unsigned 8 0x01 Enable status

errorFlags unsigned 8 0x02 All errors are registered here

ctrl_vHWREV unsigned 8 0x03 hardware revision number

ctrl_vFWREV unsigned 8 0x04 rmware revision number

ctrl_cMFGYEAR unsigned 8 0x06 manufactured year

ctrl_cMFGMONTH unsigned 8 0x07 manufactured month

ctrl_cMFGDAY unsigned 8 0x08 manufactured day

ctrl_cTUBESN unsigned 24 0x09,0A,0B tube serial number

ctrl_cPSSN unsigned 24 0x0C,0D,0E power supply serial number

ctrl_vBrdTemp unsigned 16 0x0F,10 current board temperature

ctrl_vMaxTemp unsigned 16 0x11,12 maximum recorded board temperature

ctrl_vMinTemp unsigned 16 0x13,14 minimum recorded board temperature

ctrl_vHVSet unsigned 16 0x1B,1C high voltage set point

ctrl_vUASet unsigned 16 0x1D,1E beam current set point

ctrl_vnegHVMon unsigned 16 0x1F,20 negative high voltage monitor

ctrl_vUAMon unsigned 16 0x21,22 beam current monitor

ctrl_vposHVMon unsigned 16 0x23,24 positive high voltage monitor

Reading and Writing Voltage/Current and/Temperature Values

To read or write to the registers, the code must read or write a byte at a time and convert them to their full values

(if they are larger than 1 byte). So for example, on ctrl_vBrdTemp, user would read the two bytes starting at 0x0F.

Because data is stored little-endian format, byte 0x10 is the most signicant byte (MSB), so it is shifted up by 8

and added to byte 0x0F.

Figure 3: Ribbon cable connection

Electrical Interface cont.

MOXTEK

®

Bit

Number

Decimal

Value Error Description

1 1 Low HV Will throw an error if +/- KV is 5KV or lower than the set KV

2 2 High HV Will throw an error if +/- KV is 5KV or higher than the set KV

3 4 Low UA Will throw an error if uA is 5uA or lower than the set uA

4 8 High UA Will throw an error if uA is 5uA or higher than the set uA. If uA is set to 0,

will throw an error if uA is 10uA or higher

5 16 High Temperature Will throw an error if the internal temperature is 75°C or higher (Will be

adjusted based on environmental testing)

6 32 Low Temperature Will throw an error if the internal temperature is -7°C or lower (Will be

adjusted based on environmental testing)

Operating Precautions and Warnings

The X-ray source should be ramped up to 140KV to avoid arcing within the tube. If the source has been sitting idle

for a few hours or more, 3 seconds is recommended to ramp up to full voltage and power for the rst cycle. The

suggested procedure is to turn the source on at 70KV and 20uA. At 70KV, then take 10KV steps up to 140KV. Finally

turn the lament power up to full output. This should take about 3 seconds. If the source has been running, the ramp

rate time can be decreased to 0.5 seconds. The suggested procedure is to turn the source on at 70KV and 20uA, then

take 10KV steps up to 140KV. Finally turn the lament power up to full output. This should take about 0.5 seconds.

5

Variable Denition Related Equation

KVSET Desired KV ctrl_vHVSet = KVSET * 416.5

UASET Desired Current ctrl_vUASet = UASET * 518.4

KVMONP KV monitor positive KVMONP = ctrl_vnegHVMon / 169

KVMONN KV monitor negative KVMONN = ctrl_vposHVMon /169

UAbc Monitor beam current UAbc = ctrl_vUAMon * 0.0094

TKTemperature (Kelvin) TK = ctrl_vBrdTemp / 16

TC= TK-273.15

TCTemperature (Celsius)

Table 6: Variables Dened

Table 7: Bit Description

TUB-MAN-1022 Rev A

Subject to technical change without notice

I2C Information cont.

Figure 4: Moxtek Website Software Downloads Page

MOXTEK

®

6

Software and Setup

140kV Software Guide

1. Click on link to access the 140kV folder. See below page for location of software downloads.

2. Download the MOX140G Software folder

3. Unzip the downloaded le “MOX140G Software” onto desktop

4. Navigate to the “Drivers” folder

5. Open the “Moxtek 2.12.28-Signed” folder

6. Right click the “dp-chooser.exe” and select “Run as administrator”

7. Follow the prompts to install the driver

8. Once complete, run the “CDM21228_Setup.exe” le to install the FTDI driver

9. Follow the prompts to install the driver

10. Once complete, navigate to the main 140kV folder

11. Run the “140kV PC Controller.application” le

12. Once the 140kV PC Controller software is installed, run the program

13. A taskbar search for “140kV PC Controller” can locate the new le if needed

TUB-MAN-1022 Rev A

Subject to technical change without notice

MOXTEK

®

7

1. Start by ensuring the adapter board switch is in the o position

2. Connect the red cable to the adapter board, and then the 140KV source (as seen below)

3. Plug in the 12V power supply provided to both a wall outlet and the adapter board

4. Connect the provided USB cable to the adapter board, and to a PC that has the provided software installed.

5. Connect the interlock pins of the adapter board to a shielded safety interlock. It requires an

open or short condition. If the two pins are shorted together, the interlock is closed and the unit is safe to run. If the

two pins are open, or not connected to each other, the interlock is open and the unit will cease to emit any X-rays.

6. Power on the adapter board. Turn the switch from “OFF” to “ON”.

7. A green light should turn on, which conrms power is being provided, and a red light, meaning the safety interlock is

closed. The unit is ready to run.

TUB-MAN-1022 Rev A

Subject to technical change without notice

Running the 140kV PC Controller Application

Figure 5: USB cable to the adapter board

Figure 6: Interlock Pins

Figure 7: Safety Interlock Closed

8

Figure 8: Communication Port Section

Figure 9: Successful Connection

8. Go to the PC connected via USB to the adapter board, and start the “140KV PC Controller” application.

9. In the program, go to the Communication Port section and click the drop-down box. The program will recognize

the dapter board’s serial number. Click it. If nothing shows up, click out of the drop-down box and try again.

Communication can stall, and may take multiple attemps.

10. Once the connection is successful, it will populate certain elds with information about the connected source.

11. To run the source, click the “Enable Xrays” button, and put the desired values in the “Set Total KV” and “Set uA”

boxes. For the rst run of the day, please ensure that the “Std Ramp” rate is set to 50 KV/s or less. Once the unit is

warmed up, go ahead and set the “Std Ramp” to 140 KV/s for a 1 second ramp time to full power, or check the

“Fast Ramp” option, with 600 KV/s and 70 KV for the “Switch” value, and it will ramp to full power in 0.5

seconds.

MOXTEK

®TUB-MAN-1022 Rev A

Subject to technical change without notice

Running the 140KV PC Controller Application cont.

MOXTEK

®

**NOTE** There are additional software settings that are available.

The “Data Logging” section allows for creation of a text le that will populate with all the current settings and

readings at chosen “Log Interval” you choose. Log periors are set to default to every 0.5s, but can be changed to

any value between 0.5s to 3600s if desired.

The “Cycle Testing” section allows user to automatically turn the X-rays on and o at a specied duty cycle. The

max “On Time” recommended is 30s. The corresponding minimum recommended “O Time” is 30s. The “Add

20uA above 50KV” box should remain checked, and the “Filament Only” box should be blank.

If more details on these settings are needed, contact Moxtek.

TUB-MAN-1022 Rev A

Subject to technical change without notice

9

(Initial check and warm-up settings)

(Full output with 0.5s ramp rate)

Running the 140KV PC Controller Application cont.

Figure 10: Enable X-rays

Figure 11: Inital Check and Warm-up Settings

MOXTEK

®

Suggested Settings and Operation Parameters

• The source should be run between 10KV and 140KV.

• No beam current should be applied, unless the source is at 50KV or higher.

• 20uA should be the maximum current setting when below 100KV.

• If the source has been sitting overnight, or for about 24 hours, set the “Std Ramp” to 50 for the initial start-up.

After it has been running, the “Std Ramp” can be set to 140.

• At full output, the source should be set to 140KV and 50uA. 50uA should be the maximum current setting for the

source at any KV level.

• Active cooling is recommended to keep the temperature down on the source.

TUB-MAN-1022 Rev A

Subject to technical change without notice

10

Suggested Settings and Operating Parameters

Table of contents

Other MOXTEK Medical Equipment manuals

Popular Medical Equipment manuals by other brands

KaVo

KaVo KaVo Primus 1058 Life TM Care Instructions

ulrich medical

ulrich medical Obelisc CS 2931 Series Assembly and disassembly instructions with special cleaning instructions

DJO Global

DJO Global Vectra Genisys user manual

Guldmann

Guldmann 28445 manual

Gima

Gima OXY-5 Use and maintenance book

ResMed

ResMed Ultra Mirage Clinical Guide