*Teflon is a registered trademark of E.I. duPont de Nemours & Co., Inc.

2

and other metallic parts in contact with the material

being pumped.

The third letter indicates the material of the stator. It

identifies only the stator material and not that of the tube

in which the stator is placed. The tube, a non-wetted

part, is always alloy steel.

A typical designation such as the CDQ used in our

example would result in the following:

C = Cast iron suction chamber

D = Hardened alloy steel internals including drive

shaft, connecting rod, pins, and rotor

Q = Nitrile (NBR) stator (70 durometer hardness)

The following letters identify the materials used in

standard construction:

C = Cast iron

D = Hardened alloy steel

S = Stainless steel, Type 316

Q = Nitrile (NBR), 70 durometer hardness

B = EPDM

F = Fluoroelastomer

The next position is a number identifying the current

pump revision, this manual corresponds to revision 3.

The last three letters indicate the trim code and

denote internal variations in a pump. The first letter

identifies sealing variations. The second letter indicates

internal variations. The third letter indicates rotor

variations.

A typical trim code is AAA, designating the following:

A = Standard black packing

A = Standard plated shaft

A = Standard size chrome-plated rotor

The variations available are:

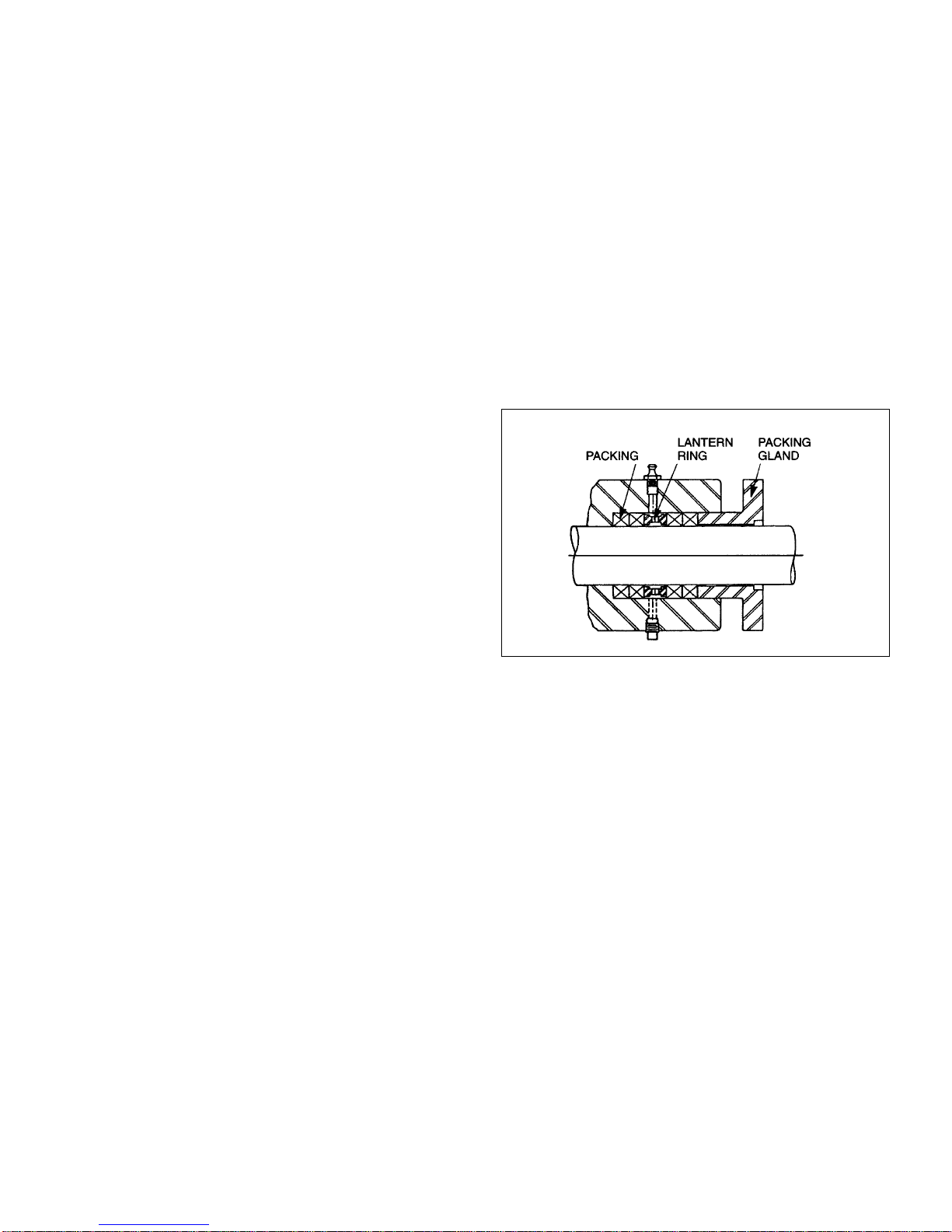

Sealing:

A – Standard black packing

C – Teflon7 white packing (not food grade)

S – single mechanical seal

D – Double mechanical seal

Internal variations:

A – Standard plated shaft

B – Non-plated shaft

P – Two-piece shaft or pinned close coupled

Rotor variations:

A – Standard plated rotor

B – Non-plated rotor

C – Standard undersize

E – Standard oversize

X – Special to order

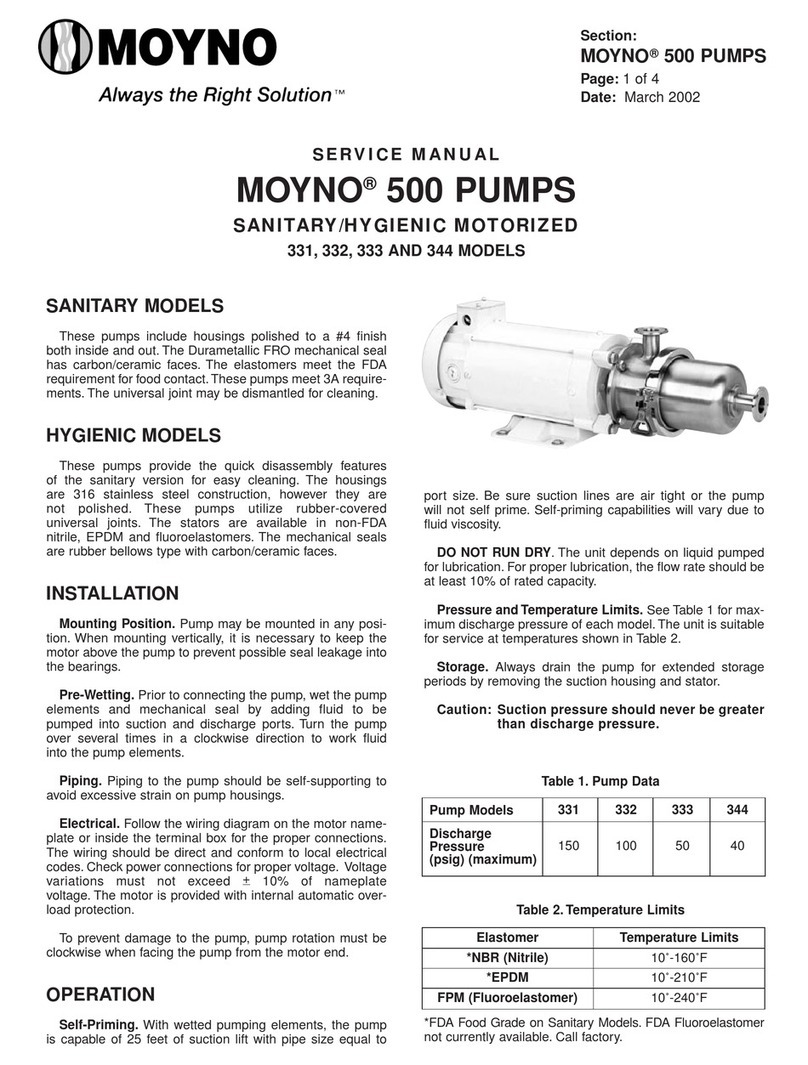

2-1. INSTALLATION

2-2. GENERAL

Accessibility to the pump and adequate clearance should

be prime considerations in any installation. Enough space

should surround the unit so that maintenance can be

performed with ease.

2-3. PIPING

2-4. Suction piping should be as short as possible.

Normally, the suction line should be the same diameter as

the pump suction; however, conditions such as high

viscosity or required minimum flow velocities may dictate

otherwise. Long-sweep 90 degree elbows or 45 degree

elbows should be used instead of the standard elbow.

Avoid using suction piping loops which trap air.

2-5. Discharge piping diameter should generally be as

large as the discharge port unless fluid conditions indicate

otherwise.

An easily-removable section of piping, at least twice as

long as the stator, should be mated to the discharge port.

This will allow the rotor and stator to be removed without

having to remove the complete pump from the base.

2-6. FOUNDATION

For maximum pump-driver unit life, each unit should be

mounted on a strong steel baseplate. The baseplate should

be mounted on a firm foundation. The motors should be

supported on close-coupled configurations above 1 HP.

2-7. SHAFT ALIGNMENT

After the base has been bolted down to the foundation,

check the following conditions:

2-8. Coupling connected units. Be sure that the pump

and drive shafts are aligned before the coupling is

connected. Care should be exercised to ensure that all

components are level and mounted in a direct line.

Check the gap between coupling halves (refer to coupling

manufacture’s recommendations). Adjustment can usually

be made by loosening the mounting bolts on either the

pump or driver and moving the loosened component into

alignment with the fixed component. Do not use a hammer!

On couplings with equal diameter hubs, it may be helpful to

lay a straight edge across the coupling halves to check

alignment.

2-9. Belt drive units. Be sure that sheaves or sprockets

are in alignment. Check belts for proper tension. Tension

requirements will vary with type of belt, center distances,

and belt speeds. Consult belt manufacturer for specific

recommendations.