TROUBLE SHOOTING

WARNING: Before making adjustments,

disconnect power source and

thoroughly bleed pressure from

system. Failure to do so could result

in electric shock or serious bodily

harm.

Failure To Pump.

1. Motor will not start: Check power supply. Voltage

must be ± 10% of nameplate rating when motor is

in locked rotor condition.

2. Motor runs and thermally kicks out: Check for

excessive pressure. Increase ventilation to motor.

Do not use less than #14 wire size.

3. Stator torn; possible excessive pressure: Replace

stator, check pressure at discharge port.

4. Flexible joint broken; possible excessive pressure:

Replace joint, check pressure at discharge port.

5. Wrong rotation: Rotation must be clockwise when

facing pump from motor end. Reverse the

connections of any two line leads to the motor.

6. Excessive suction lift or vacuum.

Pump Overloads.

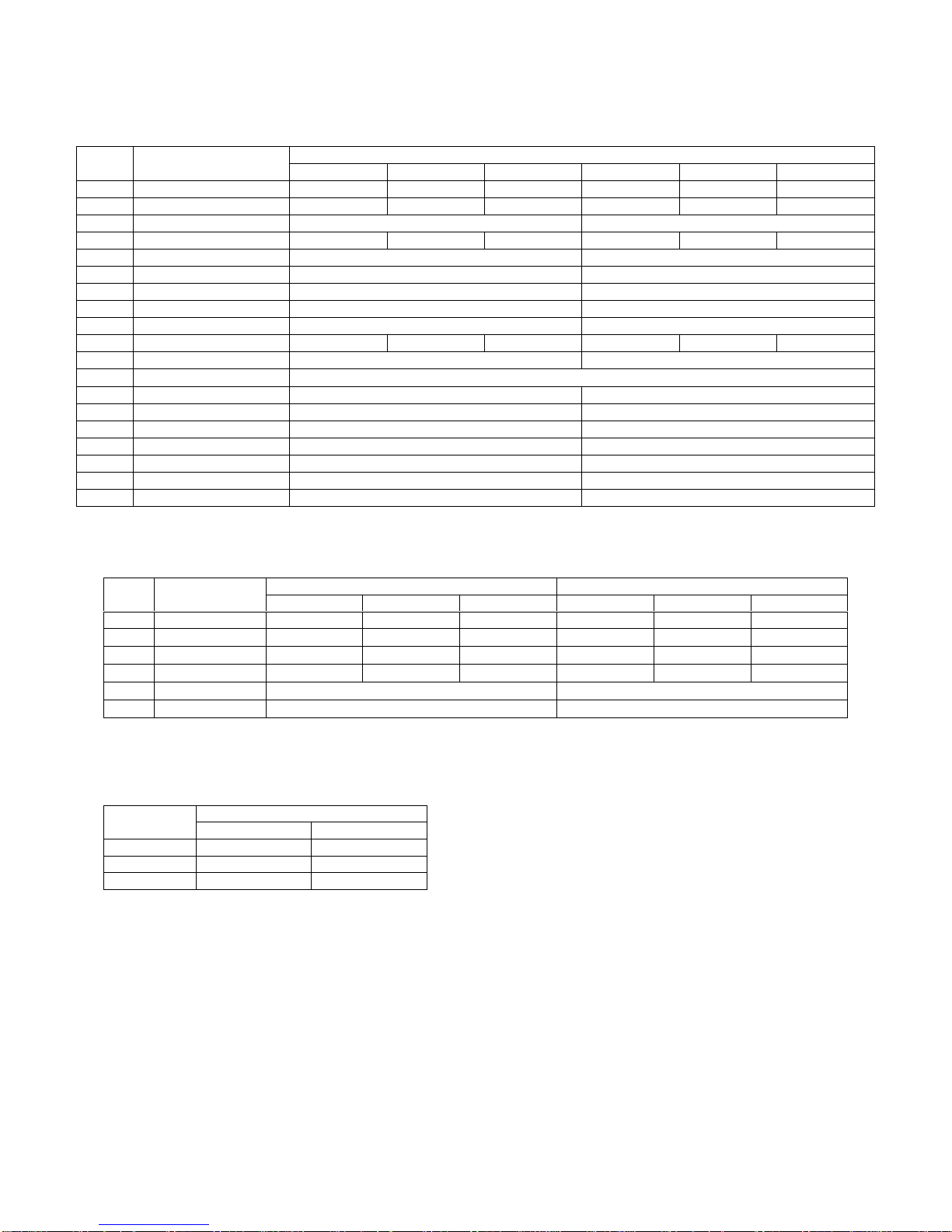

1. Excessive discharge pressure: Check pressure at

discharge port for maximum ratings given in Table

2. Fluid viscosity too high: Limit fluid viscosity to 100

CP or 500 SSU.

Noisy Operation.

1. Excessive suction lift or vacuum: Maximum suction

lift is 25 feet for water.

2. Suction line too small: Check pipe size. Be sure

lines are free from obstructions.

3. Pump cavitates: Pump speed is 1725 rpm.

Viscosity of fluid should not exceed 100 CP or 500

SSU.

4. Flexible joint worn: Replace joint. Check pressure

at discharge port.

5. Insufficient mounting: Mount to be secure to a firm

base. Vibration induced noise can be reduced by

using mount pads and short sections of hose on

suction and discharge ports.

Seal Leakage.

1. Leakage at startup: If leakage is slight, allow pump

to run several hours to let faces run in.

2. Persistent seal leakage: Faces may be cracked

from freezing or thermal shock. Replace seal.

Pump Will Not Prime.

1. Air leak on suction side: Check pipe connections.

PUMP DISASSEMBLY

WARNING: Before disassembling pump,

disconnect power source and

thoroughly bleed pressure from

system. Failure to do so could result

in electric shock or serious bodily

harm.

1. Disconnect power source.

2. Remove suction and discharge piping.

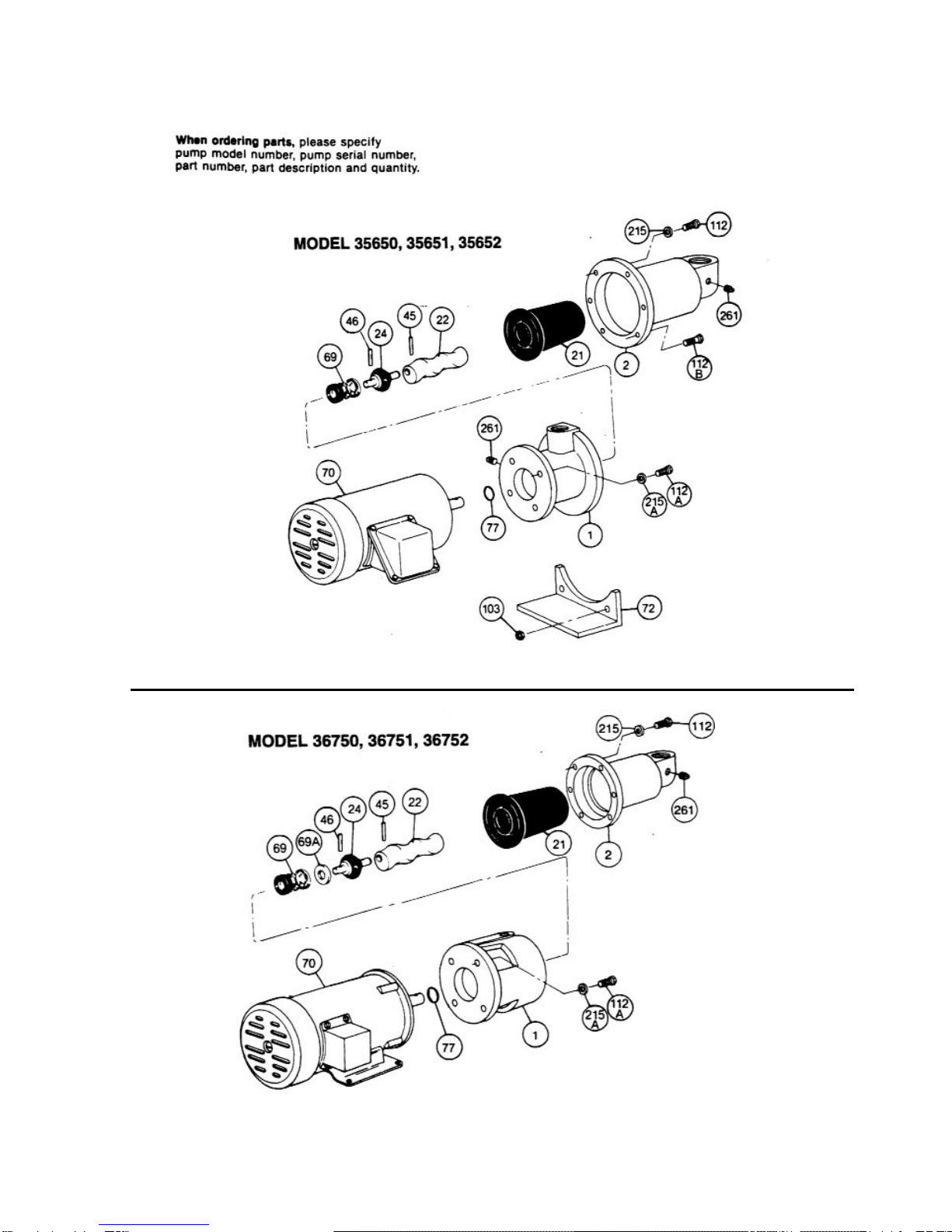

3. Remove screws (112) holding suction housing (2)

to discharge housing (1). Remove suction housing

(2) and stator (21).

4. Rotor (22) can be detached from flexible joint (24)

by using a punch to remove rotor pin (45). Support

joint when removing pin.

5. Flexible joint (24) can be removed from motor

shaft by using a punch through the discharge port

to remove shaft pin (46).

6. Carefully slide mechanical seal (69) off motor

shaft.

7. Remove discharge housing (1) from motor (70) by

removing screws (112A and 112C) and washers

(215).

8. Carefully pry seal seat out of discharge housing

(1). If any part of mechanical seal (69) is worn or

broken, the complete assembly should be

replaced. Seal components are matched parts and

not interchangeable.

9. Remove slinger ring (77).

PUMP ASSEMBLY

1. Replace slinger ring (77).

2. Attach discharge housing (1) to motor (70) using

lock washers (215) and body screws (112A).

3. Install mechanical seal (69) using the following

procedures:

a. Clean and oil sealing faces using light oil (not

grease).

Caution: Do not use oil on EPDM parts.

Substitute glycerin or soap and water.

b. Oil the outer surface of seal seat, and push

assembly over motor shaft into the bore of the

discharge housing (1) seating it firmly and

squarely.

c. After cleaning and oiling the shaft, slide the

seal body along the shaft until it meets the seal

seat.

d. Install seal spring and spring retainer on shaft.

4. On Model 367, position seal spacer (69A) on

motor shaft with slots away from seal (69).

5. Pin flexible joint (24) to motor shaft with shaft pin

(46) using a punch through the discharge port.

6. Pin rotor (22) to flexible joint using rotor pin (45).

Support joint while installing pin.

7. Slide stator (21) on rotor (22) carefully locating

stator flange in housing groove.

8. Secure stator (21) and suction housing (2) to

discharge housing (1) using screws (112).

9. Proceed as in installation instructions.

Page 2