When packing is new, frequent minor adjustments during the

first few hours of operation are recommended in order to

compress and seat the packing.

1. Upon initial start-up of the pump, adjust the gland nuts for

a leakage rate of 50-100 drops per minute until the

packing has seated and adjusted to the operating

temperature (approximately 10-15 minutes).

2. If leakage is excessive after 15 minutes of operation,

tighten the gland nuts ¼ of a turn.

3. Tighten the gland nuts ¼ of a turn after an additional 15

minutes if necessary and repeat this procedure until a

desired leakage of 1-2 drops per minute is obtained.

Adding grease may also reduce leakage by providing a

barrier at the lantern ring.

CAUTION: Do not tighten until zero leakage is obtained.

Overtightening the packing gland may result in accelerated

wear on the packing and damage to the shaft. In those

situations where no packing leakage can be tolerated, consult

your Moyno Authorized Representative.

Area To Lubricate Approved Lubricant or

Equivalent

Packing ACG-2

(Dubois Chemical, Inc.)

4-4. PACKING REPLACEMENT

Note: In this section, the first reference to each pump part will

be followed by a number or a letter in parentheses ( ). These

numbers and letters are used to identify the pump parts and

hardware items in the Exploded Views in Section 13-1.

When tightening the gland nuts can no longer regulate leakage,

remove and replace the packing. The entire pump does not

need to be disassembled to replace the packing. Briefly, replace

as follows:

1. Remove packing gland nuts and slide gland halves (152)

back along drive shaft (400).

2. Use a packing puller tool (see Figure 4-2) to remove the

packing (150).

Figure 4-2. Packing Removal Tool

3. Inspect surface of drive shaft for excessive wear or grooves

due to packing rub. If shaft is worn, or is badly scored or

grooved, it should be replaced.

4. If drive shaft is not worn, install a lantern ring and four

packing rings, lubricating them before installation with a

good grade of packing grease. Be sure to stagger the

packing ring joints at 90-degree increments.

Note: The stuffing box is supplied with four rings installed, a fifth

ring may be added after initial compression.

CAUTION: ALWAYS USE A PROPER PACKING TAMPER

TOOL TO INSTALL PACKING. Do not use a pointed or sharp

tool, as damage to the packing material or drive shaft could

result. To assure proper shaft lubrication, never use a one-piece

spiral wrap packing.

5. Replace packing gland halves and secure with packing

gland and nuts (156).

Page 3

6. Adjust packing per Section 4-3.

5-1. DISASSEMBLY

Note: In this section and in following sections on CLEANING,

INSPECTION, and ASSEMBLY, the first reference to each

pump part will be followed by a number or letter in

parentheses ( ). These numbers and letters are those used to

identify the pump parts and hardware items in the Exploded

Views in Section 13-1.

5-2. DISCONNECT PUMP

1. Disconnect the power source.

2. Close suction and discharge valves to isolate the pump

from the line.

5-3. STATOR REMOVAL

1. Remove section of discharge pipe attached to discharge

flange (200).

2. Remove discharge flange by unbolting from stator clamp

ring (210) and remove stator gasket (510). Use a

screwdriver tip to remove stator retaining ring (480), stator

clamp ring (210), and pump support (220) from stator

(500).

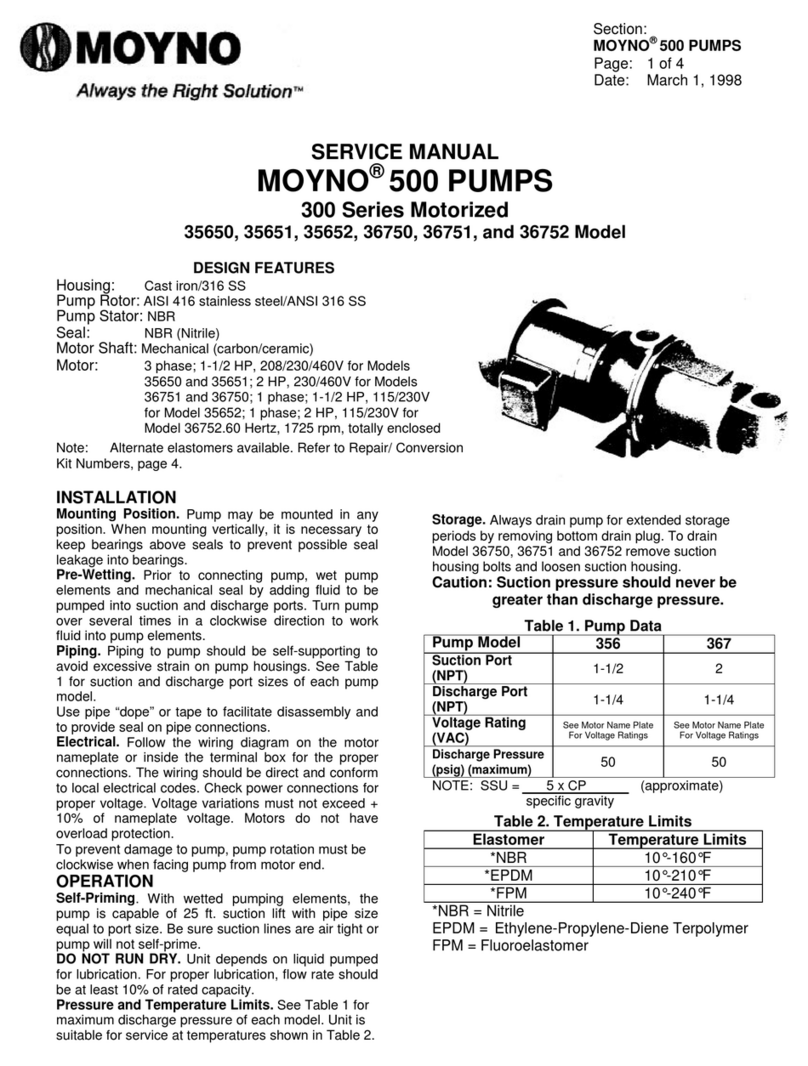

3. Unbolt stator clamp ring (210) from suction housing and

remove stator from rotor (turning stator clockwise while

removing will ease disassembly). Remove the stator

retaining ring. Remove stator clamp ring from stator. See

Figure 5-1. for the typical retaining ring removal procedure.

Figure 5-1. Typical Retaining Ring Removal

5-4. SUCTION HOUSING REMOVAL

1. Remove four bolts and lock washers (230) holding the

suction housing (100) to the drive adapter (10).

2. Pull the suction housing toward the rotor and away from

the adapter housing. Place a block of wood under the

suction housing to prevent it from dropping as you pull it

away from the adapter housing.

5-5. ROTOR/CON ROD/DRIVE SHAFT ASSEMBLY

REMOVAL

1. Slide the slinger ring (60) along the drive shaft (400),

towards the gear reducer, exposing the drive pin (70).

2. With a punch and hammer, tap the drive pin from the

drive shaft.

3. Carefully pull the rotor/con rod/drive shaft assembly from

the gear reducer. Place the assembly aside for now. On

larger sizes where it may be awkward to remove the

whole rotating unit as one piece, the rotor can be remove

first. Refer to section 5-8 for joint disassembly

instructions.