Page 2

Noisy Operation.

1. Starved suction: Check fluid supply, length of suction line, and

obstructions in pipe.

2. Bearings worn: Replace parts; check alignment, belt tension,

pressure at discharge port.

3. Broken flexible joint: Replace part; check pressure at discharge

port.

4. Insufficient mounting: Mount to firm base. Vibration-induced

noise can be reduced by using mount pads and hose on

suction and discharge ports.

Pump Overloads.

1. Excessive discharge pressure: Check discharge pressure for

maximum rating given in Table 1. Check for obstruction in

discharge pipe.

2. Excessive temperature.

3. Belt or coupling slip: Check pressure at discharge port.

4. Loose bond in stator: High temperature and caustics will cause

bond between rubber and tube to fail. Replace stator. Check

fluid temperature and pressure at discharge port.

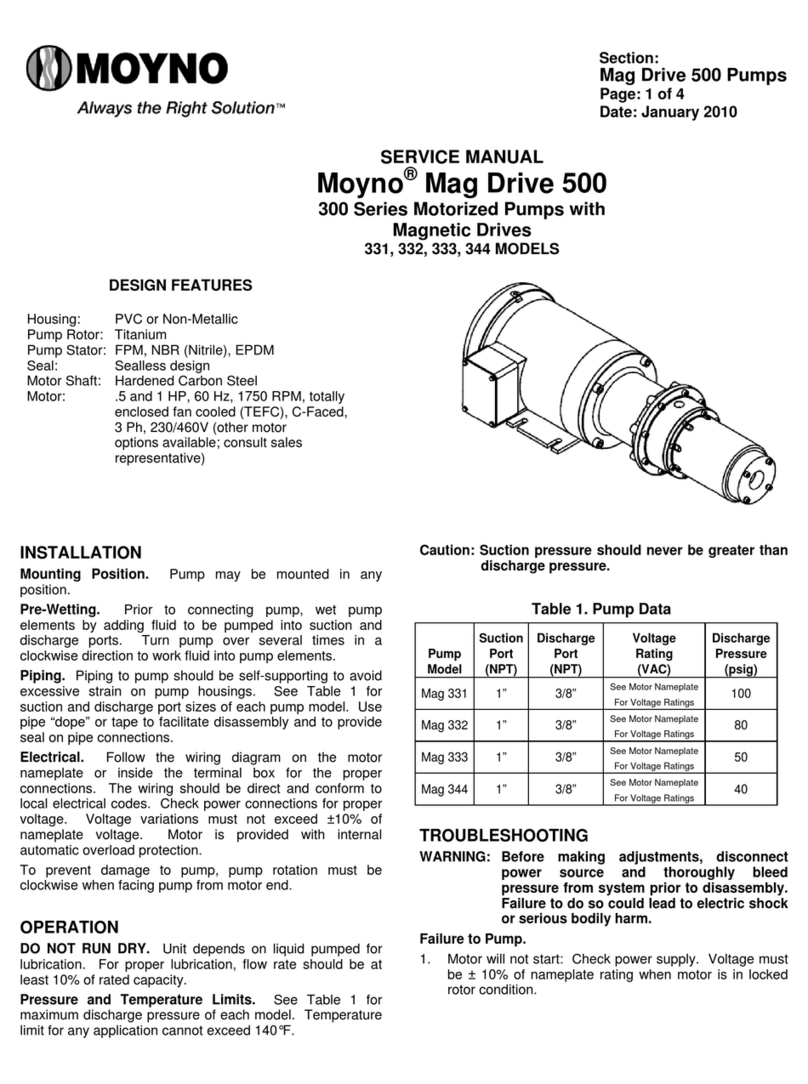

5. Fluid viscosity too high: See chart below for recommended

maximum RPM.

Viscosity CP Limit RPM

1-1,000

1750

1,000-2,500

1200

2,500-5,000

600

5,000-10,000

300

10,000-20,000

175

20,000-50,000

80

Based on 60% min. volumetric efficiency. See PEC449 or consult

Moyno representative for exact values.

6. Motor connected incorrectly: Motor wired for 230 VAC,

connected to 115 VAC service.

Poor Performance.

1. Low pressure; worn stator: Replace stator: Check for

excessive abrasive material in fluid. Check for run dry

condition.

Mechanical Seal Leakage.

1. Leakage at startup: If leakage is slight, allow pump to run

several hours to let faces run in.

2. Persistent seal leakage: Faces may be cracked from freezing

or thermal shock. Replace seal.

Pump Will Not Prime.

1. Air leak on suction side: Check pipe connections. Suction lift

over 15 ft. will cause seal faces to open.

2. Defective mechanical seal: Inspect and repair as necessary.

MAINTENANCE

General. These pumps have been designed for a minimum of

maintenance. The pump is one of the easiest to work on in that

the main elements are very accessible and require few tools to

disassemble.

Bearing Lubrication. The prelubricated, fully sealed bearings do

not require additional lubrication.

PUMP DISASSEMBLY

WARNING: Before disassembling pump, disconnect power

source and thoroughly bleed pressure from

system. Failure to do so could result in electric

shock or serious bodily harm.

1. Disconnect power source.

2. Remove suction and discharge piping.

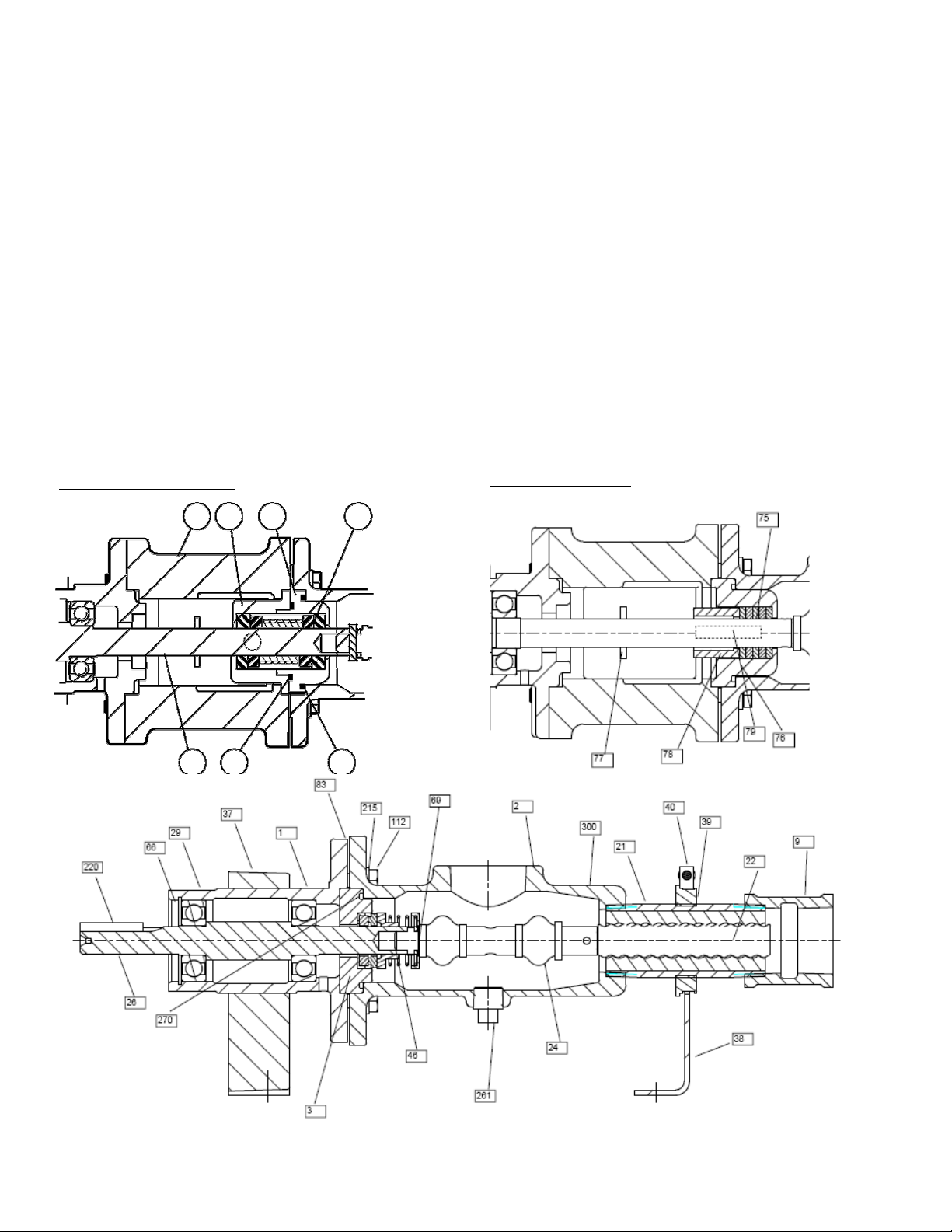

3. Discharge coupling (9) may be removed from stator (21) by

unscrewing in a counter-clockwise direction (RH thread).

4. Remove stator support clamp screw and remove top half of

stator support (38).

5. Stator (21) may be removed from suction housing (2) by

unscrewing in a counter-clockwise direction (RH thread). Use

strap wrench on stator to avoid crushing with a pipe wrench.

Pull stator (21) from rotor (22). To assist removal of stator, hold

drive shaft (26) from turning and turn stator clockwise when

facing suction housing after disengaging thread.

6. Remove screws (112) holding suction housing (2) to bearing

housing (1) or adapter (74). Remove suction housing and

suction housing gasket (83). Gaskets on cast iron models only.

Remove O-Ring (270) on other models.

7. The rotor (22) and flexible joint (24) may be removed using the

following procedure (do not bend joint more than 15 degrees).

a. Remove rotor (22) from flexible joint (24) by using a punch

to remove rotor shaft pin (46). Support joint while removing

pin.

b. Remove joint (24) from shaft (26) by using a punch to

remove shaft pin (46).

8. Single Mechanical Seal Models. Carefully slide mechanical

seal (69) off shaft (26). Carefully pry seal out of bearing

housing (1), or seal housing (3). Remove seal housing if pump

is a stainless model.

Double Mechanical Seal Models. Carefully slide seal housing

(71) from the drive shaft. Remove rotational part of mechanical

seal from the shaft. Carefully remove seal gland (73) from

adapter. Remove stationary seal faces if required.

If any parts of mechanical seal are worn out or broken, the

complete assembly should be replaced. Seal components are

matched parts and are not interchangeable.

Packing Models. Slide stuffing box assembly from the shaft.

Remove packing gland halves and replace packing.

9. The bearings (29) and shaft (26) assembly can be removed

from bearing housing (1) after snap ring (66) has been

removed. To remove the shaft assembly, lightly tap the shaft at

the flexible joint connection end using a block of wood to

protect the shaft. The bearings may be pressed off the shaft.

PUMP ASSEMBLY

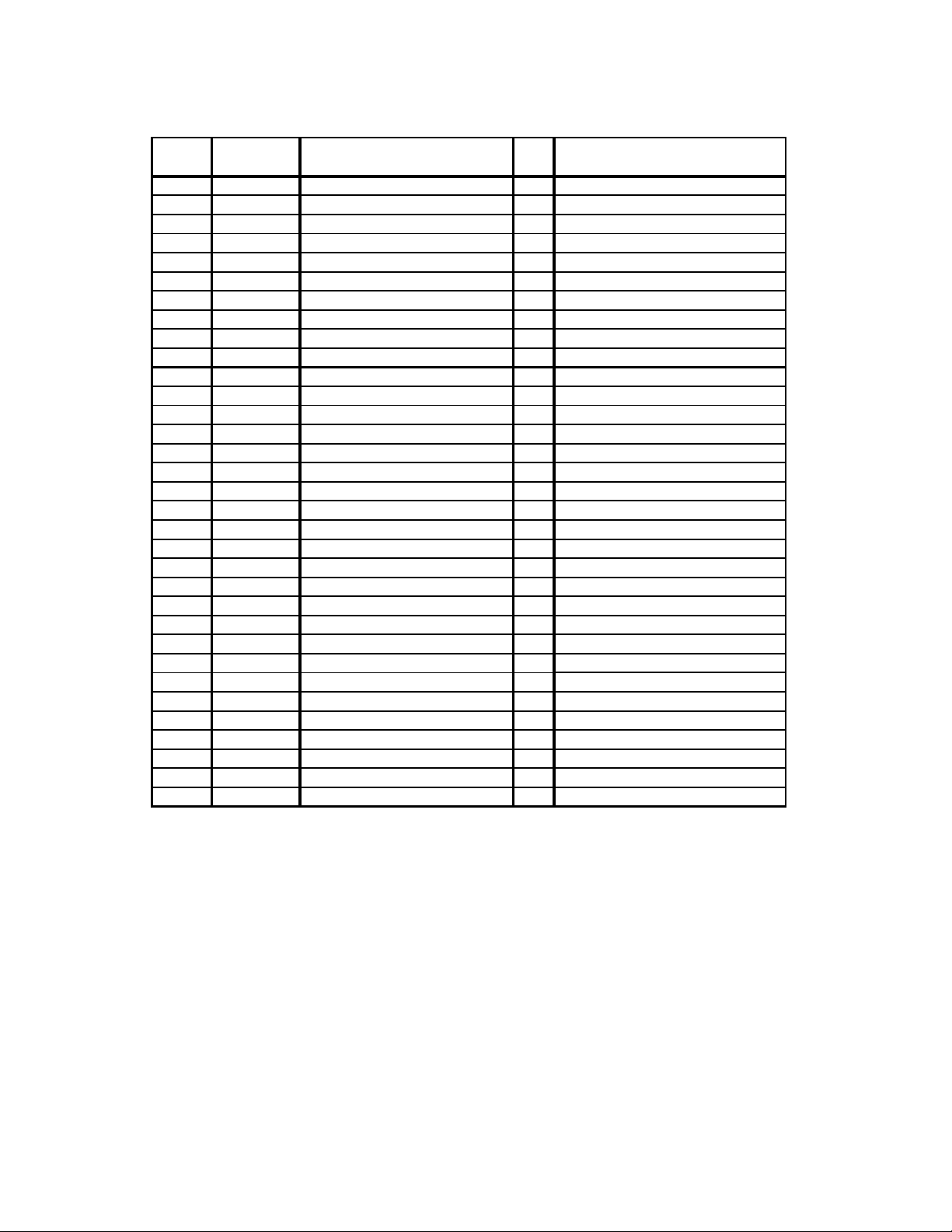

1. Press bearings (29) on shaft (26), and locate slinger ring (77)

on the shaft near the radial bearing.

NOTE: When replacing bearings, always press on the inner race

when assembling to shaft, and on the outer race when

pressing bearings into the housings.

2. Press shaft assembly into bearing housing (1) securing with

snap ring (66).

3. On stainless steel models install seal housing (3) in bearing

housing with O-Ring (270) installed in the O-Ring groove.

On packing models install stuffing box assembly (stuffing box,

packing, and packing gland) on shaft with O-ring (270) installed

in the O-ring groove.