MP 401 Parts list manual

MP Gas Controls S.p.A.

Instructions for installation, use and maintenance

Art. 401

Compile: R.A.

Rev.0 del 01/21

English

Pag. 1 of 11

Art. 401

MP Gas Controls S.p.A.

Instructions for installation, use and maintenance

Art. 401

Compile: R.A.

Rev.0 del 01/21

English

Pag. 2 of 11

Art. 401

Index

1. Chapter 1 03

1.1 Product Description 03

1.2 Technical Properties 04

1.3 Overall Dimensions 05

2. Chapter 2 - Installation 06

2.1 General Information 06

2.2 Installation and Assembling 07

2.3 Thermocouple Fixing 08

2.4 Gas Inlet and Outlet Connection 09

3. Chapter 3 - Maintenance 10

3.1 General Notes 10

MP Gas Controls S.p.A.

Instructions for installation, use and maintenance

Art. 401

Compile: R.A.

Rev.0 del 01/21

English

Pag. 3 of 11

Art. 401

Chapter 1

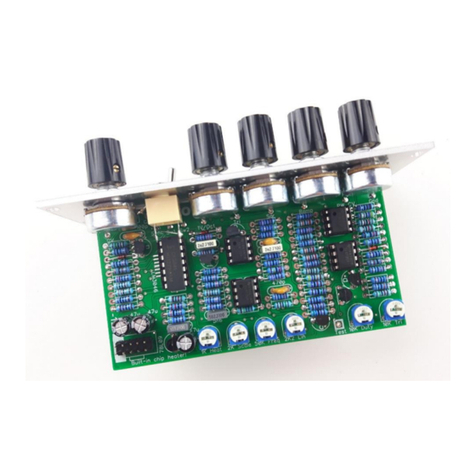

1.1 - Product description

1. Gas inlet

2. Max. working pressure

3. Max. working pressure for high pressure valve

4. Manufacturer

5. Thermocouple fixing

6. Gas flow direction

7. Gas outlet

8. Pilot outlet (if present)

9. Production date (year/week or production batch ), and range of temperature

10. Valve code

MP Gas Controls S.p.A.

Instructions for installation, use and maintenance

Art. 401

Compile: R.A.

Rev.0 del 01/21

English

Pag. 4 of 11

Art. 401

1.2 - Technical properties

CE Approval: in accordance to GAR EU/2016/426

Max. pressure

Range of temperature

N° CE certificate

250 mbar

0°-150°

0085AP0329

2,1 bar

0°-80°

0085AP0329

4 bar

0°-100°

Functioning: ON/OFF

Gas inlet connection : male or female thread according to DIN EN 10226-1; flanged pipe screw

connection; double cone ring screw connection with nut or nut screw.

Gas outlet connection: Various (male or female thread; nozzle)

Fitted with: safety device for flame control

Applications: heating

Group: 2

Kind of gas: I, II, III

Safety device endurance test : 10.000 (CE)

MP Gas Controls S.p.A.

Instructions for installation, use and maintenance

Art. 401

Compile: R.A.

Rev.0 del 01/21

English

Pag. 5 of 11

Art. 401

1.3 - Overall dimensions

Indicative dimensions; for more information see assembly drawing.

MP Gas Controls S.p.A.

Instructions for installation, use and maintenance

Art. 401

Compile: R.A.

Rev.0 del 01/21

English

Pag. 6 of 11

Art. 401

Chapter 2 - Installation

2.1 - General Information

Failure to comply with the following requirements may prevent the correct

operation and safety of the product.

1. All installation, connection and adjustment operations must be performed only

by qualified personnel and according to the specific properties of the device;

2. During installation it is important to verify that the gas flow is in accordance with

the arrow on the valve body;

3. To avoid damage that may compromise correct functioning of the valve, do

not exceed the tightening torques listed in next chapters;

4. To avoid damage that may compromise correct functioning of the valve,

handling of valve shall be taken care of: avoid falls and bumps;

5. To avoid damage that may compromise correct functioning of the valve, use

the appropriate tools for installation operations;

6. In order to avoid any foreign body to enter into the valve, which could

compromise the right functioning of the valve, manifold shall be clean. A

suitable filter should be mounted on the manifold supply inlet.

After installing or replacing the valve / valves, the installer must

always check for gas leakage.

MP Gas Controls S.p.A.

Instructions for installation, use and maintenance

Art. 401

Compile: R.A.

Rev.0 del 01/21

English

Pag. 7 of 11

Art. 401

2.2 - Installation and assembling

Fix the gas valve on the Carter by the nut , as shown on fig. 1.

fig. 1

1. Nut M12 x 1 (Cod.14307)

2. Carter

Ideal torque: 12 Nm

Max. torque: 15 Nm

MP Gas Controls S.p.A.

Instructions for installation, use and maintenance

Art. 401

Compile: R.A.

Rev.0 del 01/21

English

Pag. 8 of 11

Art. 401

2.3 –Thermocouple fixing

Fix the thermocouple to the gas valve according to the kind of connection provided, as shown on fig. 2.

fig. 2

1. Threaded connection: screw-in the nut of thermocouple with a torque of 4 Nm max.

2. Quick connection: insert the thermocouple connection till the end.

3. Fast-on connection: connect the thermocouple terminal to the fast-on.

Available magnet-on and magnet-off currents:

• 200 / 80 mA

• 290 / 110 mA

• 200 / 40 mA

• 180 / 40 mA

MP Gas Controls S.p.A.

Instructions for installation, use and maintenance

Art. 401

Compile: R.A.

Rev.0 del 01/21

English

Pag. 9 of 11

Art. 401

2.3 - Gas inlet and outlet connection

Fix the gas inlet and outlet tube to the valve, according to the type of outlet on the body; in order to avoid any

damages of the valve, please follow strictly the tightening torques shown in TABLE 1.

TABLE 1: Maximum tightening torque (C max)

Inlet

C max

Nm

Ibf*in

Nut + olive + Ø8 tube

15

133

BSPT tapered

8

70

Outlet

C max

Nm

Ibf.in

Nut + Olive + Ø8 tube

15

133

Nut + Olive + Ø6 tube

10

89

Nuzzle

4

35

For different connections, please see specification on assembly drawing.

Replacement of injector

Unscrew the injector to be replaced by the means of an exagonal spanner n°7.

Screw-in new injector with a torque of 3,5 - 4 Nm

MP Gas Controls S.p.A.

Instructions for installation, use and maintenance

Art. 401

Compile: R.A.

Rev.0 del 01/21

English

Pag. 10 of 11

Art. 401

Chapter 3 - Maintenance

3.1 - General notes

All installation, connection and adjustment operations must be performed only by qualified personnel and

according to the specific properties of the device. During installation it is important to verify that the gas flow is in

accordance with the arrow on the valve body.

The valves are designed in order to be able to operate inside the cooking appliances, protected by any possible

liquids or dirty infiltrations and by the atmospheric agents. The non-compliance of such a prescription may

prevent the right functioning and the safety of the product.

It is absolutely forbidden to tamper with the sealed parts, unscrew the assembling screws and remove any part or

marking on the valve. It’s good to avoid that the valve suffers any kind of shocks (bumps, falls etc.)

In order to avoid any foreign body to enter into the valve, which could compromise the right functioning of the

valve, it is necessary to assemble a proper filter; the inlet filter must be provided upstream of the manifold as

required by the standard.

No kind of maintenance on the valve is allowed. It is absolutely forbidden to

Tamper with the sealed parts, unscrew the assembling screws and remove any part or

marking on the valve. The parts of the device mounted or adjusted during

manufacturing and not intended for manipulation by the user or installer must be

adequately protected.

Info and contacts

MP Gas Controls S.p.A.

Instructions for installation, use and maintenance

Art. 401

Compile: R.A.

Rev.0 del 01/21

English

Pag. 11 of 11

Art. 401

MP GAS CONTROLS S.P.A.

VIA NEZIOLE 2

25055 - PISOGNE (BS) - ITALY

+39 0364 89020

info@mpgascontrols.com

Table of contents