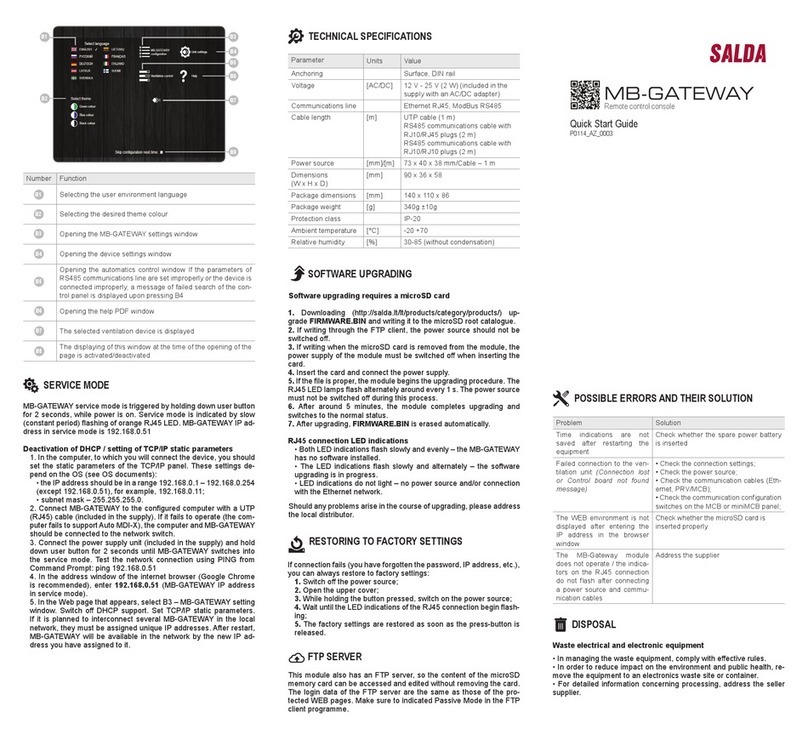

EN | 9STOUCH v2019.1

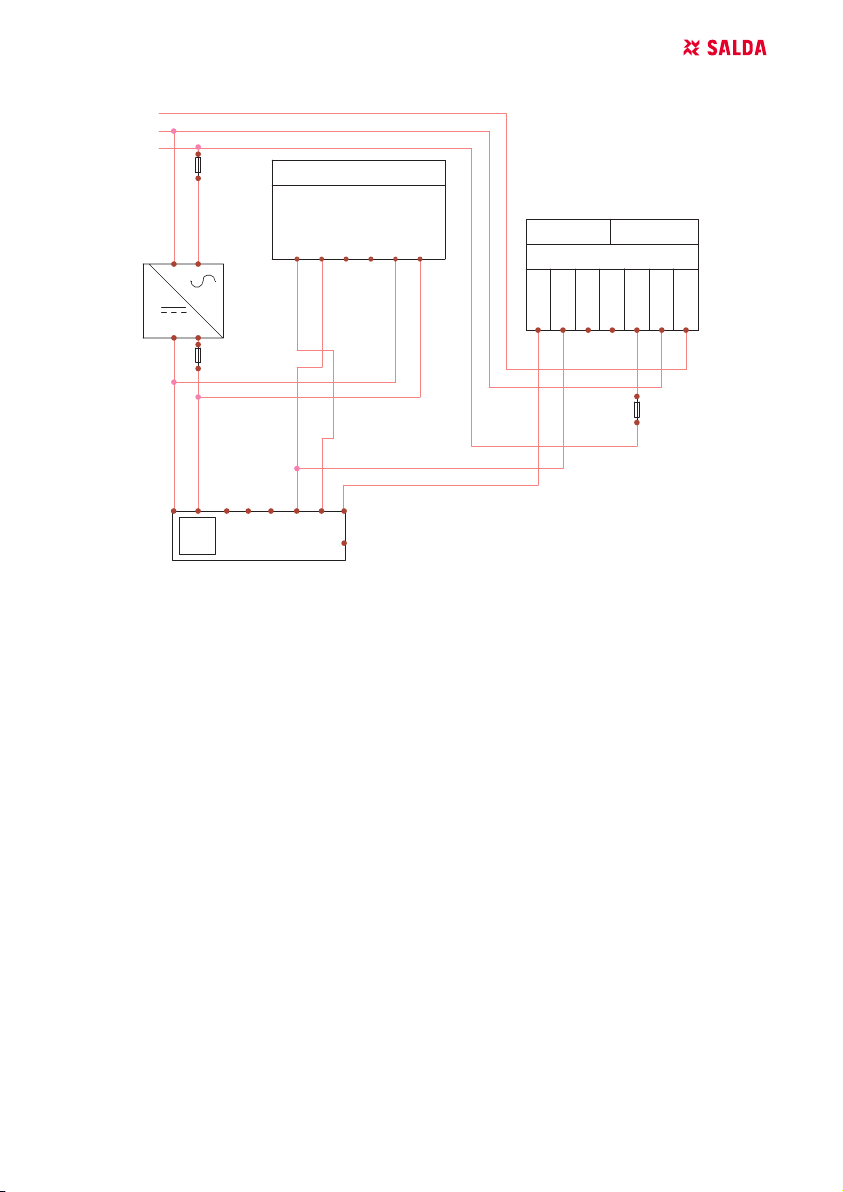

B1 B4 B6

L4-L7

Review and

cancel alarms

and warnings

Press B2 and B3

for resetting

By pressing B1

faults are tempo-

rary not shown.

In case of failure L4, L5, L6, L7 are blinking

and failure codes appear on split screen

(A.01, A.02 and etc.). In case of warning,

warning codes (.01, .02 and etc.) appear

on split screen. List of errors and warnings

can be reviewed by pressing B4 or B6.

After clearing fault or warning signal remote

controller returns into initial state. By pressing

B1 faults are not shown for one minute, thus

permitting to adjust temperature and fan

settings.

Note: it’s strictly forbidden to clear a fault

or warning without removing its cause. This

must be performed by the service represen-

tatives or maintenance personnel.

B1 B4 B6 Functional

Review

Upon pressing

B1 the functional

codes are not dis-

played temporarily

When the function is active, the segment

display shows functional codes. The list of

functional messages can be reviewed by

touching B4 or B6 buttons. Upon pressing B1

the functional codes are not displayed for one

minute, allowing manipulation of temperature

and fan settings.

NOTE: if failures are active, the functional

codes are not displayed!

B1

L2-L7 CO2 blow o

By pressing B1

indication „CO2“is

not shown tem-

porary.

L2, L3 and L7 are blinking, L4, L5, L6 are

shining. Split screen shows “CO2”. By press-

ing B1 indication “CO2” is not shown for one

minute, thus permitting to adjust temperature

and fan settings.

B2 B3 B5

On/o

“Child safety

feature”

Press down B3,

B2 and B5 for 2

seconds.

Non active elements B1, B4 and B6. After

pressing unavailable button, segment display

shows “−−−”

7. CONNECTION INDICATION

Flashing „Con“ – connecting.

Shining „noC“ – connection lost or there is no connection with the controller.

NOTE: This paragraph applies when the controller is used as a Modbus master.

8. FAN SPEED CONTROL OPTIONS

• Selecting 4 preset speeds;

• Selecting percentage value of speed (0,20 - 100 %) only for 0...10 VDC output and ECO controller;

• User menu speeds are set in intervals of 5 %;

• Service menu speeds are set in intervals of 1 %;

• Operates in 4 speeds, the values of which are displayed on Stouch in Pascals (Pa).

NOTE: the function is available when fan and pressure sensor are connected to Stouch.