OPERATION MANUAL

Heat Transfer Station eo V2.3.0en/22.04.20//17.12

3Function description 30

3.1 Function description of the temperature control unit ................................... 30

3.1.1 General functions............................................................................................30

3.1.2 Other functions...............................................................................................30

3.2 Information on the thermal fluids ................................................................ 31

3.3 To be noted when planning the test ............................................................. 32

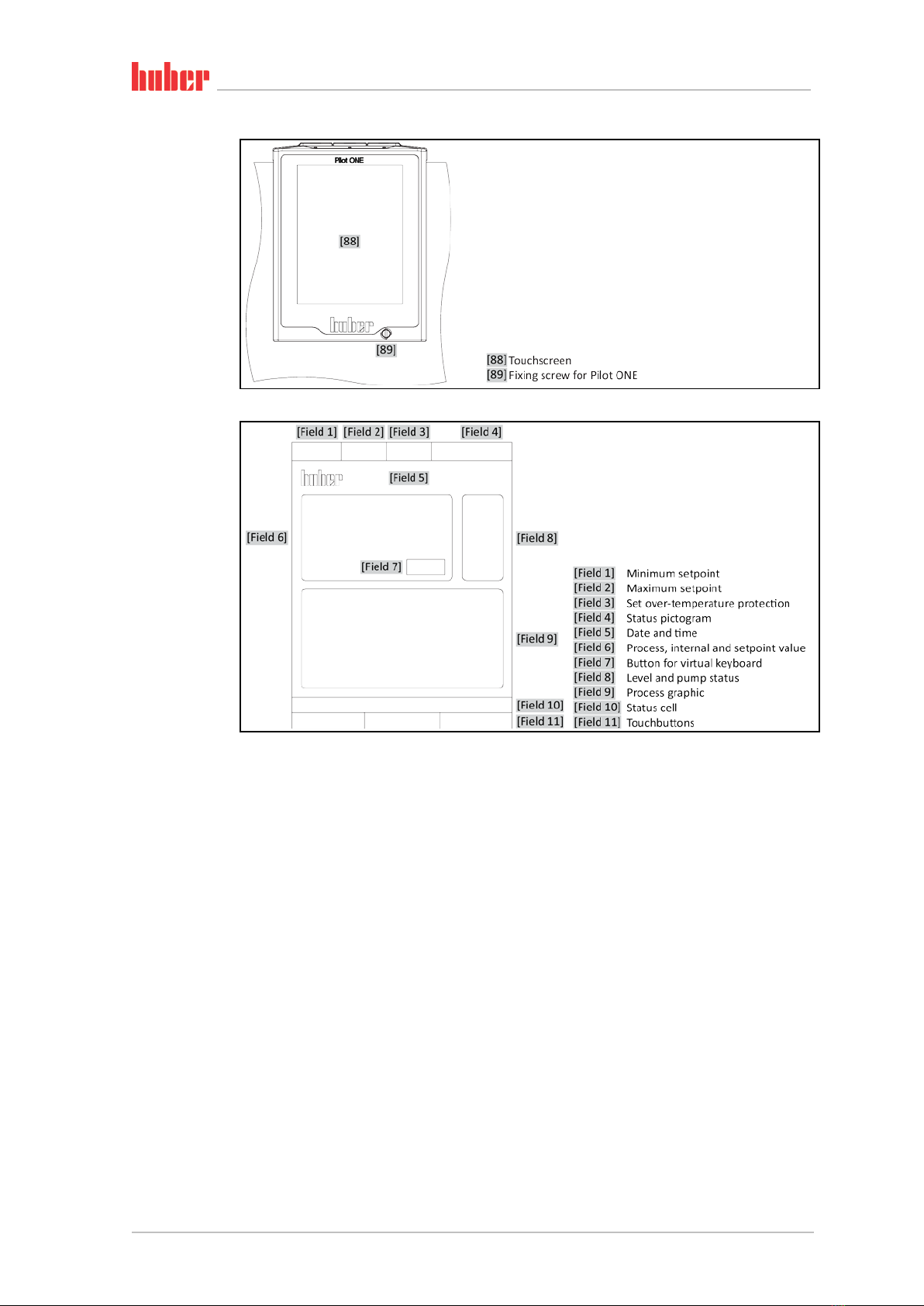

3.4 “Pilot ONE®” controller ................................................................................ 33

3.4.1 Functional overview of “Pilot ONE®” ..............................................................33

3.5 Clock/event function.................................................................................... 35

3.5.1 Rechargeable accumulator .............................................................................35

3.5.2 Programmable event function ........................................................................35

3.5.2.1 Event function “Alarm clock event” ...........................................................35

3.5.2.2 Event function “Program event” ................................................................35

3.6 Operation via the touch screen..................................................................... 35

3.7 Display instruments ..................................................................................... 36

3.7.1 The touchscreen [88] ......................................................................................36

3.8 Control instruments ..................................................................................... 36

3.8.1 The touchbuttons............................................................................................37

3.8.2 The categories.................................................................................................37

3.8.3 The sub-categories..........................................................................................37

3.8.4 The dialogs ......................................................................................................37

3.9 Function examples ....................................................................................... 37

3.9.1 Display of software version.............................................................................37

3.9.2 Start & Stop.....................................................................................................38

3.9.3 Copying the settings to a data carrier.............................................................38

3.9.3.1 Saving to a USB flash drive .........................................................................38

3.9.3.2 Loading from a USB flash drive...................................................................39

3.9.4 Restore factory settings ..................................................................................39

3.9.4.1 Restore to factory settings without overtemperature protection .............40

3.9.4.2 Restore to factory settings including overtemperature protection ...........40

4Setup mode 42

4.1 Setup mode ................................................................................................. 42

4.1.1 Turning on the temperature control unit .......................................................42

4.1.2 Turning off the temperature control unit.......................................................42

4.1.3 Setting the overtemperature protection ........................................................43

4.1.3.1 General information on the overtemperature protection .........................43

4.1.3.2 Setting “OT limit: heating” .........................................................................44

4.1.3.3 Setting “Process Safety” .............................................................................44

4.1.3.4 Monitoring via “Display OT values”............................................................44

4.1.4 Testing overtemperature protection for functionality ...................................44

4.1.5 Adjusting the Delta T limiter ...........................................................................45

4.1.5.1 Changing the Delta T limiter.......................................................................45

4.2 The temperature control circuit.................................................................... 45

4.2.1 Select temperature control: Internal or process ............................................46

4.2.2 Temperature control to internal temperature ...............................................46

4.2.3 Temperature control to process temperature................................................46

4.2.4 Delta T limiter .................................................................................................47

4.2.5 Monitoring the Pt100 temperature sensors...................................................47

4.2.6 Optimum control parameters for optimum temperature control..................47

4.2.7 Sub-category: “Select auto/expert mode”......................................................48

4.2.8 Sub-category: “Configuration auto” ...............................................................48