Five Easy Steps To Properly Select . . .

(

-

"Th

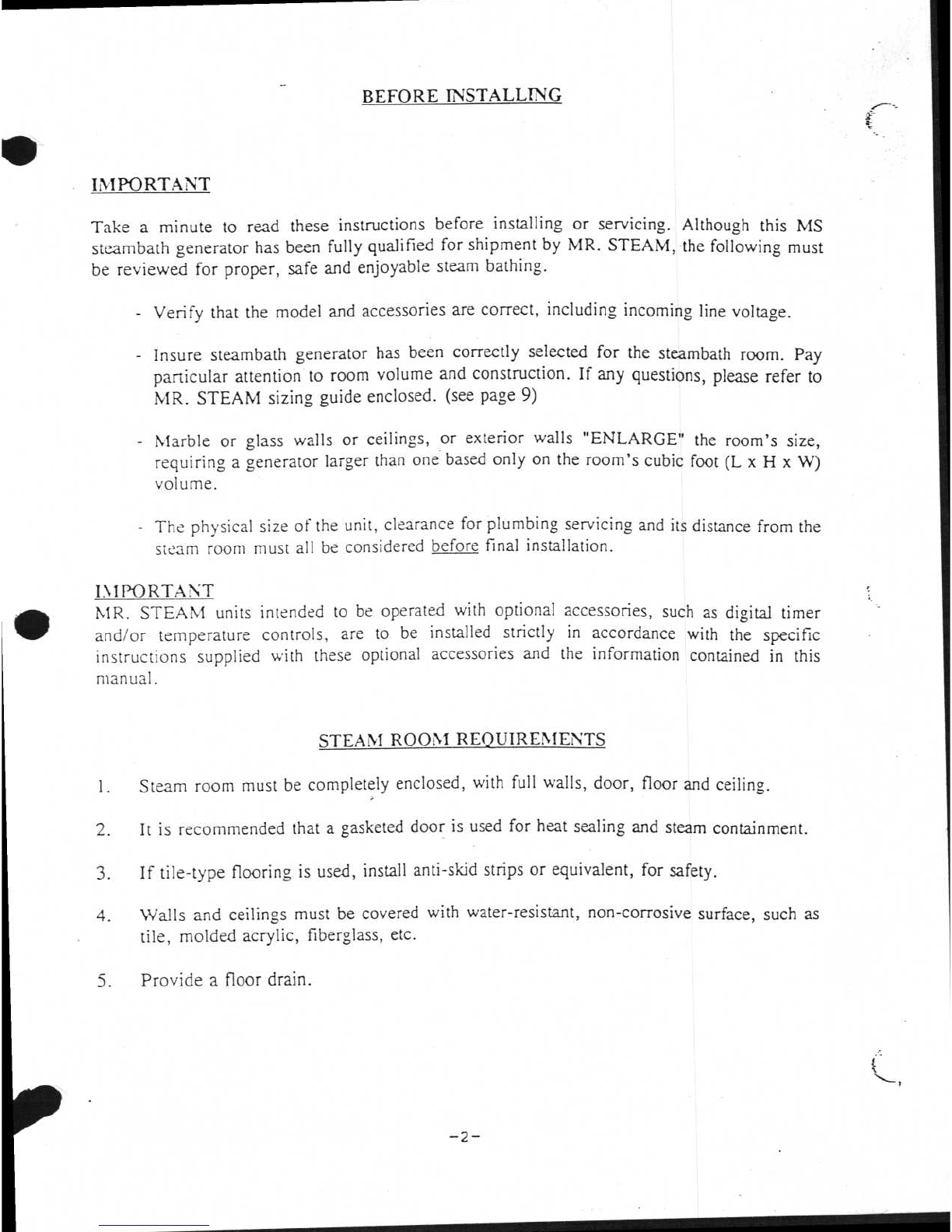

The MR. STEAM model selected depends on the steam room volume and the type of construction used.

"The Intelligent Steambath" for Your Home

1)

Measure the Length, Width and Height in feet of the steam shower or tub/shower being used.

L

,W

,H

2)

Multiply the Length X Width X Height to give you the room

volume = BASIC CUBIC FEET

(a)

3)

If the interior wall construction material within the steam area is composed of natural

marble, stone, slate, glass block or concrete, place on line (h) the same figure

appearing on line (a).

(h

)

4)

TOTAL (a) AND (h) TO OBTAIN (c).

(c)

5)

Increase (c) by 15% for each of the design features noted below ONLY if they describe your steambath

installation:

•

One exterior outside wall

(d)

•

Tile on mud wall

(e)

•

An extra glass panel in addition to the door

(t)

•

A cast iron tub

(g)

•

For steambath rooms higher than 8 ft.,

please add 15% for each foot above 8 ft.

(h)

•

If generator is more thant 20 feet from steamhath

room, add 15% for every 20 feet distance.

(i)

ADD LINES (d) TIIRU (1) TO LINE (c) = (i) TOTAL CUBIC FEET REQUIRED

(i

)

Compare the cubic foot requirements (i) to the selection chart on hack of page 6 and select the appropriate model.

If the total cubic feet required (I) is two times or more the value noted in position (a), we strongly recommend that

you specify either an optional Digital Timer & Temperature Control or a Digital Temperature Control.

It is important to specify the correct voltage. Standard voltages are 240 Volts, single phase and 208 Volts, single

phase.

IMPORTANT

The above selection formula tOr sizing the steambath generator are recommendations only. Because of all

the numerous variables in construction, materials, and insulation (values) these sizing instructions and

specifications should he considered as guidelines only.

It is best that you consult your professional bath planner to evaluate the particular requirements before a

MR. STEAM unit is selected.

MR. STEAM personnel will review the appropriateness of the unit selected as tong as we receive complete

information, incluclin

,

' working drawings, specifications, and pertinent electrical and construction details

from the owner, architect, or engineer. Otherwise, the manufacturer disclaims responsibility for the sizing

of a unit selected.

—9—