mr

.steam

®

C U S E R I E S Installation, Operating & Maintenance Manual

12

ELECTRIC

Electric shock hazard. Disconnect all power

supplies at the main disconnect switch before proceeding.

All electrical wiring must be installed by a qualified licensed

electrician in accordance with National and local Codes.

The steambath generator is factory wired and pre-tested before

shipment. Electrical power supply details are provided on the

data plate secured to the generator and as part of this manual.

Refer to applicable wiring and schematic information.

1. Check power and control circuit voltage requirements on the

data plate.

NOTE Separate 120 VAC line is not required if optional 120

VAC control transformer has been purchased and provided as

factory equipment.

2. Use minimum 90° C insulated copper conductors only for field

wiring, sized in accordance with National and local electric

Codes. Refer to Amperage Chart below.

3.Connect suitably sized copper equipment grounding conduc-

tor in accordance with National and local electric Codes to

ground terminal provided.

4. Install a separate dedicated circuit breaker or other approved

overcurrent protection device between the incoming electrical

supply and the generator, in accordance with National and

local electric Codes.

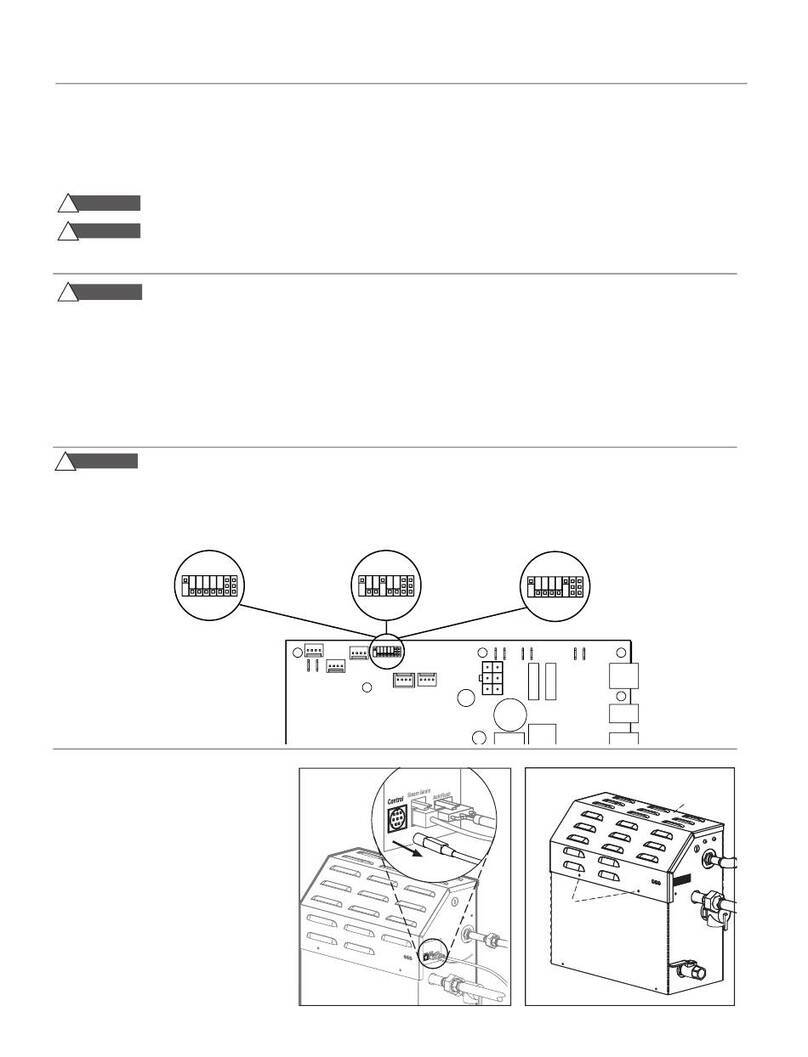

5. IMPORTANT With main disconnect switch off and no electric

power entering the generator, tighten all electrical connec-

tions including all factory connections at the terminal block,

fuse block, top and bottom of contactor and element pins

prior to energizing generator (torque values are listed on indi-

vidual components, control circuit terminal strips should be

torqued to 20 in-lbs.).

AMPERAGE CHART

Indicates Total Ampere Draw of Specific

CU Model at Voltage & Phase Specified

208V 208V 240V 240V 480V 600V

Model No. kW 1 PH 3 PH 1 PH 3 PH 3 PH 3 PH

CU-360 9 44 25 38 22 11 9

CU-500 12 58 34 50 29 15 12

CU-750 18 87 50 75 44 22 18

CU-1000 24 116 67 100 58 29 24

CU-1250 30 145 84 125 73 37 29

CU-1400 36 - 100 - 87 44 35

CU-2000 48 - 134 - 116 58 47

CU-2500 60 - 167 - 145 73 58

CU-3000 72 - 200 - 174 87 70

CU-4500 108 - 300 - 260 130 104

IMPORTANT

Use minimum 90° C insulated copper conductors only for field

wiring sized in accordance with National and local electric Codes.

NOTE

Consult factory for other voltage/phase combinations. CU generators

are suitable for 50/60 hz. Standard control circuit voltage for above V/PH com-

binations for United States, Canada and Mexico is 120 VAC. Exception: 220-240

VAC control circuit voltage is provided on non-domestic product where power

voltage is 220-240 V/3 PH, 380V/3PH, 415V/3 PH, etc.

WARNING

!

WIRING

To avoid possible electric shock,

the steambath generator shall be suitably

grounded in accordance with National Electric

and local Codes. Disconnect all power supplies

at the main disconnect switch before |

proceeding.

1. Electric wiring to the steambath generator must

be in accordance with National Electrical and

local wiring Codes following wiring diagram

supplied. Such wiring shall be done by a

licensed electrician. See Amperage Chart and

Notes, Page 9.

2. The unit is wired and pre-tested before ship-

ment. Follow all instructions provided for safely

and properly wiring steambath generator and

accessories.

Installer shall use a safety switch

of adequate capacity employing suitably rated

circuit breakers or fuses between main electri-

cal power source(s) and the generator.

Location of safety switch to be in accordance

with National and local electric codes.

3. IMPORTANT Insure all electrical connections

are sufficiently tightened prior to energizing

generator. See pg. 9, Item 5.

Substitution of components or

modification of wiring systems voids warranty

and can lead to dangerous operating condi-

tions.

4. The Digital 1 Temperature Sensor and High

Limit Temperature sensor(s) must be located

inside the steam room. Locate approximately 5

feet above the steam room floor, preferably

away from steam heads.

5. The steam solenoid valve(s) shall be located

outside the steam room and shall be wired to

the Digital 1 controller(s) in accordance with

wiring diagram provided. See applicable wiring

diagrams included as part of this manual.

Ensure all splices in the sensor

cable are securely crimped soldered and sealed

with heat shrink tubing.

WARNING

!

CAUTION

!

CAUTION

!

CAUTION

!