INSTALLATION

Since there is no moter output in this sound decoder, it can be used in any locomotive, regard-

less of scale that already has a working power decoder installed. If used in large scales where

track voltage exceeds 16 volts, (O/G scales), a special voltage reducer is required to be used

in-line to the Sounder. Contact Model Rectifier Corp. for details and price.

To install the Sounder into a locomotive, simply solder the red and black wires to any power pick

up points, left and right side wheel pick ups, along with the red and black wires of your power

decoder. If using with higher voltage DCC applications for larger scales, solder the MRC voltage

reducer to either the red or black wire between the Sounder, and the power pick up point. You

should have some basic electrical knowledge and soldering skills. If you do not have the above

requirements, please ask the dealer for help with the installation.

LIGHT EFFECTS WIRING*

If your locomotive has ditch lights, or any type of accessory lights, you can solder wires to the

three solder tabs on the Sounder. The center tab is the common for the light effects. You would

then program CV’s #118 and #119 to choose the desired light effect. Both light effects are

controlled on & off by function 3 (F3). There is no independent selection of either light effect. If

you program the effect for ditch lights, F3 turns them steady on/off, but activation of your horn

function, F2, makes them alternately blink automatically.

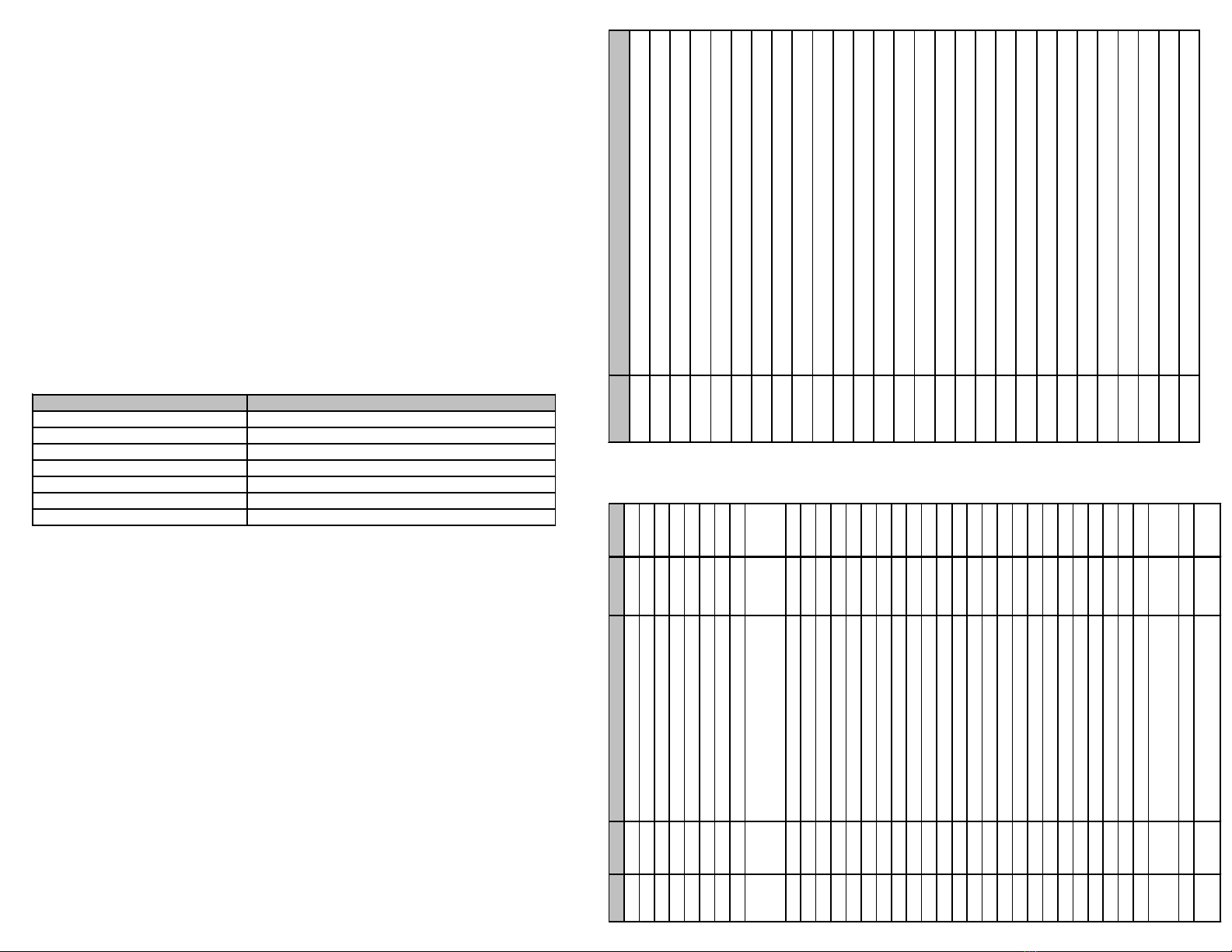

LIGHT EFFECTS PROGRAMMING CHART FOR CV118/CV119

You would program CV #118/119 to choose the desired light effect. CV118 for ACC1 and CV119

for ACC2. For ditch light both CV118 and CV119 must to 0.

*Note- The light effects operate on the track output voltage supplied by your DCC system. Please

contact the locomotive manufacturer as to the operational voltage of these extra lights, so you

can then choose the proper current limiting resistor (1k to 3k) to add into the circuit to prevent

light bulb or LED failure. Also be careful not to bridge the tabs with solder or wire strands, as to

cause a short circuit and damage the MRC Sounder.

SPEAKER SELECTION

The “MRC Sounder” diesel sound only decoder comes with a 28mm round 8-ohm speaker. If it is

too large for your application, smaller speakers, 20mm, or 16 X 35mm rectangular, can be

purchased from MRC, or other manufacturers. Reducing speaker size will affect the overall

sound quality of this decoder. Placement of the speaker inside the locomotive is up to you. Use

hot glue or double-sided sticky tape to affix the speaker inside the locomotive shell.

OPERATION

There are sixteen horn sounds and six bell sounds, along with an “off” setting for each built into

this decoder for you to choose from. See programming chart for selecting the type you want.

The “off” setting is useful for trailing locomotives in a consist so only the lead unit sounds its

horn and bell.

If your DCC system supports higher functions, F13 to F28, you can use these functions to

change the type of bell sound, F18, or horn sound, F19 on the move, without having to go into

“ops mode” programming or by changing CV values.

*Note- Bell, Dynamic Brake, and Rail-Wheel Clack, cannot play at the same time. If you activate

the bell sound, F1, while either the Dynamic Brake or Rail-Wheel Clack sounds are activated, the

Bell sound will override the other two sounds.

CV118/119 value ACC#1/ACC#2 Light effect

0 Ditch light

1 Gyra light

2 Marslight

3 Prime strato light

4 Single strobe light

5 Double strobe light

6 on/off

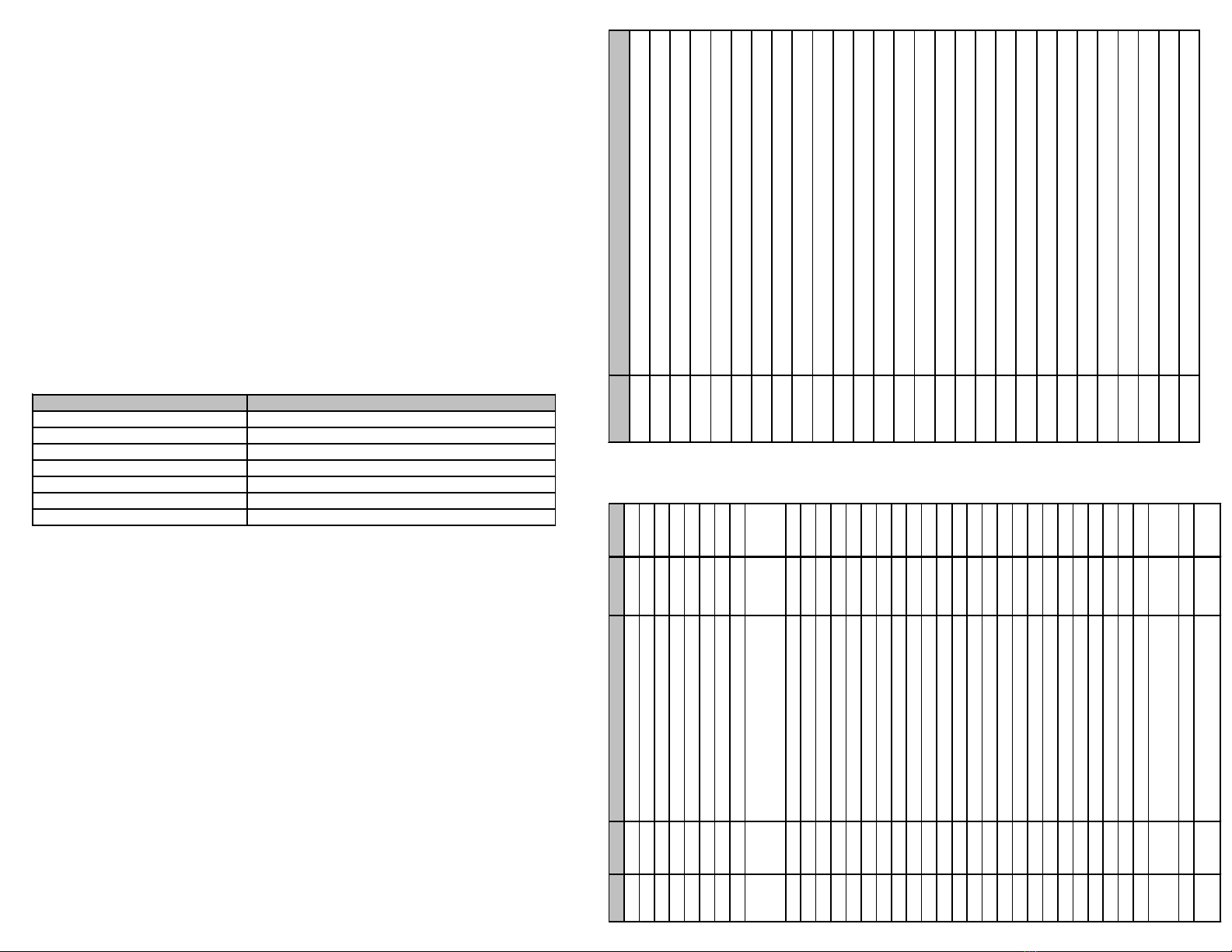

Function Idle/Moving

F1 Bell on/of f

F2 Horn

F3 Air release and Accessory light on/off

F4 Coupling

F5 Brake release (idle) / brake squeal (moving)

F6 Dynamic brake on/off

F7 Air hose f iring/uncoupling lever

F8 3 times w ill shut dow n w hen in idle / manual notch dow n

F9 Engine cooling fan / manual notch up

F10 Rail w heel clack (only moving)

F11 Traction air compressor

F12 Change diesel prime mover (2-types)

F13 short air release

F14 Coupling crash

F15 Air pump

F16 Associated loco sound

F17 flange noise

F18 Change bell type (use F1 to turn of f bell after adjustment)

F19 Horn type select

F20 Reverse Gear

F21 Change bell volume (use F1 to turn off bell after adjustment)

F22 Change horn volume

F23 Change diesel rumble volume

F24 Coupling

F25 air release

F26 flange noise

F27 A ir hos e f iring

F28 short air release

CV Register Description Range Default

CV1 R1 Short address 1-127 3

--- R6 Page number --- ---

CV29 R5 Basic configuration --- 2

CV7 R7 Manufacturer version number --- 32

CV8 R8 Manufacturer ID --- 143

CV17 --- Long address upper byte 192-231 192

CV18 --- Long address lower byte 0-255 3

CV19 --- Advanced consist address 0-127 0

CV50 --- Horn type 0-16 4

CV51 --- Horn volume 0-3 3

CV52 --- Bell type 0-6 3

CV53 --- Bell volume 0-7 3

CV54 --- Bell ring rate 0-50 3

CV55 --- Diesel rumble volume 0-3 3

CV56 --- Brake squeal volume 0-3 3

CV57 --- Dynamic brake volume 0-3 3

CV58 --- Air release volume 0-3 3

CV59 --- Air pump volume 0-3 3

CV60 --- Safety pop valve volume 0-3 3

CV61 --- Engine cooling fan volume 0-3 3

CV62 --- Coupling volume 0-3 3

CV63 --- Random noise volume 0-3 3

CV64 --- Rail wheel clack 0-3 3

CV105 --- User identification number 0-255 0

CV106 --- User identification number 0-255 0

CV112 Random noise enable 0-1 1

CV113 --- Coupling fire volume 0-3 3

CV114 --- brake release volume see chart 0

CV115 --- Auto brake squeal enable/disable 0-1 1(enable

CV116 --- Coupling sound type 0-2, 0=off 1

CV120 R3 Acceleration 0-32 0

CV121 R4 Deceleration 0-32 0

Diesel notch mode, 0=auto-notch

3=manual notch

CV123 --- Prime mover sound (2- types) 0-1 0

CV125 --- Factory default setting: Programming to 1

w ill res tore all CV's to def ault s etting --- 0

CV122 --- 0-3 0

0CV21 ---

When CV21=0, all accessory functions w ill

follow its ow n address. When CV21=1, all

functions w ill follow the consist address

---