INSTALLATION

It is quite a challenge to install a decoder into a standard locomotive. You should have some basic

electrical knowledge and soldering skills. If you do not have the above requirements, please ask

the dealer for help in installation.

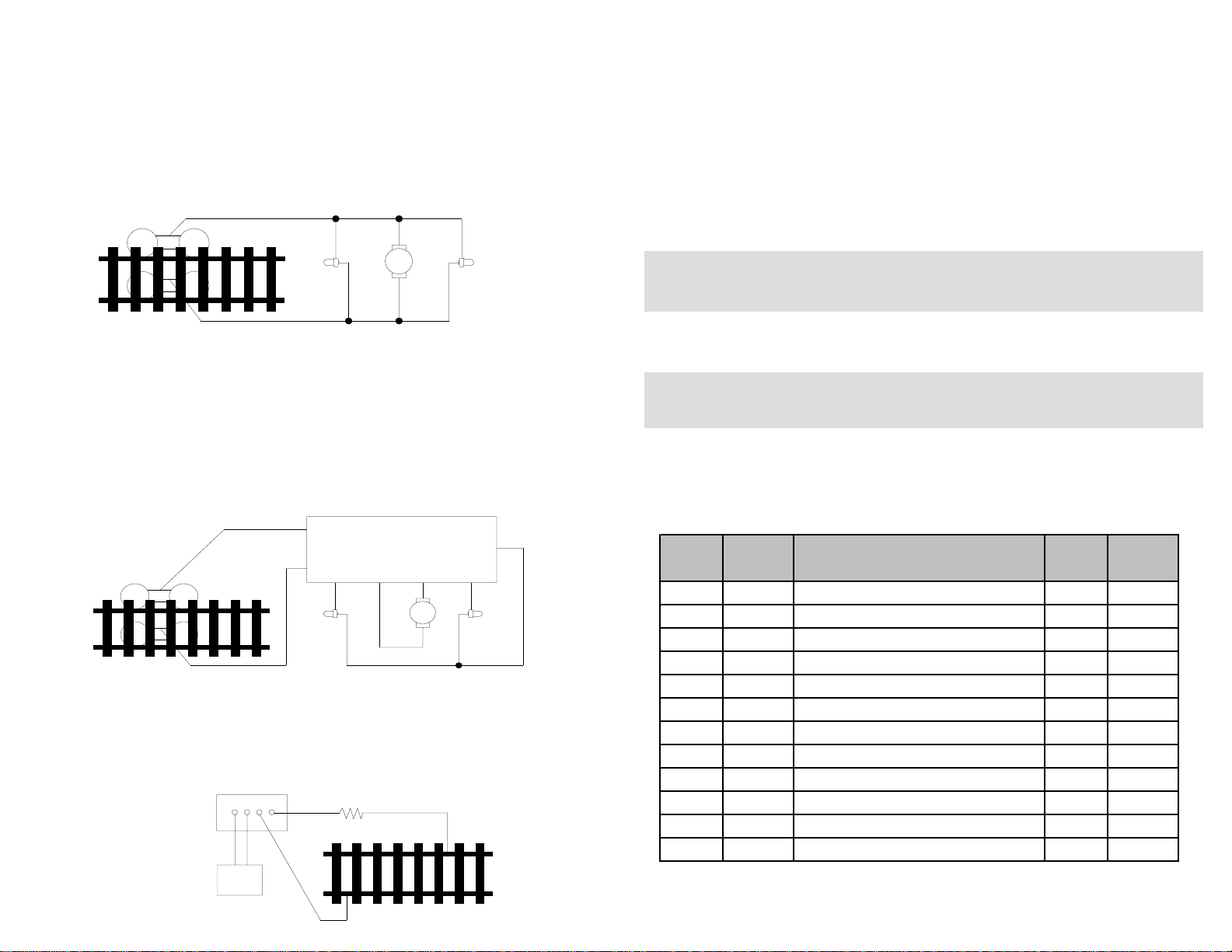

Figure 1 shows the electrical circuit of most standard locomotives. The terminals of the motor and

lights are directly connected to the wheel pick-ups. Each type of loco has its own method of

electrical pick-up and distribution. The connection between the wheels, motor and lights could be

wires, clips, the body or chassis, a PC board or any other type of conductor. Figure out your loco’s

electrical system and how to disconnect (isolate) the motor and lights.

Figure 1. Connection of standard locomotive. Note: The ‘X’ marks indicate where to disconnect

(isolate).

Figure 2 shows you how to wire the decoder. After disconnecting the motor terminals from pick-

ups, connect the red wire to the right side pickup and the black wire to the left side pick up.

Connect the orange wire to the motor terminal that originally connected to the right pickup.

Connect the gray wire to the motor’s other terminal. Connect the front light to the blue wire and the

white wire. Connect the rear light to the blue wire and the yellow wire.

The blue wire is the common terminal for lights. You may use the black wire or the red wire to

replace the blue wire. This is very useful when you find that it is hard to isolate one of the light

terminals from the pickup. Wiring the bulb this way will also make the light dimmer. If your loco has

only a front light, you should connect the white and the yellow wires together.

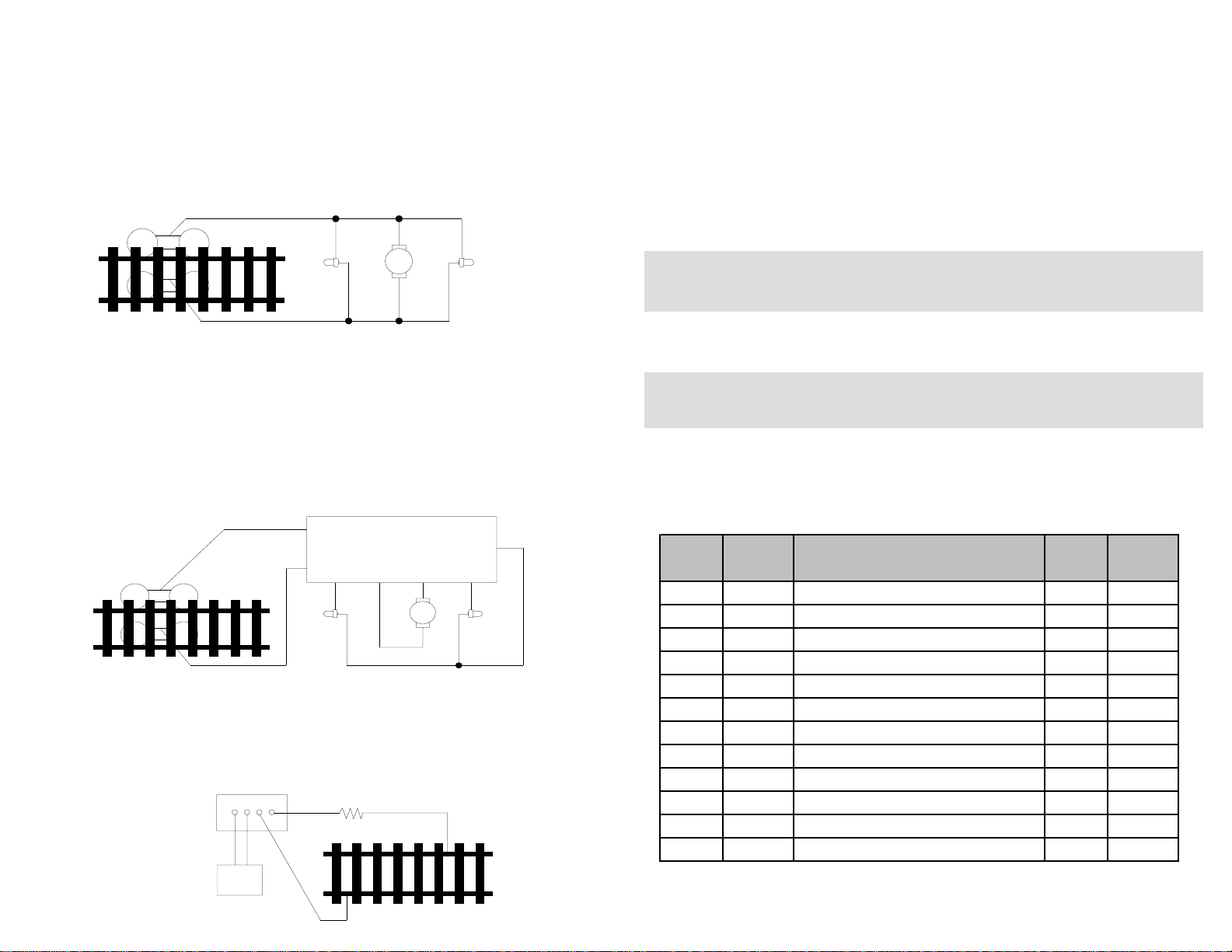

MAKE A TEST TRACK

Before you start with your decoder installation, we strongly recommend building a test track that

uses a 20-ohm resistor to limit current. Only test your installed decoder on the test track. The

test track will prevent any damage due to an incorrectly wired decoder.

Figure 3. Diagram of test track

TEST

All MRC decoders have been factory programmed with address #3, 28/128 speed steps and

maximum top voltage. After you have finished your decoder installation, you are ready to test it.

Never run the installed decoder on your layout without first passing the test. You may

damage the decoder if it is not wired correctly or if you have not properly isolated the motor and

the lights.

Put the loco on the test track. Select the Run Mode of your DCC system and select or acquire

address #3. Move up throttle and the loco should move forward. Push the light button and the front

light of your loco should turn on. Push the reverse direction button. The loco should move

backward and the rear light should turn on. The loco cannot get normal speed because there is a

20-ohm protection resistor in the test track. If you are able to turn on/off the front and rear lights

and you are able to move the loco forward and reverse, you did a great job. Congratulations! Do

not test the loco on the test track for an extended period of time. To do so will cause the

protection resistor to overheat.

If your installed decoder does not pass the test, find the problem, correct it and test it again.

As long as you test the decoder on the test track there is little chance of damaging your

decoder. This is why making a test track is so important.

PROGRAMMING

The AD332 decoder supports the following register and CV programming.

MRC PRODIGY DCC and MRC Command 2000 users do not need to know all these register/CV

numbers because the MRC DCC systems use model railroading terminology. It is easy to

understand and easy to program.

The MRC AD332 decoder should perform well when used with other brand command systems.

See your DCC command station’s manual to learn how to program and operate the decoder. For

more information about register/CVs and their functions, please refer to the NMRA DCC Standard

& Recommended practices, RP-9.2.2 This is available directly from the NMRA or their website at

www.nmra.org.

Right side pickup

Front

light Motor Rear

light

Left side pickup

X X

X X X

X

Figure 2. AD332 wiring diagram

Front

light Rear

light

Red

OrangeGray

White

Black Yellow

AD332 Decoder

Motor

Blue

DCC base unit

Power supply Test track

20 ohm resistor

CV Register Description Range Factory

Value

CV1 R1 Shortaddress 1-127 3

CV2 R2 Startvoltage 0-32 0

CV3 R3 Acceleration 0-32 0

CV4 R4 Deceleration 0-32 0

CV5 --- Maxvoltage 0-32 0

CV29 R5 Basic configuration --- 2

CV7 R7 Manufacturer version number --- 32

CV8 R8 Manufacturer ID --- 143

CV17 --- Long address upper byte 192-231 192

CV18 --- Long address lower byte 0-255 3

CV19 --- Advanced consist address 1-127 0

--- R6 Page number 0-31 1