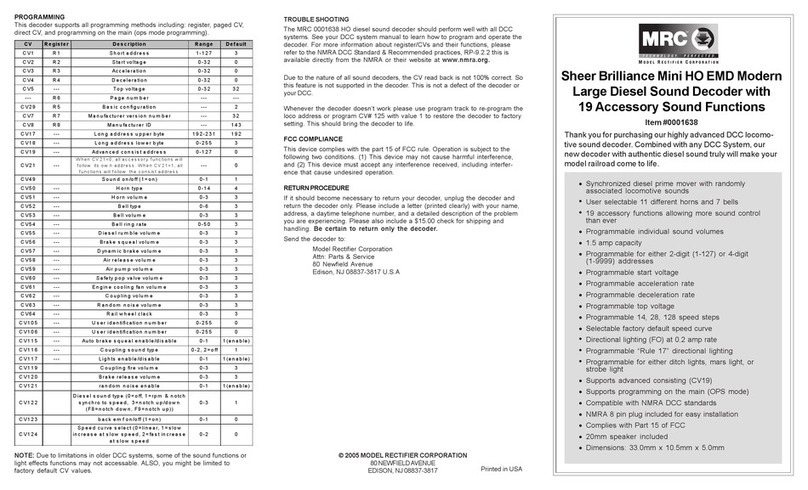

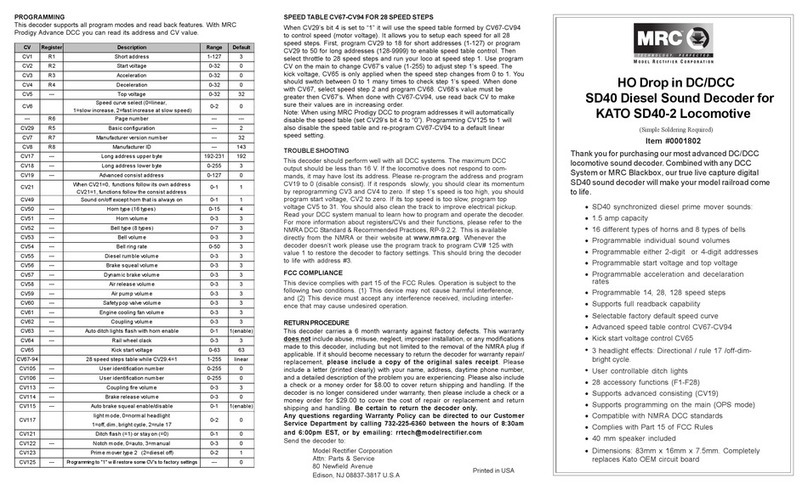

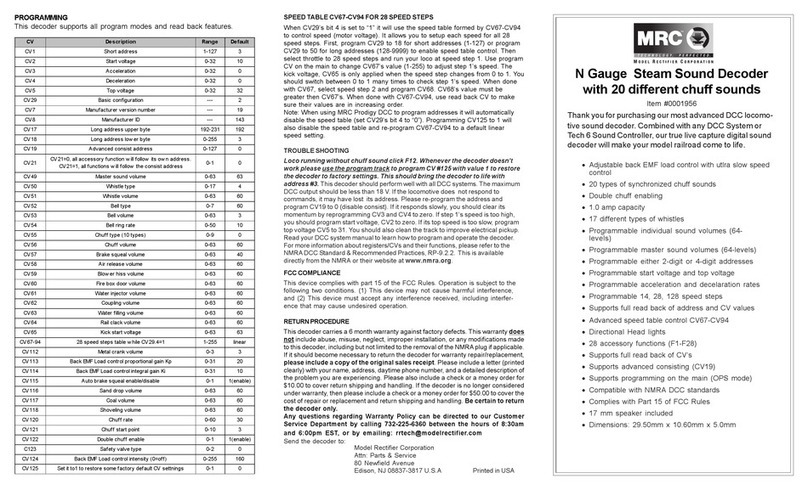

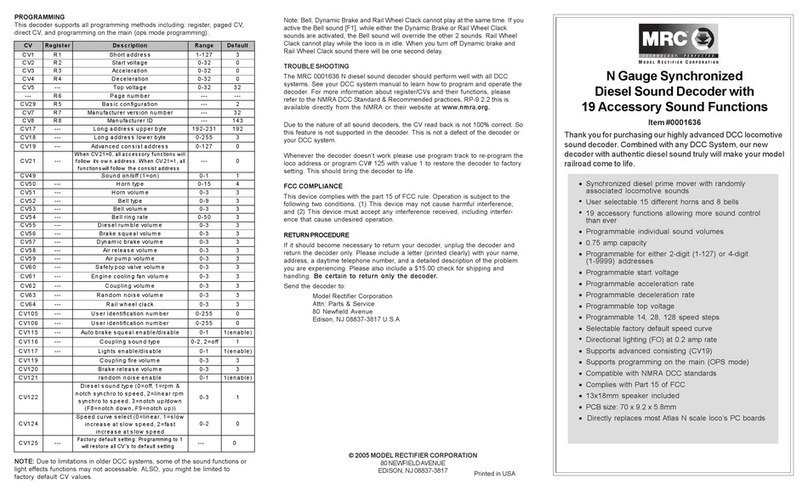

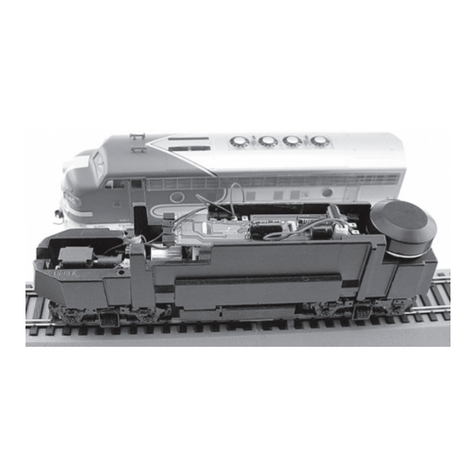

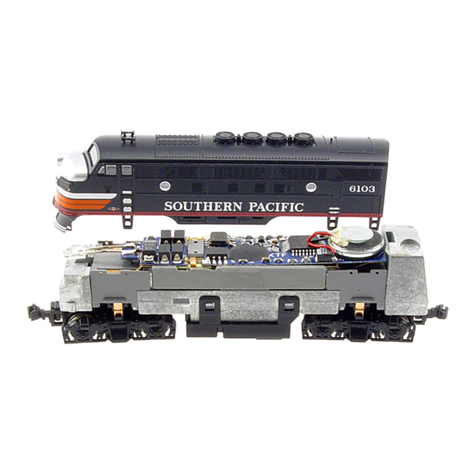

HO Gauge DC/DCC Diesel Sound Decoder

Fits Many Atlas/Kato/Athearn/Intermountain Locomotives

Item #0001905

Thankyouforpurchasingourmostadvanced16bitDC/

DCClocomotivesounddecoder.CombinedwithanyDCC

System, MRC Blackbox or Tech 6, our true live capture

digital sound decoder will make your model railroad come

to life.

•Three types of synchronized prime mover sounds:

Alco 539T /SD70/Electric Loco

•1.5 amp capacity

•22 different types of horns and 8 types of bells

•Adjustable individual sound volumes (16 levels)

•Programmable either 2-digit or 4-digit addresses

•Programmable start voltage and top voltage

•Programmable acceleration and decelaration rates

•Programmable 14, 28, 128 speed steps

•Back EMF load control

•Supports read back address and CV value

•Selectable factory default speed curve

•Advanced speed table control CV67-CV94

•Kick start voltage control CV65

•Easy function mapping

•7 accessory light effects: ditch lights, mars light,

gyra light, strobe light, prime strobe light and on/off

•28 accessory functions (F1-F28)

•Supports advanced consisting (CV19)

•Supports programming on the main (OPS mode)

•Compatible with NMRA DCC standards

•Complies with Part 15 of FCC Rules

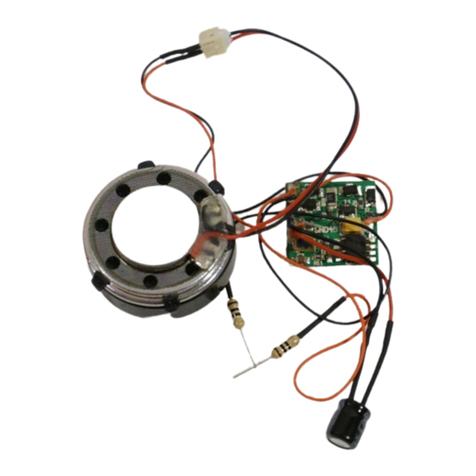

•18 mm speaker included

•Dimensions: 73.0mm x 17.8mm x 7.7mm

PROGRAMMING

This decoder supports all program modes and read back features. With MRC

Prodigy Advance DCC you can read its address and CV value.

Printed in USA

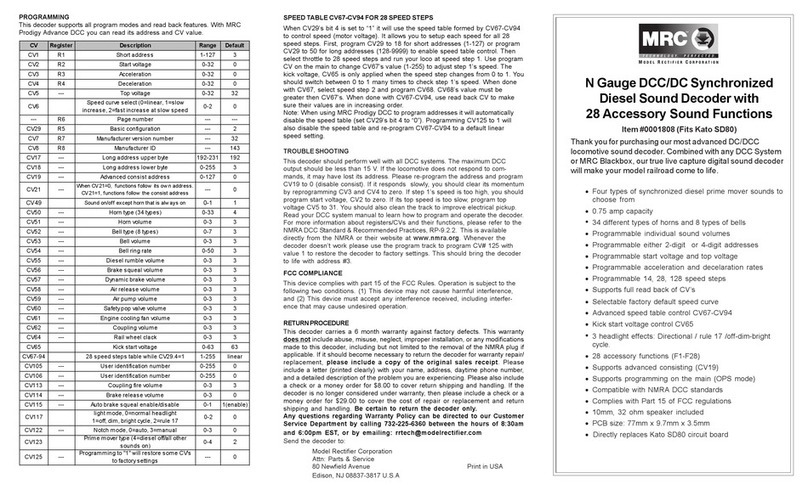

SPEED TABLE CV67-CV94 FOR 28 SPEED STEPS

When CV29’s bit 4 is set to “1” it will use the speed table formed by CV67-CV94

to control speed (motor voltage). It allows you to setup each speed for all 28

speed steps. First, program CV29 to 18 for short addresses (1-127) or program

CV29 to 50 for long addresses (128-9999) to enable speed table control. Then

select throttle to 28 speed steps and run your loco at speed step 1. Use program

CV on the main to change CV67’s value (1-255) to adjust step 1’s speed. The

kick voltage, CV65 is only applied when the speed step changes from 0 to 1. You

should switch between 0 to 1 many times to check step 1’s speed. When done

with CV67, select speed step 2 and program CV68. CV68’s value must be

greater then CV67’s. When done with CV67-CV94, use read back CV to make

sure their values are in increasing order.

Note: When using MRC Prodigy DCC to program addresses it will automatically

disable the speed table (set CV29’s bit 4 to “0”). Programming CV125 to 1 will

also disable the speed table and re-program CV67-CV94 to a default linear

speed setting.

TROUBLESHOOTING

Loco runing without sound click F12 turn on prime mover sound. Whenever

the decoder doesn’t work please use the program track to program CV# 125

with value 1 to restore the decoder to factory settings. This should bring the

decoder to life with address #3. This decoder should perform well with all DCC

systems. The maximum DCC output should be less than 21 V. If the locomotive

does not respond to commands, it may have lost its address. Please re-program the

address and program CV19 to 0 (disable consist). If it responds to slowly, you

should clear its momentum by reprogramming CV3 and CV4 to zero. If step 1’s

speed is too high, you should program start voltage, CV2 to zero. If its top speed is

too slow, program top voltage CV5 to 31. You should also clean the track to improve

electrical pickup. Read your DCC system manual to learn how to program and

operate the decoder. For more information about registers/CVs and their functions,

please refer to the NMRADCC Standard & Recommended Practices, RP-9.2.2. This

is available directly from the NMRA or their website at www.nmra.org.

FCC COMPLIANCE

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions. (1) This device may not cause harmful interference,

and (2) This device must accept any interference received, including interfer-

ence that may cause undesired operation.

RETURNPROCEDURE

This decoder carries a 6 month warranty against factory defects. This warranty

does not include abuse, misuse, neglect, improper installation, or any modifications

made to this decoder, including but not limited to the removal of the NMRA plug if

applicable. If it should become necessary to return the decoder for warranty repair/

replacement, please include a copy of the original sales receipt. Please

include a letter (printed clearly) with your name, address, daytime phone number,

and a detailed description of the problem you are experiencing. Please also include

acheckor a money orderfor$9.00tocoverreturnshipping and handling. If thedecoder

is no longer considered under warranty, then please include a check or a money order

for $35.00 to cover the cost of repair or replacement and return shipping and handling.

Be certain to return the decoder only.

Any questions regarding Warranty Policy can be directed to our Customer

Service Department by calling 732-225-6360 between the hours of 8:30am

and 6:00pm EST, or by emailing: rrtech@modelrectifier.com

Send the decoder to: Model Rectifier Corporation

Attn: Parts & Service

80 Newfield Avenue

Edison, NJ 08837-3817 U.S.A

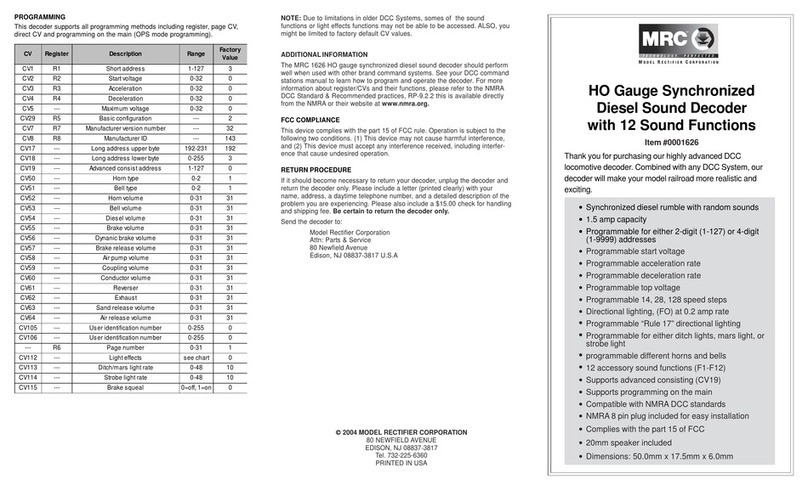

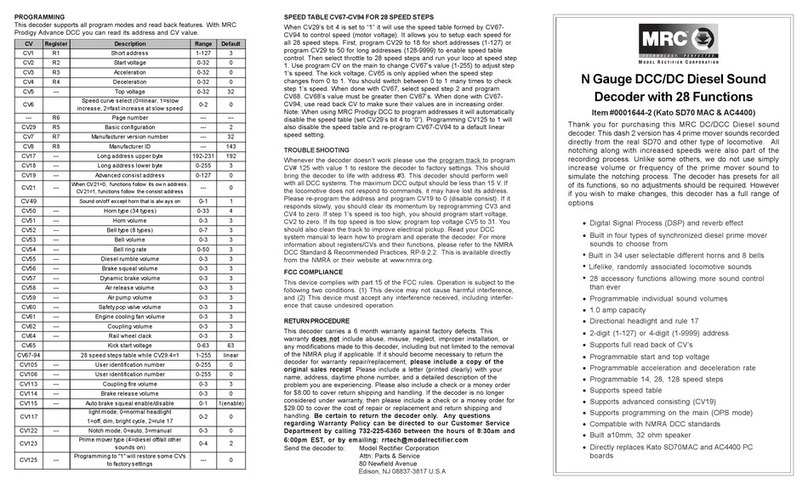

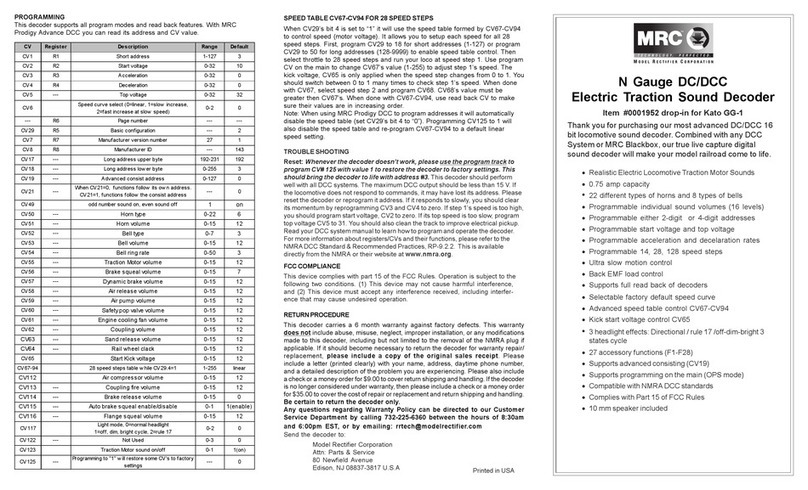

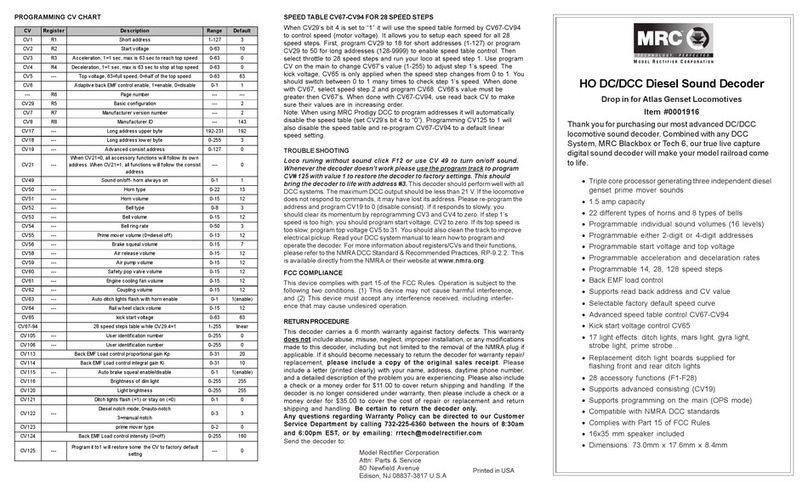

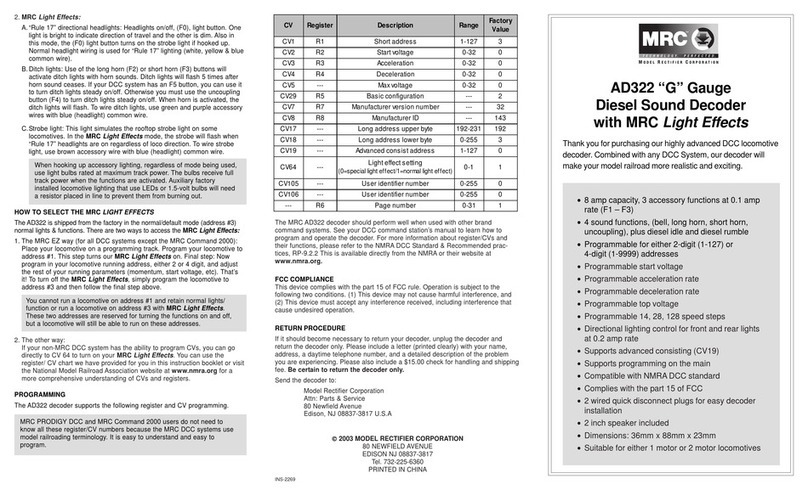

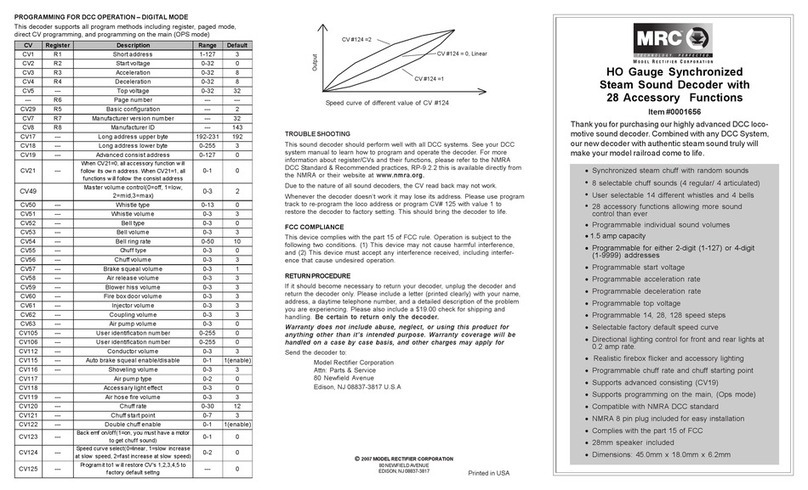

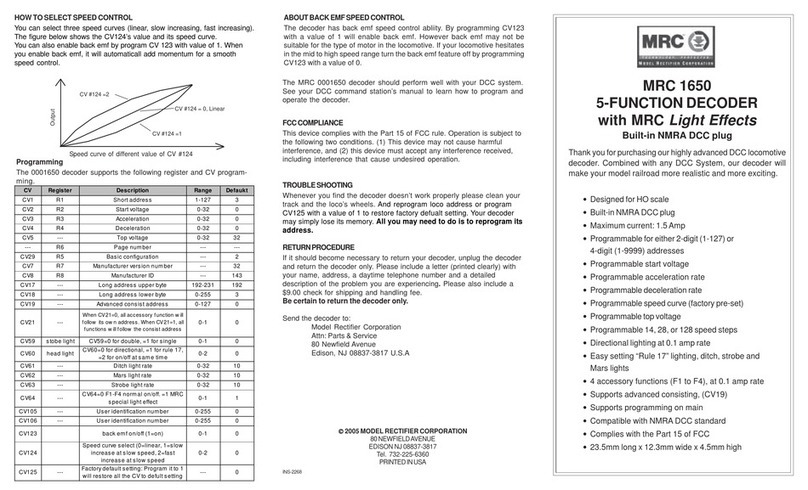

CV Register Description Range Default

CV1 R1 Short address 1-127 3

CV2R2Startvoltage0-320

CV3 R3 Acceleration 0-32 0

CV4 R4 Deceleration 0-32 0

CV5 --- Top voltage 0-32 32

CV6 Speed curve select (0=linear, 1=slow increase,

2=fast increase at slow speed 0-2 0

--- R6 Page number --- ---

CV29 R5 Basic configuration --- 2

CV7 R7 Manufacturer version number --- 2

CV8 R8 Manufacturer ID --- 143

CV17 --- Long address upper byte 192-231 192

CV18 --- Long address lower byte 0-255 3

CV19 --- Advanced consist address 0-127 0

CV37 0=normal, 1=F3 and F4 exchange 0-1 0

CV39 0=normal, 1=F5 and F6 exchange 0-1 0

CV42 0=normal, 1=F8 and F12 exchange 0-1 0

CV49 All sounds on/off 0-1 1

CV50 --- Horn type 0-22 13

CV51 --- Horn volume 0-15 12

CV52 --- Bell type 0-6 3

CV53 --- Bell volume 0-15 12

CV54 --- Bell ring rate 0-50 3

CV55 --- Prime mover volume 0-15 12

CV56 --- Brake squeal volume 0-15 7

CV57 --- Dynamic brake volume 0-15 12

CV58 --- Air release volume 0-15 12

CV59 --- Air pump volume 0-15 12

CV60 --- Safety pop valve volume 0-15 12

CV61 --- Engine cooling fan volume 0-15 12

CV62 --- Coupling volume 0-15 12

CV63 --- Auto ditch lights flash with horn enable 0-1 1(enable)

CV64 --- Rail w heel clack 0-15 12

CV65 Kick start voltage 0-63 63

CV67-94 28 speed steps table w hile CV29.4=1 1-255 linear

CV113 --- Back EMF Load control proportional gain Kp 0-31 20

CV114 --- Back EMF Load control integral gain Ki 0-31 10

CV115 --- Auto brake squeal enable/disable 0-1 1(enable)

CV118-119 Accessory light mode 0-6 0

CV118 ACC1 light mode 0-6 0

CV119 ACC2 light mode 0-6 0

CV121 --- Mars lights flashing on/off(F28) 0-1 0

CV122 --- Diesel Notch mode, 0=auto, 3=manual 0-3 0

CV123 --- Prime mover type 0-3 0

CV124 0-255 160

CV125 ---

Programming to "1" will restore some CV's to factory

settings --- 0

Back EMF Load control intensity (0=off)

0CV21 --- When CV21=0, functions follow its ow n address.

CV21=1, functions follow the consist address ---