User Manual - PolyGard®2 / µGard®2

Sensors for Toxic Gases and Oxygen

PolyGard/ µGard® are registered trademarks of MSR GA_SC2_MC2_Tox_D_0618

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Würdinger Str. 27, D 94060 Pocking www:msr-electronic.de Printed in Germany

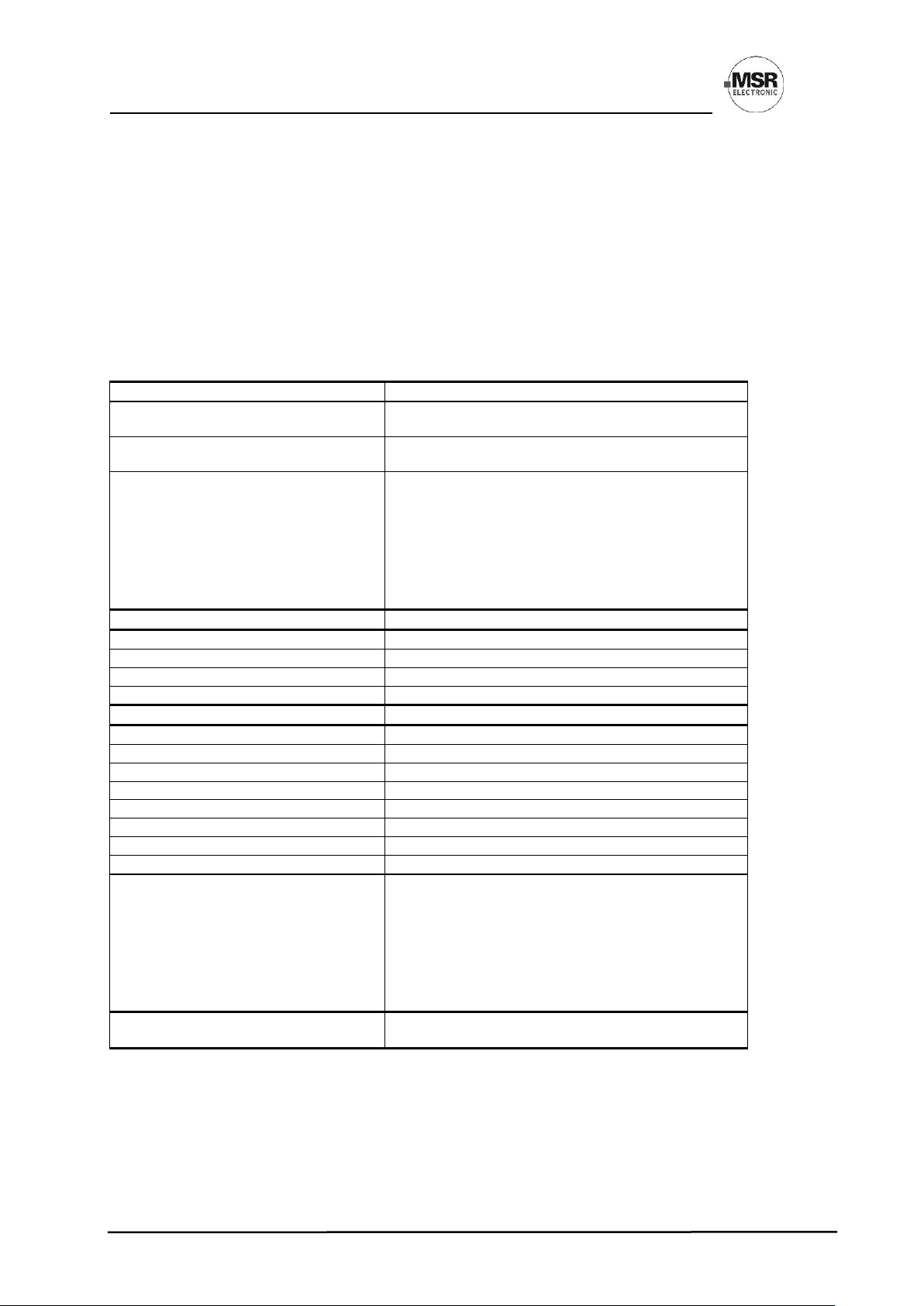

1Functional Description.............................................................................................................................3

1.1 General.............................................................................................................................................3

1.2 Measuring Mode...............................................................................................................................3

1.3 Special Mode....................................................................................................................................3

1.4 Sensor Element for Toxic Gases and Oxygen .................................................................................3

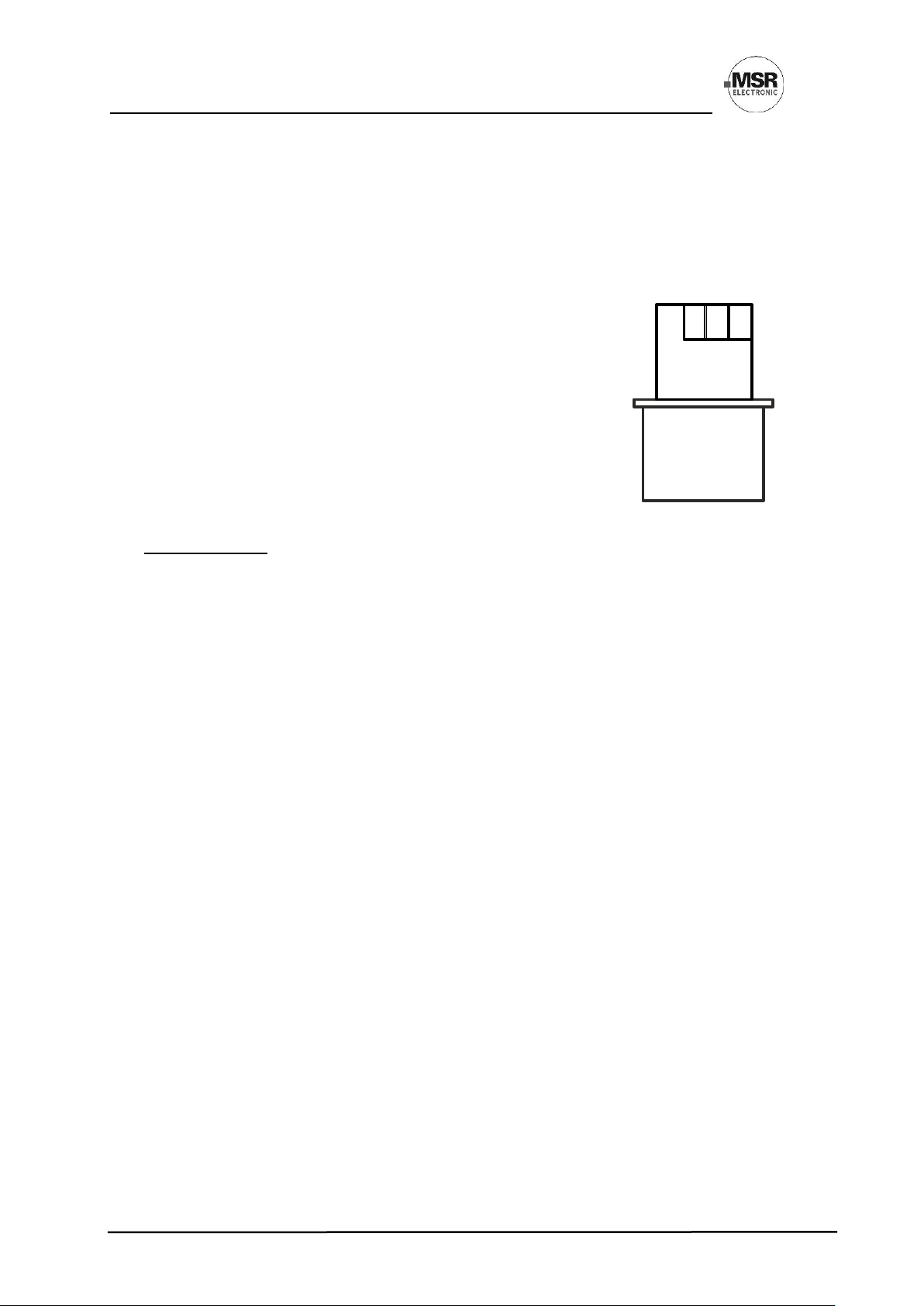

2Installation.................................................................................................................................................4

2.1 Mounting Instructions........................................................................................................................4

3Electrical Connection...............................................................................................................................5

3.1 Plug Connection (SC2) in SB2, MSB2, MSC2, MGC2.....................................................................5

3.2 Terminal Connection (MC2) .............................................................................................................5

4Commissioning.........................................................................................................................................5

4.1 Installation of Sensor Cartridge ........................................................................................................5

4.2 Registration of the Sensor Cartridge................................................................................................5

5Calibration.................................................................................................................................................6

5.1 Calibration Work...............................................................................................................................6

5.2 Exchange of Sensor Cartridge .........................................................................................................7

6Inspection and Service ............................................................................................................................8

6.1 Inspection .........................................................................................................................................8

6.2 Service and Calibration.....................................................................................................................8

7Troubleshooting .......................................................................................................................................9

7.1 Indicators at the SC2........................................................................................................................9

7.2 Indicators at the MC2........................................................................................................................9

7.3 Basic Sensor Board..........................................................................................................................9

7.4 Sensor Cartridge (Messages at the Tool / Controller)......................................................................9

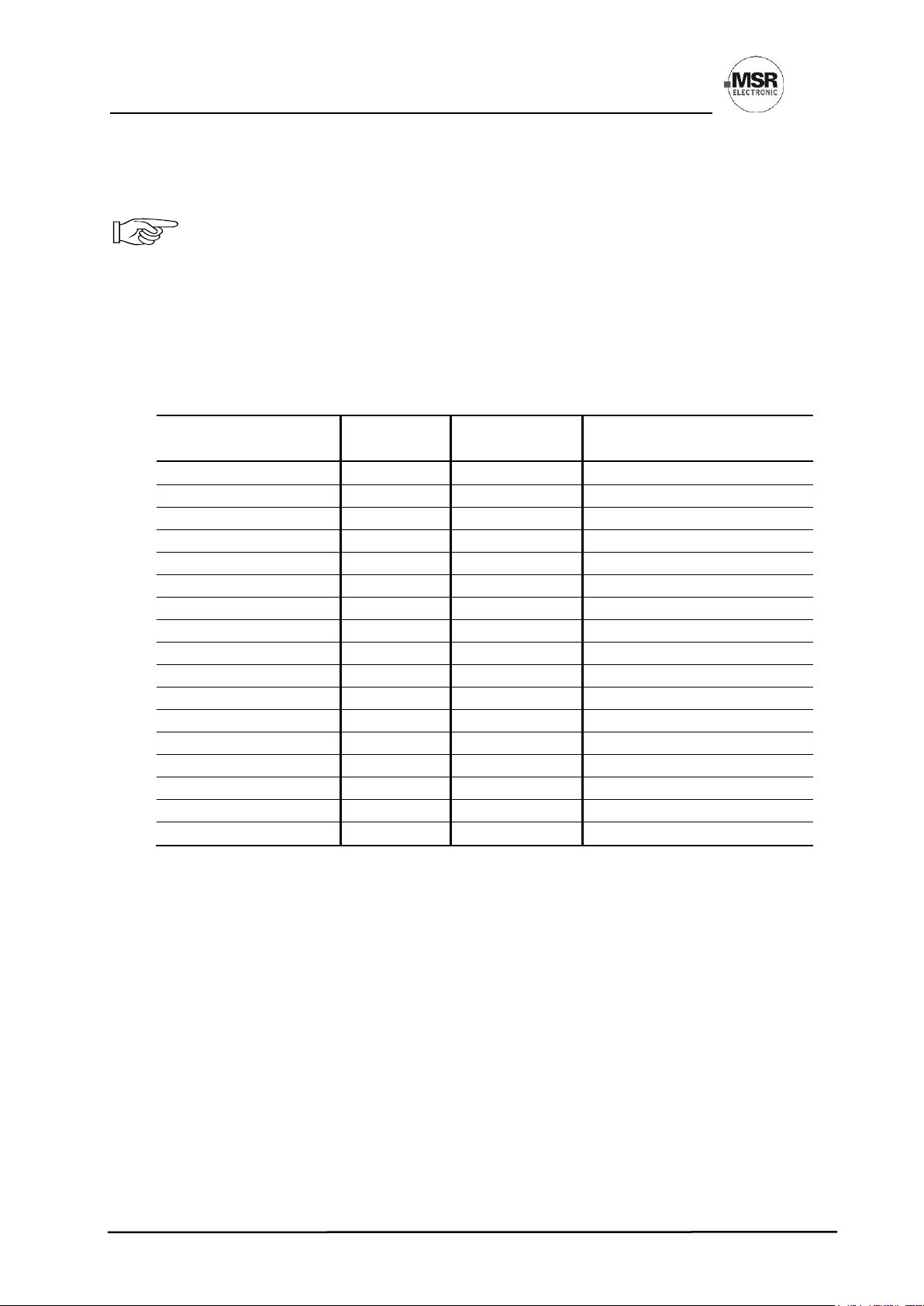

8Cross-sensitivity Data............................................................................................................................10

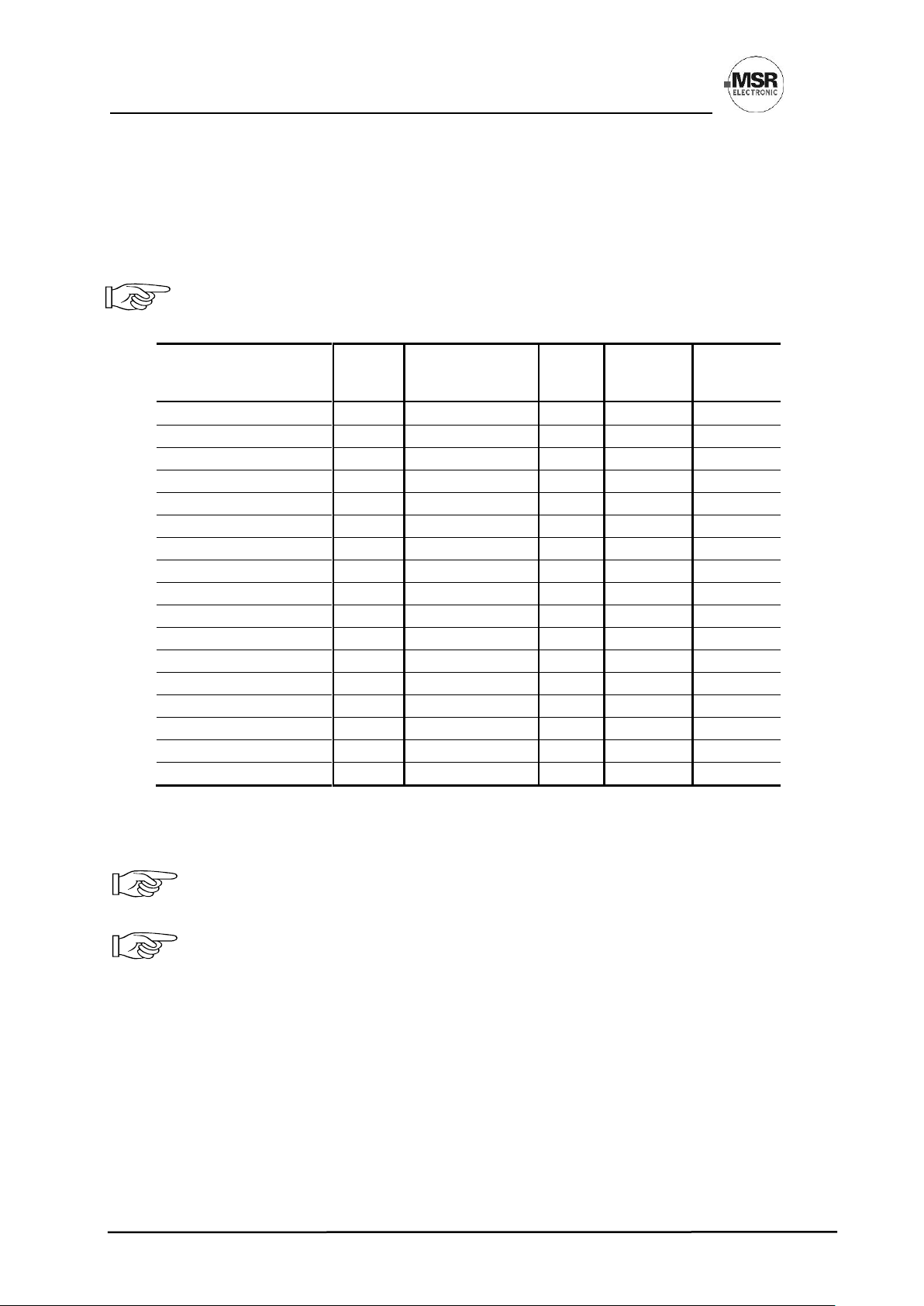

9Technical Data ........................................................................................................................................10

9.1 MC2................................................................................................................................................10

9.2 Sensor Cartridge (SC2)..................................................................................................................11

9.3 Sensor Element..............................................................................................................................12

10 Figures.....................................................................................................................................................14

11 Part Disposal...........................................................................................................................................15

12 Notes and General Information.............................................................................................................15

12.1 Intended Product Application......................................................................................................15

12.2 Installers’ Responsibilities ...........................................................................................................15

12.3 Maintenance................................................................................................................................15

12.4 Limited Warranty.........................................................................................................................15