U

't.

Do

notwearloosefittingclothing

get

caughtonthe

tiller.

Do

not

starttheengine

unlessthe

isintheneutral

(N)

position.

11. Do not fill gasoline

tank while engine is

running.

Spilling

gasoline

on hot

enginemay

causeafireor

explosion.

Donotrunthe

engine

whileindoors.Exhaust

gases

aredeadly

poisonous.

Be

careful

notto touch

the

muffler

after

the

enginehas

been

running,

itishot.

Before

any

maintenance

workisperformed

or

adjustments

aremade,

removethespark

plug

wireand

ground

it on the

engineblock

for

added

safety.

Usecautionwhen

tillingnear

buildingsand

fences,rotating

tines

cancausedamage

or

in

jury.

Beforeattemptingto removerocks,bricks

andotherobjectsfromtines,

stoptheengine

and be sure the tines have stopped

completely.Disconnect

thespark

plugwire

and

ground

to

prevent

accidentalstarting.

Check

the

tine

and

engine

mounting

bolts

at

frequent

intervals

for

proper

tightness.

Keepall nuts,boltsandscrews

tightto be

sure the equipment

is in safe working

condition.

Neverstore

theequipment

with gasoline

in

the

tank

inside

ofabuilding

where

fumes

may

reachan open flame or spark. Allow the

engine to cool before storing in any

enclosure.

12.

13.

14.

2.

3.

(+- 15.

16.

5.

6.

that

could

shift lever

7. Do not stand in front of the tillerwhile

starting

the

engine.

8. Donot place

feetand handson or nearthe

tines

whenstarting

theengine

or whilethe

engine

is

running.

9. Do not leavethe tillei unattended

with the

engine

running.

10. Do not walk in frontof the tiller

while

the

englne

isrunning.

17.

18.

+tMPoRrANr

Itissuggested

thatthis

manual

be

readinits

entirety

beforeattemptingtoassembleoroperate.Keep

this

manual

in

asafe

place

forf

uture

reference

andfor

orderingreplacement

parts.

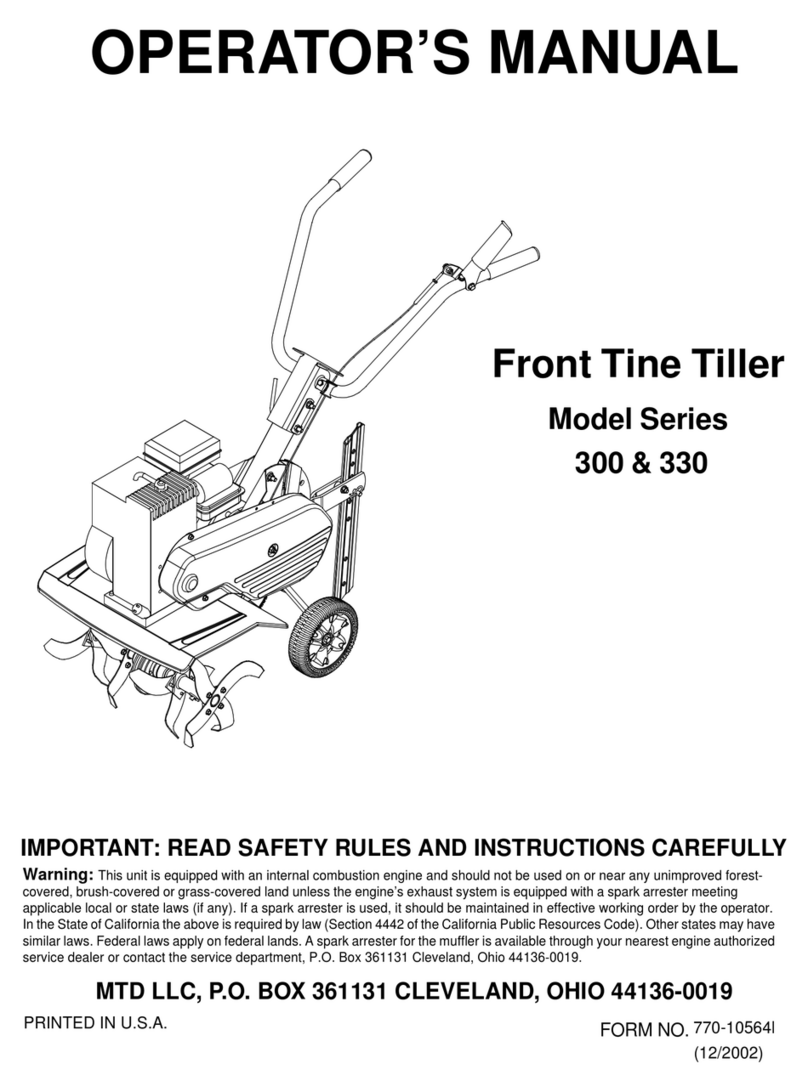

Thisunit

isshipped

WITHOUT

GASOLINE

or

OlL.

Af

terassembly,seeoperating

section

of this manual

f

or

proper

f

uel

and

amount.

your

tiller

isa precisron

piece

of power

equipment,

not

a play

thing.

Therefore,exercise

extremecaution

atalltimes.

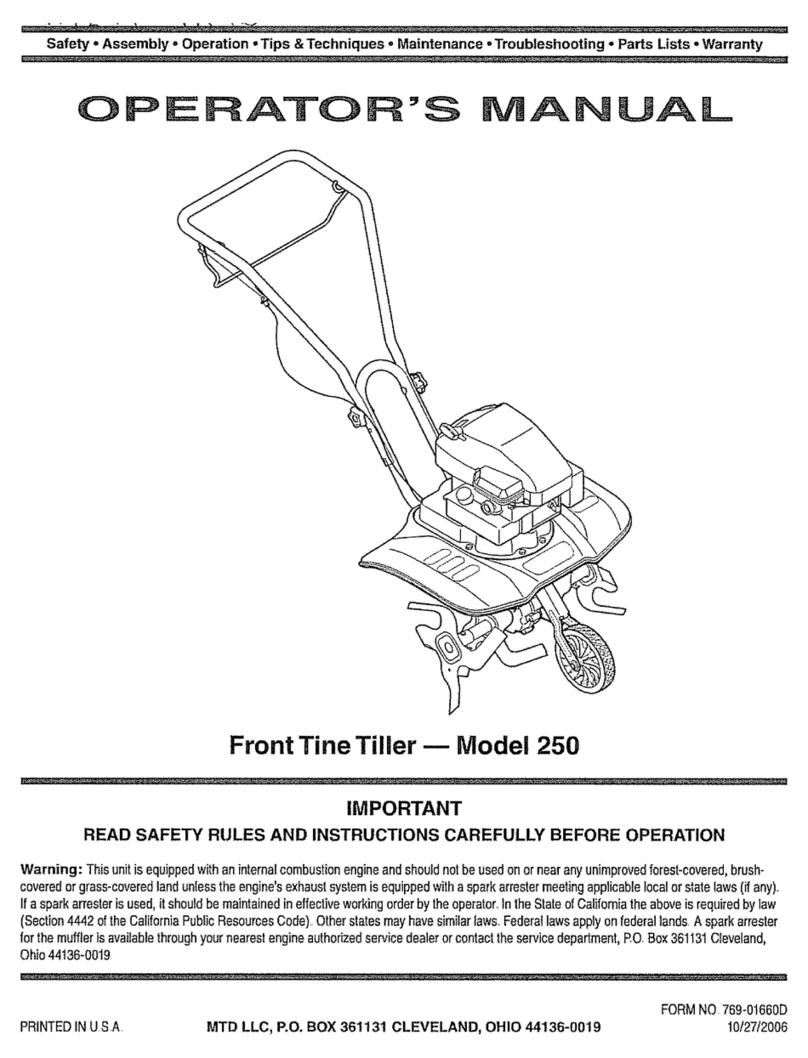

SAFE

OPERATION

PRACTICES

FOR

TILLERS

Read the Operating

and ServiceOwner's

Manual

carefully.

Be

thoroughly

familiarwith

the controls and the proper use of the

equipment.

Neverallowchildren

to operatea power

tiller.

Only

persons

wellacquainted

withthese

rules

of safe operation

should be allowed to use

your

tiller.

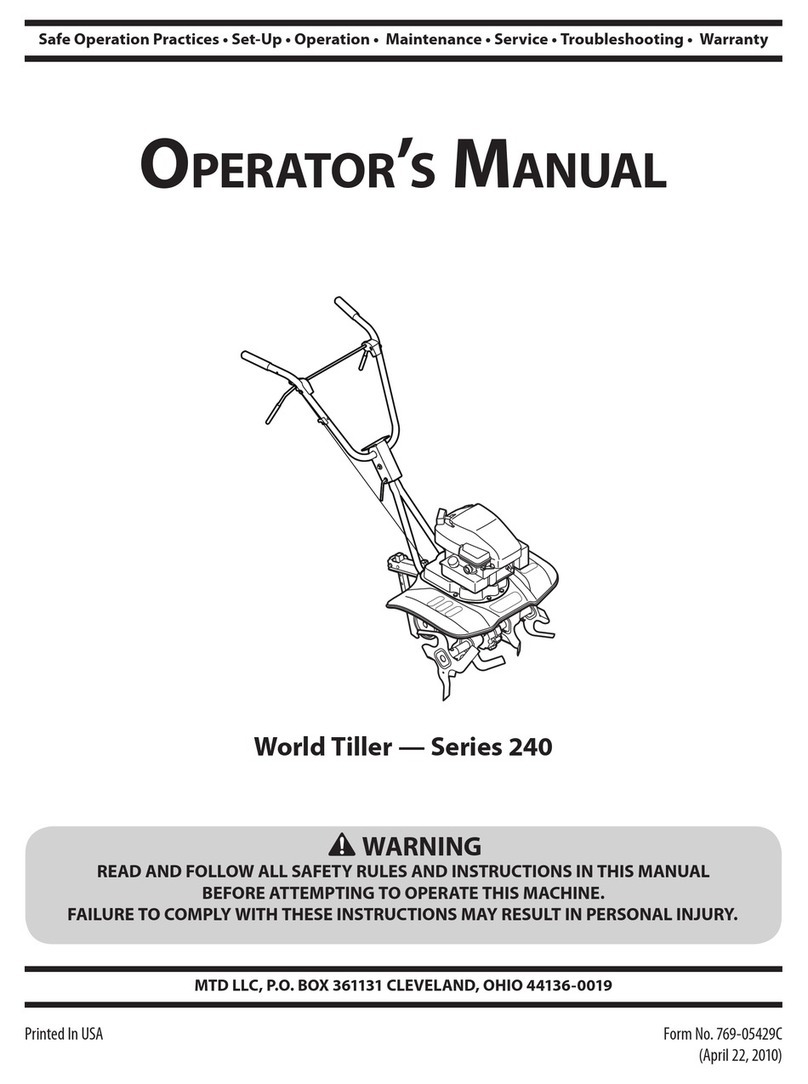

Keep the a(ea of operation clear of all

persons,particularly

small

children

and

pets.

Do not operate

equipment

when barefoot

or

wearing

opensandals.

Alwayswearsubstan-

tialfootwear.

19.