MTHTrains RAILKING M-1a MOUNTAIN STEAM ENGINE User manual

Other MTHTrains Toy manuals

MTHTrains

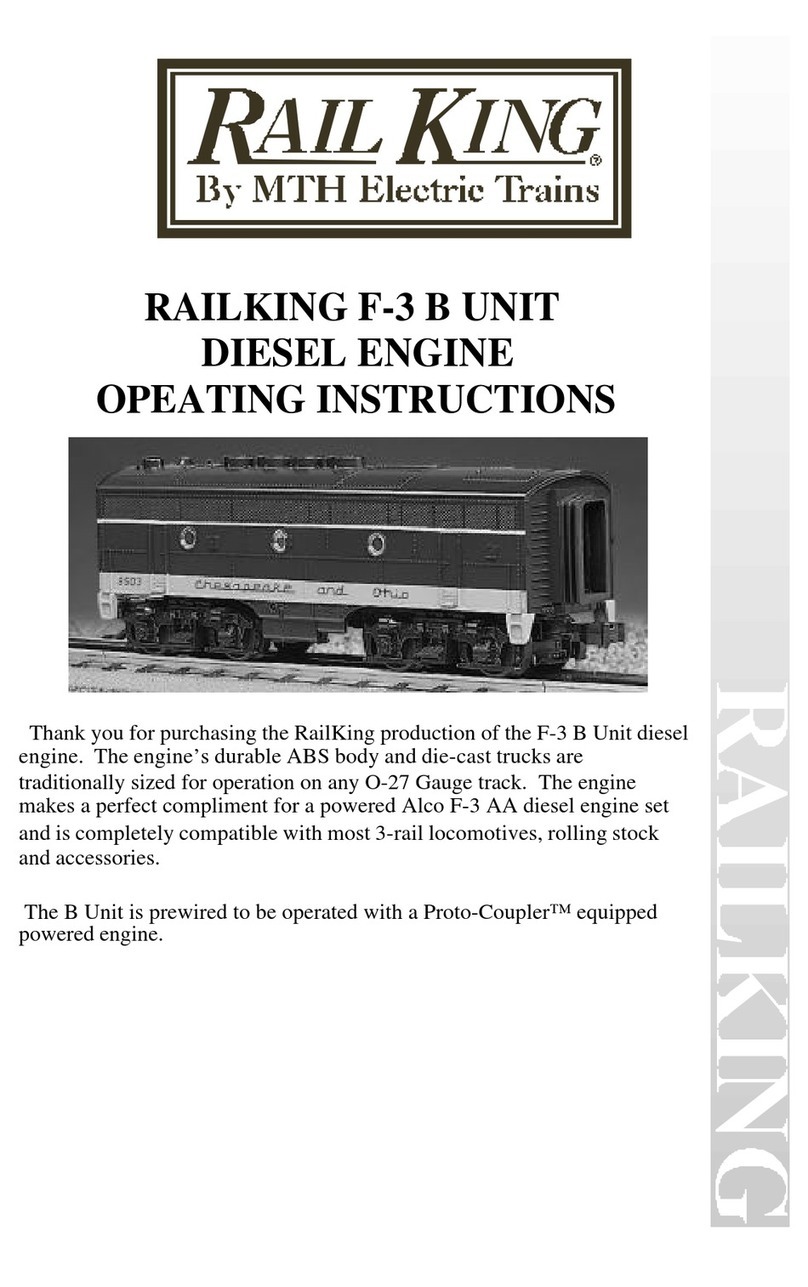

MTHTrains RAILKING MP-15 DIESEL ENGINE User manual

MTHTrains

MTHTrains RailKing 30-2132 User manual

MTHTrains

MTHTrains RailKing 30-9006 User manual

MTHTrains

MTHTrains Premier GP60 User manual

MTHTrains

MTHTrains 30-2519-0 User manual

MTHTrains

MTHTrains 20-20776-1 User manual

MTHTrains

MTHTrains Center Copula Steel Caboose User manual

MTHTrains

MTHTrains RS-27 User manual

MTHTrains

MTHTrains 30-5114-1 User manual

MTHTrains

MTHTrains RailKing 60ft Streamlined Passenger Cars User manual

MTHTrains

MTHTrains Jordan Spreader User manual

MTHTrains

MTHTrains PREMIER GP-40 DIESEL ENGINE User manual

MTHTrains

MTHTrains RAILKING ES44 User manual

MTHTrains

MTHTrains BIG BOY User manual

MTHTrains

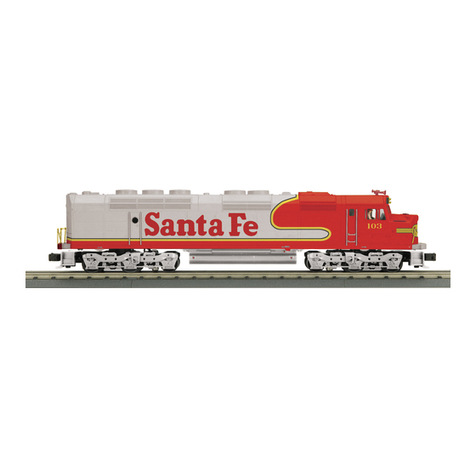

MTHTrains RAIL KING FP45 DIESEL ENGINE User manual

MTHTrains

MTHTrains PREMIER GP-7 DIESEL ENGINE User manual

MTHTrains

MTHTrains RAILKING 4-6-2 K-4s User manual

MTHTrains

MTHTrains RailKing NYC 4-6-4 User manual

MTHTrains

MTHTrains Premier BL-2 Diesel Engine User manual

MTHTrains

MTHTrains DL-109 DIESEL ENGINE User manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions