Table of Contents

1 Safety

1.1 Important requirements for all products 5

1.2 Personnel and organizational requirements 6

1.3 Transport 7

1.4 Safety requirements for startup and

operation 9

1.5 Safety requirements for maintenance and

repair work 10

1.6 Fire prevention and environmental

protection, fluids and lubricants, auxiliary

materials 13

1.7 Standards for safety notices in the text 15

2 General Information

2.1 Tightening specifications for screws, nuts

and bolts 16

2.2 Engine side and cylinder designations 27

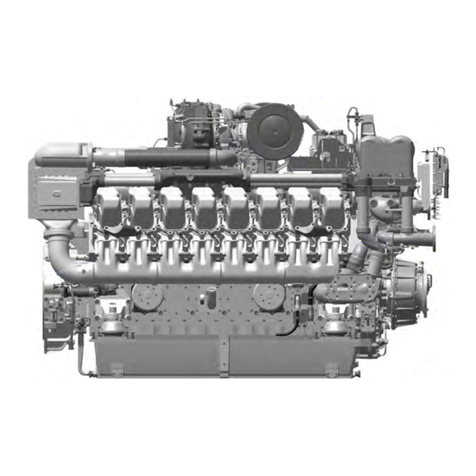

2.3 Product description 28

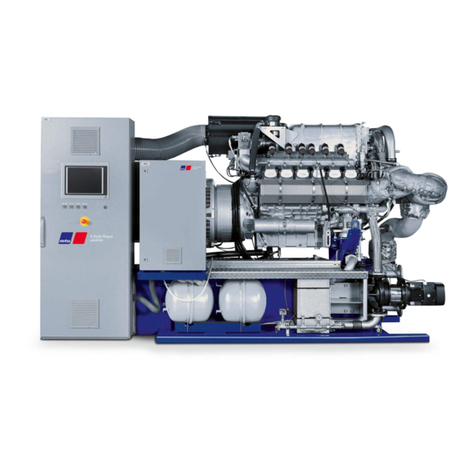

2.4 Engine layout 34

2.5 Sensors and actuators – Overview 36

3 Technical Data

3.1 12V 2000 M84 engine data 41

3.2 16V 2000 M84 engine data 44

3.3 Firing order 47

3.4 Engine – Main dimensions 48

4 Operation

4.1 Putting the engine into operation after

extended out-of-service periods (>3 months) 49

4.2 Engine – Putting into operation after

scheduled out-of-service-period 50

4.3 Tasks after extended out-of-service periods

(>3 weeks) 51

4.4 Checks prior to start-up 52

4.5 Fuel treatment system – Putting into

operation 53

4.6 Operational checks 55

4.7 Fuel treatment system – Switching on 56

4.8 Starting the engine 57

4.9 Engine – Shutdown 58

4.10 Emergency engine stop 59

4.11 After stopping the engine 60

4.12 Fuel treatment system – Shutdown 61

4.13 Plant – Cleaning 62

5 Maintenance

5.1 Maintenance task reference table [QL1] 63

6 Troubleshooting

6.1 Fuel treatment system – Troubleshooting 64

6.2 Troubleshooting 65

7 Task Description

7.1 SOLAS 68

7.1.1 SOLAS shielding as per MTN 5233 –

Installation 68

7.1.2 SOLAS shielding – Installation 69

7.1.3 Installation locations for SOLAS shielding 70

7.2 Engine 75

7.2.1 Engine – Barring manually 75

7.2.2 Engine – Cranking on starting system 76

7.3 Cylinder Liner 77

7.3.1 Cylinder liner – Endoscopic examination 77

7.3.2 Instructions and comments on endoscopic and

visual examination of cylinder liners 79

7.4 Crankcase Breather 81

7.4.1 Crankcase breather – Cleaning oil pre-

separator element 81

7.4.2 Crankcase breather – Oil separator element

replacement, diaphragm check and

replacement 82

7.5 Valve Drive 84

7.5.1 Valve clearance – Check and adjustment 84

7.5.2 Cylinder head cover – Removal and

installation 86

7.6 Injection Valve / Injector 87

7.6.1 Injector – Replacement 87

7.6.2 Injector – Removal and installation 88

7.7 Fuel System 90

7.7.1 Fuel system – Venting 90

7.8 Fuel Filter 91

7.8.1 Fuel filter – Replacement 91

7.8.2 Fuel prefilter – Differential pressure check

and adjustment of gauge 93

7.8.3 Fuel prefilter – Draining 94

7.8.4 Fuel prefilter – Flushing 96

7.8.5 Fuel prefilter – Filter element replacement 98

7.9 Charge-Air Cooling 100

7.9.1 Intercooler – Checking condensate drain line

for coolant discharge and obstruction 100

7.10 Air Filter 101

MS150063/02E 2014-03 | Table of Contents | 3

DCL-ID: 0000016266 - 002