Page 44 Page 9

Page 84 Page 117

With or Without Electric Heat

Page 171 Page 148

Page 233

Page 207

Page 259

CWA2 With or Without Electric Heat 2-Pipe

CWA4 Chilled & Hot Water 4-Pi

e

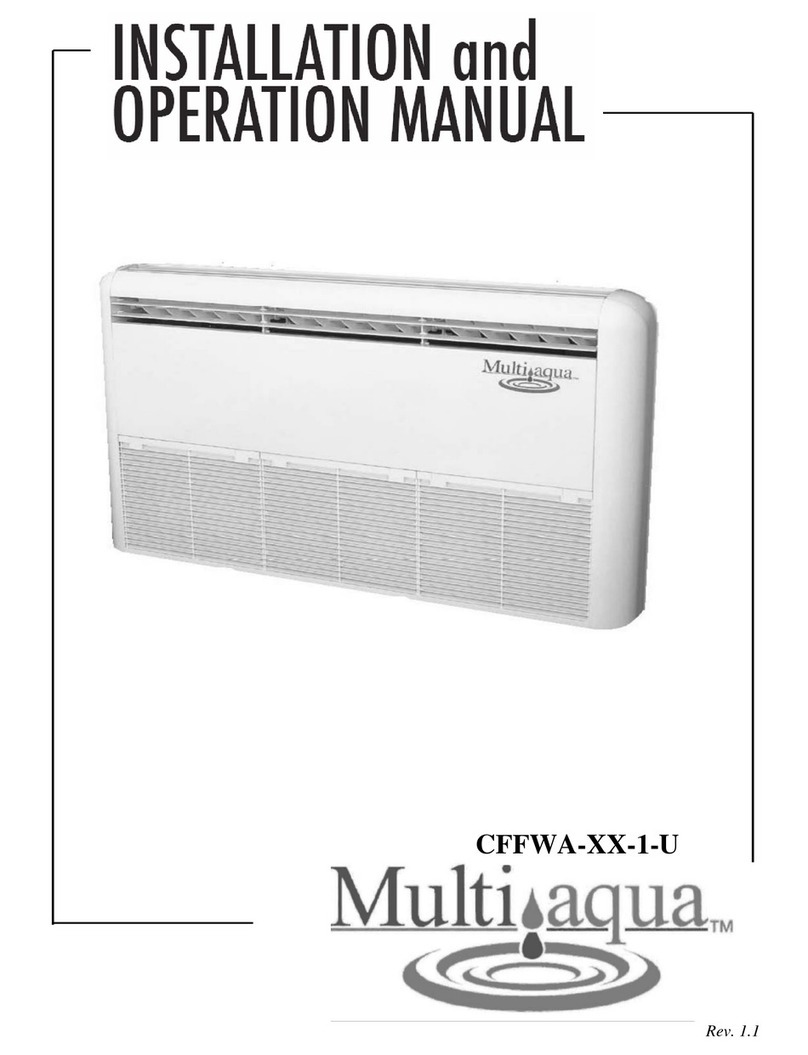

• Available in 2 or 4-Pi

e Confi

uration

• 18

000- 60

000 BTUH

• Floor

Low Wall or Horizontal Ceilin

Mountin

• U

Flow

Left or Ri

ht Hand Horizontal Installatio

• E

ui

ed with R4.2 Insulation

• CWA2 in 208/240-1-60 & CWA4 in 120-1-60

• Electric or Hot Water Heat

MHWW (Hi-Wall) Chilled/Hot Water 2-Pipe

• Powder Painted Galvanized Steel

• Discharge May be Ducted for Small Spaces

• Manual Air Vents

• Attractive Seamless Appliance Design

• Cleanable Air Filter Provided

• Heavy Gauge Metal Cabinet

• Manual Air Vents

• Powder Painted Galvanized Steel

• Double Field Reversible Hand of Connection Coil

• Discharge May be Ducted for Small Spaces

• Heavy Gauge Metal Cabinet

• Ceiling Concealed Design for Clean Installation

• Two Stages of Coolin

• Removes Equipment from Conditioned Space

MHNCCW (Ceiling Concealed) Chilled/Hot Water 4-Pipe

• Available with or without Electric Heat

• 12,000-36,000 BTUH

• Ceiling Concealed Design for Clean Installation

MCCW (Ceiling Concealed) Chilled/Hot Water 2-Pipe

• Removes Equipment from Conditioned Space

• 48,000 – 60,000 BTUH

• Ceiling Concealed Design for Clean Installation

• Horizontal Air Discharge

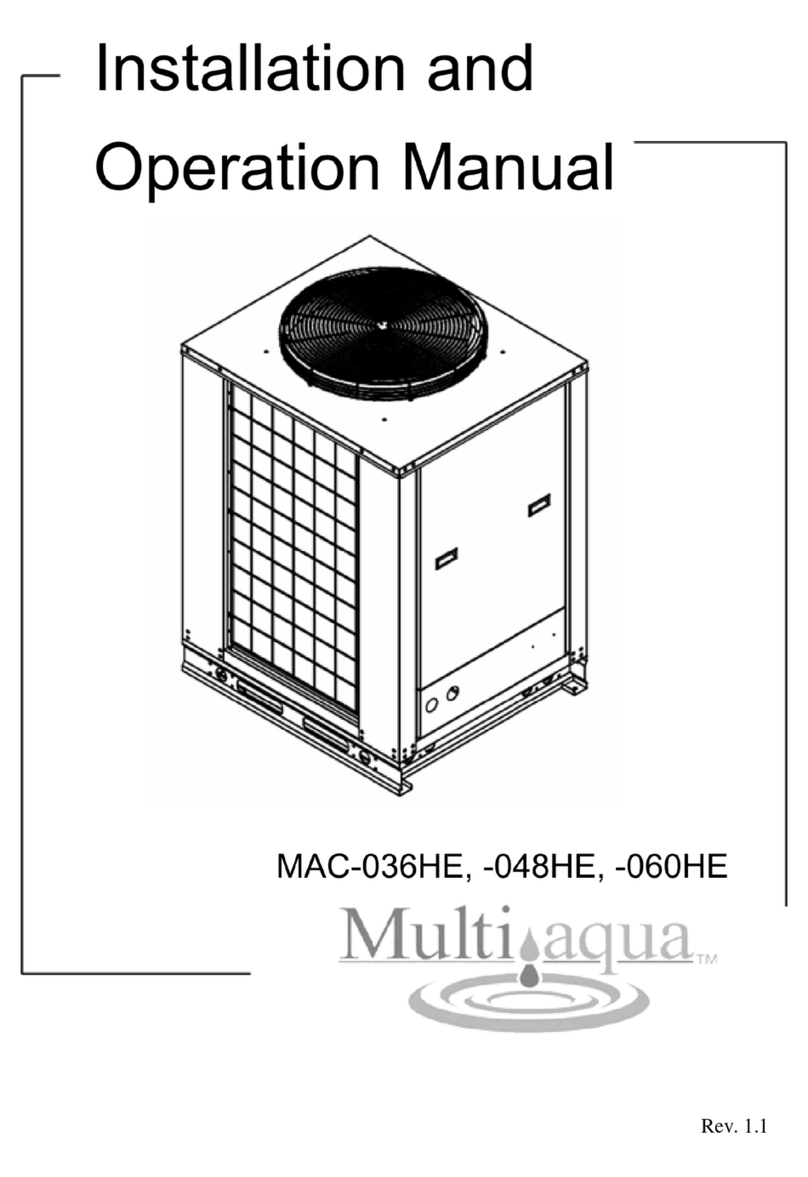

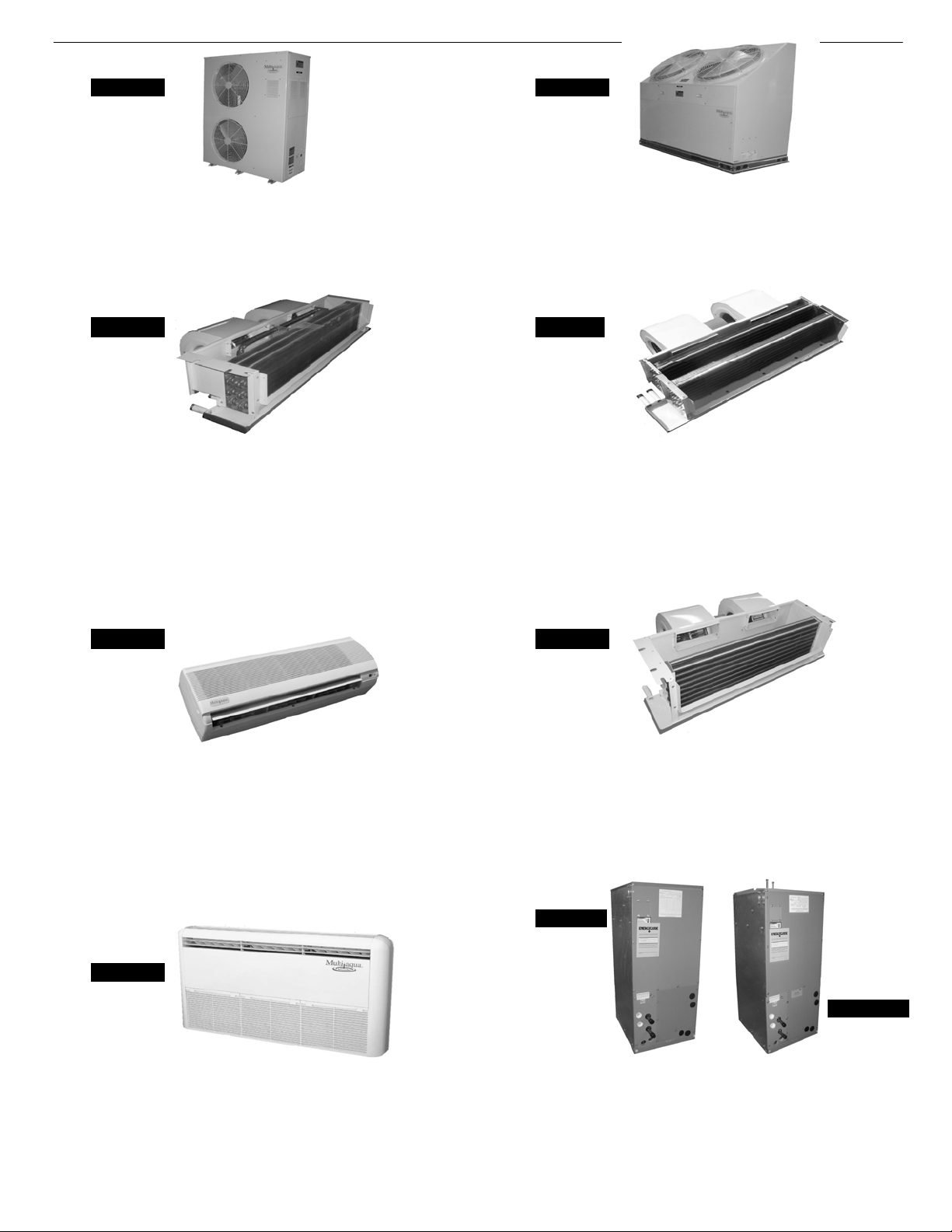

• 3, 4 & 5 Ton Air Cooled Chiller

• Field Reversible Hand of Connection Coil

• Heavy Gauge Metal Cabinet

• Stainless Steel Pump Included

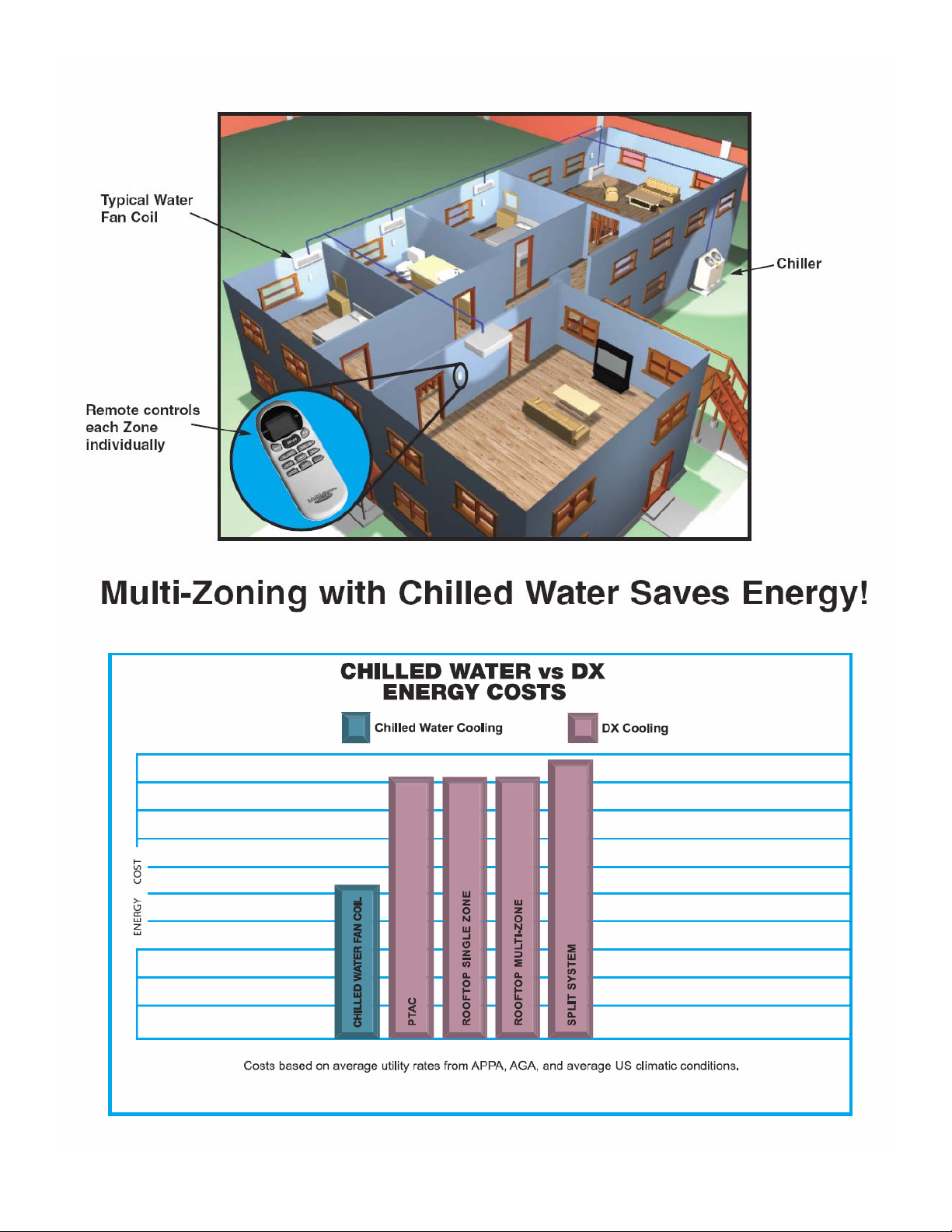

Water Product Overview

MAC036, 048 & 060 Air Cooled Chiller MAC120 Air Cooled Chiller

• R 407c Refrigerant

• 10 Ton Air Cooled Chiller

• R 407c Refrigerant • Copeland Scroll Compressor Technology• Copeland Scroll Compressor Technology

• Vertical Air Discharge

• 9,000- 36,000 BTUH

• High Wall Mounting

• Manual Air Vents

• Powder Painted Galvanized Steel

MHCCW (Ceiling Concealed) Chilled Water 2-Pipe

• Removes Equipment from Conditioned Space

• 12,000- 36,000 BTUH

• Discharge May be Ducted for Small Spaces

5

• Wired Controller Option

• Wireless Infrared Remote Included

• Attractive Modular Design

• Cleanable Air Filter Included

• Optional Wireless Remote

CFFWA Universal Mount Fan Coil 2-Pipe

• 12,000- 60,000 BTUH