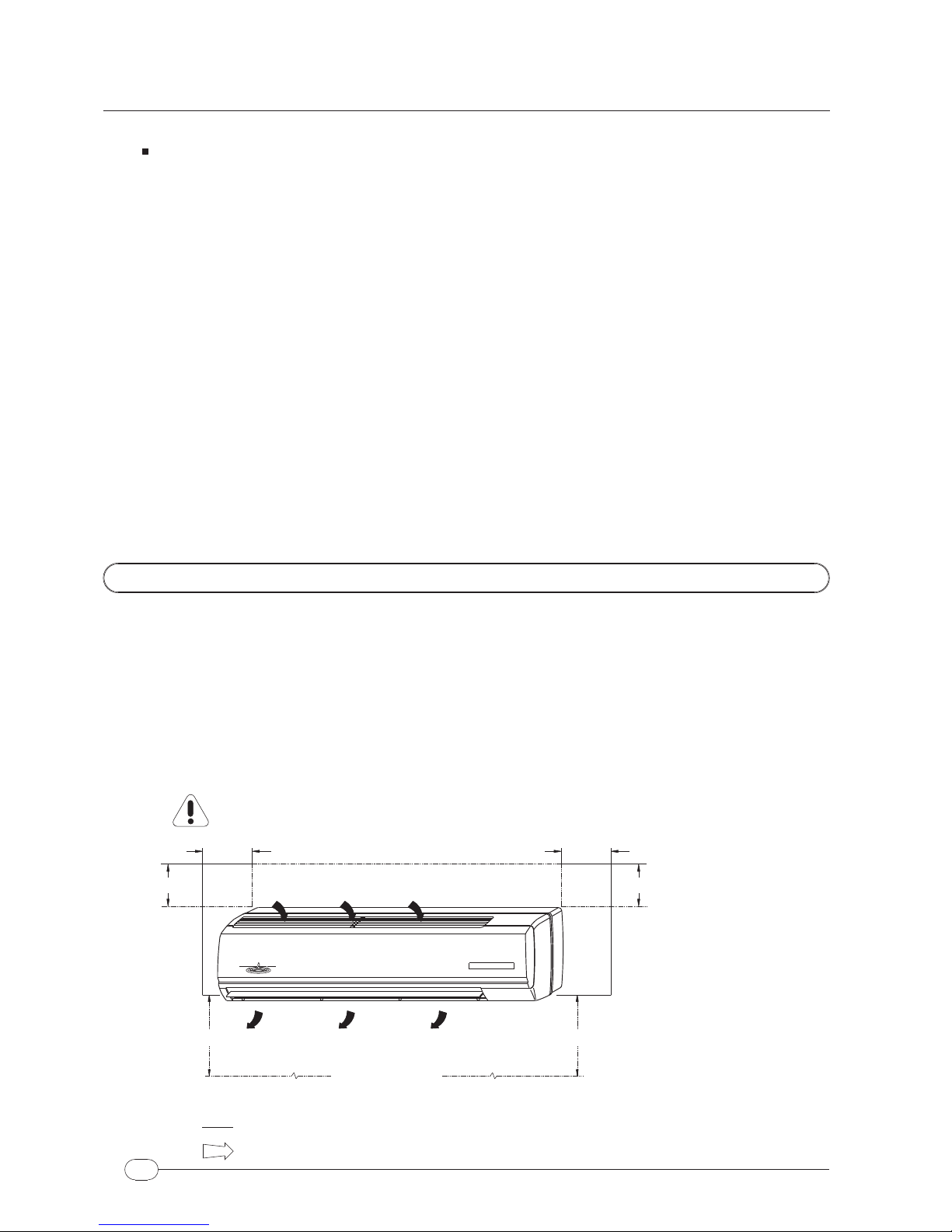

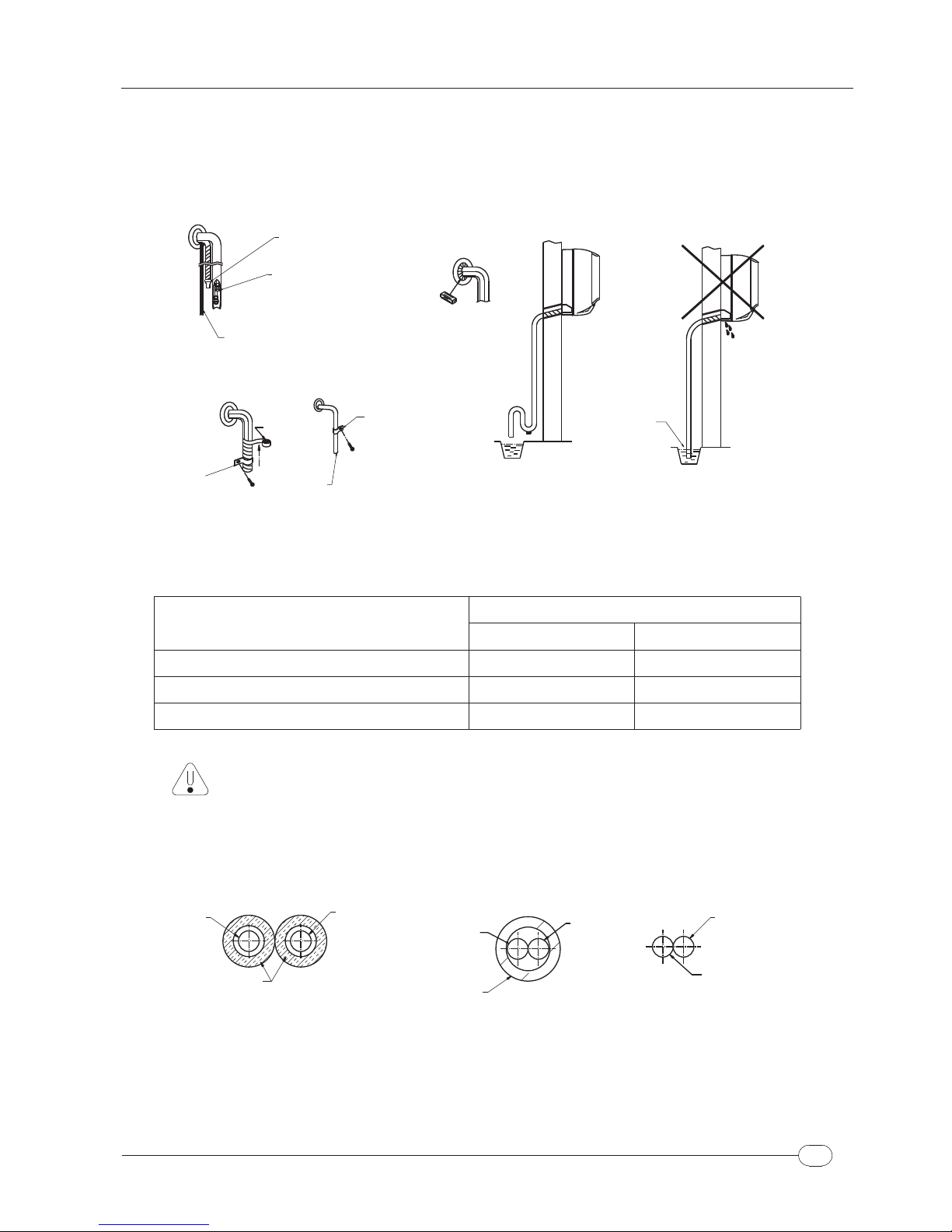

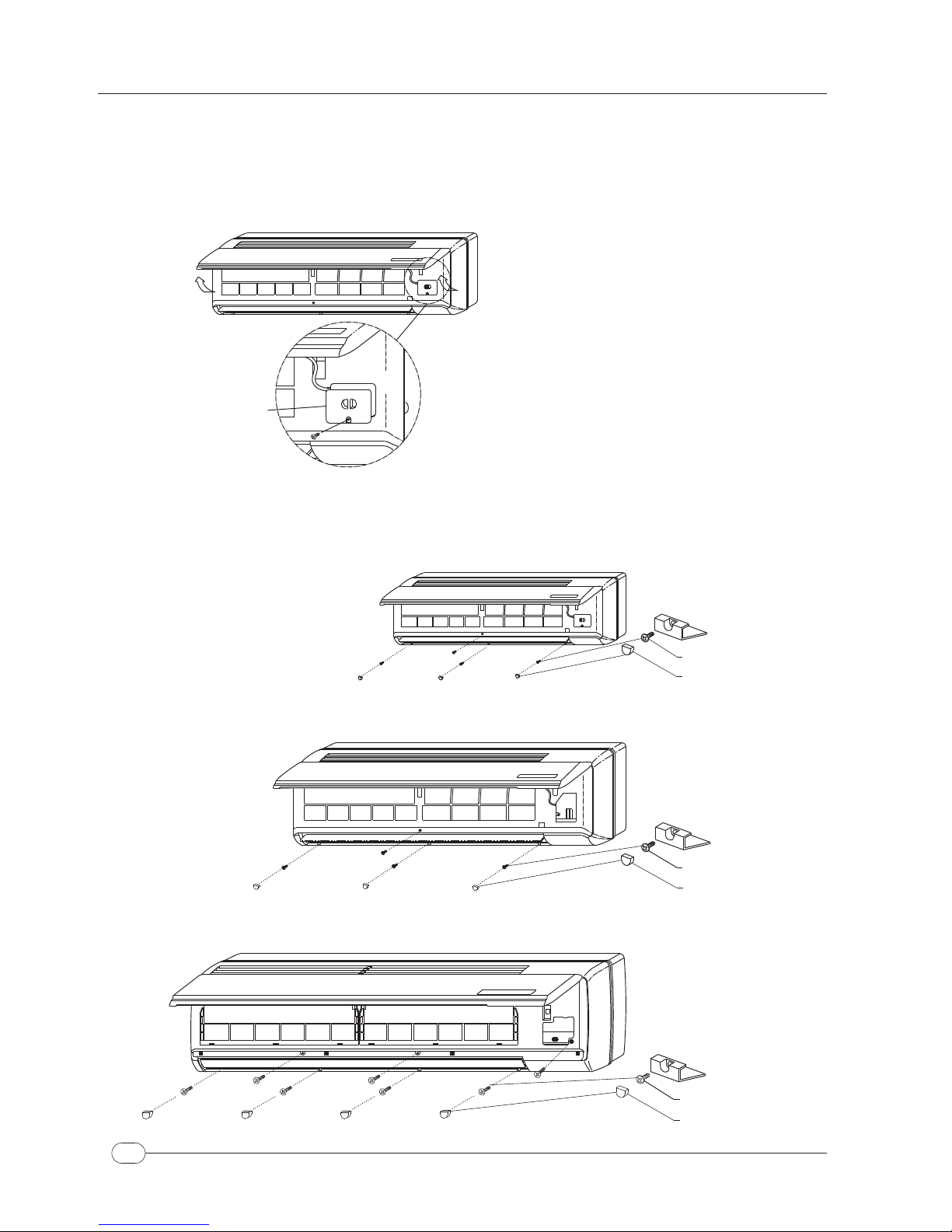

* Refer to dimensiona l drawings f or l ocation of liquid solution piping, c ondensate drain,

* Check e lectrical s ervice p rovided by utility f or the s ite t o be s ure t he electrical

service c apacity c an handle the load i mposed by this u nit.

and electrical c onnections before s etting in p lace.

* This a ir conditioner must b e p roperly i nstalled in accordance with t he Installation M anual.

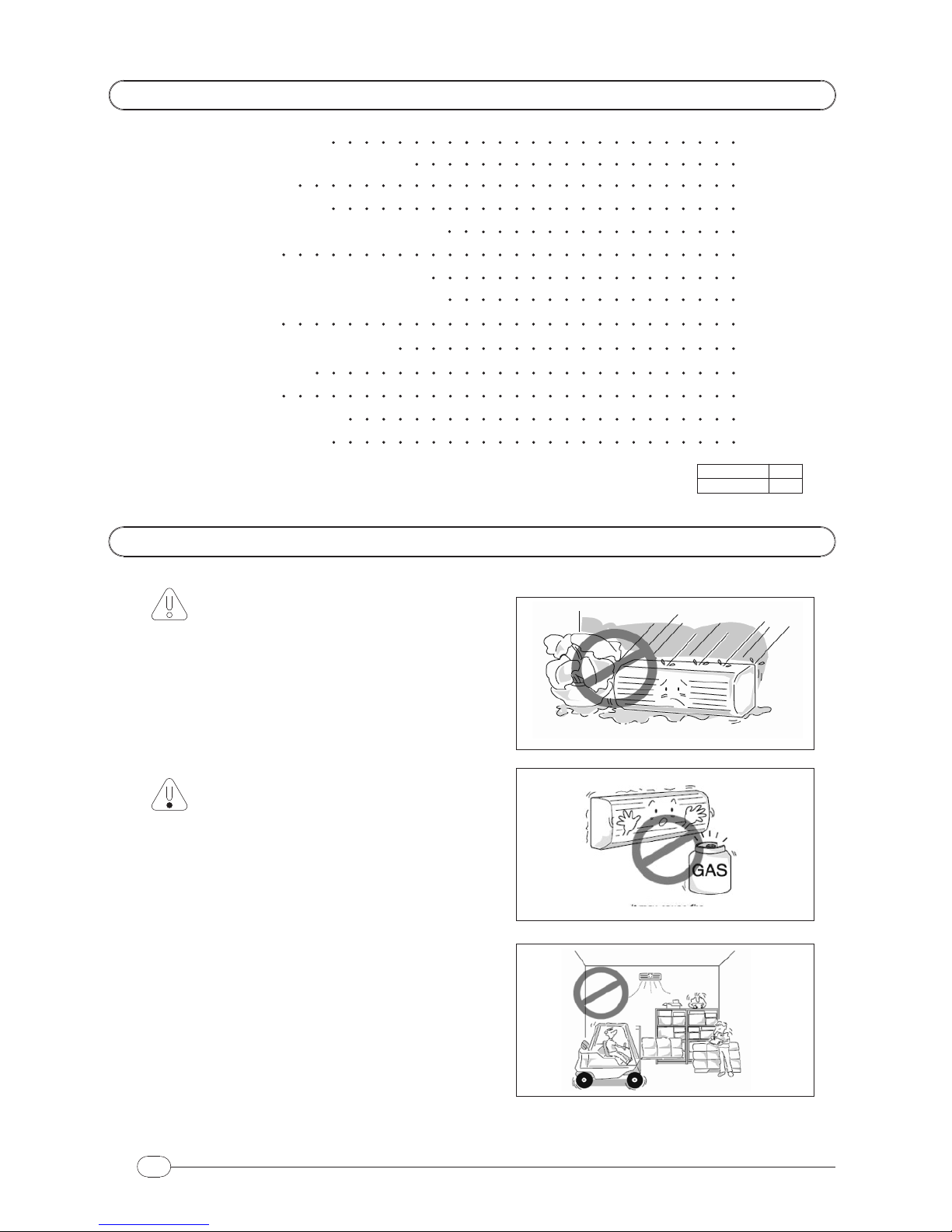

READ ALL S AFETY I NFORMATION BEFORE INSTALLATION:

* Installations m ust be p erformed by a q ualified technician.

* Check a ll local c odes a nd ordinances that c ould a ffect installation o f this u nit.

* Refer to rating plate on e ach unit f or the c orrect v oltage, f requency a nd amperes.

* Be sure t hat t he p ower s upply c orresponds to t he s pecified r ating i n t he nameplate.

* Do n ot u se e xtension cords. I n t he c ase e xtended c ables a re n eeded, install longer power

cord from terminal block.

* Before c arryi ng o ut installation, p ut on p roper i ndividual p rotection d evice(s).

Sharp e dge s and coil s urfaces a re a p otential injury hazard. A void c ontact

Moving m achinery a nd e lectrical p ower is hazardous. It m ay c ause s evere

injury or d eath. T urn o ff a nd d isconnect t he power d uring installation a nd

THIS PRODUCT MUST BE P ROPERLY G ROUNDED.

with t hem.

repair bef ore a ny s ervices are a ttempted on t he u nit.

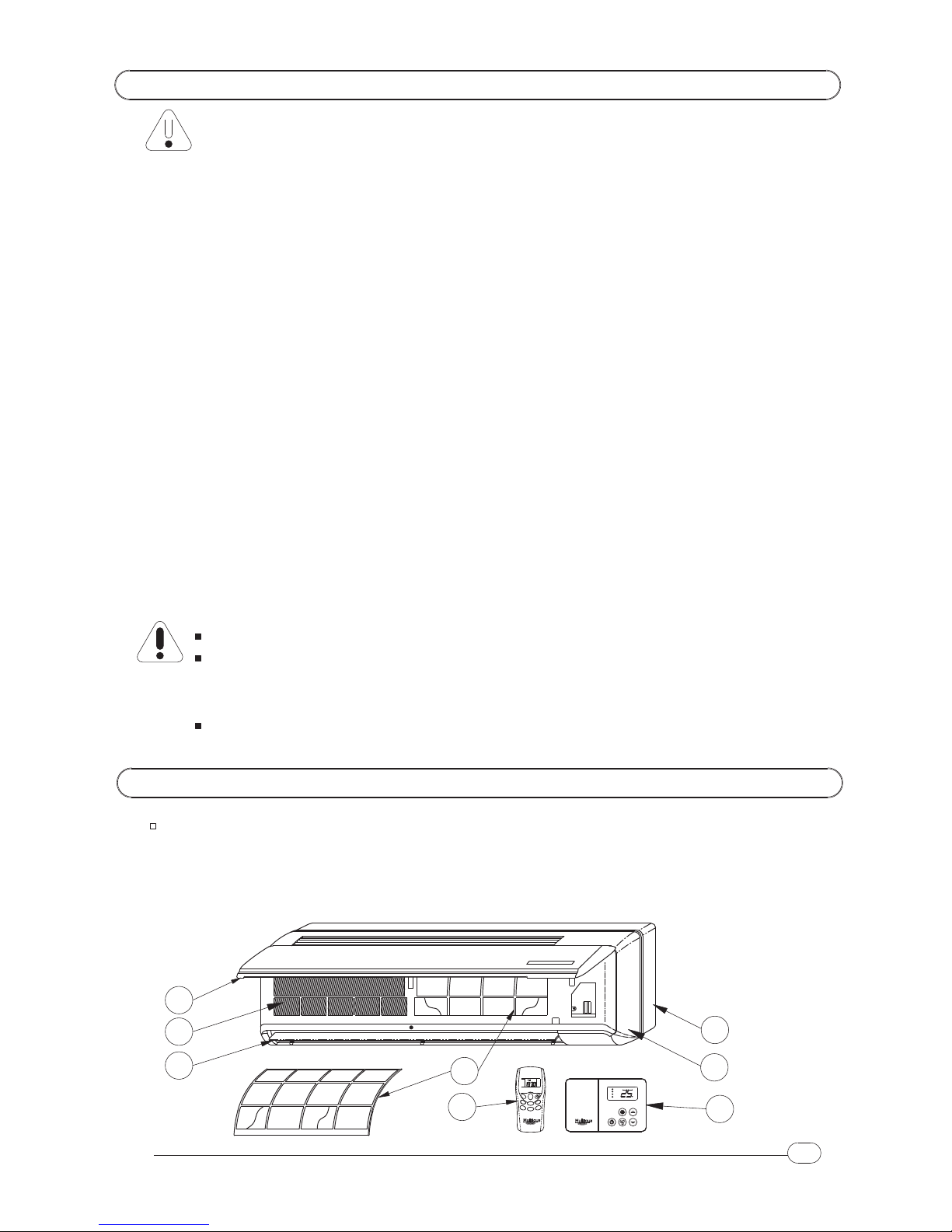

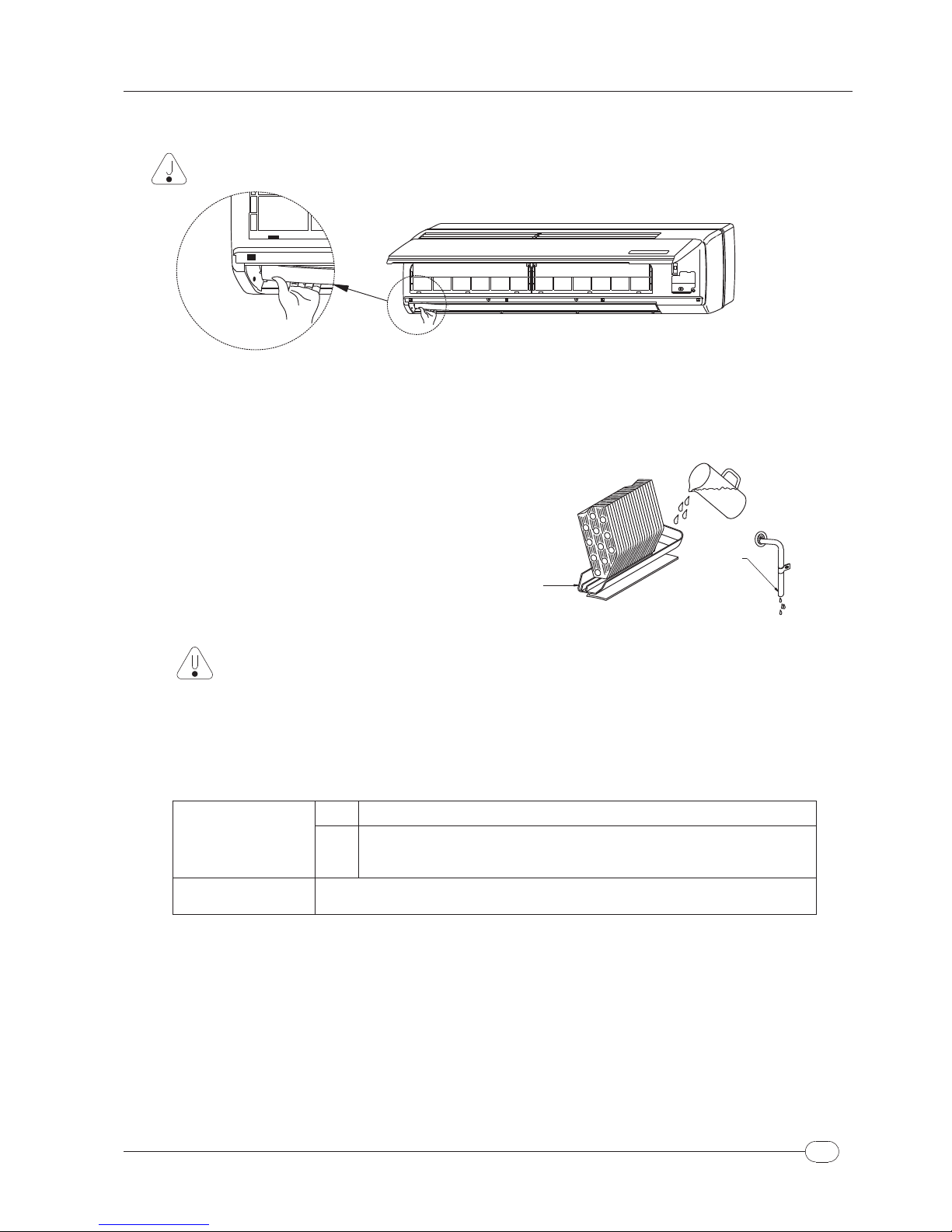

1. D eco P anel

2. E vaporator C oil

3. H orizontal L ouver

8. T hermostat C ontroller

6. B ase P an

7. F rame G rille

5. R emote Control U nit

4. Air Filters

PREP ARATIONS B EFORE INSTALLATION

MAIN C OMPONENTS

FAN C OIL U NIT

* The a ppliance s hall b e installed in a ccordance w ith n ational and local w iring r egulations.

* This a ppliance is n ot i ntended f or u se by persons not experienced or knowledgeable

on this product

.

* Means for disconnection must be inc orporated in the fixed wiring i n accordance

with t he w iring rules and local codes.

2

1

2

34

6

5

7

2. I s air i nlet o r o utlet o bstructed?

1. I s the set temperature

3. A re filters dirty?

2. I n s ufficient C ooling

or H eating.

4. I s t he re a ny o ther h eat s ource

in the r oom?

2. R emove o bjects that o bstruct

1. R eset s uitable s et tempe-

5. Is t he re a la rge n umber o f

people i n t he r oom?

suitable? rature.

the air inlet a nd o utlet.

3. C lean filters a nd o ther p art.

3. W ireless r emote

controller is not

functioning.

3. A re t he b atteries low ?

1. I s t he remote c ontrol u nit o ut

2. A re ther e any o bstructions b et-

of e ffective d istance f rom the

thermostat?

ween t he r emote controller

and thermostat ?

1. Use t he remote c ontroller w ithi n

2. R emove or c lean t he o bstruction.

sufficient d istance o f the thermostat.

3. R eplace w ith n ew b atteries.

TROUBLE S HOOTING G UIDE

If the unit appears to be malfunctioning, check the f ollowing p oints before calling

for service.

PROBLEM PROBLEM C AUSE REMEDY

2. I s t he w iring c onnection l oose?

1. H as p ower b een s hut down

3. Is t he p ower protection

1. A ir c onditioner

doesn't o perate.

in operation?

2. T ighten t he c onnection.

1. W ait for p ower to resume.

3. R eset t he power button.

4. R eplace f use

or r eset the

circuit breaker.

4. I s the fuse b lown o r circuit

breaker open?

or h as power f ailure o ccurred?

Problems that needs qualified personnel assistance.

PROBLEM PROBLEM C AUSE REMEDY

3. T erminal loose.

1. F aulty transformer, r elay a nd/or 1. Air c onditioner

doesn't run. 2. C heck the c ause o f malfunctioning

1. R eplace faulty c omponents.

3. C heck a nd retighten a ny loose

fan m otor c apacitor.

2. C ontrol b oard n ot f unctioning. and r eplace control b oard

if n ecessary.

4. I s w ater v alve or circulator

functioning ? terminals.

4. C heck to s ee if w ater v alve o r

circulator is opening o r actuating.

21

AUTO

LOW

MED

HIGH

8

CANCEL

SLEEP SEND

SWEEP MODE

HIGH COOL

TM

Multi

aqua

TM

Multi

aqua