- 4 -

14. BEFORE USING TOOL, carefully check if

there is any part damaged to obtain ideal results. Do

not use the tool if the tool has any air leaks,

uncompleted, damaged parts and needs repairing.

15. NEVER USE TOOL if safety, trigger or spring is

inoperable, missing or damaged. Do not alter or

remove safety, trigger or springs Make daily

inspections for free movement of trigger and safety

mechanism.

16.ONLY USE PARTS AND FASTENERS

recommended by us.

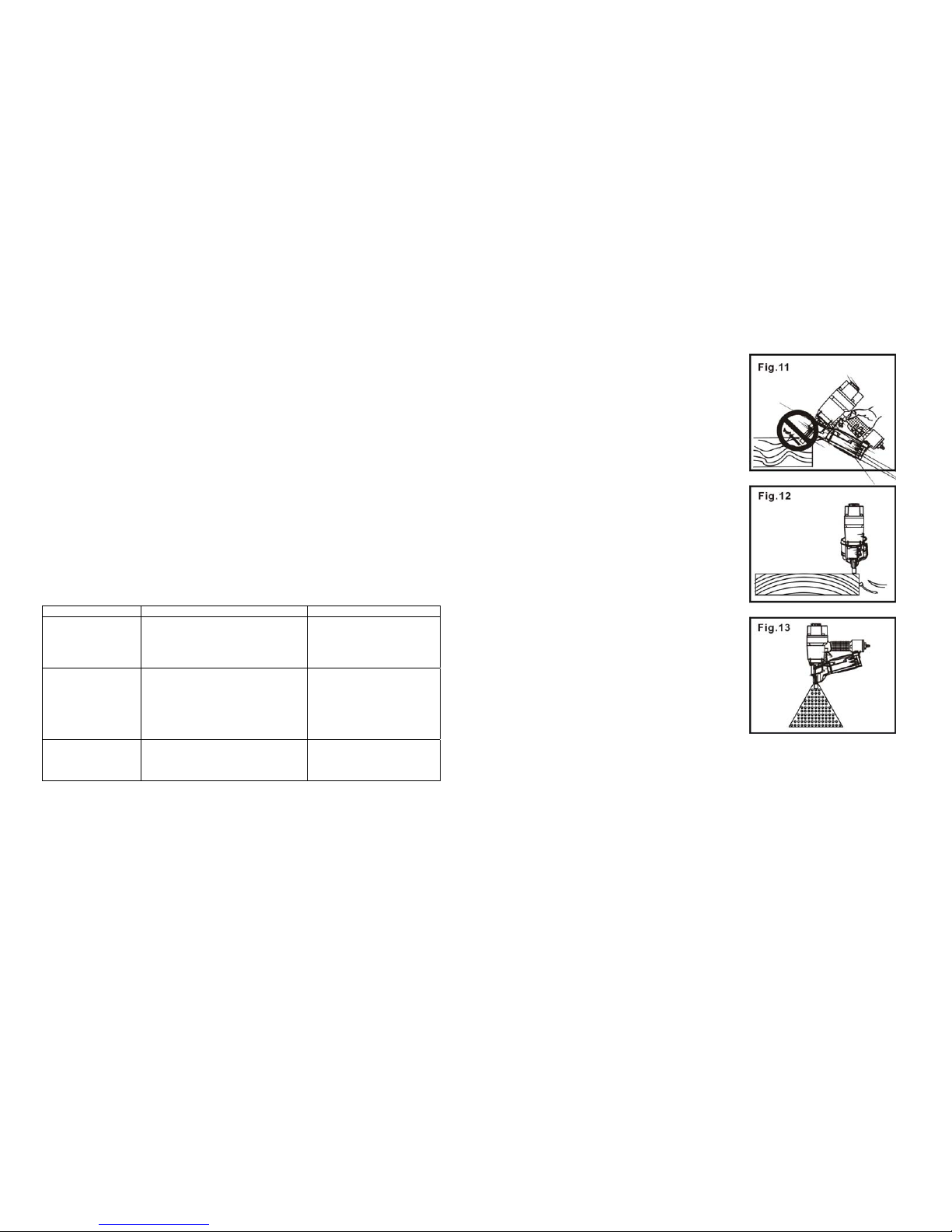

17. CONNECT TOOL TO AIR SUPPLY BEFORE

loading fasteners to prevent fastener from being fired

during connection. The tool driving mechanism

may cycle when tool is connected to the air supply.

When not in use remove all fasteners from the nail

housing.

18. ALWAYS ASSUME THE TOOL CONTAINS

FASTENERS. Keep the tool pointed away from

yourself and others at all times. No horseplay. Respect

the tool as a working implement.

19. DO NOT LOAD FASTENERS with trigger or

safety depressed to prevent unintentional firing of a

fastener.

20. REMOVE FINGER FROM TRIGGER when

not driving fasteners. Never carry tool with finger on

trigger: tool will fire a fastener if safety is bumped

while trigger is depressed.

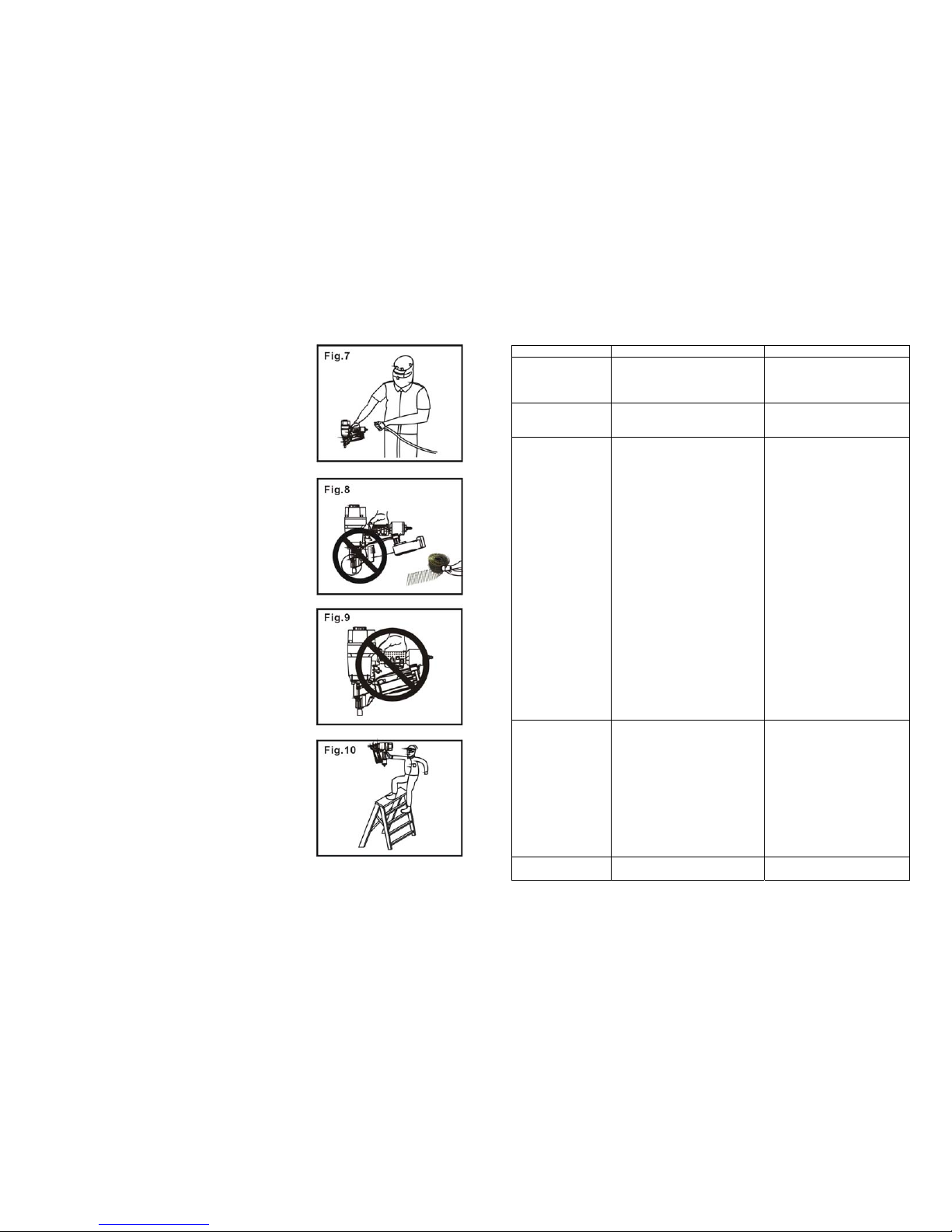

21. DON'T OVER REACH. Keep proper footing

and balance at all times when using or handling the

tool.

22. FIRE FASTENERS INTO WORK SURFACE

ONLY: NEVER into materials too hard to penetrate.

PROBLEM CAUSE SOLUTION

Failure to start tool. 1. Tool dry, lacks lubrication.

2. The spring in the cylinder cap is

damaged.

3. Valve sticks with cylinder cap.

1. Use pneumatic tool oil

2.Replace the spring in the

cylinder cap.

3.Disassemble/check/lubricate

Blade driving fasteners

too deeply 1. Safe bracket poison is not correct.

2. Air pressure is too high. 1. Rotate knob of the adjuster to

move safe bracket down.

2. Decrease air pressure.

Skipping

fasteners/ feeding

intermittently

1. Having foreign matters between the

small piston and small cylinder.

2. O-ring on the small piston is worn

and damaged.

3. Tool dry and lacks lubrication.

4. The spring on the small piston is

damaged.

5. Air pressure is lower.

6. Connecting screw of nose and body

is loose.

7. Stopped hook can't stop the

fasteners.

8. Bent fasteners.

9. Wrong size fasteners.

10. Gasket is damaged.

11.Dry small piston

12. Small piston bumper is worn and

damaged.

13. Feed hook is binding.

14. Nail length is not correct with

loading space of nail housing.

15. Weld wires in nail coilare broken.

1. Disassemble/ clean/lubricate.

2.Check/replaceO-ring/ lubricate

3. Use pneumatic ic tool oil.

4. Replace small piston the spring.

5. Increase the air pressure, but don't

exceed 120 PSI (8.3 bar).

6. Tighten al l screws.

7.Replace taper spring of the

stopped hook.

8. Use recommended fasteners.

9.Use recommended fasteners

10. Replace gasket/t tighten screw.

11. Open nai l housing, place several

drops of pneumatic tool oil into end

cover hole of the small piston.

12.Replace bumper and lubricate

small piston.

13. Clean feed hook and torsion

spring.

14.Adjust adjusting nut at the nail

housing tail portion according to the

recommended nail length to make

arrow on the nail housing tail point

to correct direction.

15. Stop using.

Runs slowly or has

power loss 1. Tool dry, lacks lubricate ion

2. The spring in the cylinder cap is

damaged.

3. Having foreign matters between

piston assembly and cylinder.

4. Have not assembled the cylinder to

home posit ion.

5. O-ring on the valve is dry after

disassembly.

6. Air pressure is too low.

7.Driver is worn (sort)

8. Inner diameter of hose is small.

1. Use pneumatic tool oil.

2. Replace the spring in the cylinder

cap.

3. Disassemble/clean/lubricate.

4. Reassemble after disassembling.

5.Reassemble after lubricating

6. Increase the air pressure, but don't

exceed 120 PSI (8.3 bar).

7. Replace piston assembly.

8. Use bigger inner diameter of the

hose.

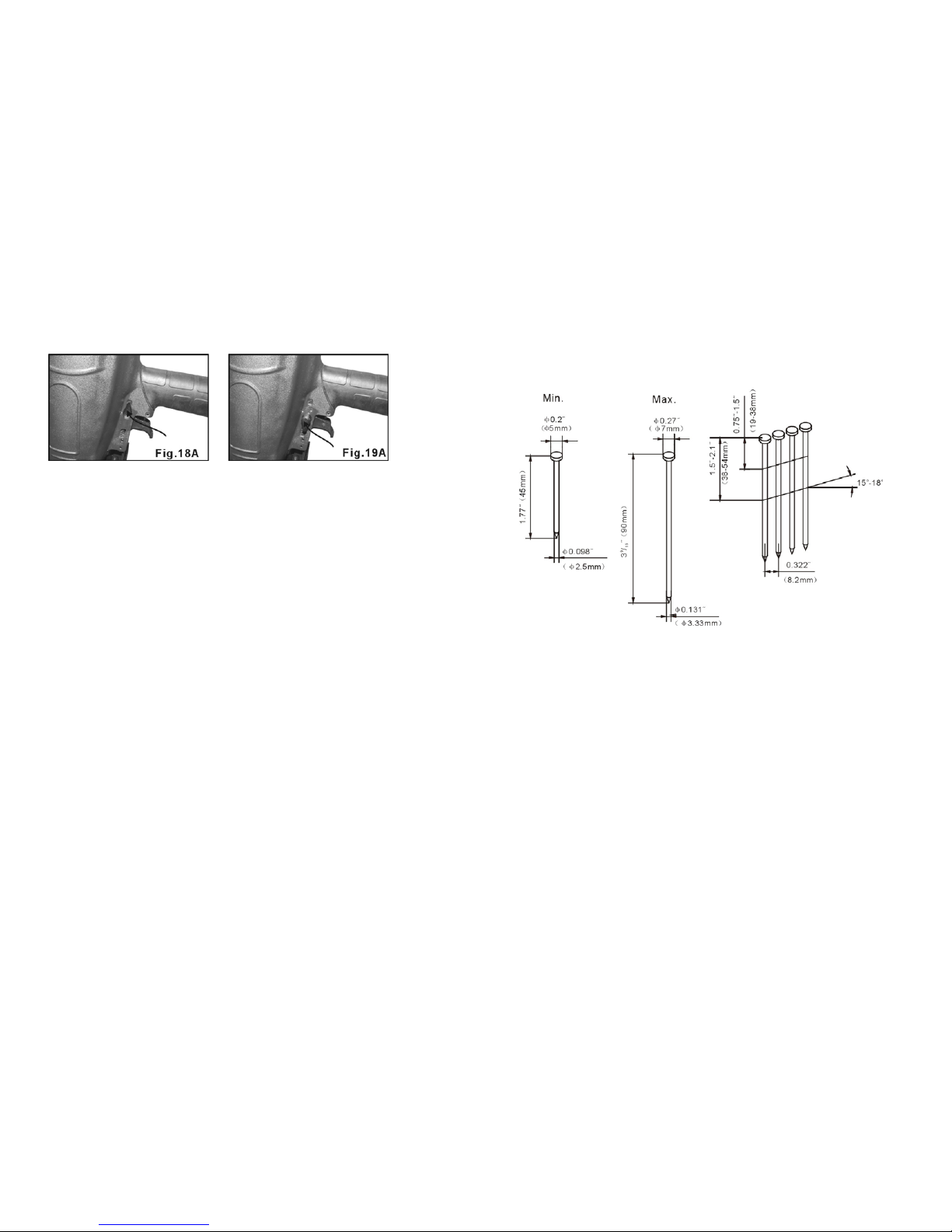

Fasteners are jammed 1. Fasteners are wrong size.

2. Weld wires in nail coil are broken. 1. Use recommended fasteners.

2. Stop using.