Introduction

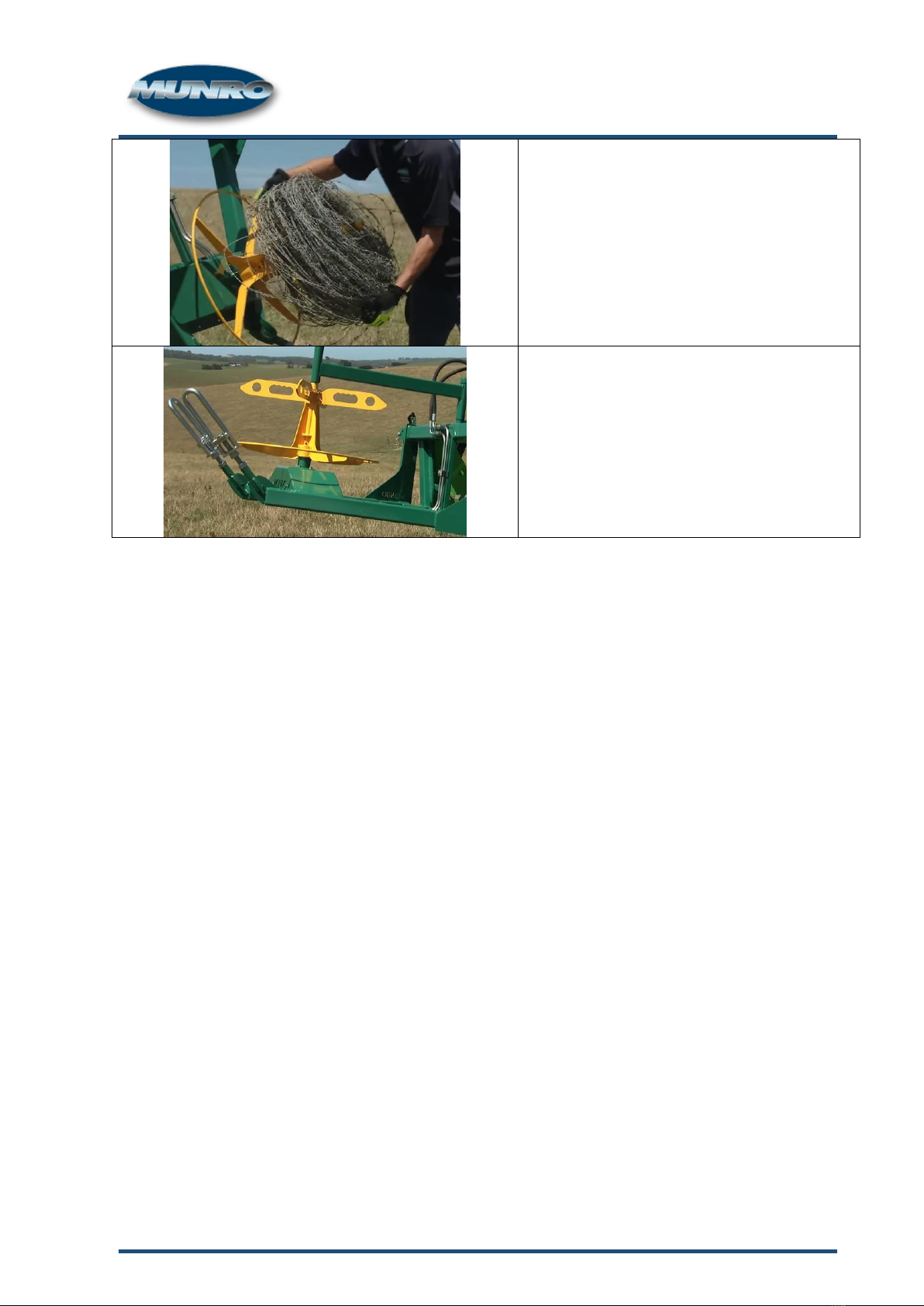

This manual has been written to assist the operator/owner with training,

operating, servicing and preventive maintenance of the Munro Wire Winder.

All safety and maintenance procedures should be followed to prevent

operator injuries and damage to the Wire Winder.

Please read thoroughly and familiarize with all points in this manual before

operating.

Safety

Please read and familiarize yourself with the following safety points before

operating the Wire Winder.

•Always use caution and care when operating, check all clearances

before engaging winder.

•When operating the Wire Winder ensure spool top and brace are

installed and that the main shaft wedge and retaining pin are

installed securely.

•Do not over fill the spool.

•Ensure that the Wire Winder is in good working order. Do not

operate if equipment is damaged or defective.

•Do not allow any person/s to approach the Wire Winder or wire/s

connected to the Wire Winder when it is being operated.

•Do not dismount from vehicle while Wire Winder is operating.

•Ensure that maintenance is carried out regularly as listed in this

manual.

•It is recommended that the operator wear safety clothing/equipment

when practical.

Warranty

A 12-month warranty covers that the equipment manufactured shall be free

from defects in workmanship and materials when the Wire Winder has been

properly operated, maintained and used under normal conditions. The

warranty period shall commence when the Wire Winder is shipped from Munro

Engineers.

The warranty shall not cover ordinary wear and tear of the equipment and any

modifications the owner has carried out.

Munro Engineers makes no warranty of any kind whatsoever with respect to

Parts manufactured or supplied by other persons; however Munro Engineers

shall assist the buyer in connection with warranties provided by others.