■Specifications and Test Methods (Only for mobile devices)

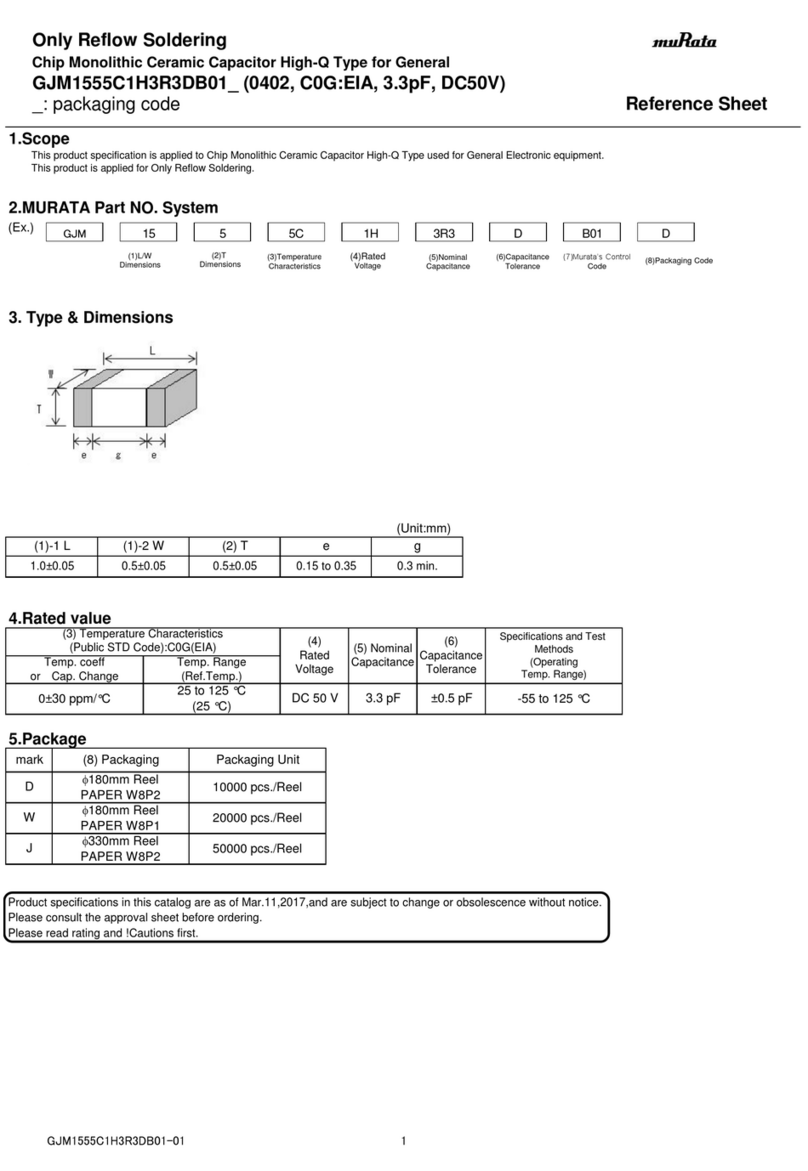

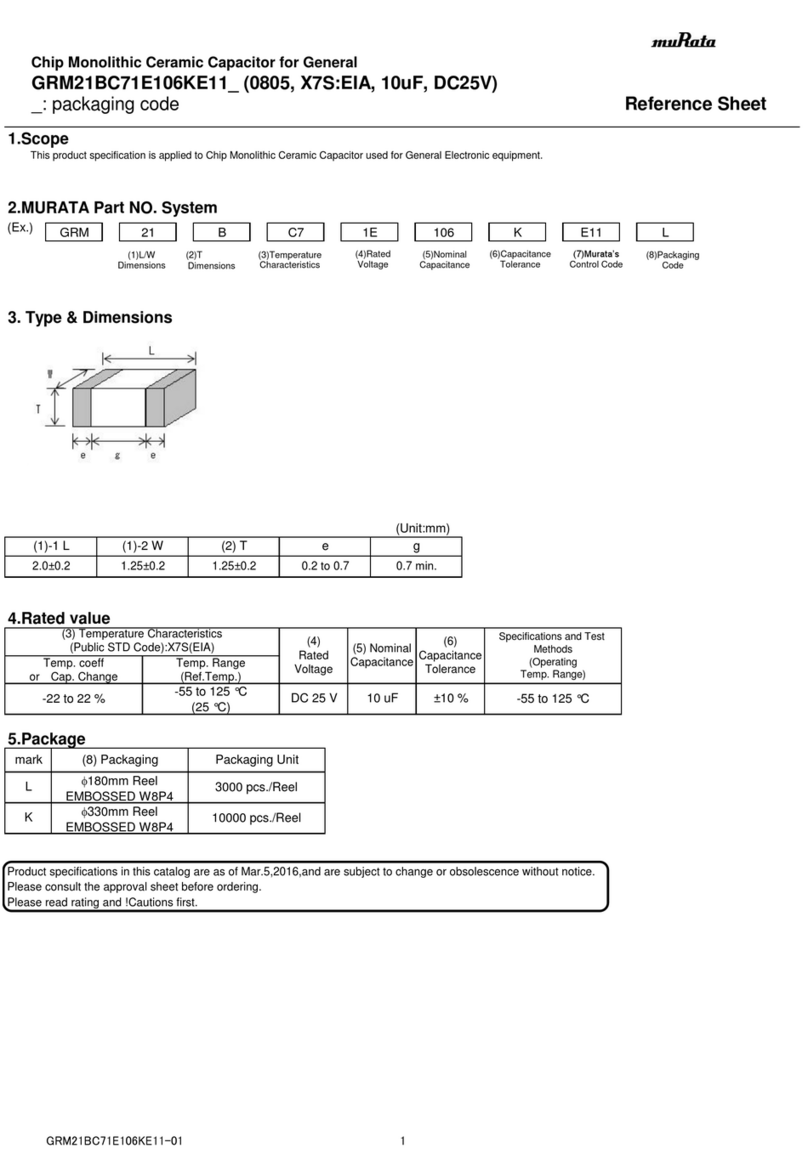

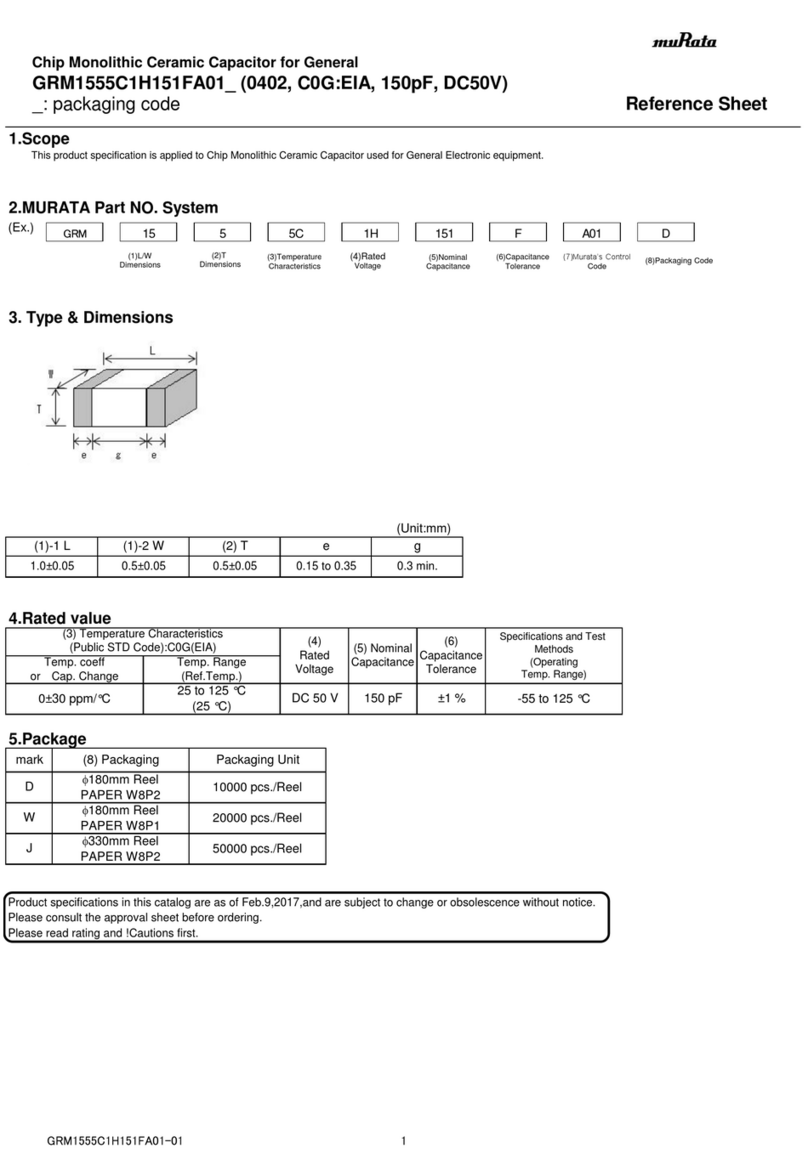

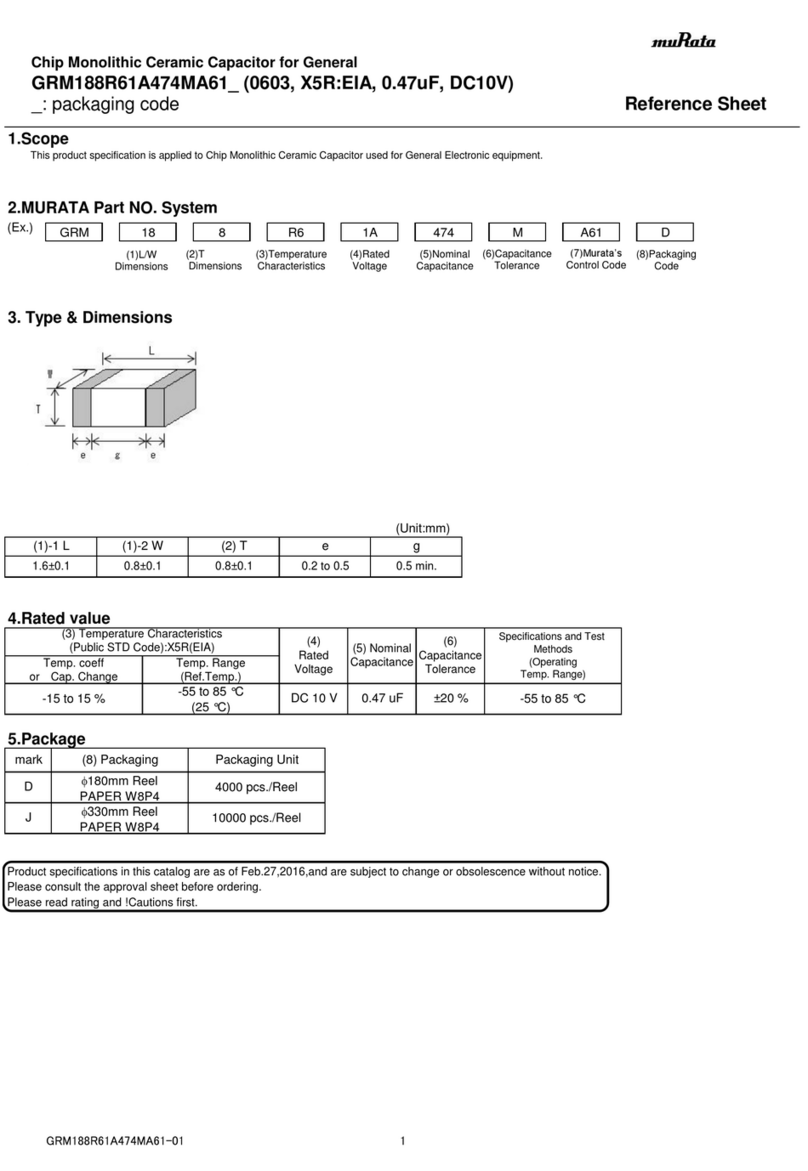

1 Rated Voltage Shown in Rated value. The rated voltage is defined as the maximum voltage which may be

applied continuously to the capacitor.

When AC voltage is superimposed on DC voltage, VP-P or VO-P,

whichever is larger, should be maintained within the rated voltage

range.

2 Appearance No defects or abnormalities. Visual inspection.

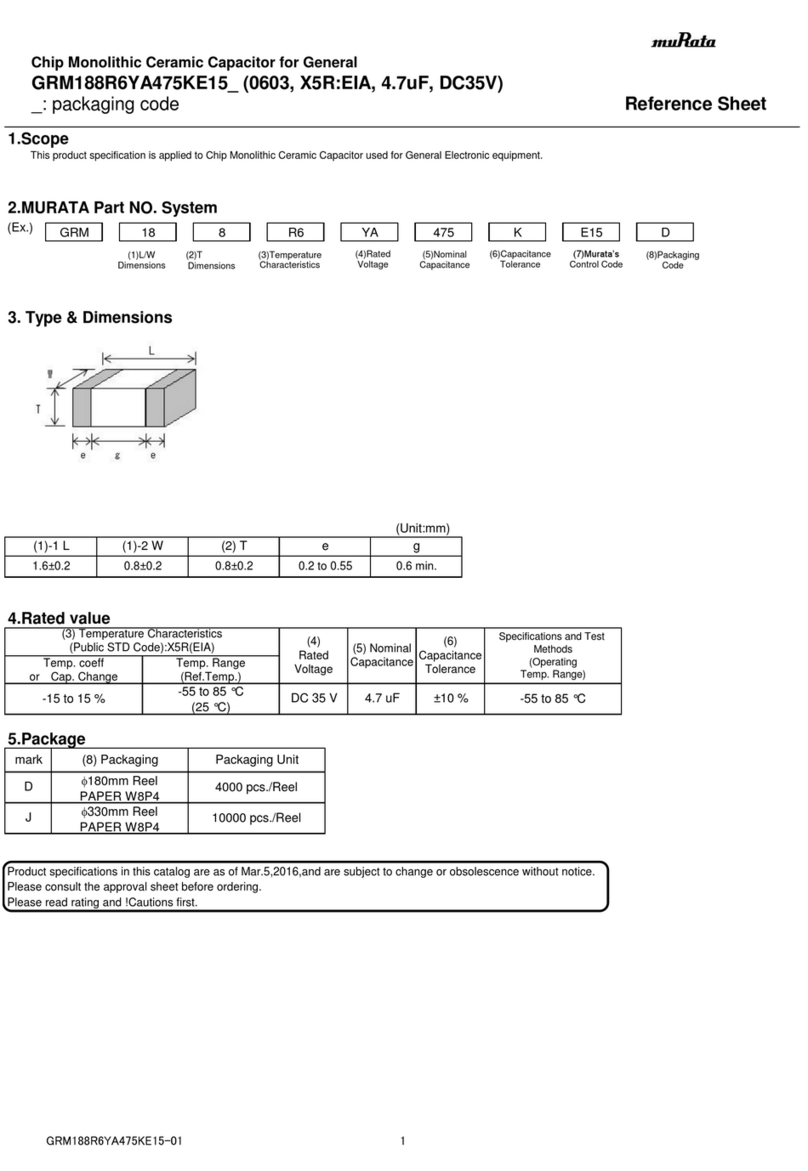

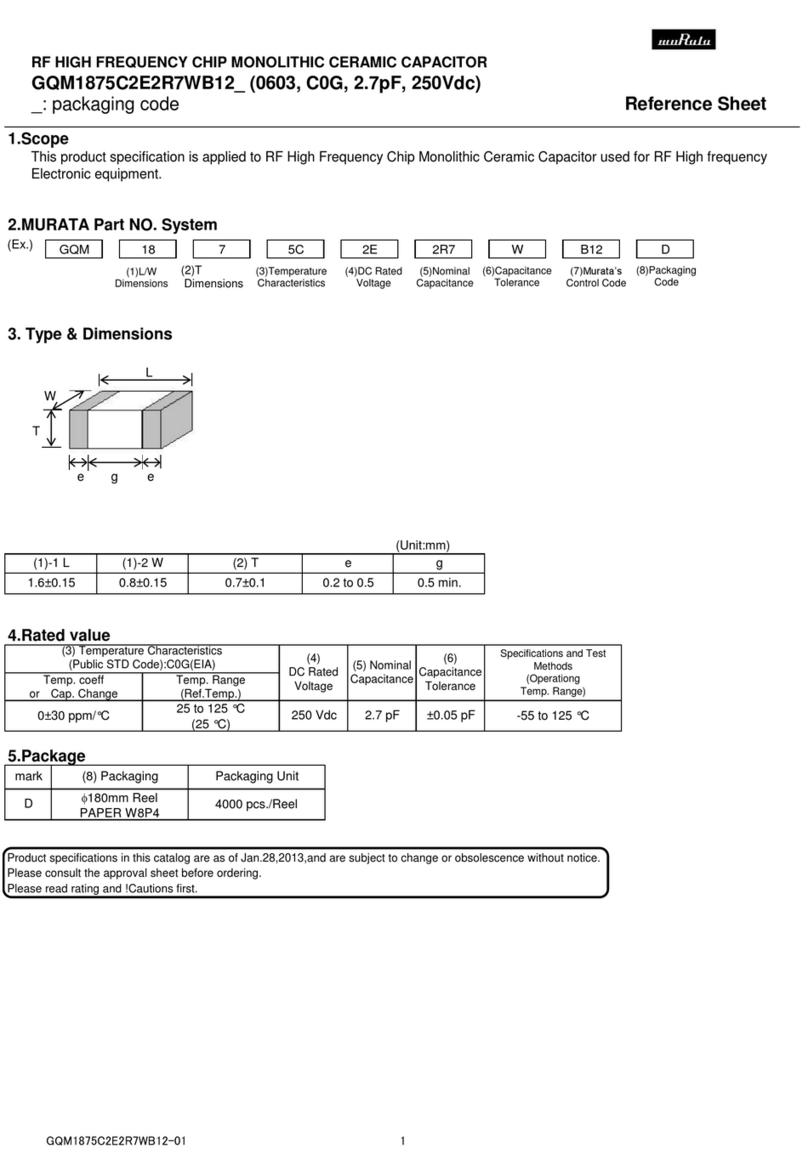

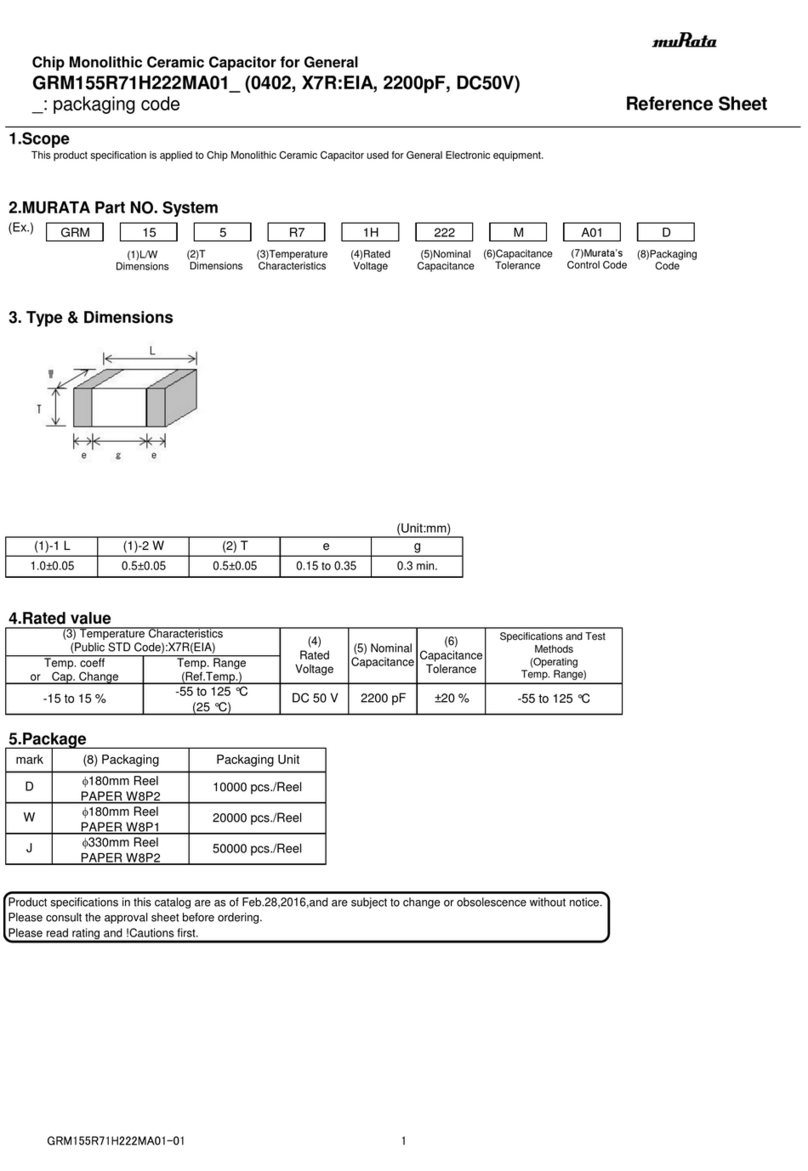

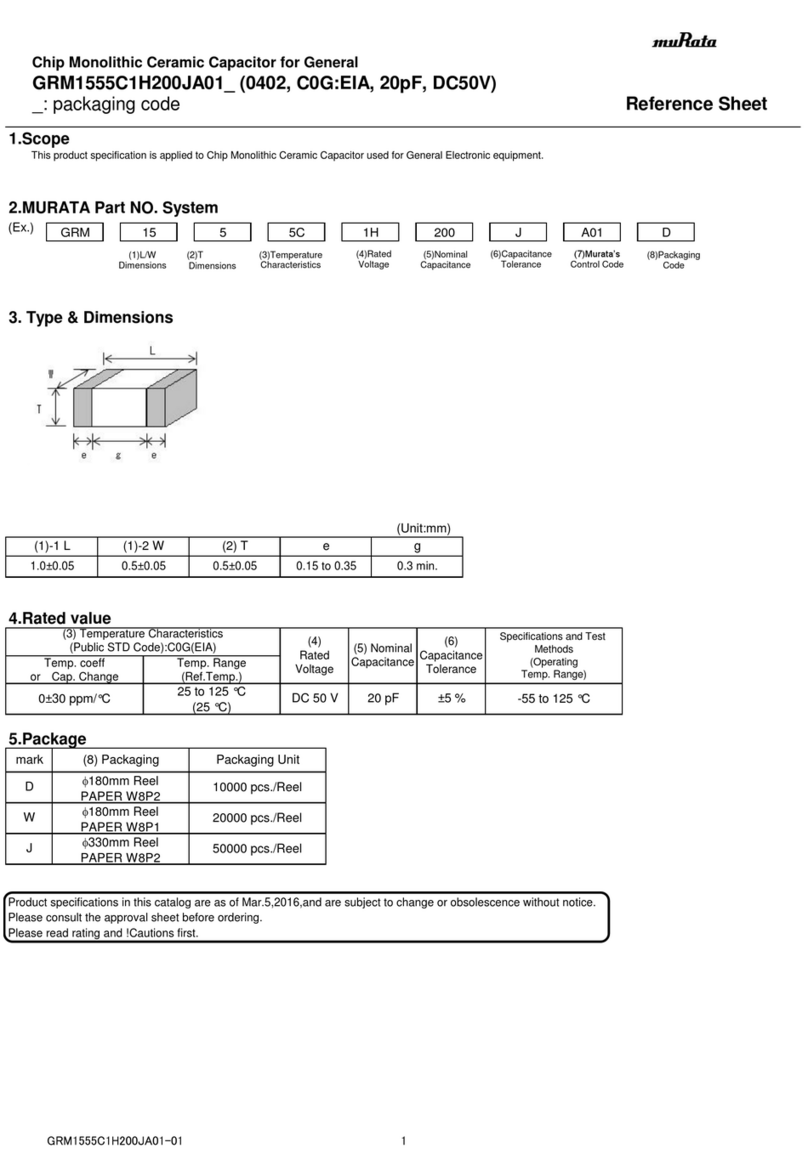

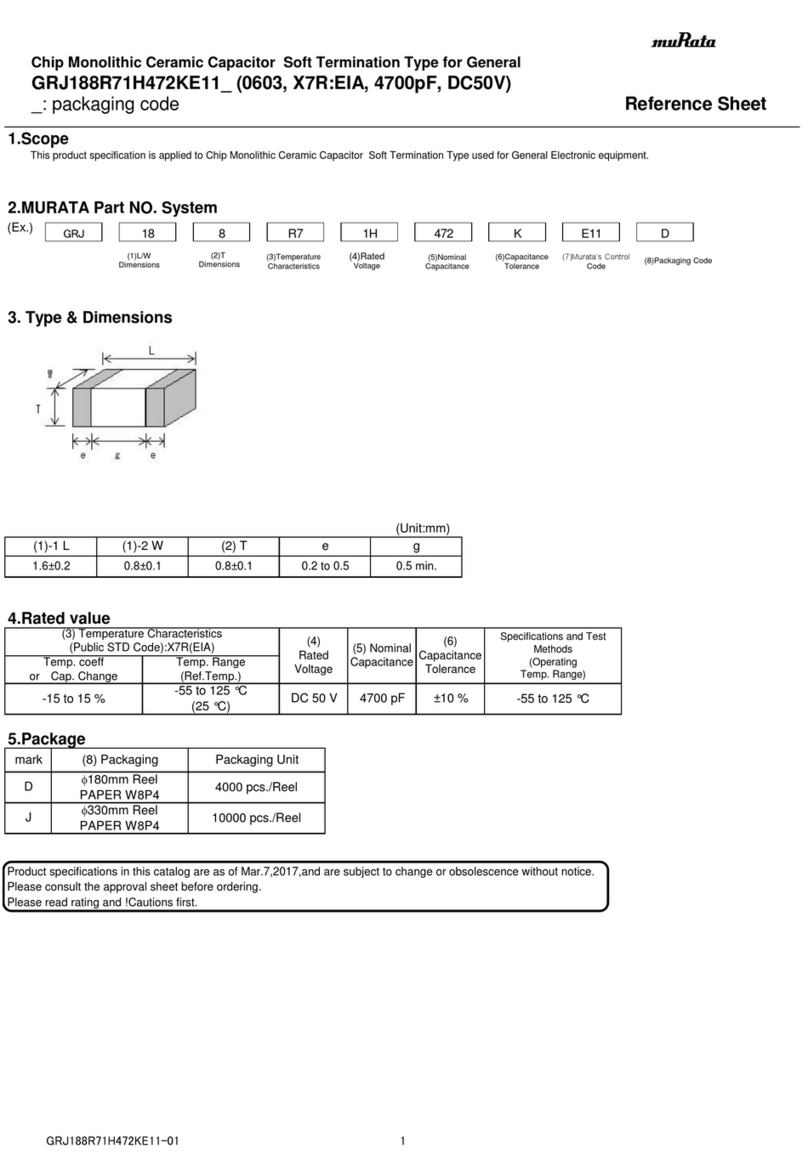

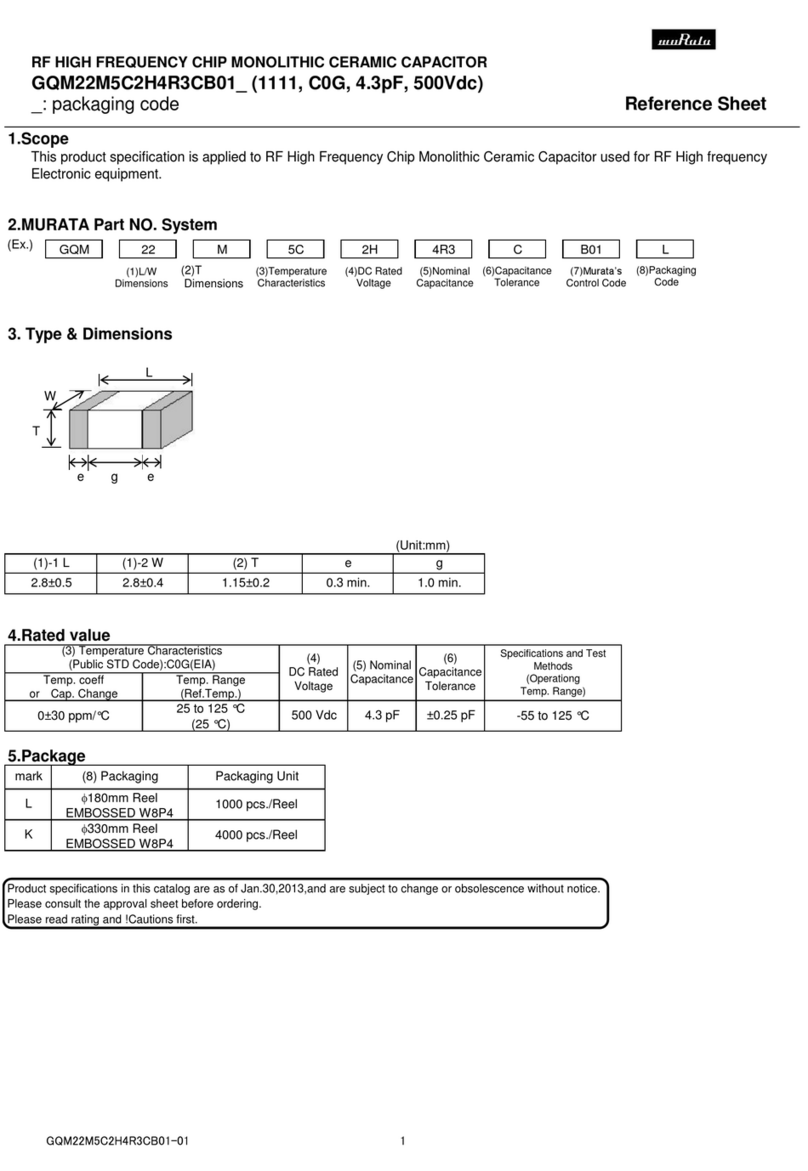

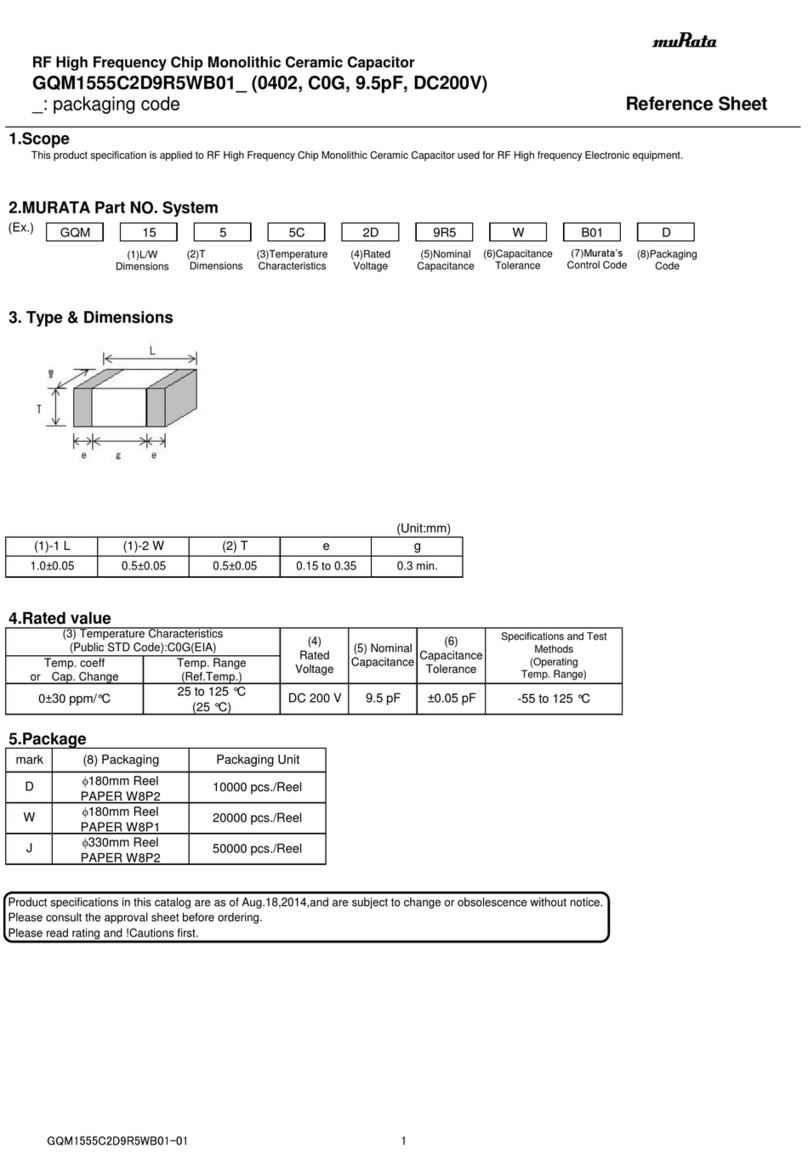

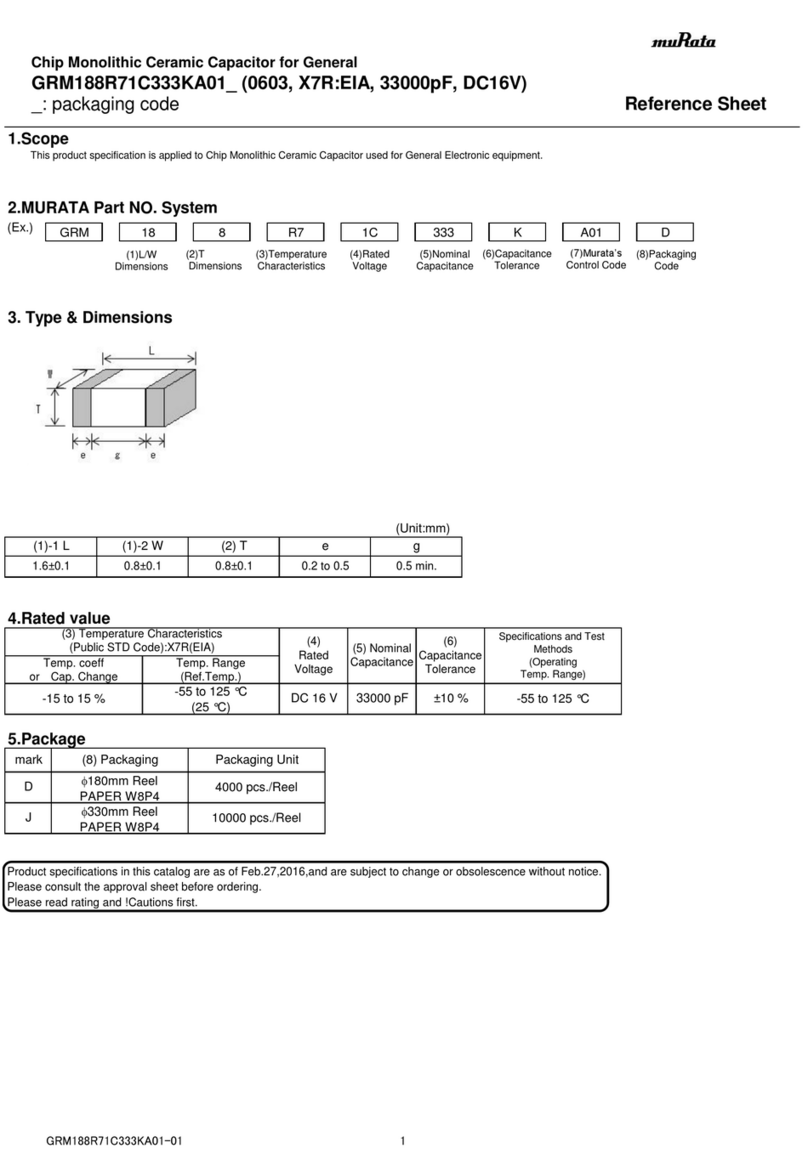

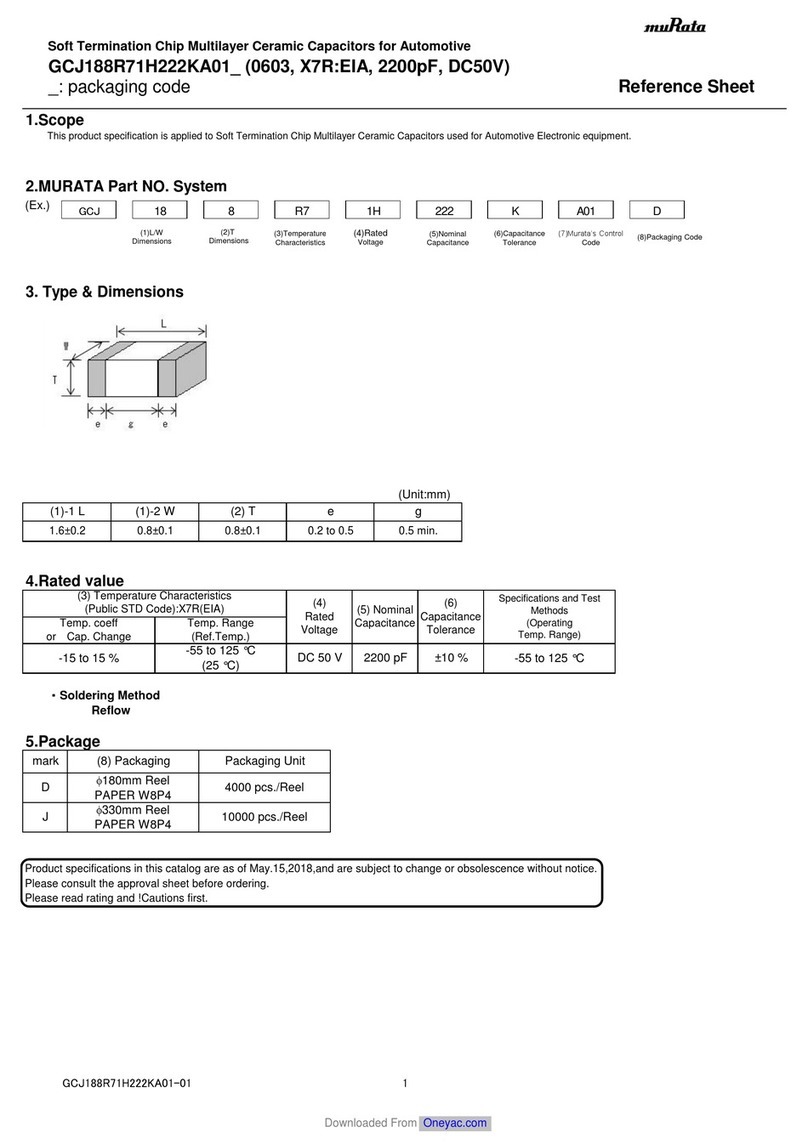

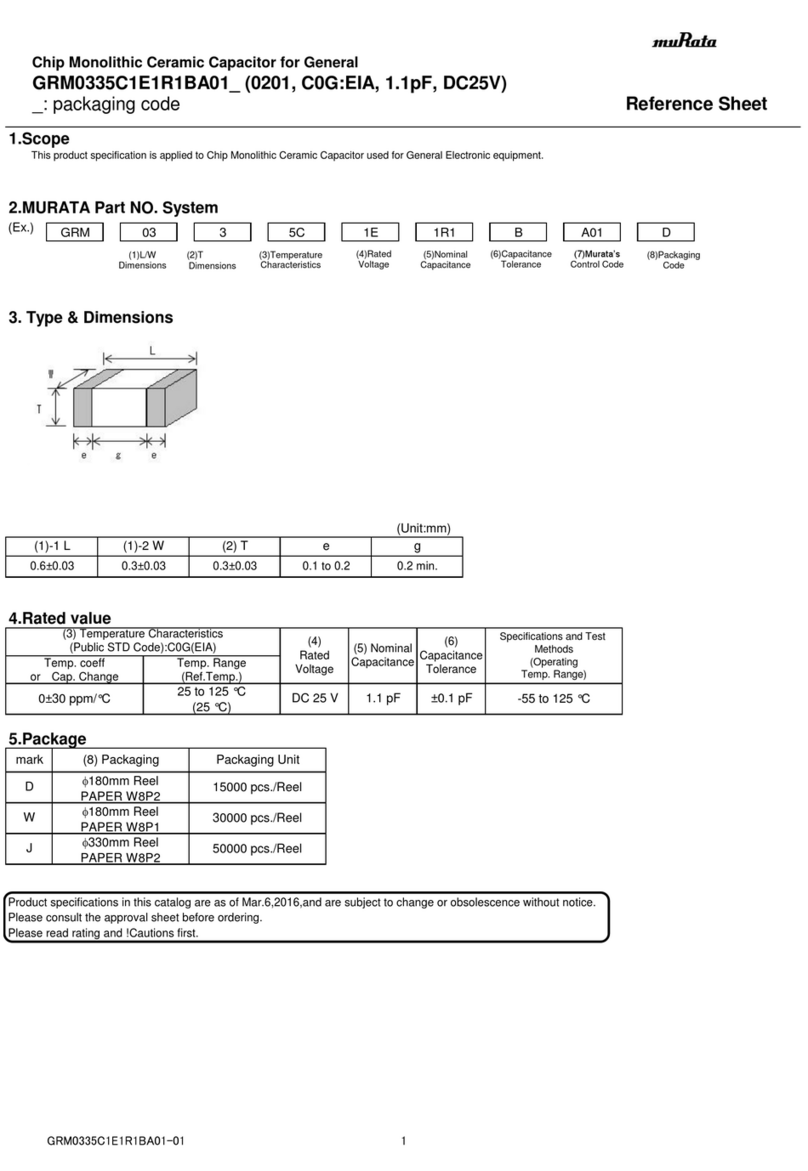

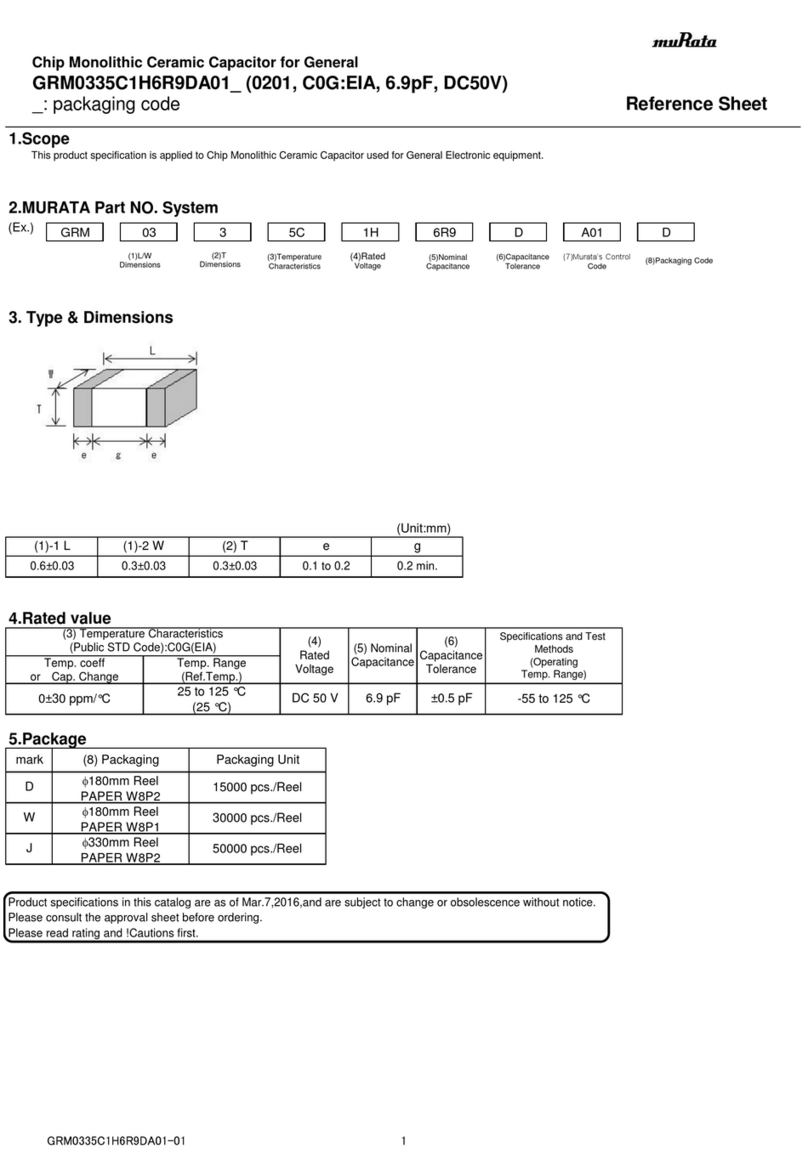

3 Dimension Within the specified dimensions. Using calipers. (GRM02 size is based on Microscope)

4 Voltage proof No defects or abnormalities.

250% of the rated voltage

Charge/discharge current :

5 Insulation Resistance(I.R.)

Measurement Point : Between the terminations

Charge/discharge current :

Measurement Temperature :

6 Capacitance Shown in Rated value.

Measurement Temperature :

7 Dissipation Factor (D.F.) B1,R1,B3,R6,R7,C6,C7,C8,E7,D7 : 0.1 max.

D8,GRM31CR60J107 : 0.15 max

GRM31CR71E106 : 0.125 max

*1 For items listed in Table 1 on the left, the capacitance should

be measured using a voltage of 0.5+/-0.1Vrms instead of

1.0+/-0.2Vrms.

*2 For item GRM188R70J105, the capacitance should be measured

using a voltage of 1.0+/-0.2Vrms instead of 0.5+/-0.1Vrms.

6.Capacitance

Perform a heat treatment at 150+0/-10°C for 1h and then

let sit for 24+/-2h at room temperature,then measure.

8

Temperature No bias B1,B3 : Within +/-10% (-25°C to +85°C) The capacitance change should be measured after 5 min.

Characteristics R1,R7 : Within +/-15% (-55°C to +125°C) at each specified temp. stage.

of Capacitance R6 : Within +/-15% (-55°C to +85°C) In case of applying voltage, the capacitance change should be

C6 : Within +/-22% (-55°C to +85°C) measured after 1 min. with applying voltage in equilibration of

C7 : Within+/-22% (-55°C to +125°C) each temp. stage.

C8 : Within +/-22% (-55°C to +105°C) Capacitance value as a reference is the value in step 3.

E7 : Within +22/-56% (-55°C to +125°C)

D7 : Within +22/-33% (-55°C to +125°C) · Measurement Voltage : 0.20+/-0.03Vrms

D8 : Within +22/-33% (-55°C to +105°C)

50% of B1: Within +10/-30%

the rated R1: Within +15/-40%

・Initial measurement

Perform a heat treatment at 150+0/-10°C for 1h and then

let sit for 24+/-2h at room temperature,then measure.

9 Adhesive Strength No removal of the terminations or other defect Solder the capacitor on the test substrate shown in Fig.3.

of Termination should occur.

Holding Time : 10+/-1s

Applied Direction : In parallel with the test substrate and vertical with the

capacitor side.

Test Method

(Ref. Standard:JIS C 5101, IEC60384)

Type Applied Force(N)

GRM02 1

GRM03 2

GRM15/GRM18 5

GRM21/GRM31/GRM32 10

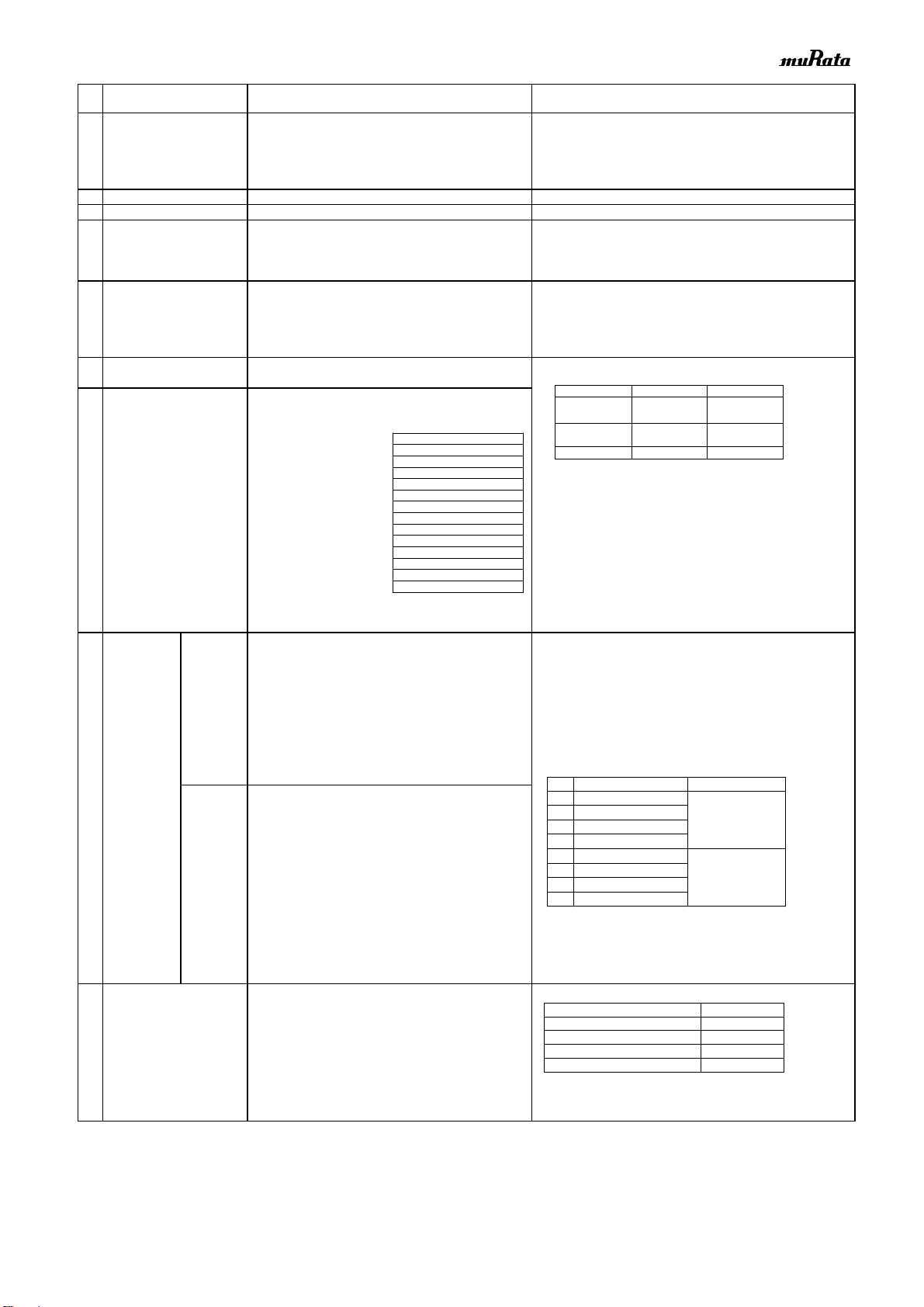

These Part Numbers are designed for use in the circuits where

continuous applied voltage to the capacitor is derated than rated

voltage, and guarantee Durability Test with 100% × rated voltage

as testing voltage at the maximumoperating temperature.

The voltage and temperature derating conditions on the left are

recommended for use to ensure the same reliability level as

These MLCC products are designed for use in devices with a typicallifetime of less than 5 years.

(Examples: Cellular phone, Smartphone, Tablet PC, Digitalcamera, Watch, Electronics dictionary,

Small-scale server, IPC-9592Bclass1 equipment, etc.)

These MLCC products are designed so that the useful lifetime can be extended longer than 5 years

under the following conditions:

「80% of the rated voltage or less, Maximumoperating temperature -20 degree Cor less」

Extended useful lifetime, under specific operating conditions, can be estimated from

the chart on the left.

※The useful lifetime is the time when cumulative failure rate becomes 1%.

※Please note that the useful lifetime data is for reference only and not guaranteed.

0.1

1

10

100

40 50 60 70 80 90 100 110 120 130

at rated voltage x 80%

85℃Type 105℃Type

50% of

the rated voltage

(For B1,R1)

GRM033 B3/R6 1A 123 to 823

GRM155 B3/R6 1A124 to 105