Murata GRT31CR61C335KE01 Series User manual

Other Murata Industrial Electrical manuals

Murata

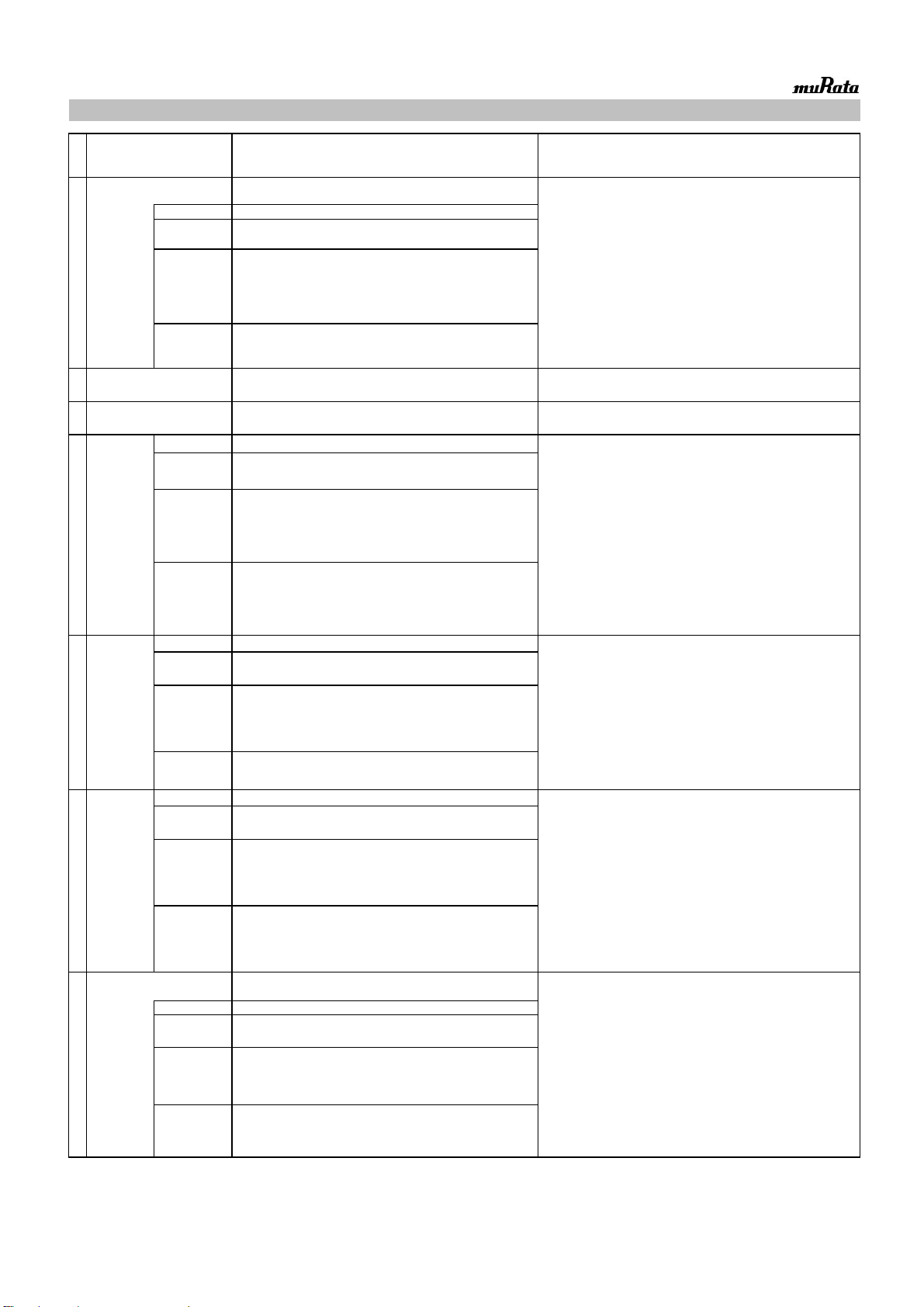

Murata GRM185C81A475KE11 Series User manual

Murata

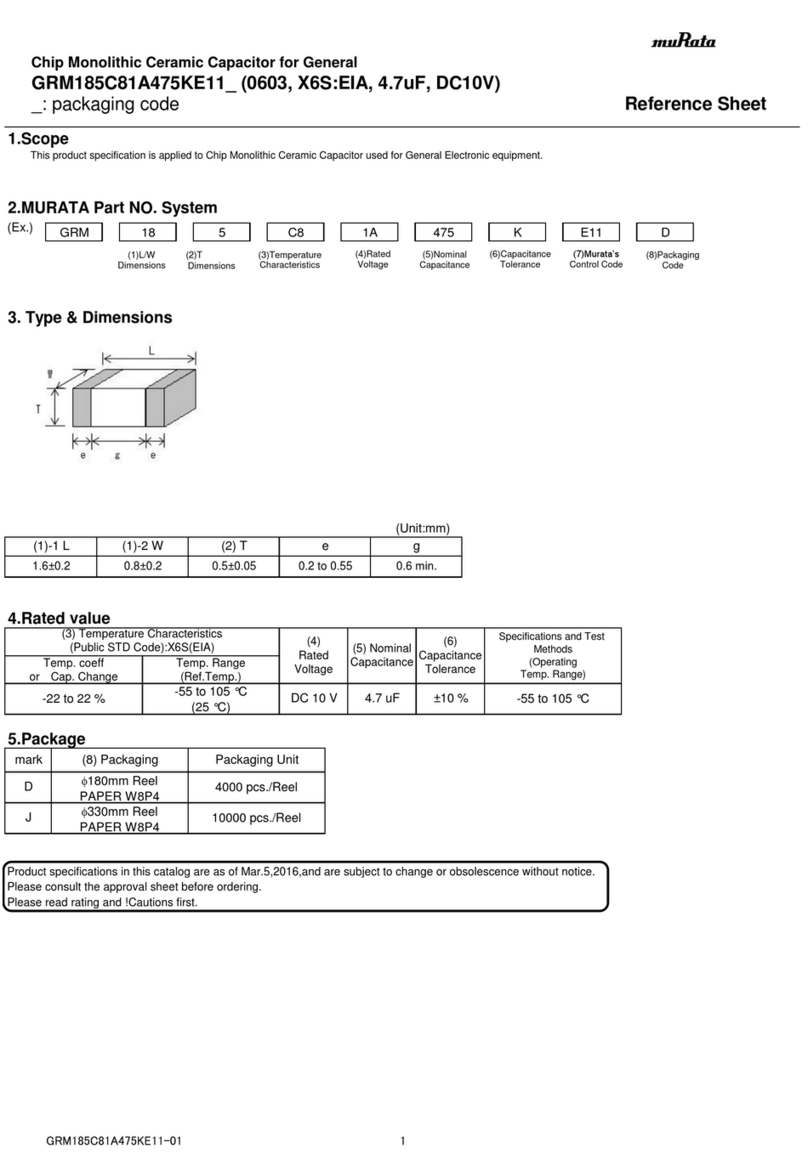

Murata GRM0225C1C150JD05 Series User manual

Murata

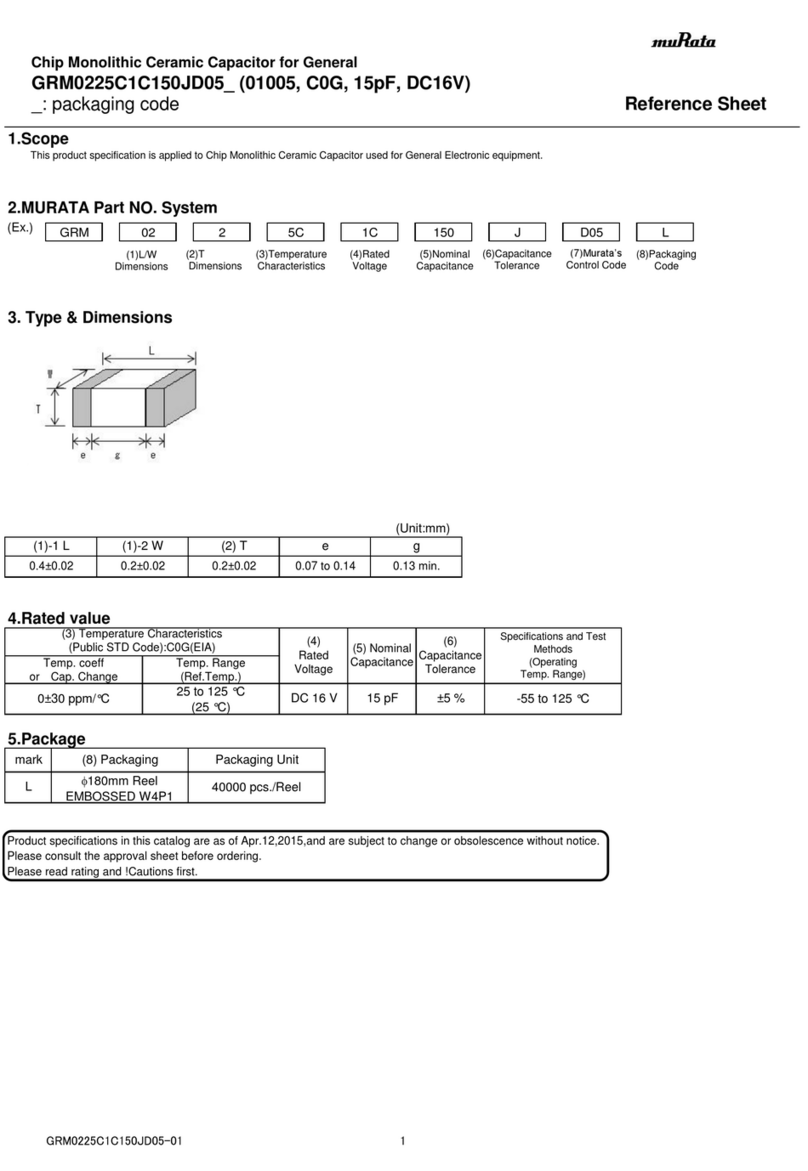

Murata GRM2197U1A563JA01 Series User manual

Murata

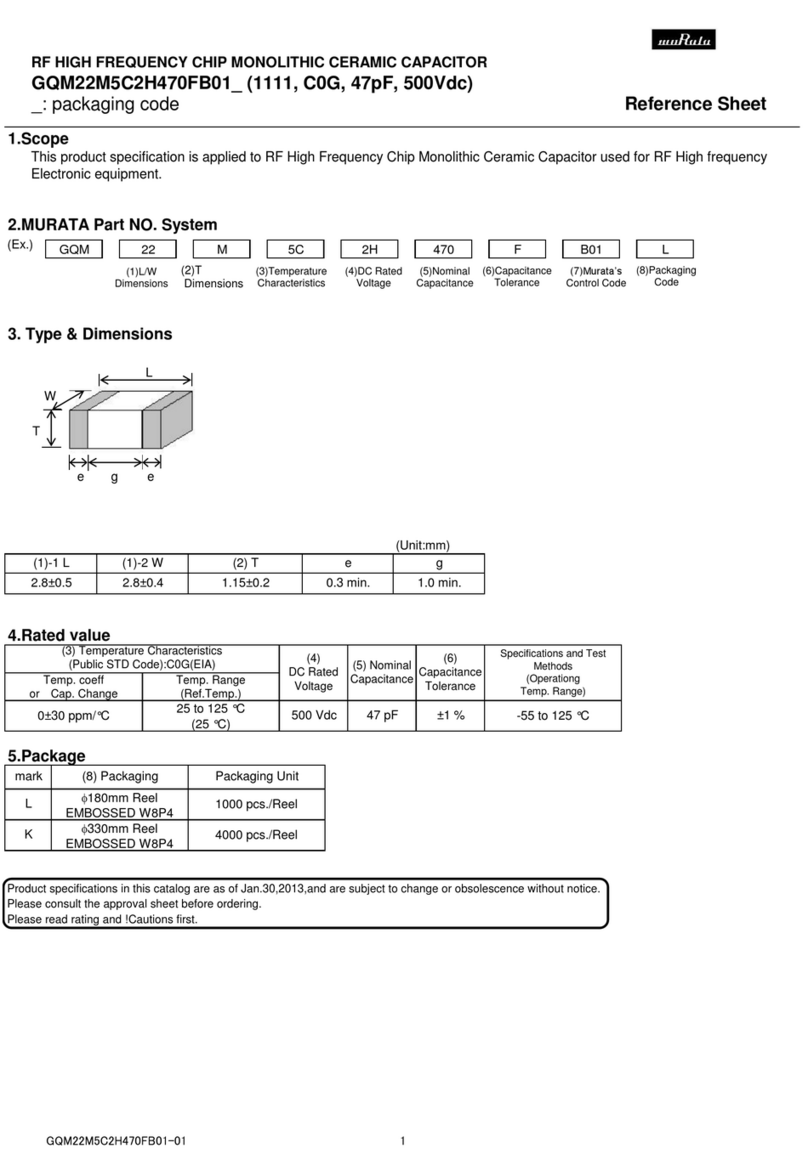

Murata GQM22M5C2H470FB01 Series User manual

Murata

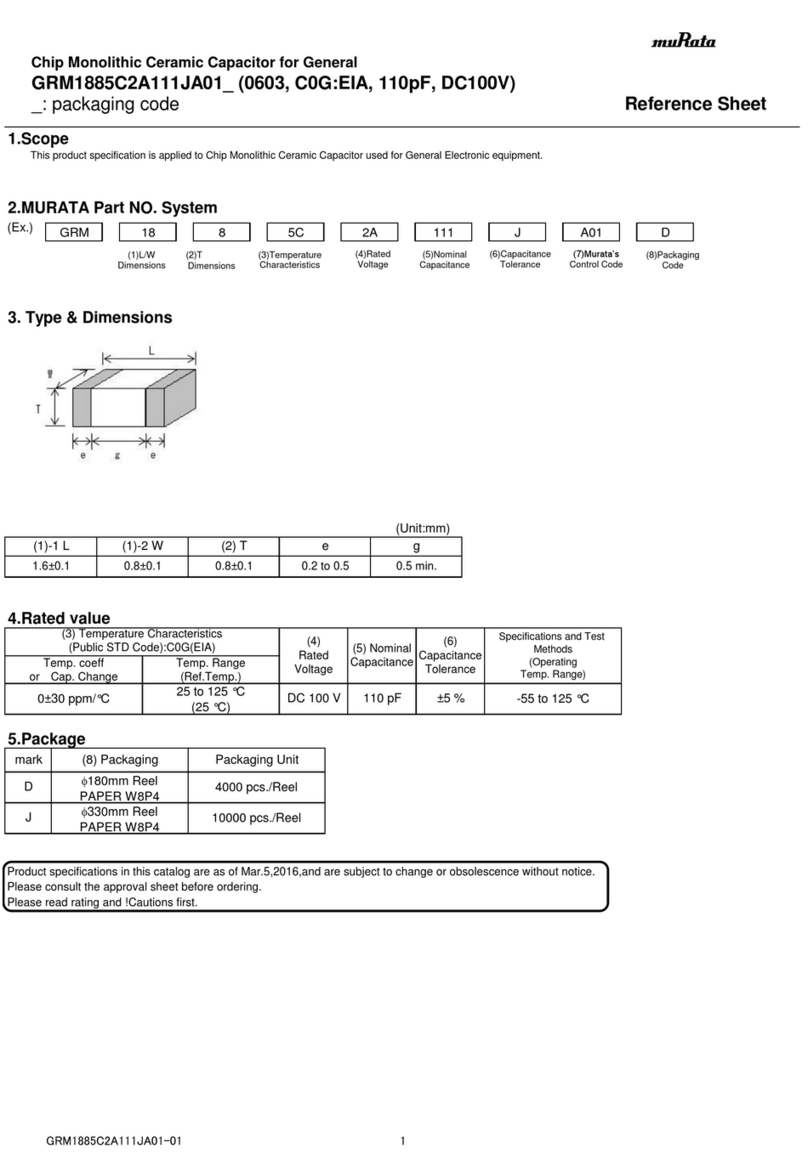

Murata GRM1885C2A111JA01 Series User manual

Murata

Murata GJM1555C1H130GB01 Series User manual

Murata

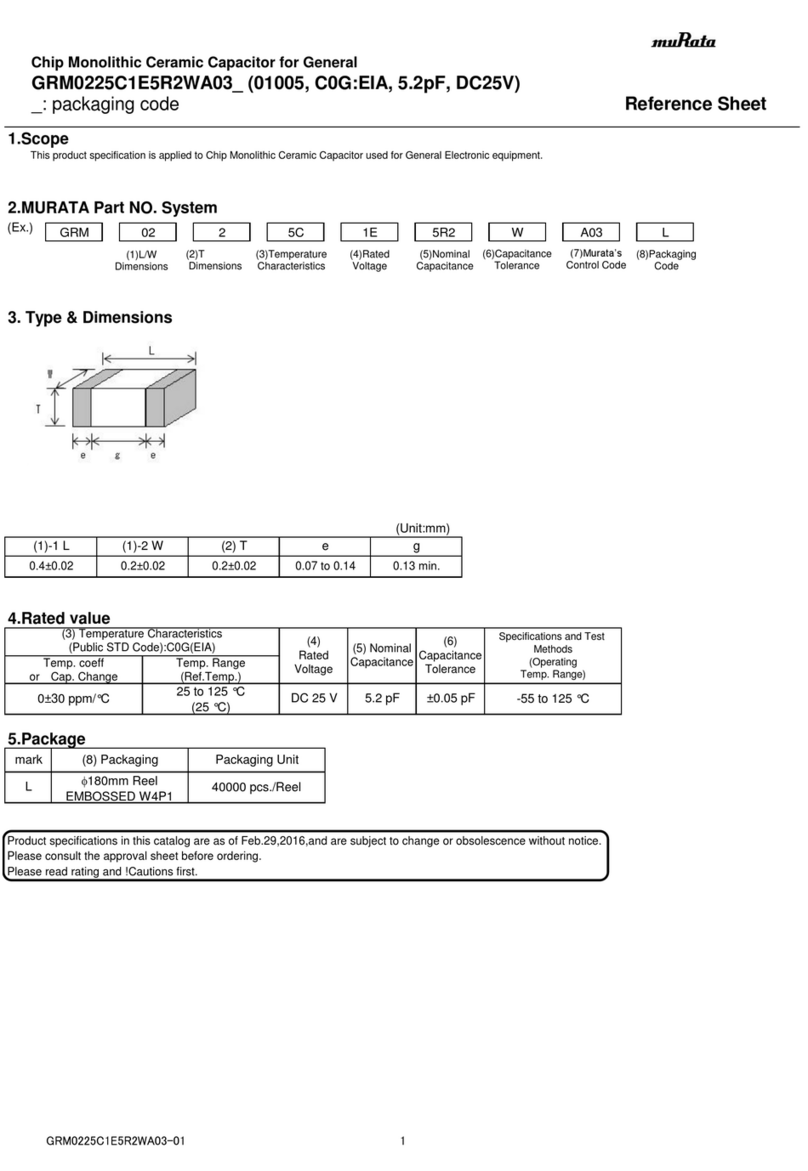

Murata GRM0225C1E5R2WA03 Series User manual

Murata

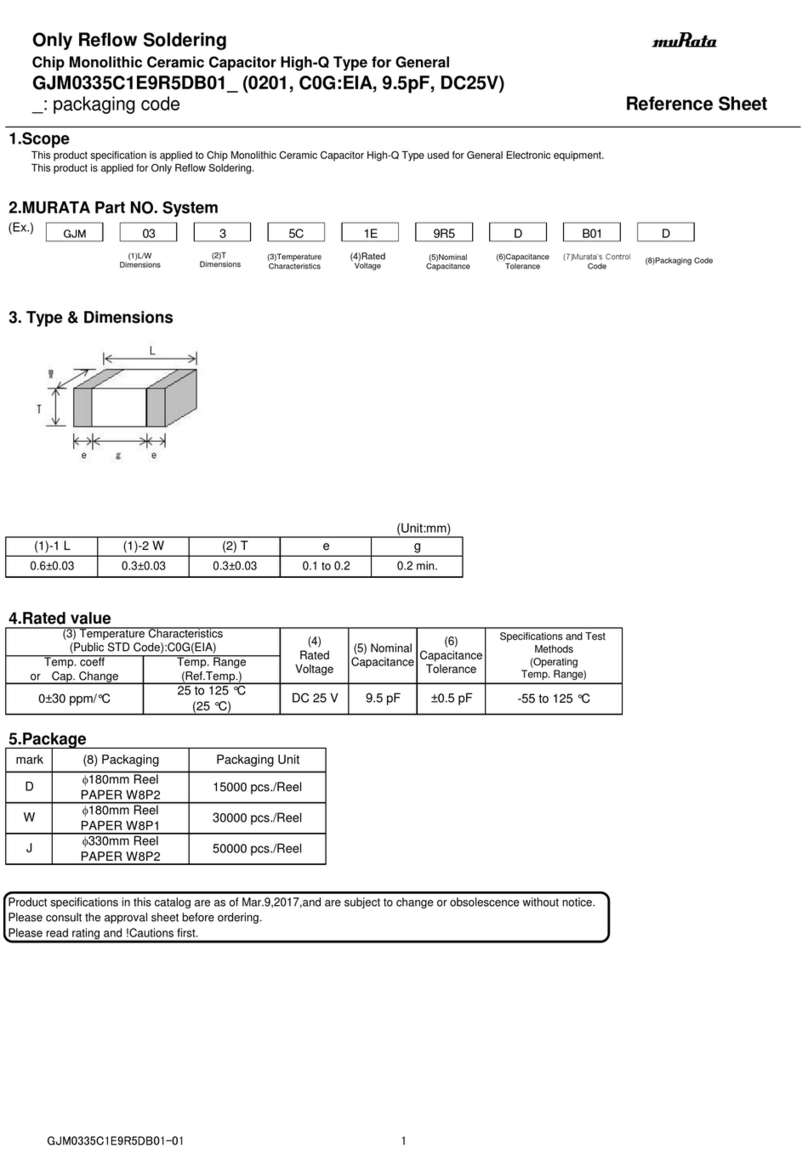

Murata GJM0335C1E9R5DB01 Series User manual

Murata

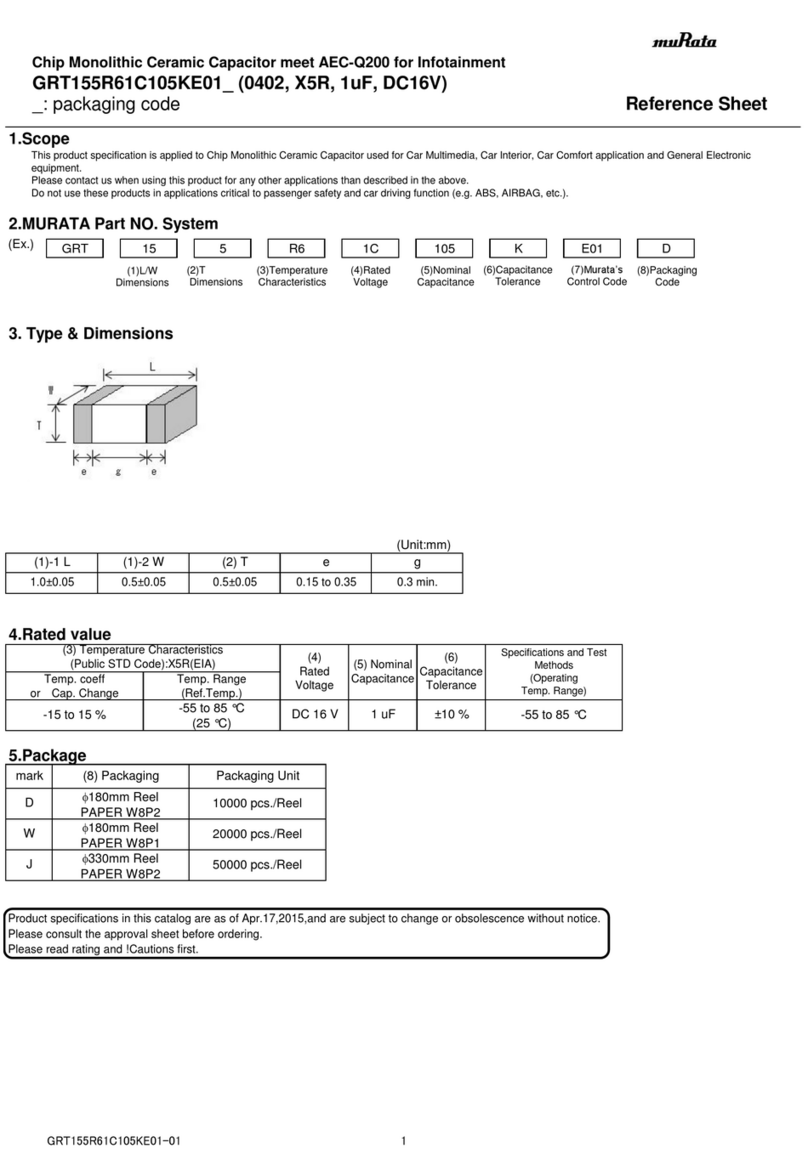

Murata GRT155R61C105KE01 Series User manual

Murata

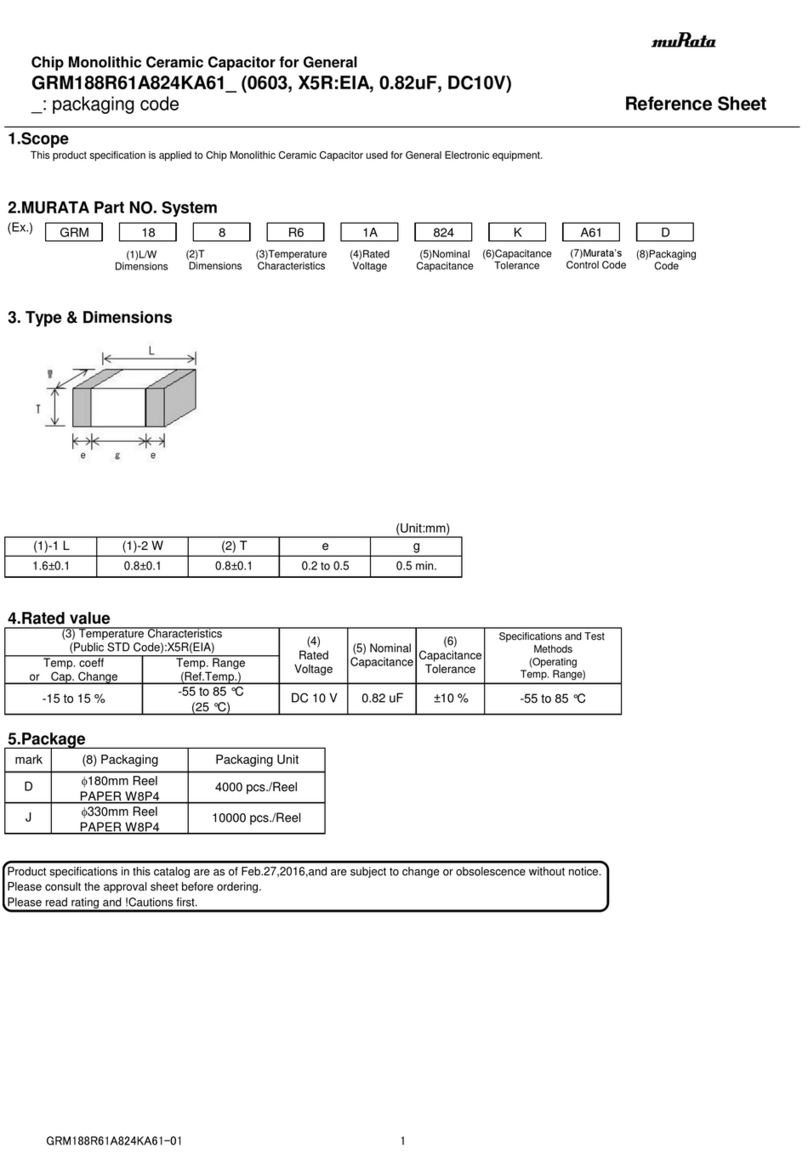

Murata GRM188R61A824KA61 Series User manual

Murata

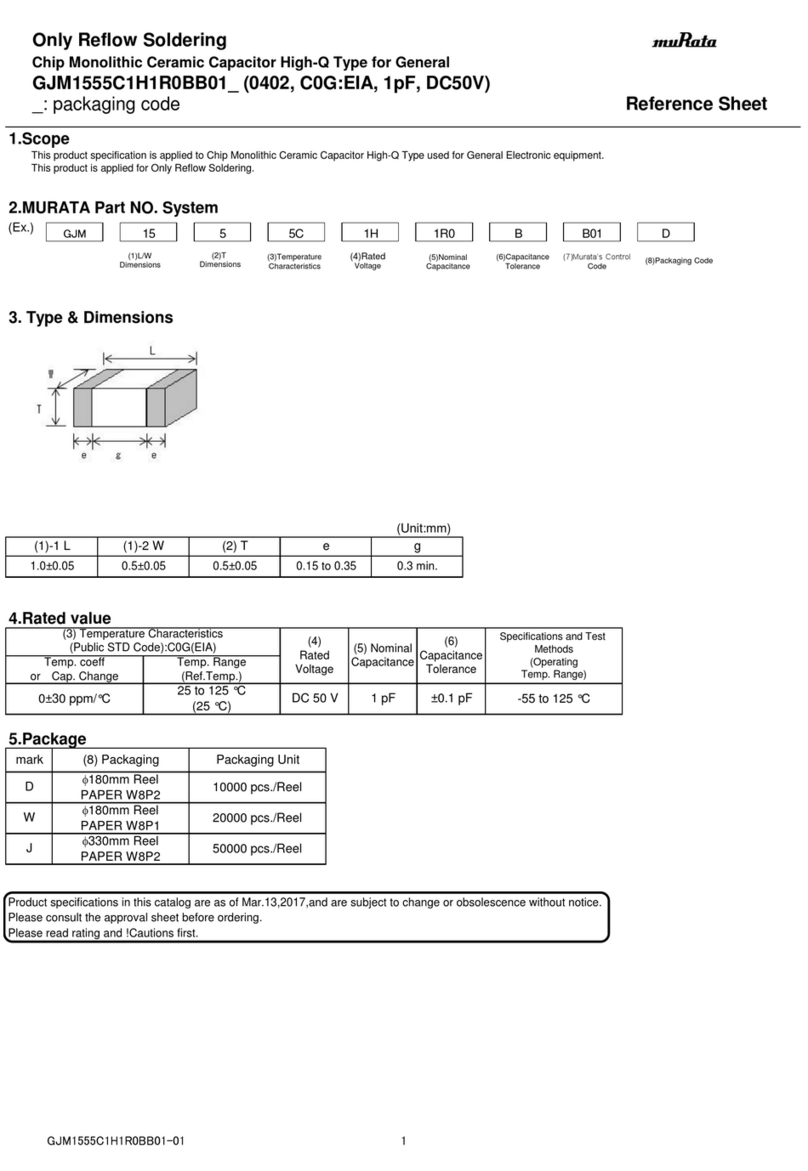

Murata GJM1555C1H1R0BB01 Series User manual

Murata

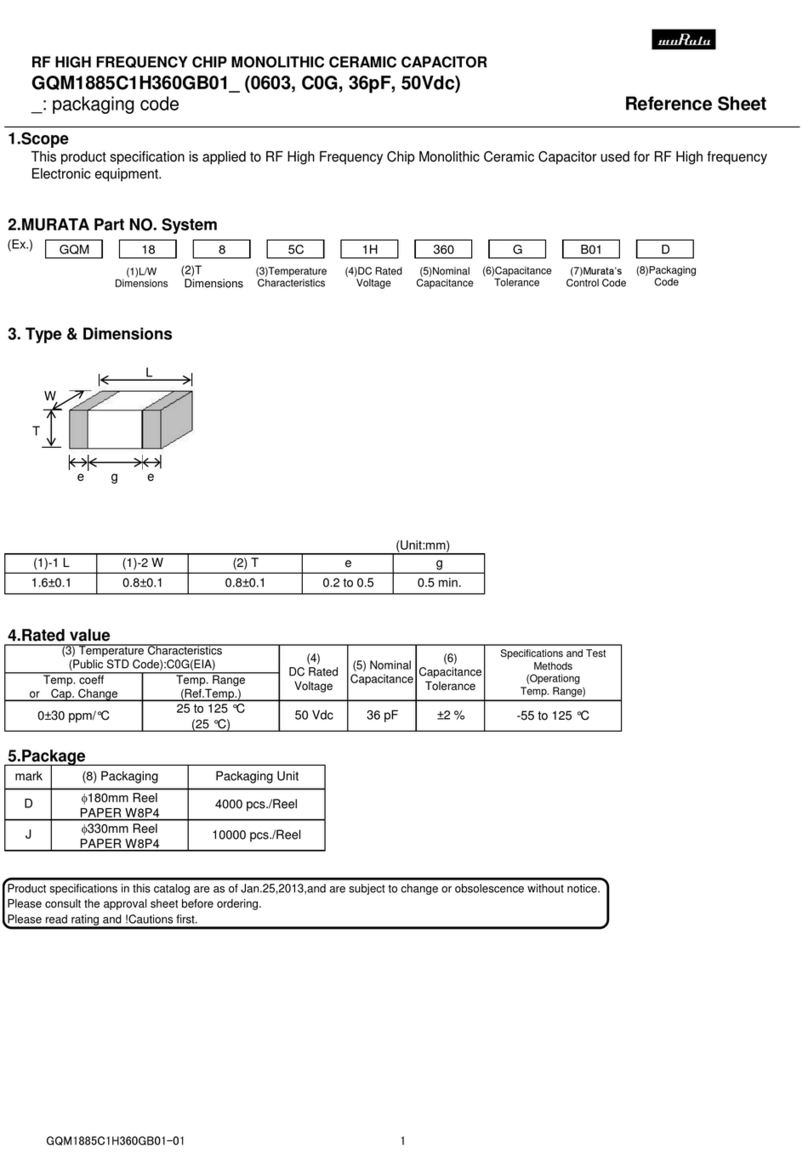

Murata GQM1885C1H360GB01 Series User manual

Murata

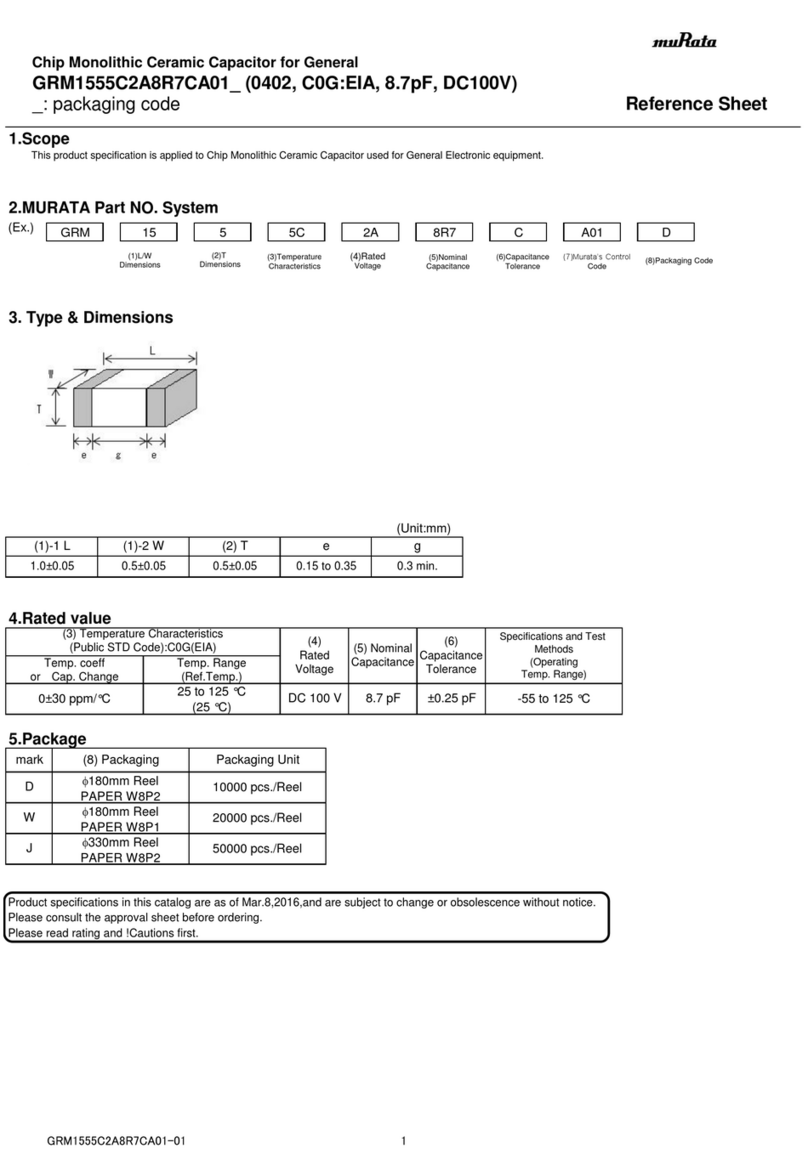

Murata GRM1555C2A8R7CA01 Series User manual

Murata

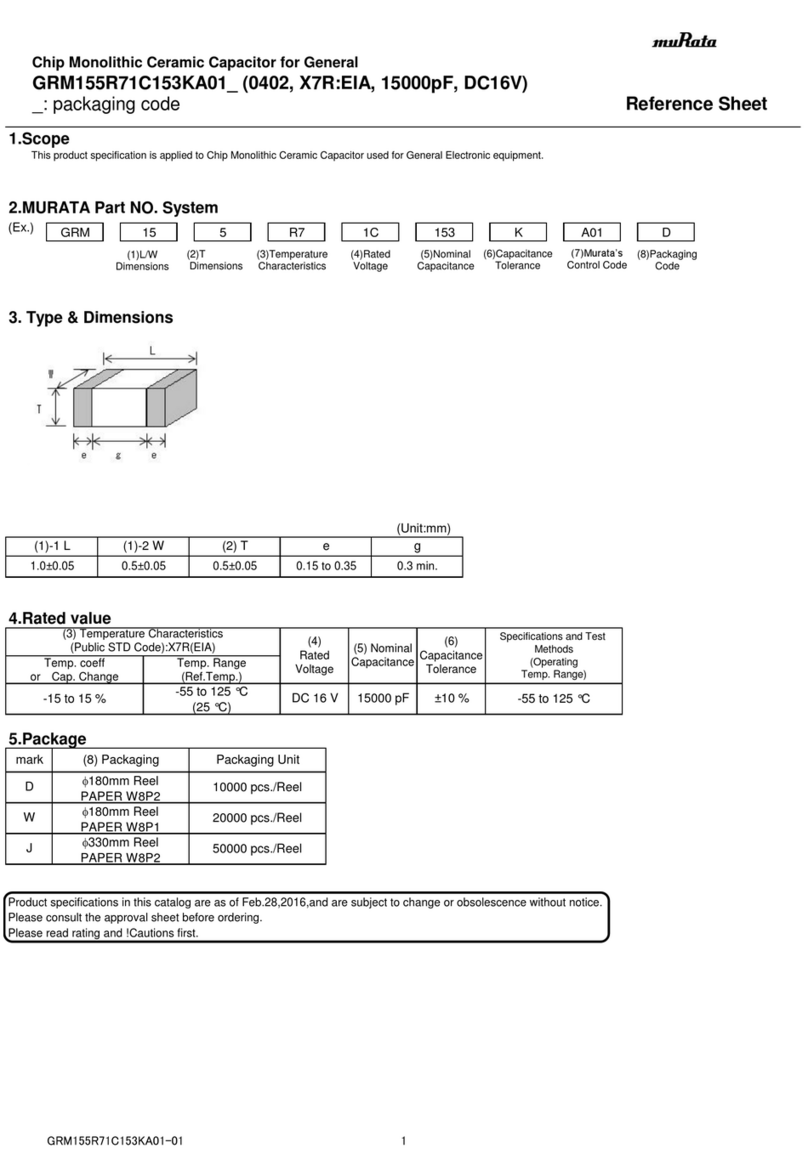

Murata GRM155R71C153KA01 Series User manual

Murata

Murata GJM1555C1H3R7BB01 Series User manual

Murata

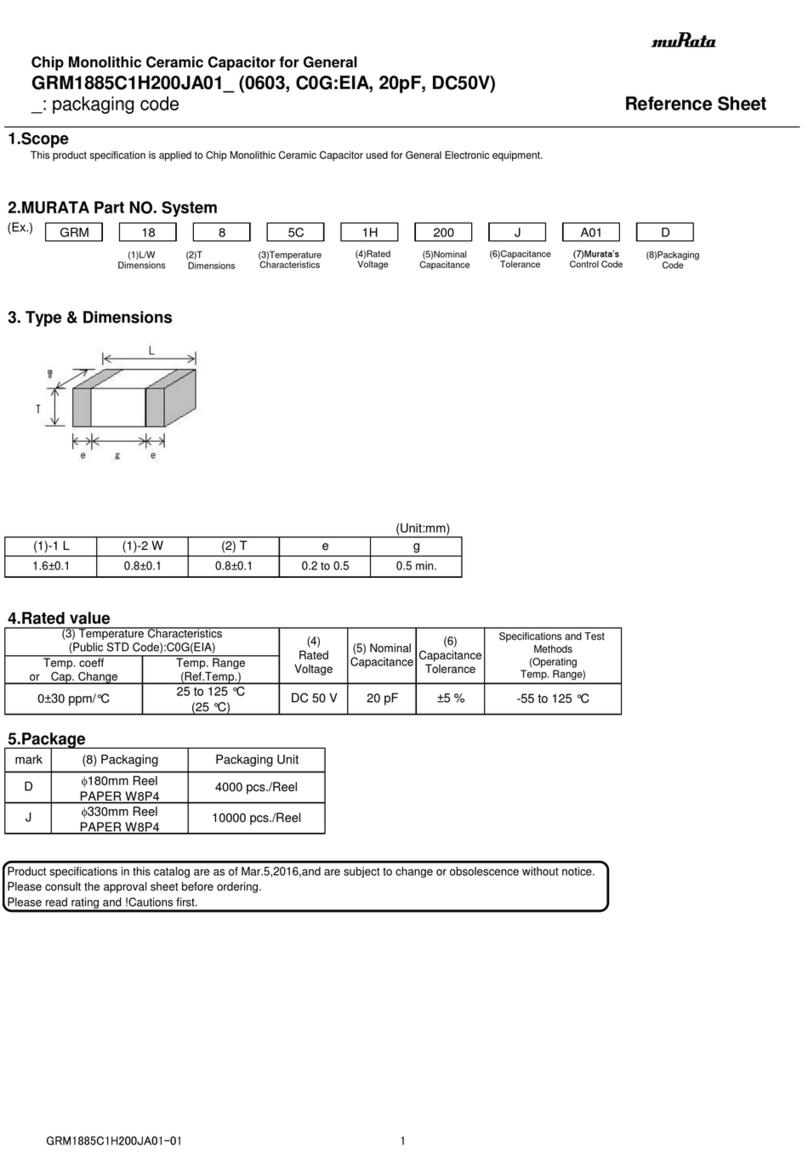

Murata GRM1885C1H200JA01 Series User manual

Murata

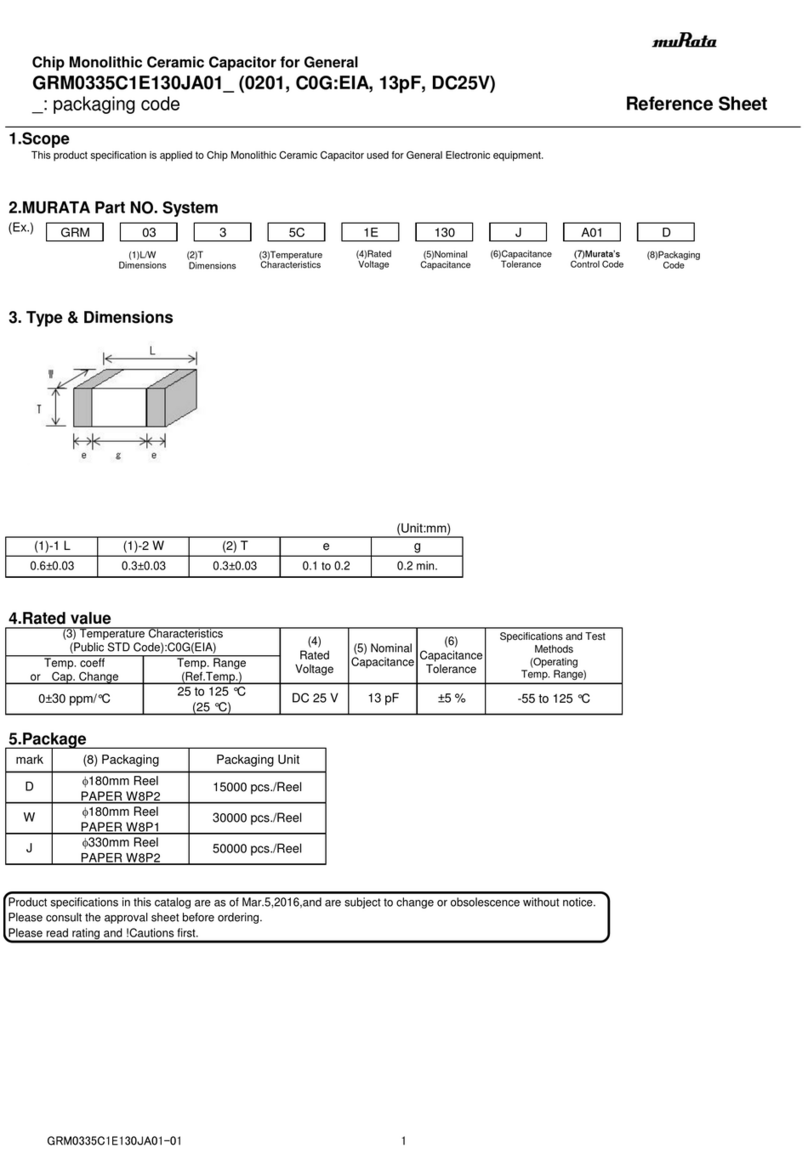

Murata GRM0335C1E130JA01 Series User manual

Murata

Murata GRM21BR71E474KA01 Series User manual

Murata

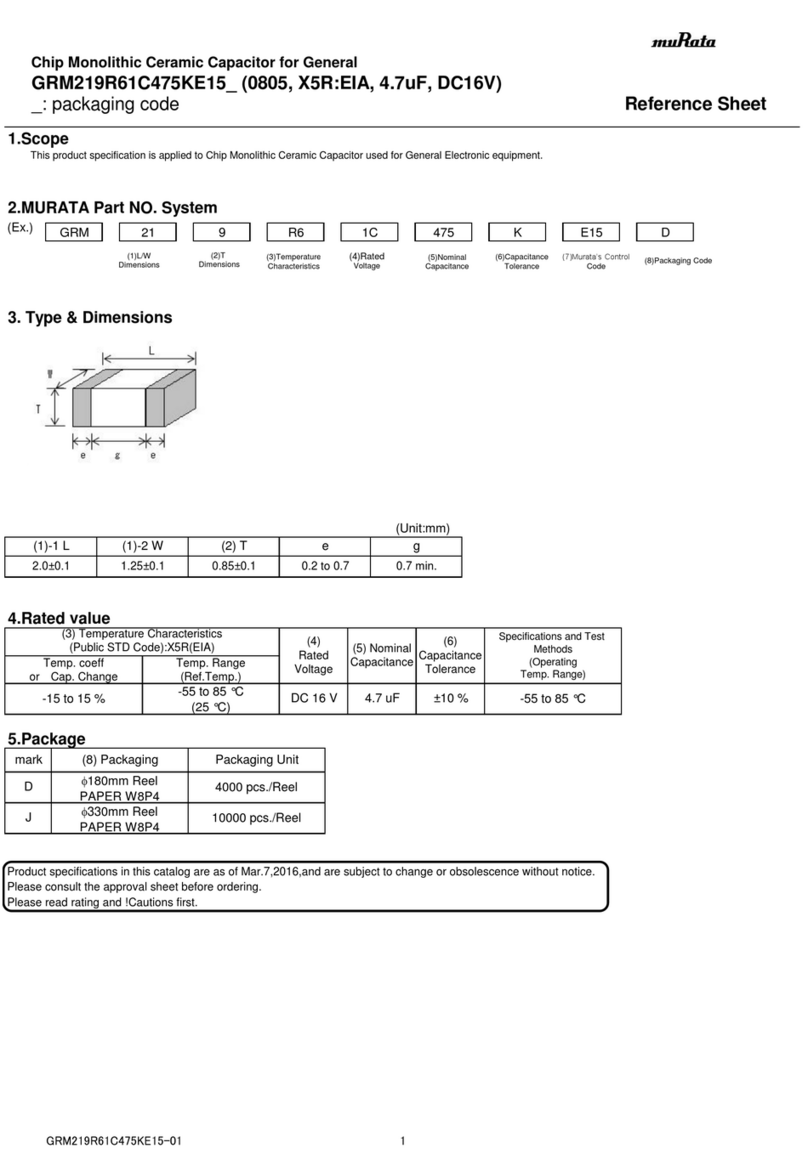

Murata GRM219R61C475KE15 Series User manual

Murata

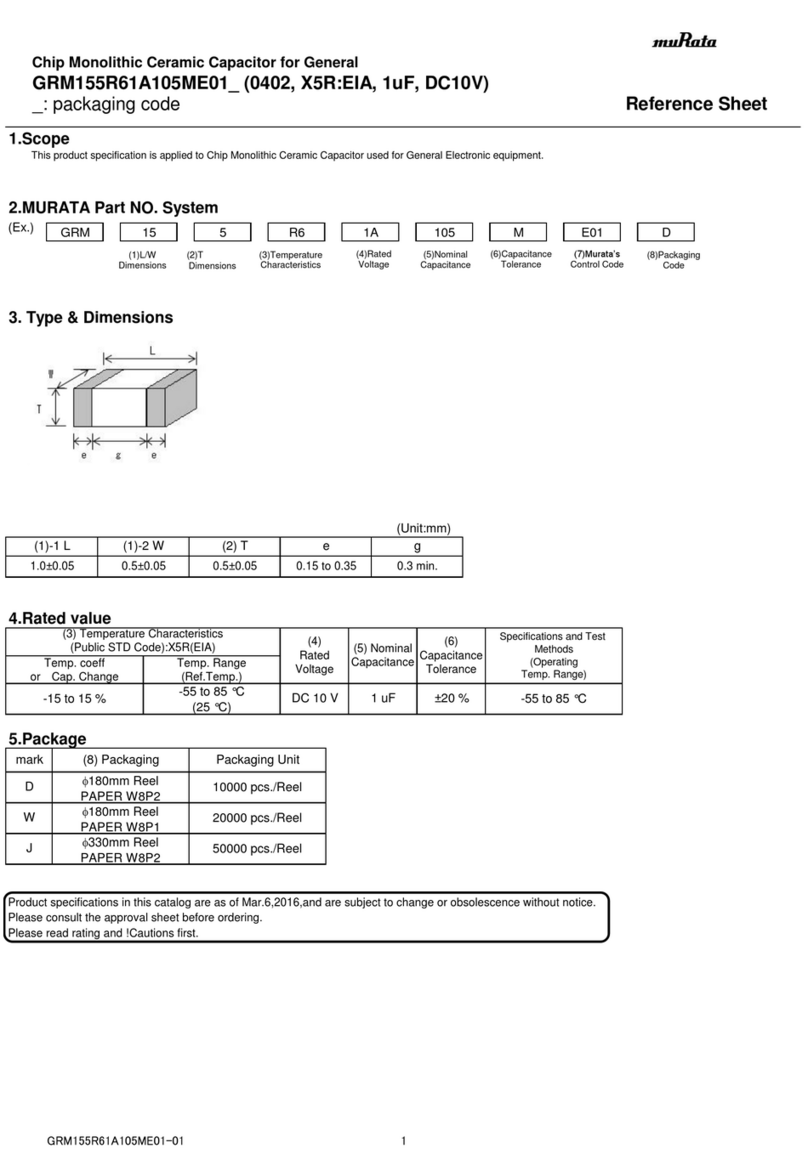

Murata GRM155R61A105ME01 Series User manual

Popular Industrial Electrical manuals by other brands

Rexroth Indramat

Rexroth Indramat DURADRIVE SYSTEM200 Project planning manual

Abtech

Abtech HVJB Series Installation, operation & maintenance instructions

SAF-HOLLAND

SAF-HOLLAND CBX 5415.5 Installation and operation manual

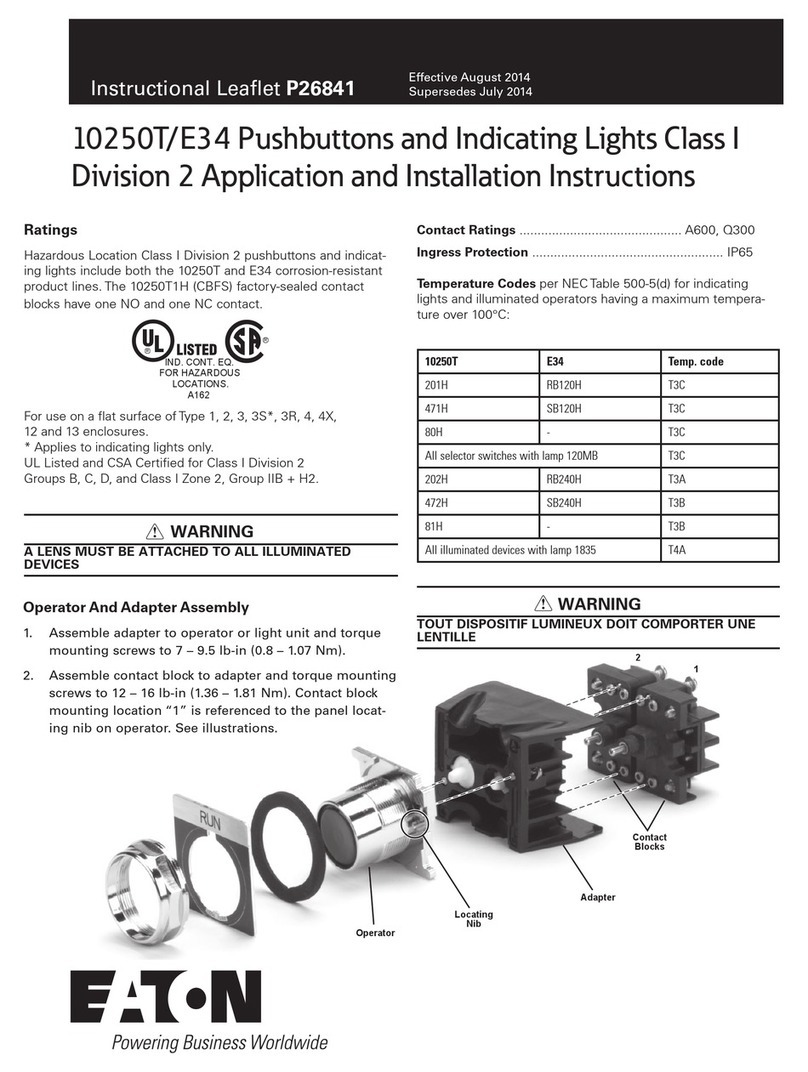

Eaton

Eaton Ulusoy HMH24-04 user manual

Newlong

Newlong NP-7H NSTRUCTION MANUAL/PARTS LIST

Stahl

Stahl 8575/12 operating instructions

SI

SI Pegasus installation instructions

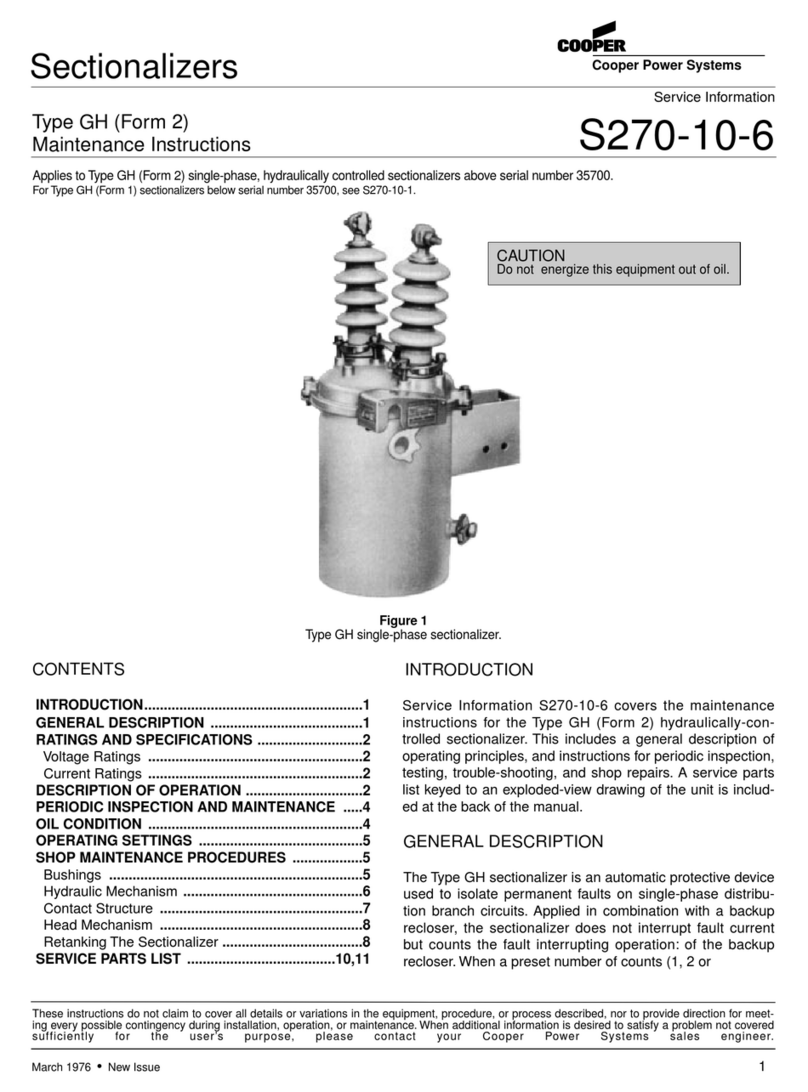

Cooper Power Systems

Cooper Power Systems VXE15 Installation and operation instructions

S&C

S&C Vista SD manual

Siemens

Siemens 3VA9988-0BM10 operating instructions

Siemens

Siemens SITRANS LVS100 operating instructions

Rockwell Automation

Rockwell Automation Allen-Bradley MP-Series installation instructions