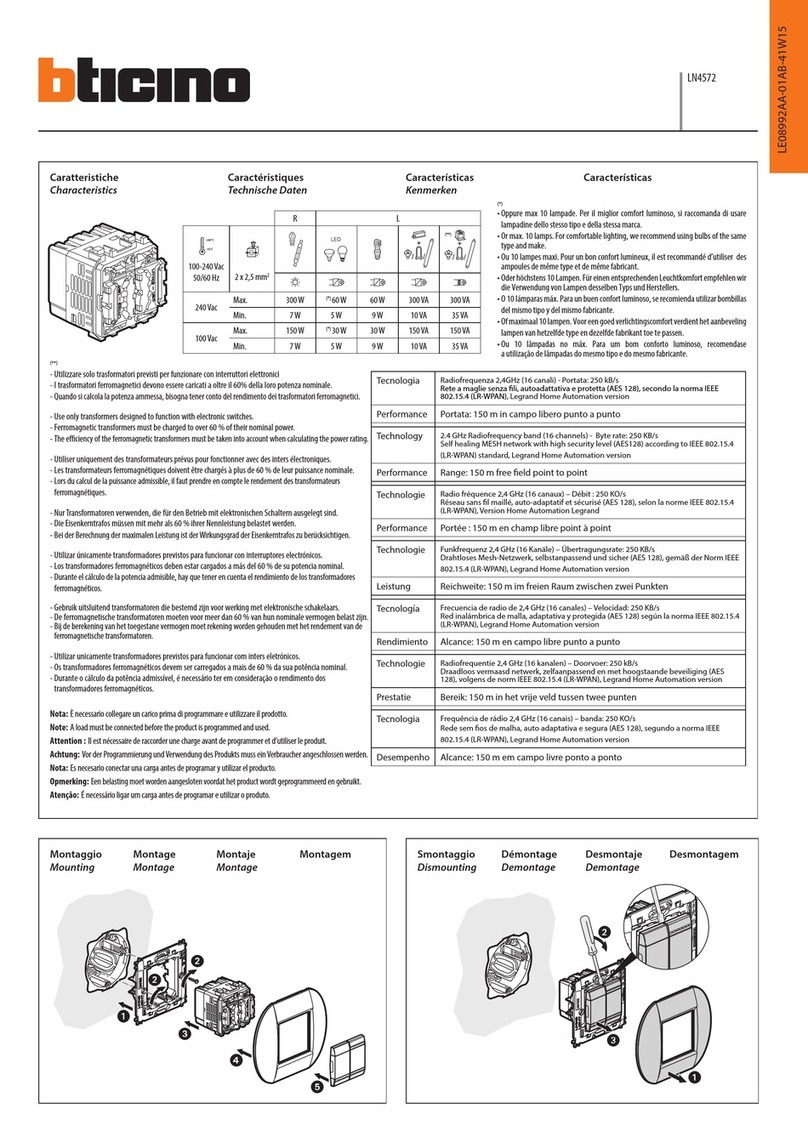

Murata ZRB157R61C225KE11 Series User manual

Other Murata Industrial Electrical manuals

Murata

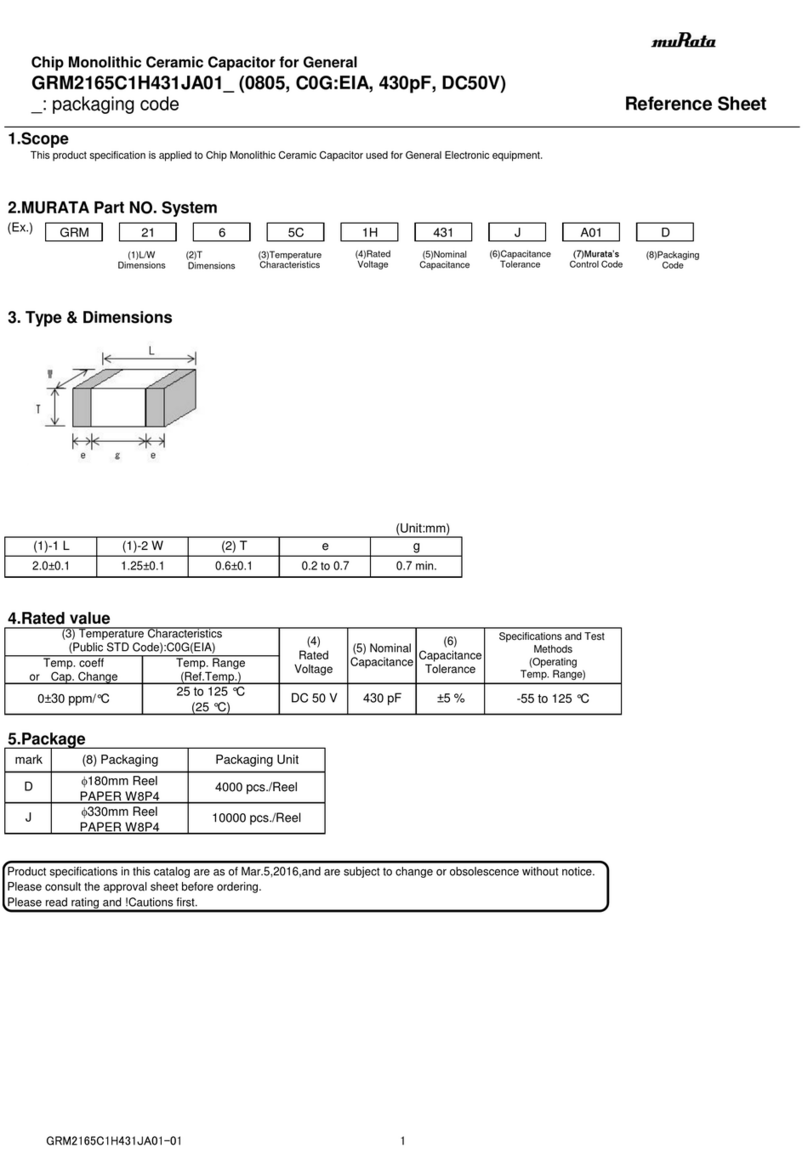

Murata GRM2165C1H431JA01 Series User manual

Murata

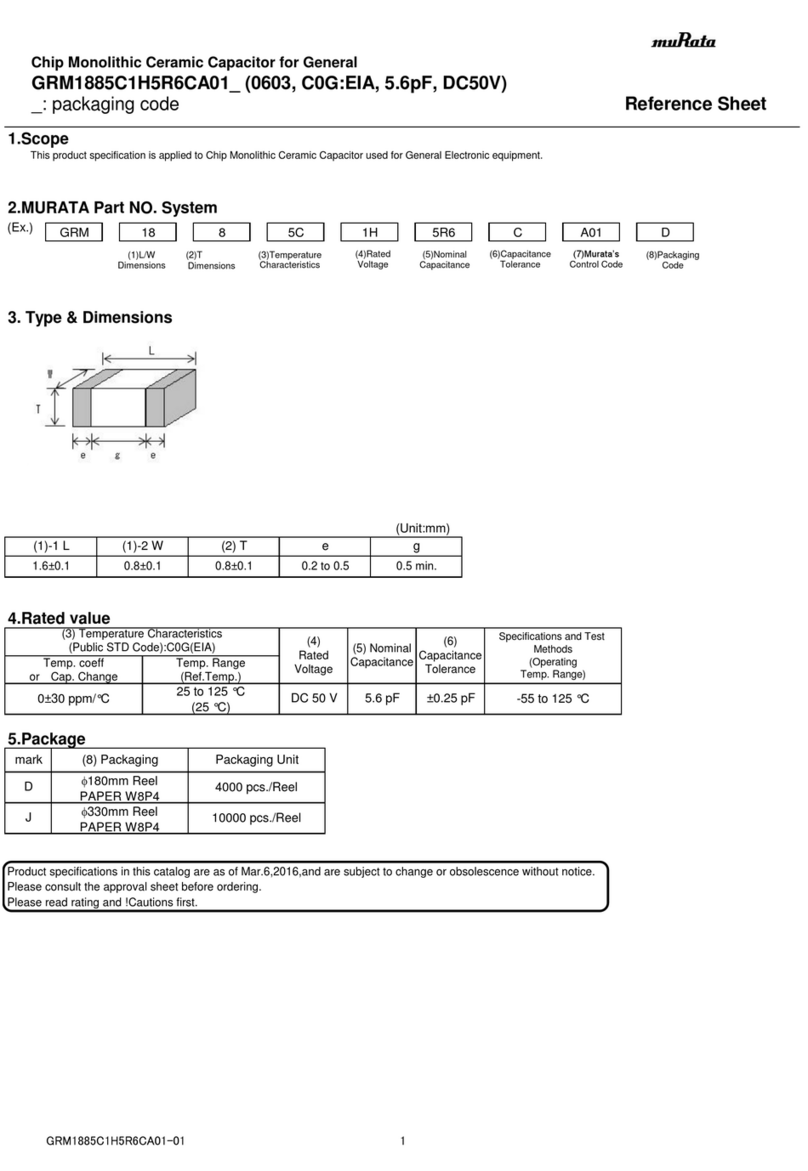

Murata GRM1885C1H5R6CA01 Series User manual

Murata

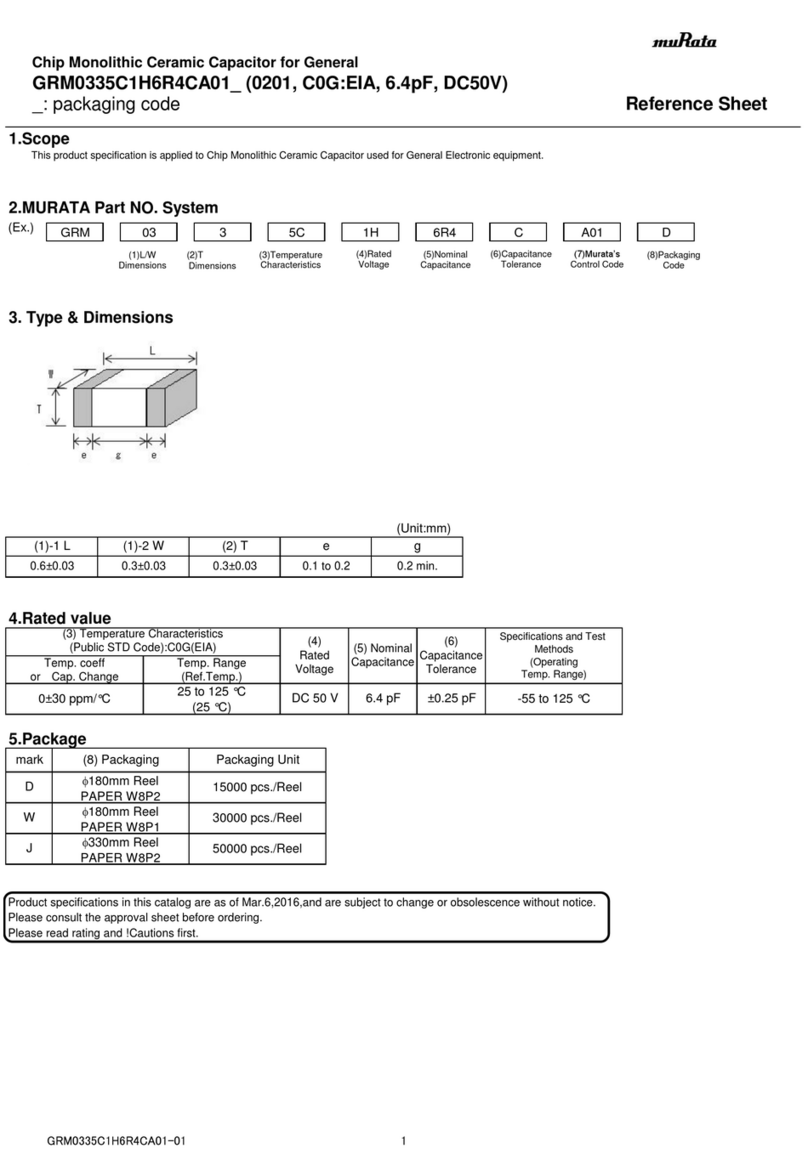

Murata GRM0335C1H6R4CA01 Series User manual

Murata

Murata GRM219R71E224KA01 Series User manual

Murata

Murata GRM32ER60G227ME05 Series User manual

Murata

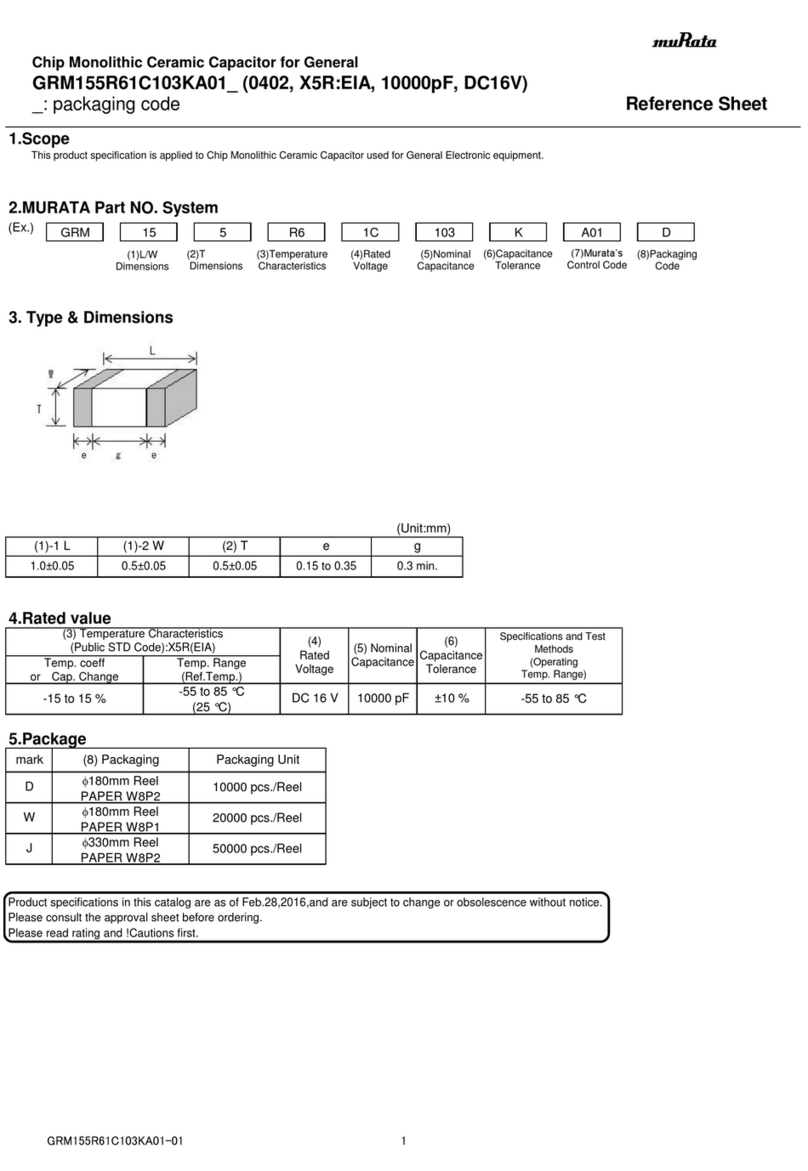

Murata GRM155R61C103KA01 Series User manual

Murata

Murata GRM216R61E105KA12 Series User manual

Murata

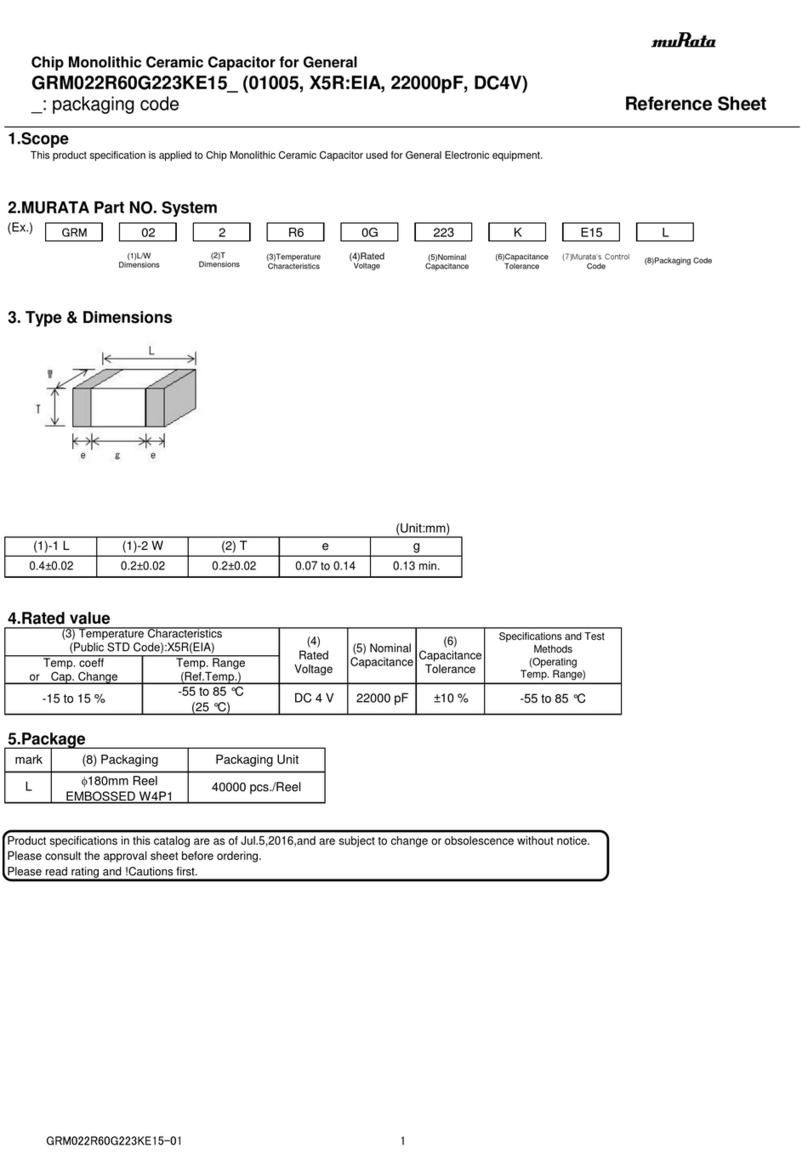

Murata GRM022R60G223KE15 Series User manual

Murata

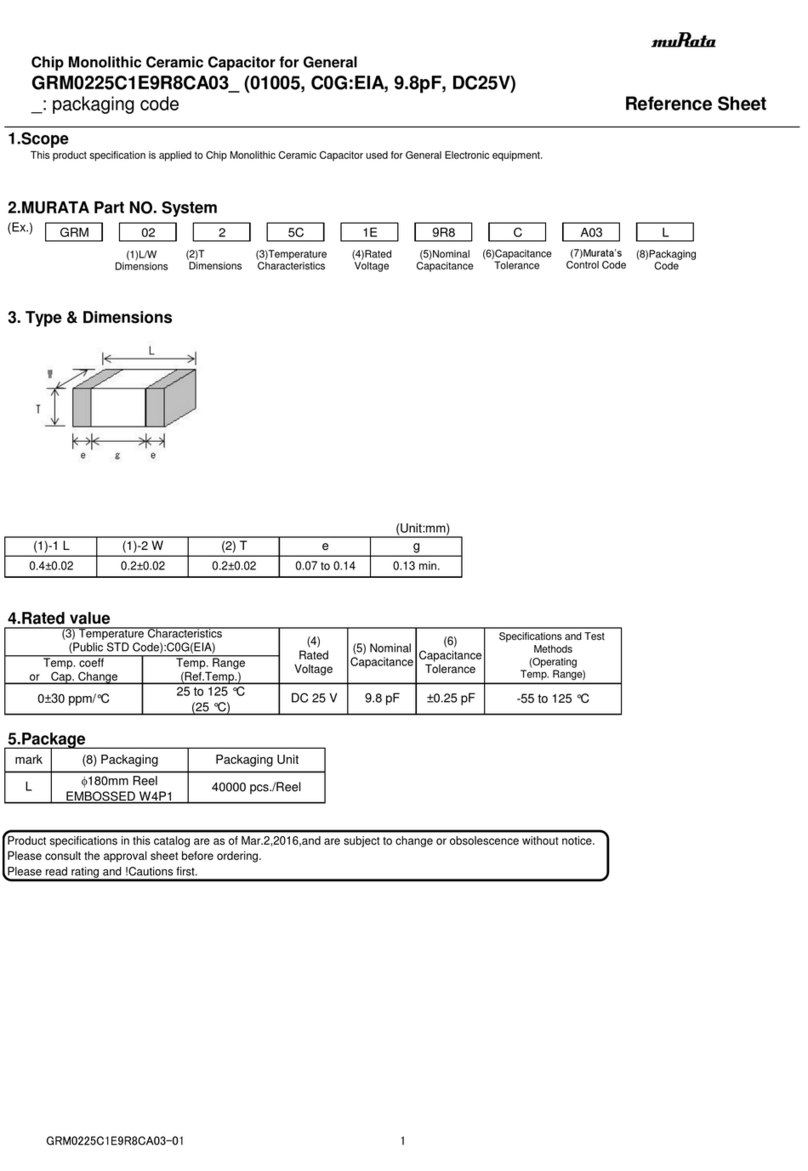

Murata GRM0225C1E9R8CA03 Series User manual

Murata

Murata GRM188R60G476ME15 Series User manual

Murata

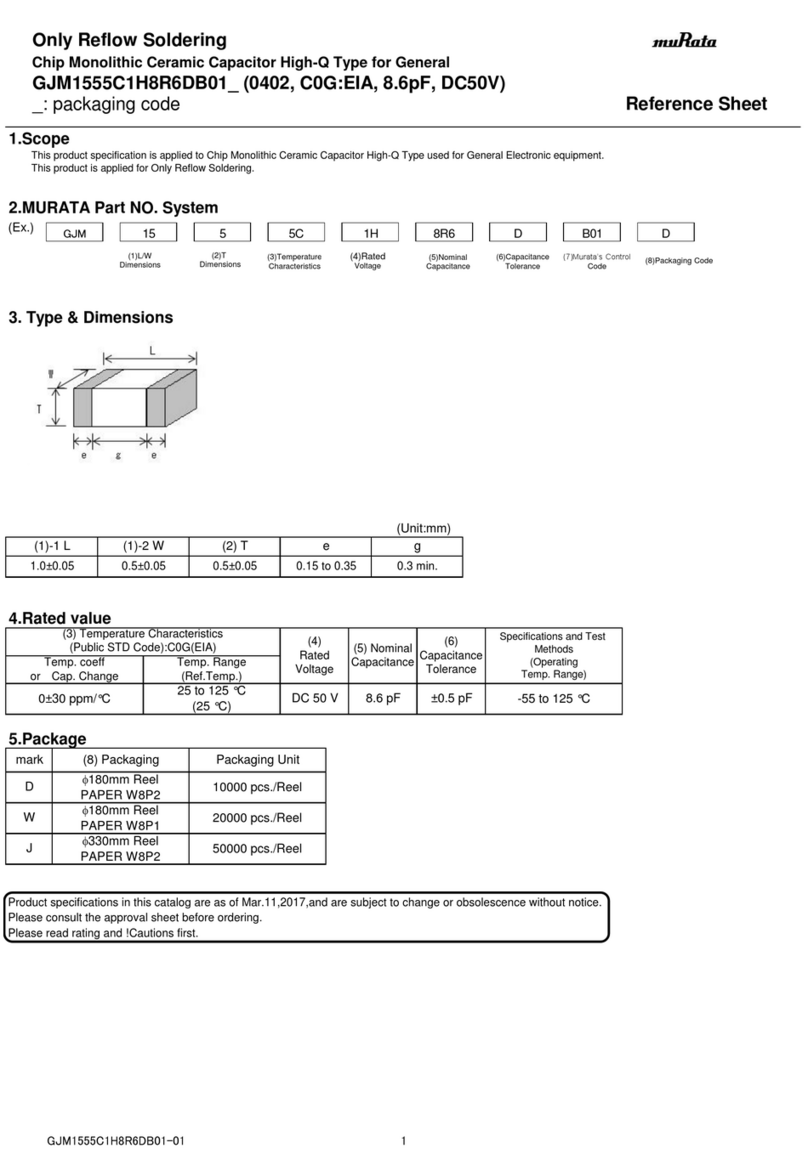

Murata GJM1555C1H8R6DB01 Series User manual

Murata

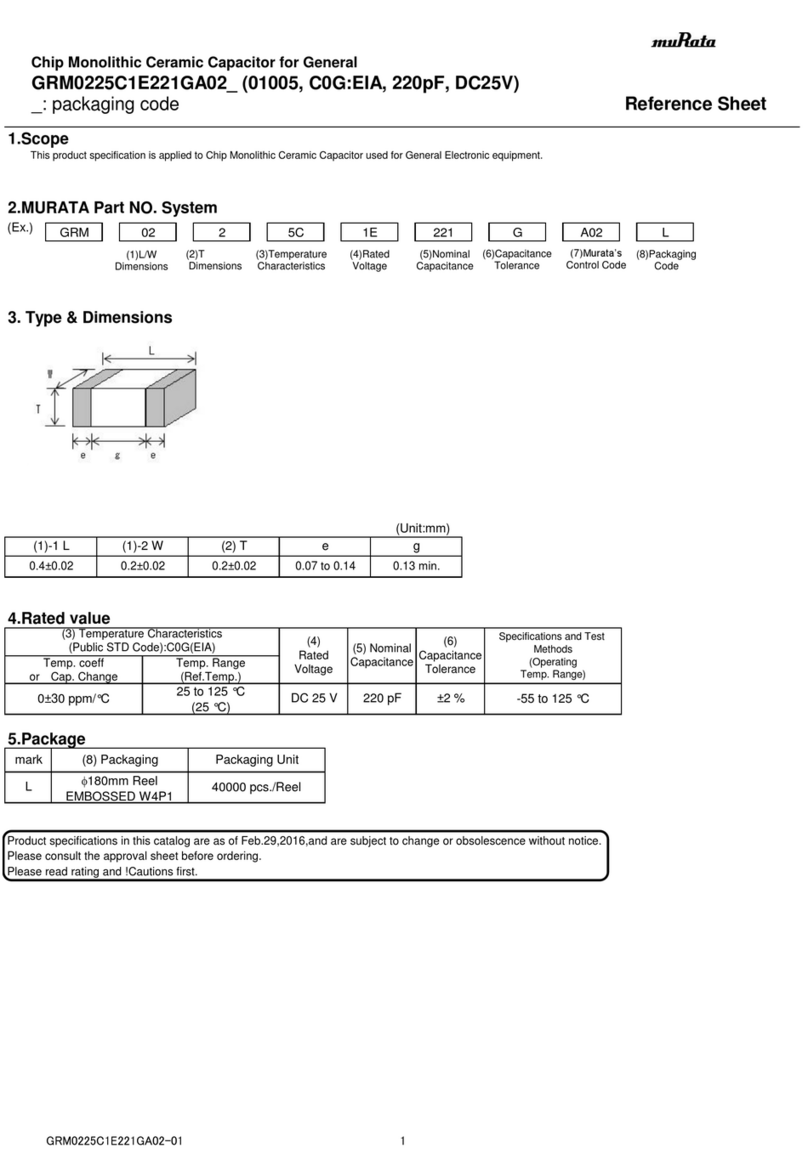

Murata GRM0225C1E221GA02 Series User manual

Murata

Murata GJM1555C1HR90BB01 Seies User manual

Murata

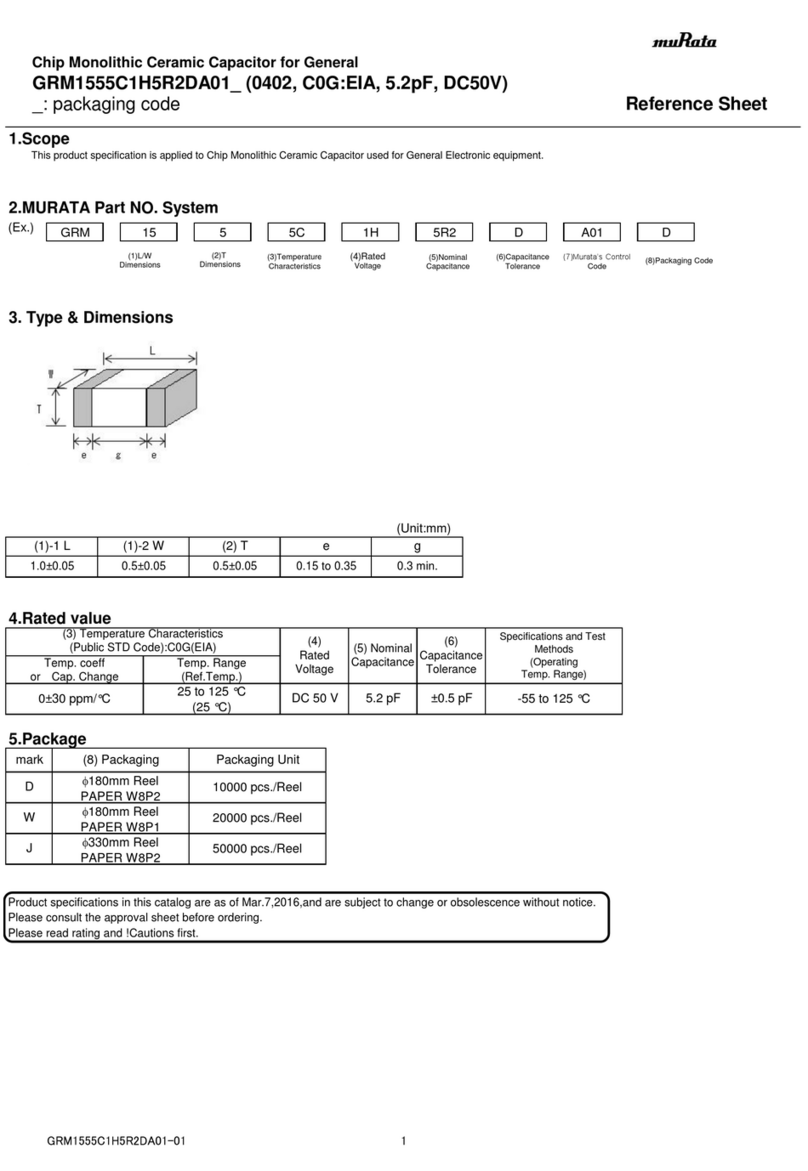

Murata GRM1555C1H5R2DA01 Series User manual

Murata

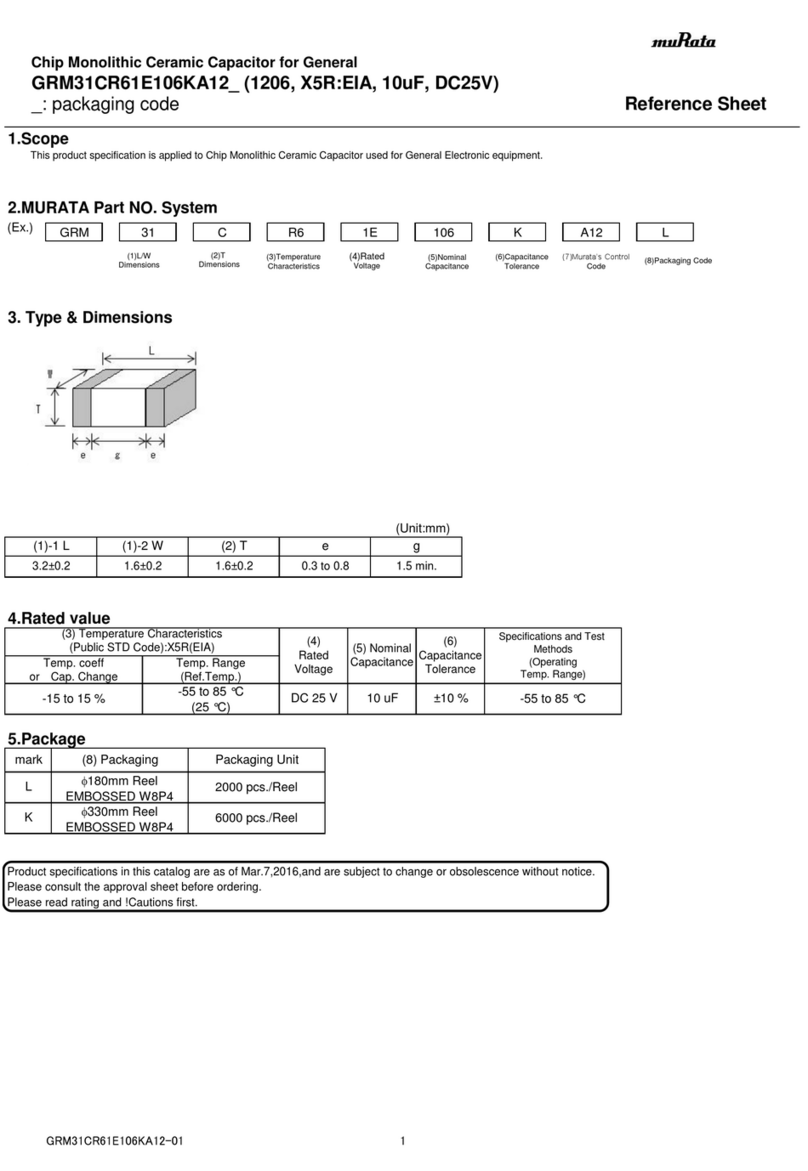

Murata GRM31CR61E106KA12 Series User manual

Murata

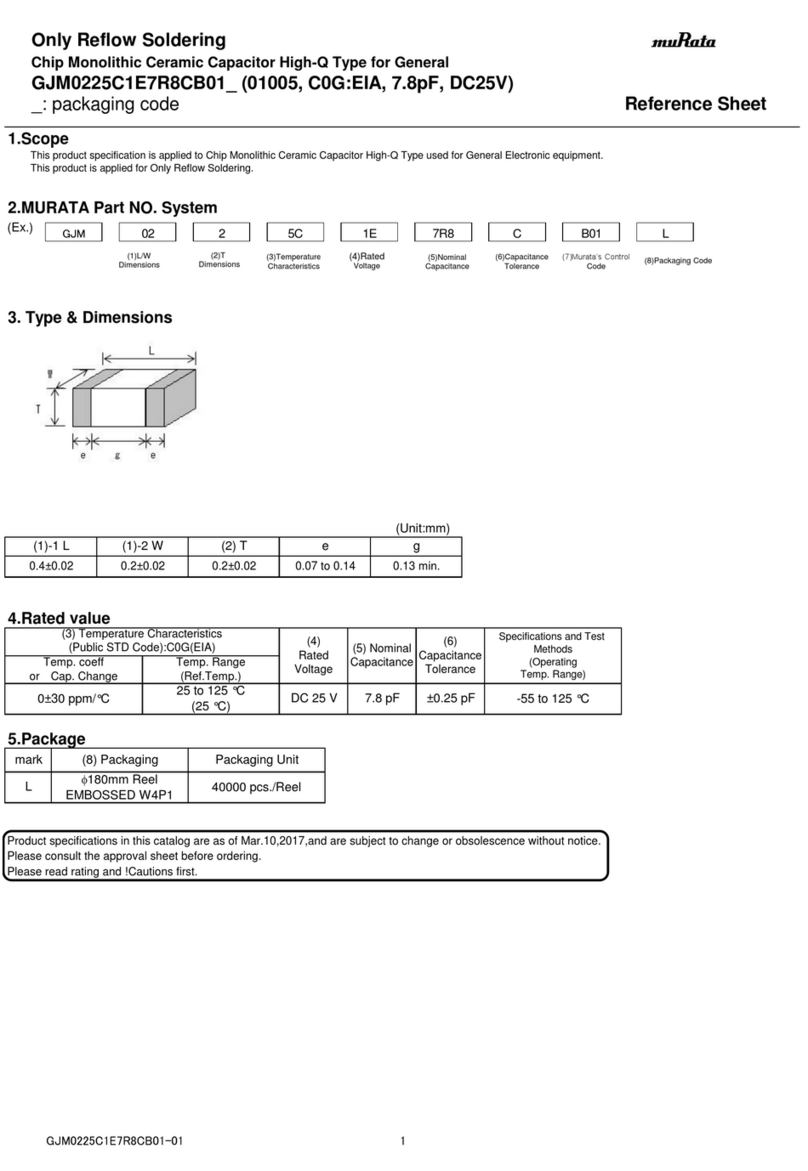

Murata GJM0225C1E7R8CB01 Series User manual

Murata

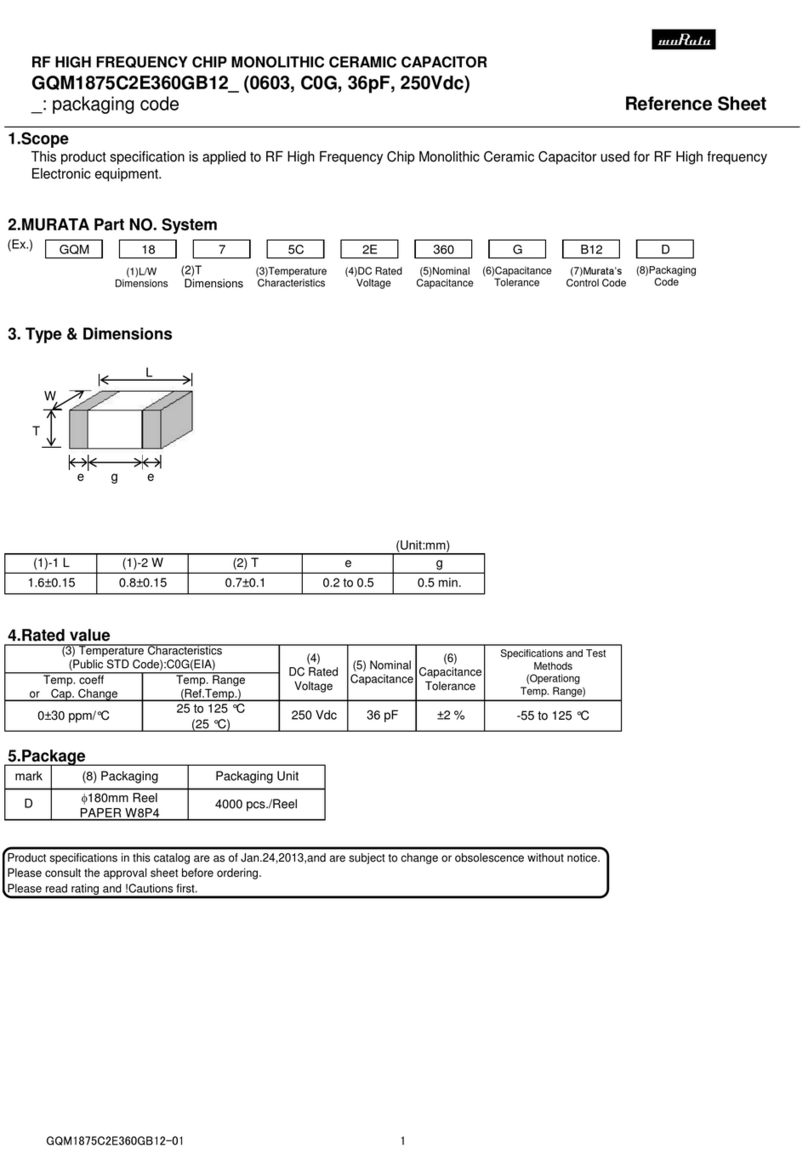

Murata GQM1875C2E360GB12 Series User manual

Murata

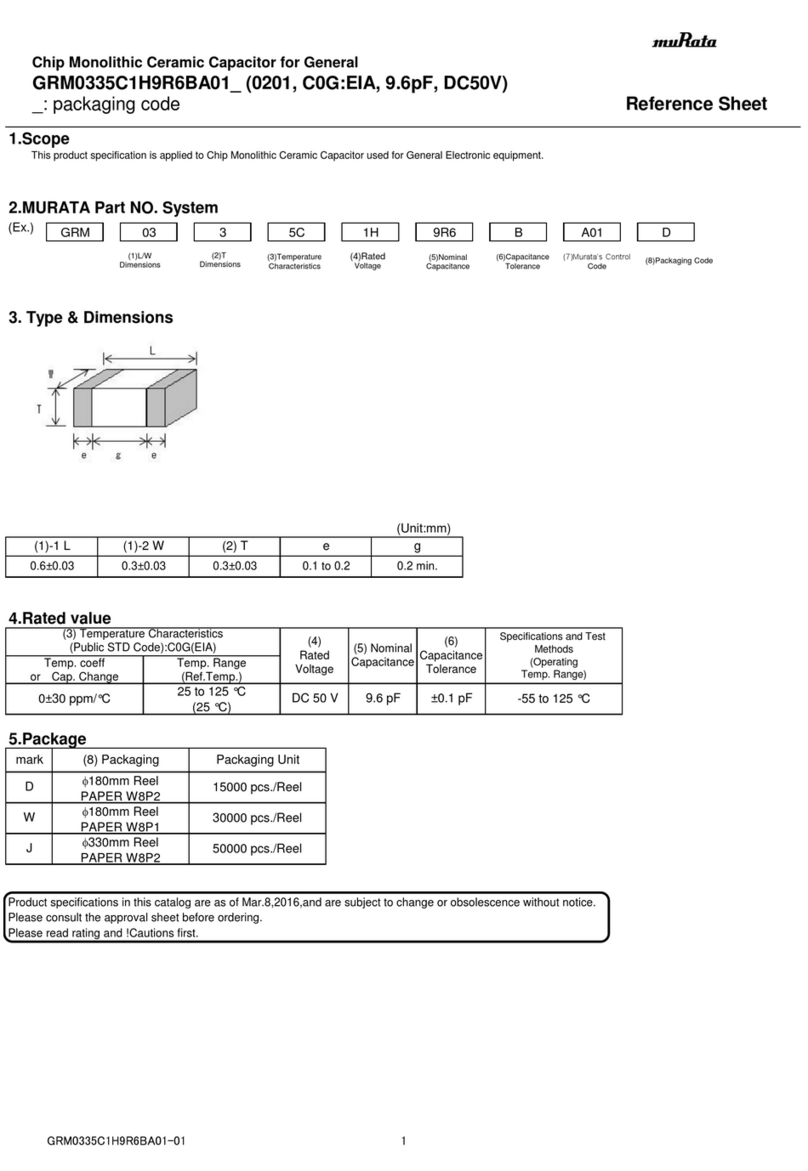

Murata GRM0335C1H9R6BA01 Series User manual

Murata

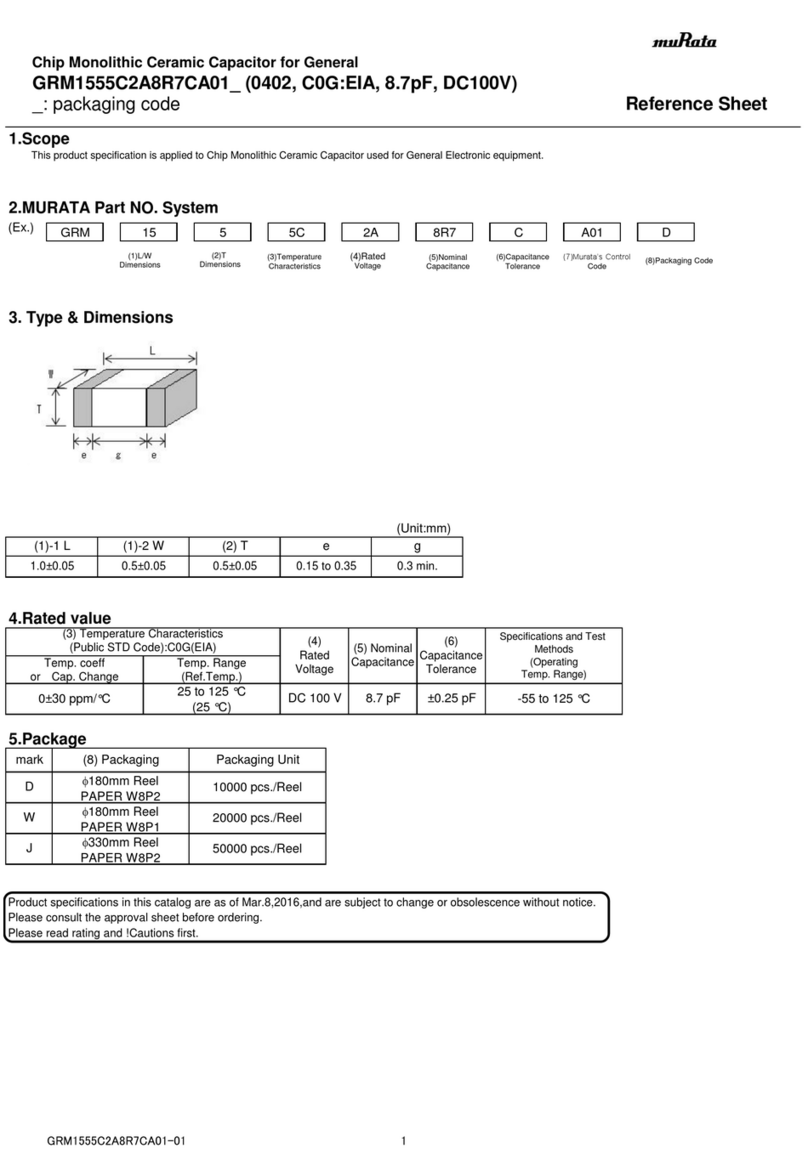

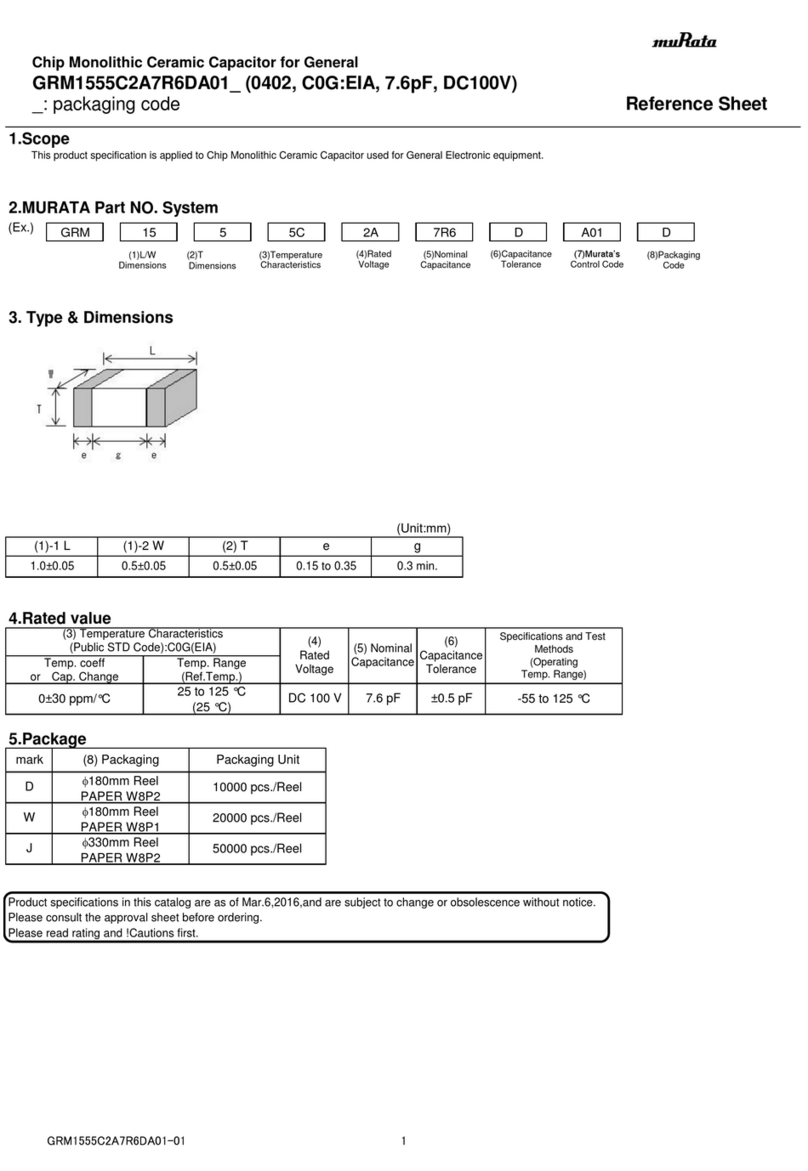

Murata GRM1555C2A7R6DA01 Series User manual

Murata

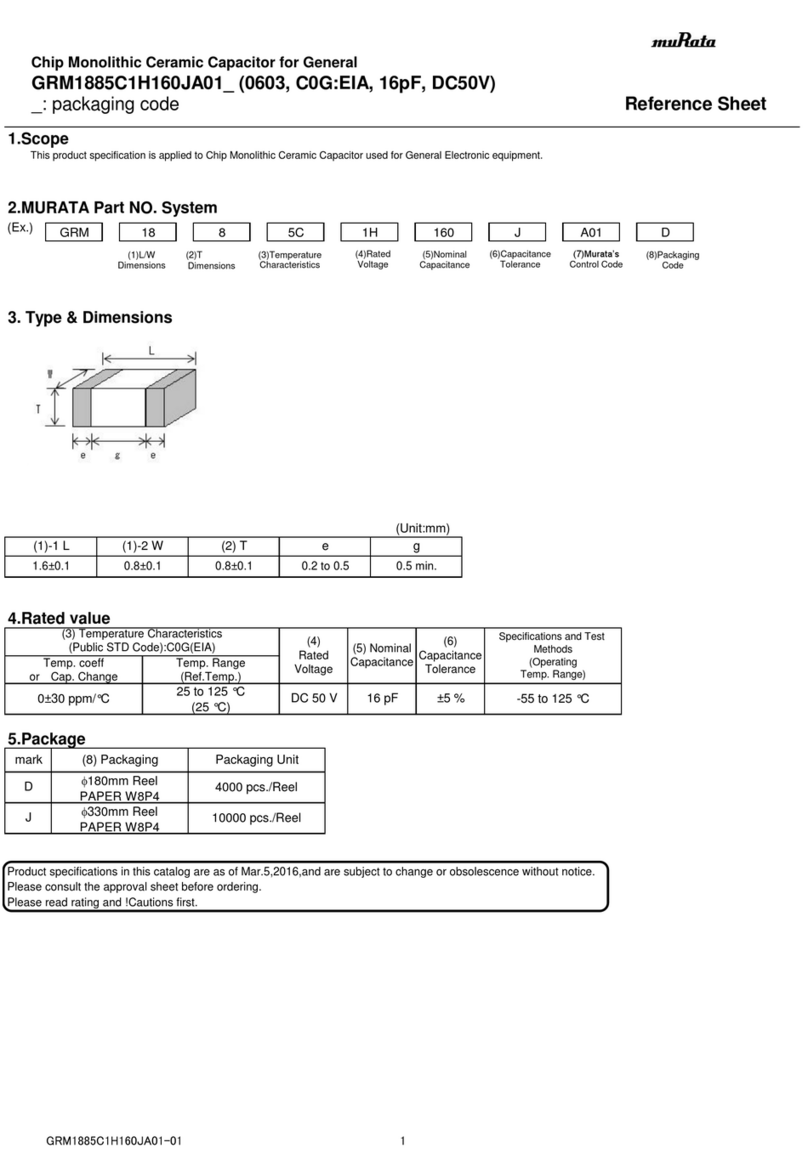

Murata GRM1885C1H160JA01 Series User manual

Popular Industrial Electrical manuals by other brands

Rexroth Indramat

Rexroth Indramat DURADRIVE SYSTEM200 Project planning manual

Abtech

Abtech HVJB Series Installation, operation & maintenance instructions

SAF-HOLLAND

SAF-HOLLAND CBX 5415.5 Installation and operation manual

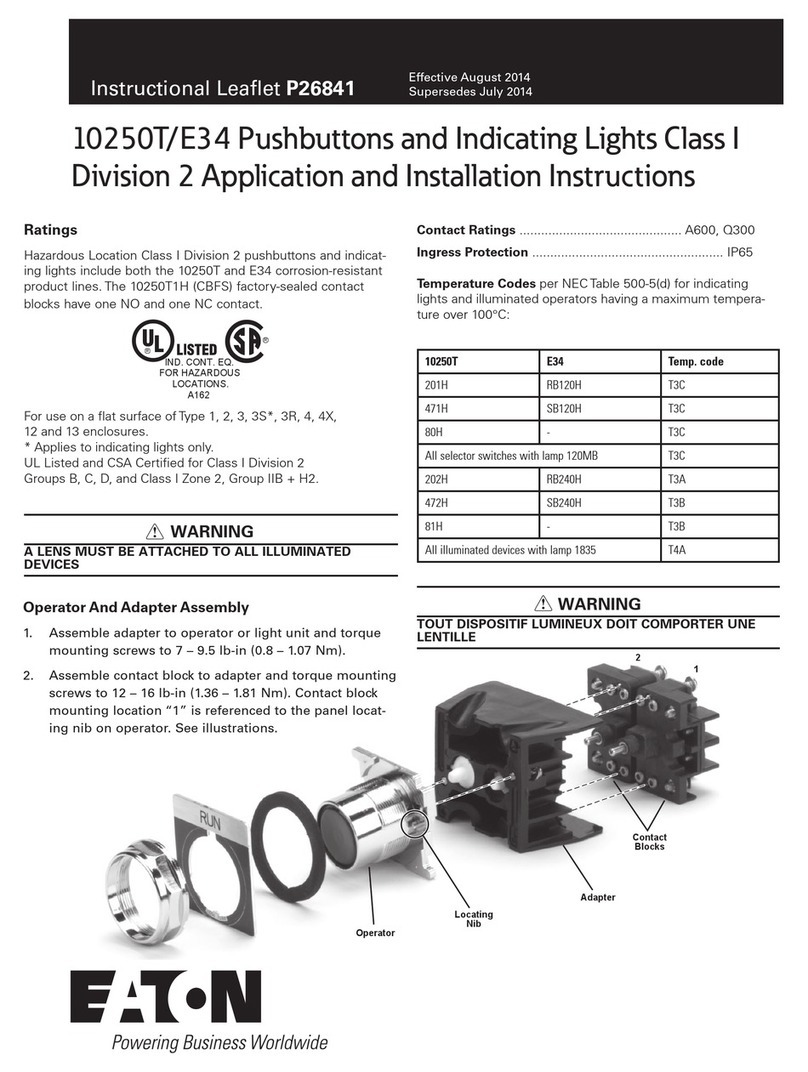

Eaton

Eaton Ulusoy HMH24-04 user manual

Newlong

Newlong NP-7H NSTRUCTION MANUAL/PARTS LIST

Stahl

Stahl 8575/12 operating instructions

SI

SI Pegasus installation instructions

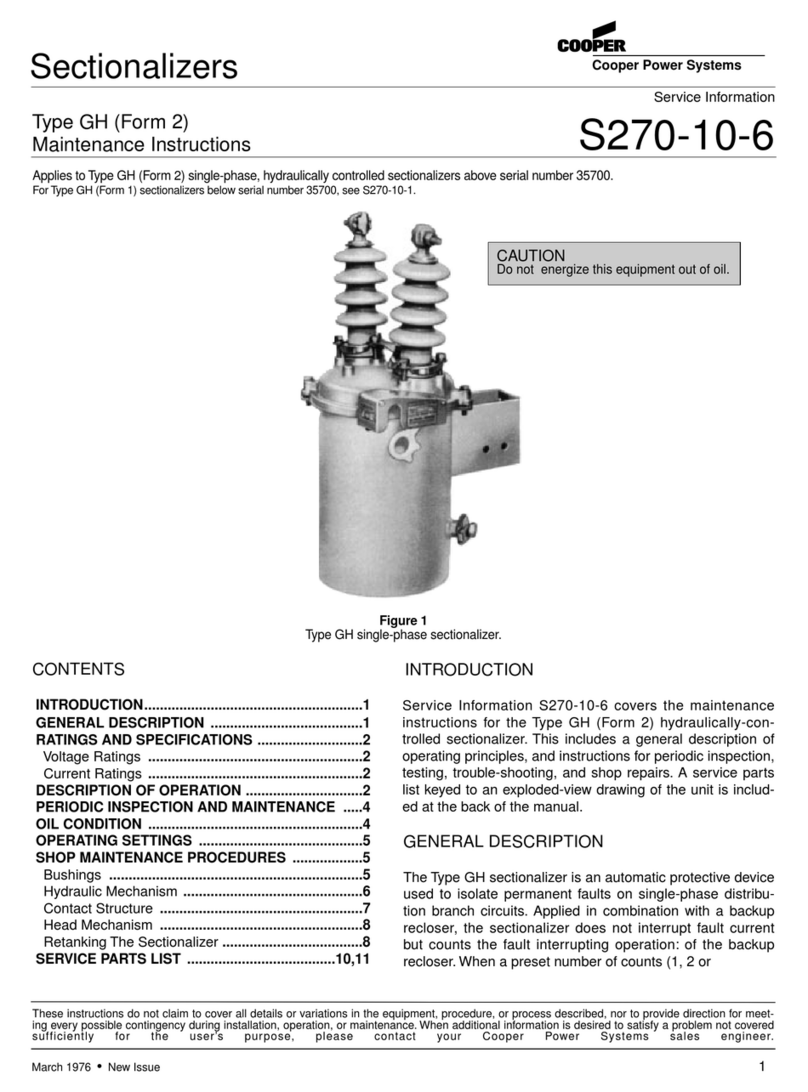

Cooper Power Systems

Cooper Power Systems VXE15 Installation and operation instructions

S&C

S&C Vista SD manual

Siemens

Siemens 3VA9988-0BM10 operating instructions

Siemens

Siemens SITRANS LVS100 operating instructions

Rockwell Automation

Rockwell Automation Allen-Bradley MP-Series installation instructions