P E T F O U N T A I N

I N S TA L L AT I O N / M A I N T E N A N C E I N S T R U C T I O N S

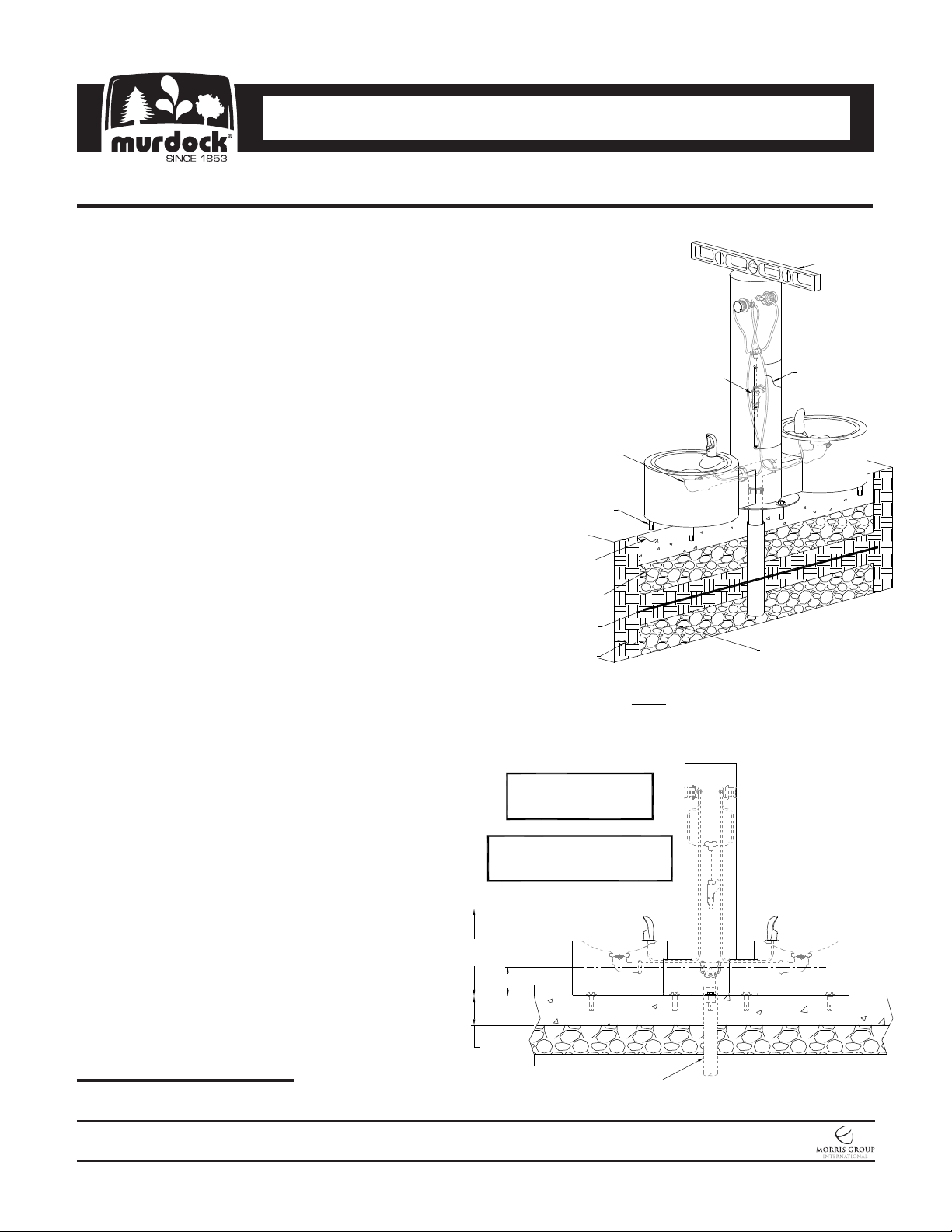

INSTALLATION INSTRUCTIONS FOR M-PM74 PET FOUNTAIN

l An in-line PRV installed on the supply line is

recommended to ensure a working water pressure

of 40- 60 psi.

Important: Read all instructions and refer to local

codes prior to installation.

l Local soil conditions may require more gravel for

drainage.

l It is recommended to include a supply stop

appropriate located on the supply line.

Depending on code and design requirements, drain

may be open, french or sanitary connection. For french

drain place a minimum of three cubic feet of gravel

under drain opening. Local soil conditions may require

more gravel drainage.

l Piping and valve must be drained prior to being

subjected to freezing temperatures.

Refill trench and hole, compacting back fill as required.

Leave sufficient depth in hole to accommodate

concrete pour, 4” minimum recommended.

Prepare slab area surrounding fountain spreading and

compacting gravel as necessary. Prepare form

approximately 6” diameter to protect supply and waste

stub outs. Protect exposed valve assembly, tubing and

tube openings to prevent damage to equipment or to

prevent tubes from becoming filled with soil or debris.

Then pour concrete, ensure concrete is flat and level.

Prepare trench for water supply lines and waste line (if

required). At fountain location prepare hole to trench

depth and large enough for a person to work in. Lay

supply and waste into trench and above ground

allowing extra line to be trimmed during hook up, refer

to details for roughs.

l Supply line must be flushed of all foreign materials

such as pipe dope, chips, etc.

l A water filter should be installed on the supply line if

sediment or mineral content is a problem.

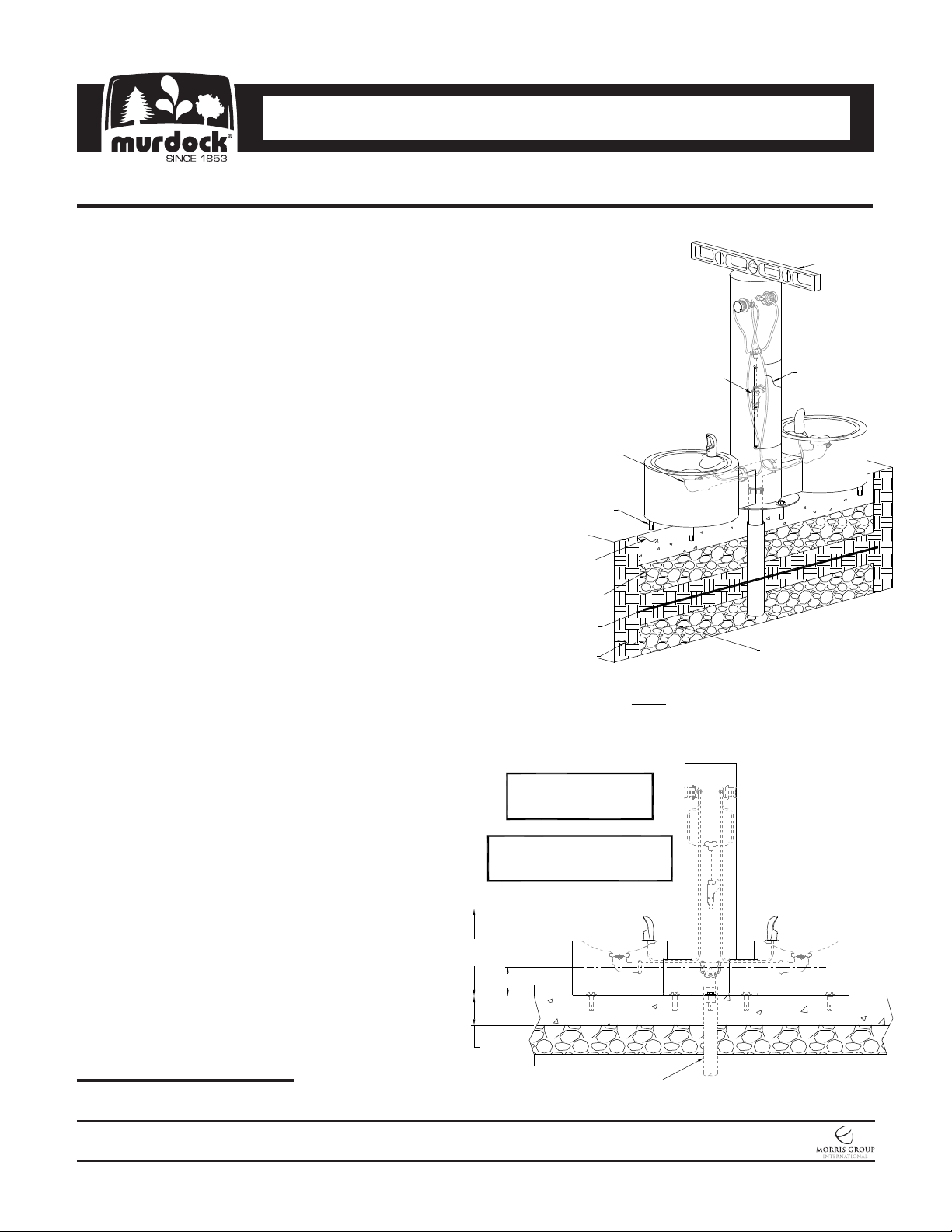

4" REC

MIN 2" PVC DWV DRAIN

PIPE RECOMMENDED,

BY OTHERS

12"

REF

4" REF

LEVEL

ACCESS PANEL

SUPPLY INLET

CONNECTION FOR

Ø1/4" PLAIN END,

BY OTHERS

EARTH

GRAVEL

POURED

CONCRETE

1/2"-13 UNC MTG

HARDWARE,

PROVIDED

FROST LINE MINIMUM 3 CUBIC

FEET OF POROUS

GRAVEL FILL

NOTE: FRENCH DRAIN SHOWN.

CONSULT LOCAL CODE

REQUIREMENTS.

FOR FREEZE RESISTANT

OPTION REFER TO -FRU

MANUAL #9938-340-0M1

VALVE SPECIFICATIONS:

MINIMUM/MAXIMUM PRESSURE:

30/100 PSI

WASTE CONNECTION

FOR Ø1-1/4" OD CLOSE

ELBOW, BY OTHERS

TYP

Please visit www.murdockmfg.com

for most current specifications.

M-PM74

Page 1 of 3

Revised: 08/31/18

7020-971-001

MURDOCK MFG. • 15125 Proctor Avenue • City of Industry, CA 91746 USA

Phone 800-453-7465 or 626-333-2543 • Fax 626-855-4860 • www.murdockmfg.com Member of