MAKING ADJUSTMENTSTO THE ASM150

continued

SEQUENCE OF OPERATIONS

Sequence of Operations with Panel in “Auto”

When the ASM150 receives an automatic start signal from the remote start con-

tacts, it cranks the engine until CRANK DISCONNECT speed is reached. At this

time, the SHUTDOWN LOCKOUT time delay will begin timing and the ENGINE

RUNNING light will be lit. It will continue to run until it is no longer needed or a

malfunction occurs. The SHUTDOWN LOCKOUT DELAY serves a dual purpose.

It causes the ASM150 to disregard the signals to the OIL PRESSURE and WATER

TEMPERATURE terminals at engine start-up. It is also a delay which, if the engine

false starts before the delay expires, causes the engine to RE-CRANK after a fixed

delay (35 seconds), to let the engine stop moving before engaging the starter.

If the engine fails to start after the user adjustable number of crank and rest

attempts, the ASM150 will annunciate an OVERCRANK condition on the LED's

and lockout the engine from any further start attempts. The OVERCRANK condi-

tion can be reset by moving the Test - Off - Auto switch into the "OFF" position and

back into the "AUTO" position.

If the engine speed exceeds the OVERSPEED setpoint (user adjustable), the ASM

150 will shut down the engine, and annunciate OVERSPEED as the cause of shut-

down on the LED's, and lockout the engine from any further start attempts. The

OVERSPEED condition can be reset by moving the Test - Off - Auto switch into

the "OFF" position and back into the "AUTO" position.

If a low oil pressure condition occurs while the engine is running, the ASM150 will

shut down the engine and annunciate "LOW PRESSURE" on the LED's and lock-

out the engine from any further start attempts. Please note that the SHUTDOWN

LOCKOUT DELAY must have expired to get a shutdown on low oil pressure or

high water temperature. This is also reset by moving the Test - Off - Auto switch

into the "OFF" position and back into the "AUTO" position.

If a high engine temperature condition occurs while the engine is running and after

the SHUTDOWN LOCKOUT DELAY has expired, the ASM150 will shutdown

the engine and annunciate "HIGH TEMPERATURE" on the LED's and lockout the

engine from any further start attempts. This is also reset by moving the Test - Off -

Auto switch into the "OFF" position and back into the "AUTO" position.

Sequence of Operations with Panel in “Test”

When the Test - Off - Auto switch is placed in the "TEST" position, an automatic

start signal is simulated. Therefore, the controller will operate the same as it does in

"AUTO." However, it will continue to run as long as there are no signals from mon-

itored conditions or until the Test - Off - Auto switch is moved to the "AUTO" or

"OFF" positions. Keep in mind, it will still shut down the engine if a monitored

condition occurs such as low oil pressure or high temperature.

Crank Disconnect (R2 Pot)

The CRANK DISCONNECT adjustment is used to let the ASM150 know when the

engine has started so that it will disengage the starter. First, set the throttle at a slow

idle (as slow as the Engine will run while cold, plus 100 or 200 RPM). Now, turn the

Pot (R2) fully clockwise, loosen the crank wire at Terminal #6. Cause the engine to

start and immediately disconnect the crank wire (terminal #6) to prevent further

cranking. Slowly turn the Pot (R2) counter-clockwise until the green light (Engine

Running) turns ON. This adjustment must be complete within 90 seconds, or the

engine will shut down indicating OVERCRANK. If this happens, simply connect

the crank wire (terminal #6), enable starter circuit, manually reset and try again.

Crank / Rest Time (R3 Pot)

The CRANK/REST TIME refers to the length of time the ASM150 will crank the

engine and then rest the starter between cranks. This time is adjustable between 4

and 25 seconds. To increase the setting, turn the Pot (R3) clockwise; to decrease

the setting, turn Pot (R3) counterclockwise.

Shutdown Lockout Delay (R4 Pot)

The SHUTDOWN LOCKOUT DELAY adjustment is used to disregard any signal

from the Low Oil Pressure and High Temperature switches. When an engine first

starts, there is no oil pressure. Because of this, the SHUTDOWN LOCKOUT

DELAY must be set so the engine oil pressure and coolant temperature can reach

normal operating ranges. When starting a cold engine, it takes a few seconds for the

oil pressure to build up which would cause the unit to shutdown the engine unnec-

essarily. This is also true with coolant temperature when starting a hot engine. This

delay is adjustable between 1 and 25 seconds and begins timing as soon as CRANK

DISCONNECT occurs. To increase the setting, turn the Pot (R4) clockwise; to

decrease the setting, turn Pot (R4) counterclockwise.

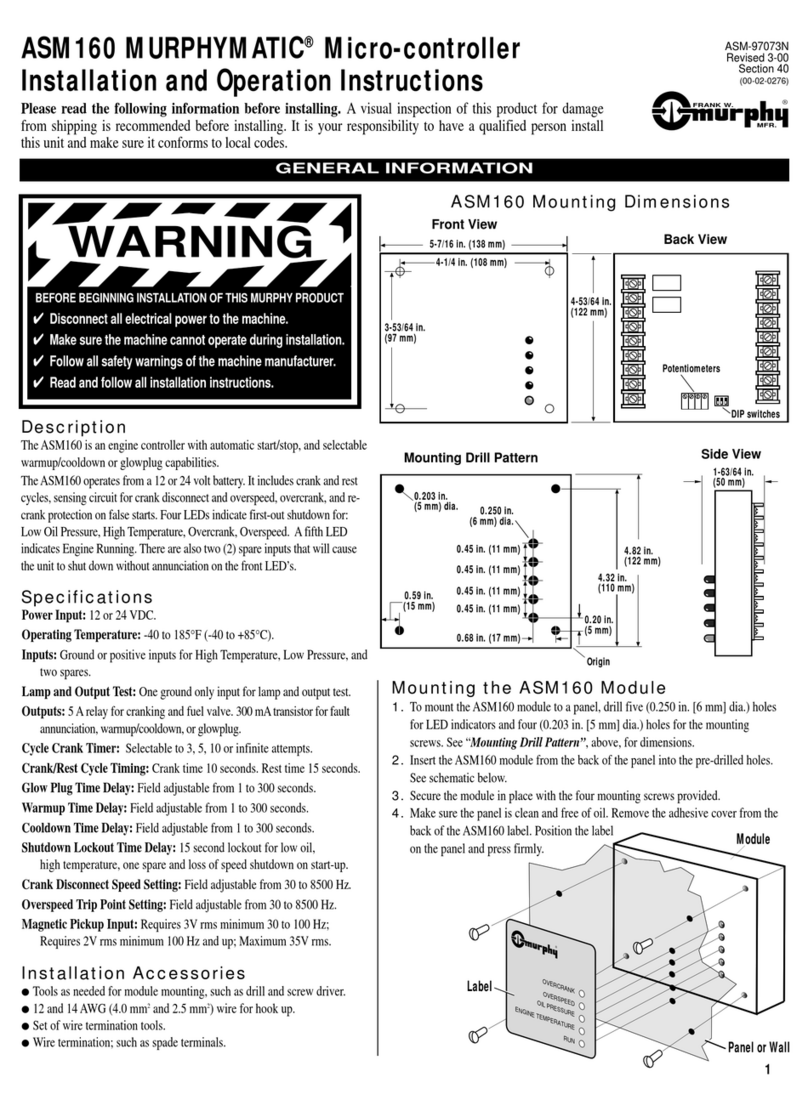

Overcrank Adjustments (DIP Switches)

The ASM150 allows you to crank the engine once and signal OVERCRANK if it

fails to start, or you can configure it to crank the engine several times before it sig-

nals OVERCRANK. See the “DIP Switch Setting Chart” (at right) for the number

of cranking attempts you would like to have for your specific application.

If you would like only one crank, move Switch 4to ON. Remember, that by

switching Switch 4ON, the ASM150 will only

crank one time. Now, move Switch 1through

Switch 3to the number you would like to multiply

the CRANK/REST TIME by and then add to the

CRANK/REST TIME. The formula for calcu-

lating single crank time is as follows:

Single Crank Time = (Crank/Rest Time

X

Dip

Switch Attempts) + Crank/Rest Time.

For example, if Switch 1through Switch 3were

all OFF and the CRANK/REST TIME is set to 10

seconds, then the single crank would be 20 seconds

because (10

X

1) + 10 = 20.

If Switch 1through Switch 3were all ON and the CRANK/REST TIME is set to

10 seconds, then the single crank would be 90 seconds because (10

X

8) +10 = 90.

You can also achieve a single crank by setting Switch 1through Switch 4to OFF.

However, this single crank can only range between 4 and 25 seconds depending on

the setting of the CRANK/REST TIME pot.

If the engine false starts and the ASM150 RE-CRANK's the engine, it will count

this as a cranking attempt. This way, if the engine false starts the same number of

times as your cranking attempts, then the unit will show OVERCRANK.

Please note: Switch 5is not used for any function on theASM150.

Crank Attempts Switch 1 Switch 2 Switch 3

1 OFF OFF OFF

2 OFF ON OFF

3 ON OFF OFF

4 ON ON OFF

5 OFF OFF ON

6 OFF ON ON

7 ON OFF ON

8ONONON