Description

The L150 Series Level SWICHGAGE®is a combination liquid

level gauge and low limit switch; each unit includes (1) a chamber

with pivotal float, (2) an indicating dial with pointer, and (3) a low

level contact. When properly installed and maintained, the float

operates the pointer which, in turn, both indicates level during nor-

mal operation, and closes a switching circuit if the level falls to the

low-limit set point.

Applications

The primary use of the L150/EL150K1 is for engine cooling sys-

tems, surge or expansion tanks, condenser radiator or vapor

phase systems, pressurized or atmospheric systems. The Level

SWICHGAGE®can also be used to monitor lube oil, hydraulic

fluid or diesel fuel reservoirs and activates alarms and/or shut-

down at a predetermined minimum level.

These instruments are built for low pressure systems with a

maximum of 25 psi (172 kPa) [1.72 bar].

Specifications

Level SWICHGAGE®Series

For Engine Liquids

L-6795B

Revised 10-99

Catalog Section 15

(00-02-0058)

L150/EL150K1 Series for Coolants,

Lube Oils, Fuel and Hydraulic Fluid

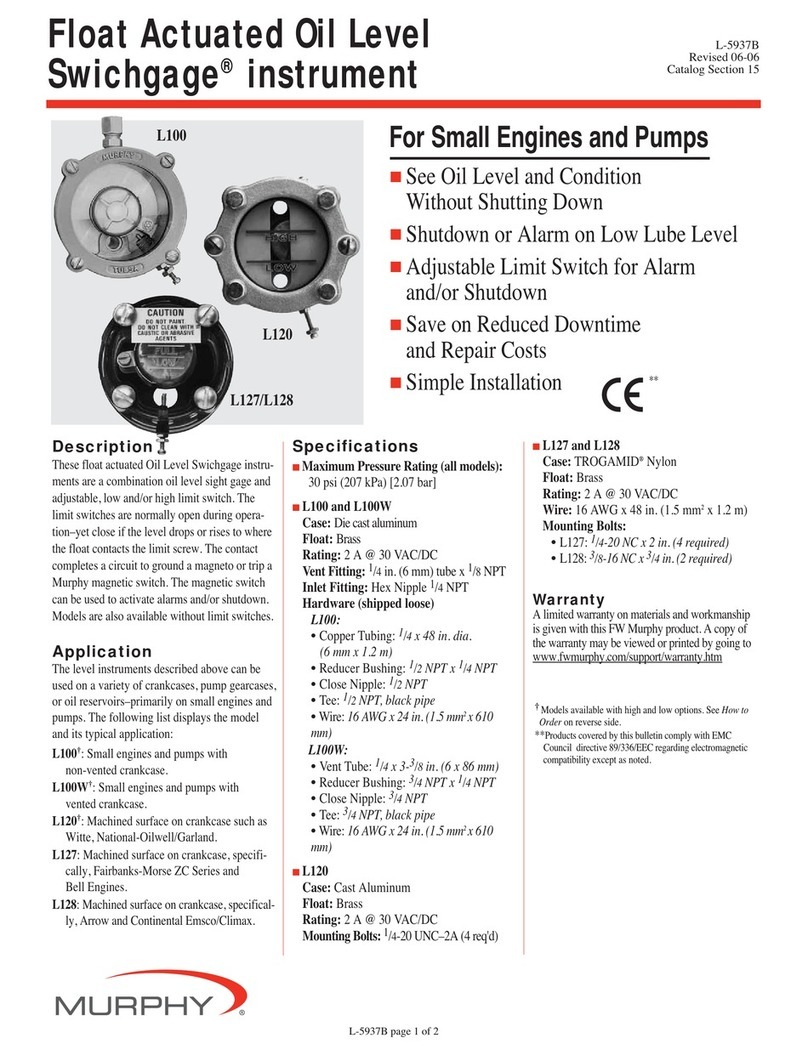

L150

Case: Die cast aluminum, poly-urethane coat-

ed; approximate dimensions; 4-1/2 x 4-3/4 x

2-3/4 in. (114 x 121 x 70 mm).

Mounting Holes: (2) 9/32 in. (7 mm) diameter

at 4-1/2 in. (114 mm) on center.

Float: Brass.

Lens: Polycarbonate.

O-rings: Saturated Nitrile, are suitable for

coolant or hydrocarbons. Maximum tempera-

ture 250°F (121°C).

Gasket: Neo-cork.

Vent Tube: 1/4 x 5 in. (6 x 127 mm) copper

cane with 1/4 NPT x 1/4 in. (6 mm) tube fitting.

Contact Rating: 2 A @ 30 VAC/DC.

Wire: (1) 16 AWG x 26 in. (1.5 mm2x 660 mm)

with terminals.

Shipping Weight: 29 oz. (0.82 kg.).

Shipping Dimensions: 5-1/4 x 5-1/4 x

5-1/2 in. (133 x 133 x 140 mm).

EL150K1

Case: Die cast aluminum, poly-urethane coat-

ed; approximate dimensions; 5 x 4-3/4 x 2-3/4

in. (127 x 121 x 70 mm).

Mounting Holes: (2) 9/32 in. (7 mm) diameter

at 4-1/2 in. (114 mm) on center.

Float: Brass.

Lens: Polycarbonate.

O-rings: Saturated Nitrile, are suitable for

coolant or hydrocarbons. Maximum tempera-

ture 250°F (121°C).

Gasket: Neo-cork.

Vent Tube: 1/4 x 5 in. (6 x 127 mm) copper

cane with 1/4 NPT x 1/4 in. (6 mm) tube fitting.

Snap-Switch: SPDT rated 10 A @ 125 VAC;

0.5 A @ 125 VDC; 10 A 30 VDC.

Wire: (3) 18 AWG x 14 in. (1.0 mm2x 356 mm).

Shipping Weight: 42 oz. (1.2 kg.).

Shipping Dimensions: 5-1/4 x 5-1/4 x

5-1/2 in. (133 x 133 x 140 mm).

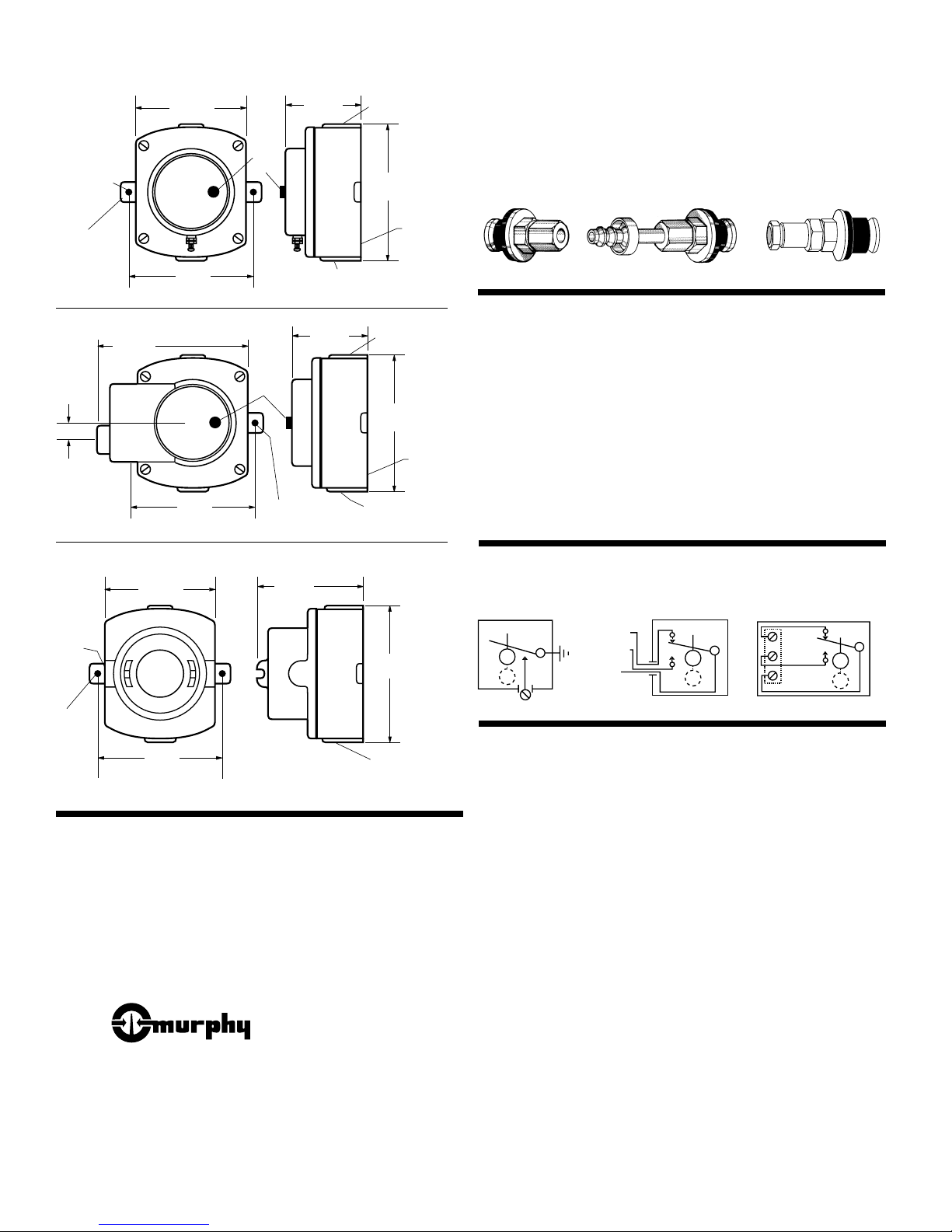

EL150EX

Case: Sand cast aluminum, painted;

approximate dimensions; 6-1/2 x 5-3/4

x 5-1/4 in. (165 x 146 x 133 mm).

Mounting Holes: (2) 5/16 in. (8 mm)

diameter at 5-1/2 in. (140 mm) on center.

Float: 304 Stainless steel.

Lens: Tempered glass.

O-rings: Saturated Nitrile, are suitable for

coolant or hydrocarbons. Maximum tempera-

ture 250°F (121°C).

Gasket: Neo-cork.

Vent Tube: 1/4 x 5 in. (6 x 127 mm) copper

cane with 1/4 NPT x 1/4 in. (6 mm) tube fitting

and 1/2 NPT to 1/4 NPT reducer fitting.

Snap-Switch: SPDT rated 10 A @ 125 VAC;

0.5 A @ 125 VDC; 10 A 30 VDC.

Wire: Wired to terminal block.

Shipping Weight: 5 lbs. (2.26 kg.).

Shipping Dimensions: 6-1/2 x 6-3/4 x6-3/8

in. (165 x 171 x 162 mm).