3/5/2010

7

IF YOU ORDERED A PARTIALLY ASSEMBLED KIT, BEGIN WORKING HERE:

____13. Use a medium (150 grit) sandpaper to smooth out all surfaces so they feel good to your

hand. Work the sandpaper with the grain so you don't scratch the surface.

Carefully check all the joints and glue seams to remove any glue residue that might remain visible,

because that will show up as ugly smudges under the finish.

____14. Sand the maple bridges to remove any rough spots. We like to leave the blackened insides

of the bridge “legs” for contrast. It looks great on the finished instrument.

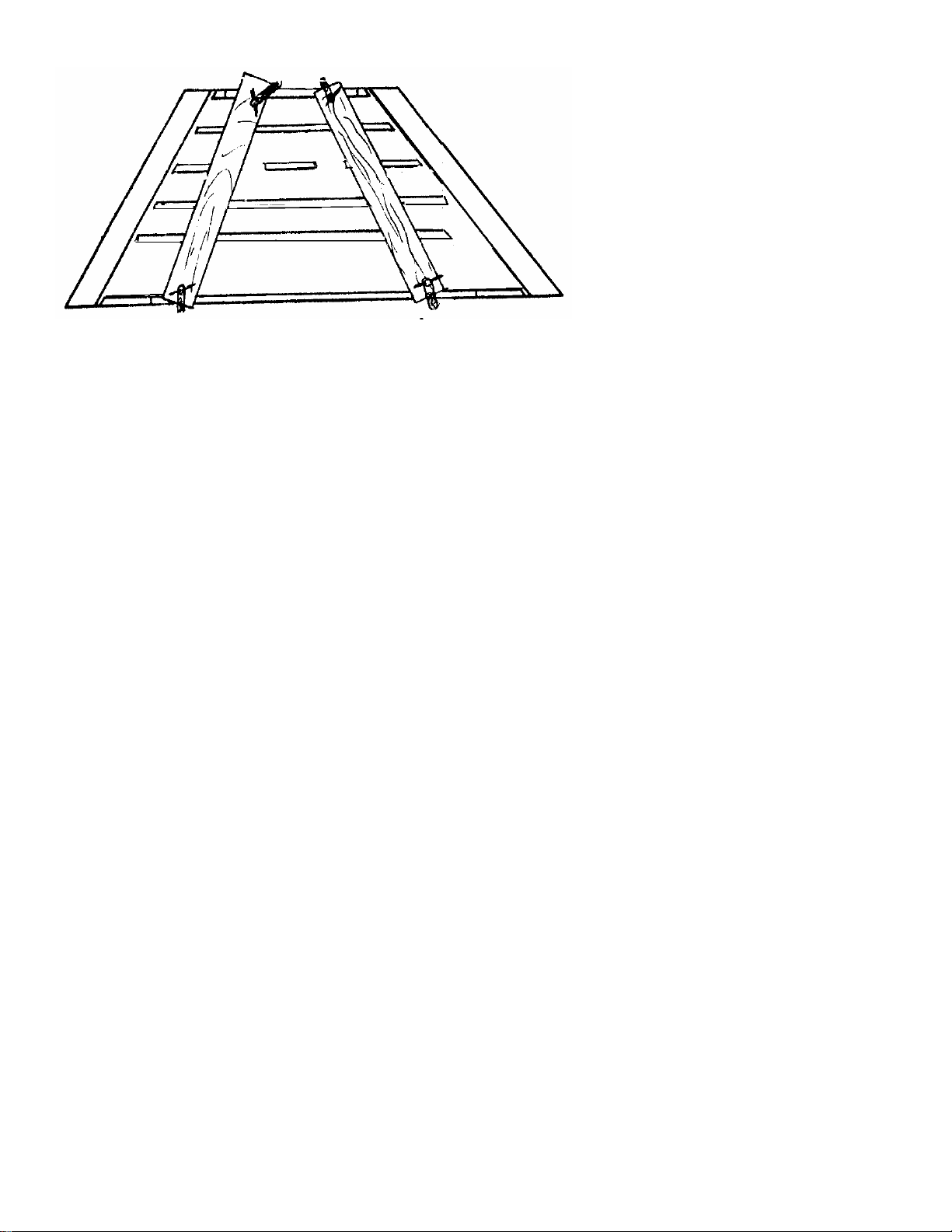

____15. Notice that the

bridges have a few tiny

holes drilled along the tops.

These are for marking dots

to help guide you in your

playing. You need to fill

these holes with short

pieces of the black delrin

(plastic) rod provided in the kit. Push one end of the delrin rod into a hole and clip it off as close to

the wood as you can with a wire cutter. Repeat this procedure for each hole.

CAUTION: IF YOUR KIT HAS SEVERAL PIECES OF BLACK DELRIN, BE SURE TO

LEAVE TWO PIECES LONG ENOUGH TO SPAN THE LENGTH OF THE TWO BRIDGES.

____16. Sand these marking dots smooth with the surface of the bridges.

____17. When satisfied with your sanding, apply the finish of your choice. Here are a few

suggestions:

STAIN -- STAINS are coloring agents and should only be used if you dislike the natural color of the wood. We

usually do not apply stains to our projects, especially when they are made with naturally beautiful hardwoods

such as mahogany, cherry or walnut. These woods look very nice with just a clear finish. But, if you want to

color the wood differently, your staining should be accomplished before applying a surface finish such as oil,

varnish, or lacquer.

OIL -- An oil finish will give your wood a low luster appearance, bringing out the natural color of the grain,

but it tends soak into the wood and appear dry and "thirsty" after awhile. The principal advantage of an oil

finish is that it can be applied and wiped dry immediately, so you can proceed to installing hardware (and

strings) right away. The disadvantages of oil are that it usually does not give much surface protection or

sheen, although there are some brands that include waxes and/or varnishes to give more surface build-up

and luster.

VARNISH -- Any regular varnish will work fine on this project, but we recommend our wipe-on polyurethane

called MUSICMAKER'S INSTRUMENT FINISH. Our complete finishing kit (code FINISHKIT) includes detailed

instructions, sandpaper sheets, along with a 1/2 pint can of wipe on gel urethane varnish. The advantages of

finish are its simple application, durability, and deep, soft luster.

LACQUER -- Many professional instrument makers still use lacquer for their finish. The most readily

available lacquer is called Deft Clear Wood Finish. It is best to purchase a can of liquid to brush on as a

sealer coat first, and then use an aerosol can of the same product to spray on the final coats. The advantage

of this finish is its quick drying time, but the disadvantage is the strong odor of the toxic lacquer fumes.

CAUTION: Lacquer finish will not work over Heat Transfer decorations -- it dissolves the toner.