© Musicmakers 6/29/2018

3

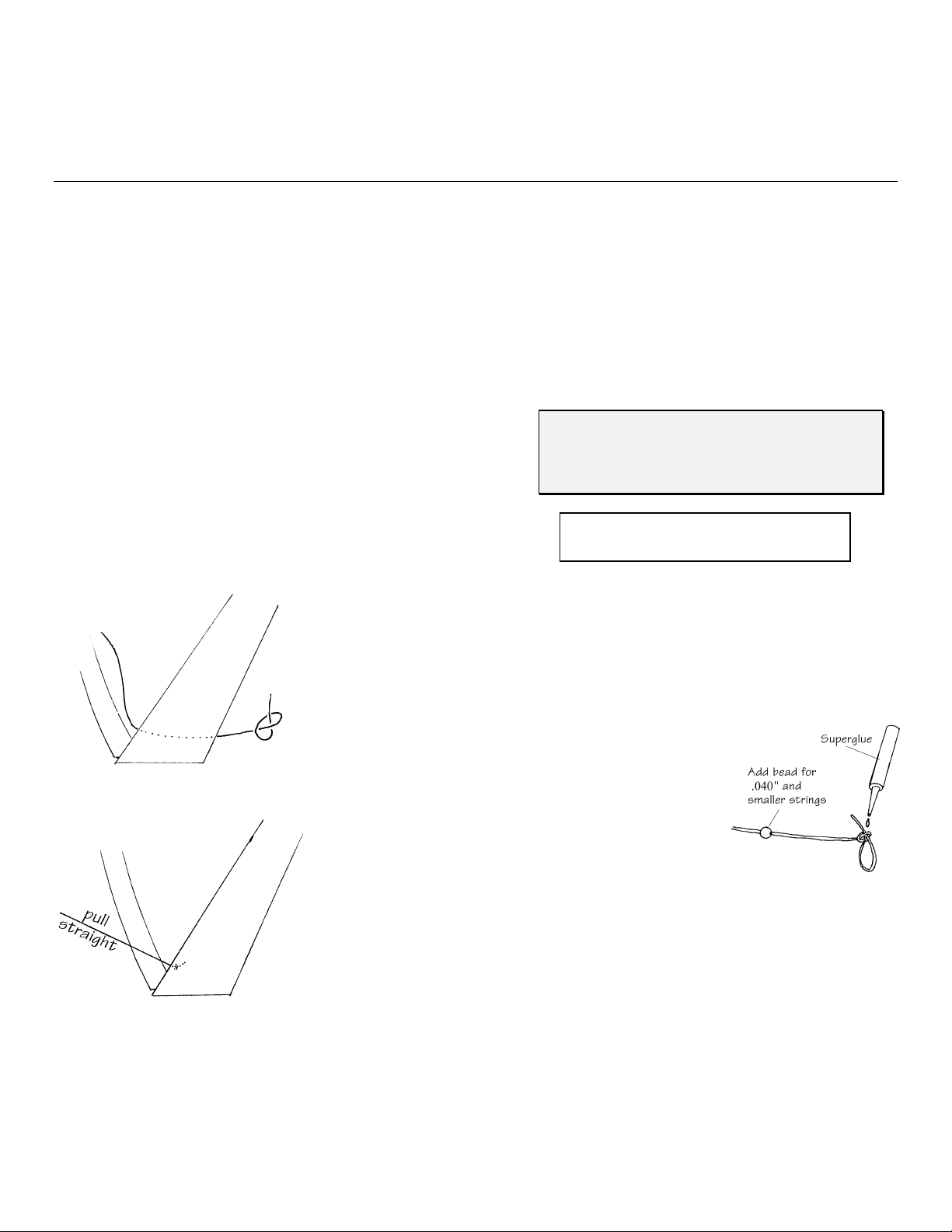

Thread the other end of the string through the last TUNING PIN at the point of the NECK. Pull it

through the PIN until there is some slack below the pin.

Turn the PIN clockwise with the tuning wrench and guide

the windings of the string downward toward the wood. As

the string begins to tighten, place it in the groove of the

GUIDE PIN.

HINT: Do not accumulate a lot of windings of string

around the TUNING PINS, especially in the bass. They

become bulky and cumbersome. If you find yourself with

that problem, turn the TUNING PIN backwards to unwind

the string and then pull more slack through the hole

before tightening again.

_____4. When you come to the .050” and higher strings, tie

the bottom knot a little differently to give it more bulk. Start

with the same overhand knot, but before tightening it; push

the loose end part way back into the knot, just to add one

more thickness of string to the knot.

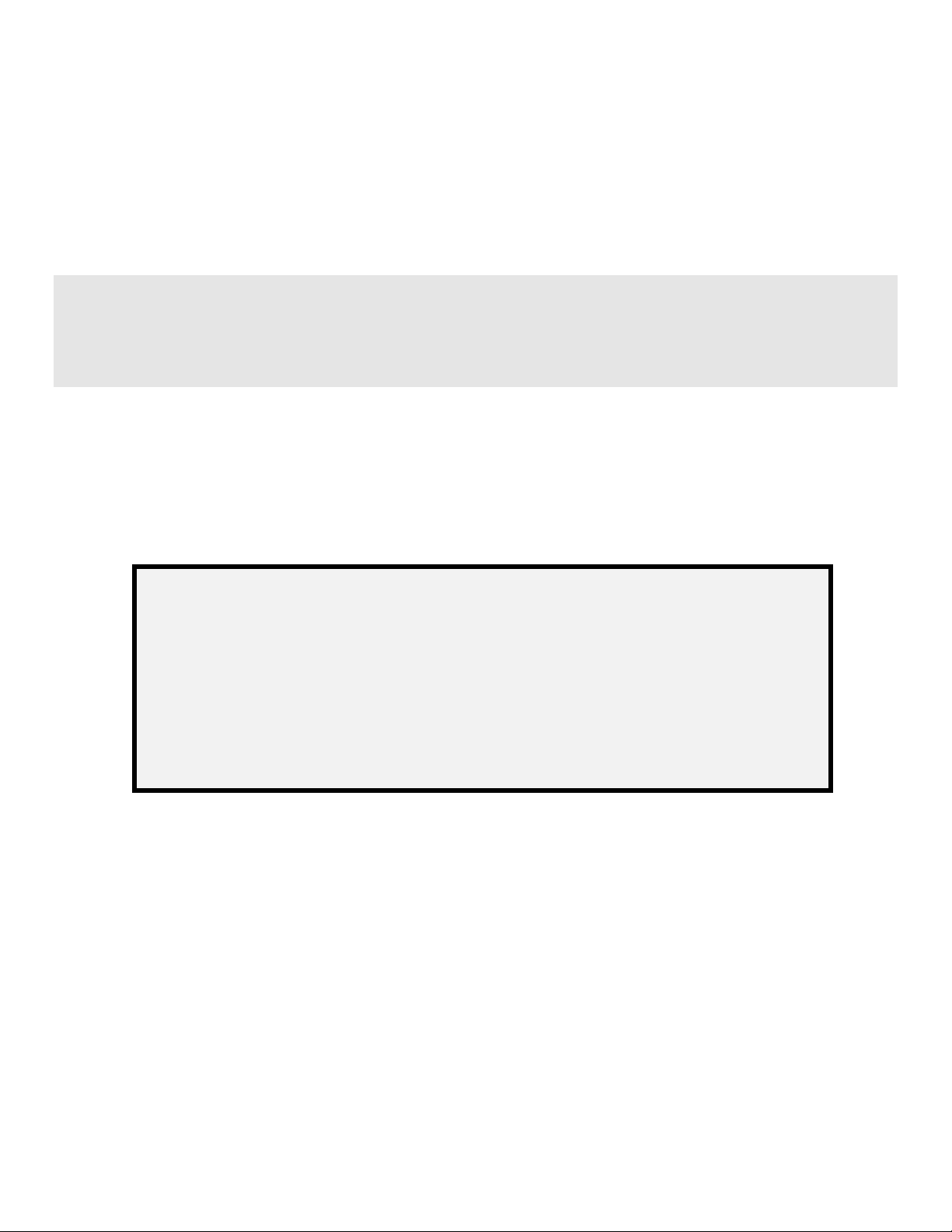

_____5. For the rest of the strings (sizes .040” and higher),

thread a small plastic bead onto each string before tying the

knot. The bead will prevent the knotted string from pulling

through the hole in the SOUNDBOARD.

ANOTHER HINT: We also like to anchor the tops of these

lighter strings securely to the tuning pins, as follows: Make

one or two windings of string around the tuning pin, then

cross the next winding over the others so the string is

holding itself tightly around the PIN. Otherwise we often

experience string slippage and breakage, especially in the

upper half of the instrument.

CAUTION: Nylon strings are somewhat fragile, especially in

the upper octaves. Try to avoid scratching them as you

install them. Most string breakage occurs at the tuning pin,

when the string is pulled forcefully around the sharp corner

of the small hole in the metal. You can minimize the problem by installing the string carefully and

by anchoring the windings before applying too much tension to

the strings, so the nylon does not begin to slip back through the

hole under tension and become scratched.

_____6. When you come to the lightest strings (.025”

diameter), you will need to add a short piece of heavier

string into the knot in order to make the knot bulky enough

to keep from pulling through the hole in the plastic bead.

Just use some scraps of excess nylon from the bottom

strings. When all the strings are installed, tighten them to

pitch and allow the instrument to adjust itself to the tension.