© 2008 Musicmaker’s Kits, Inc.

2

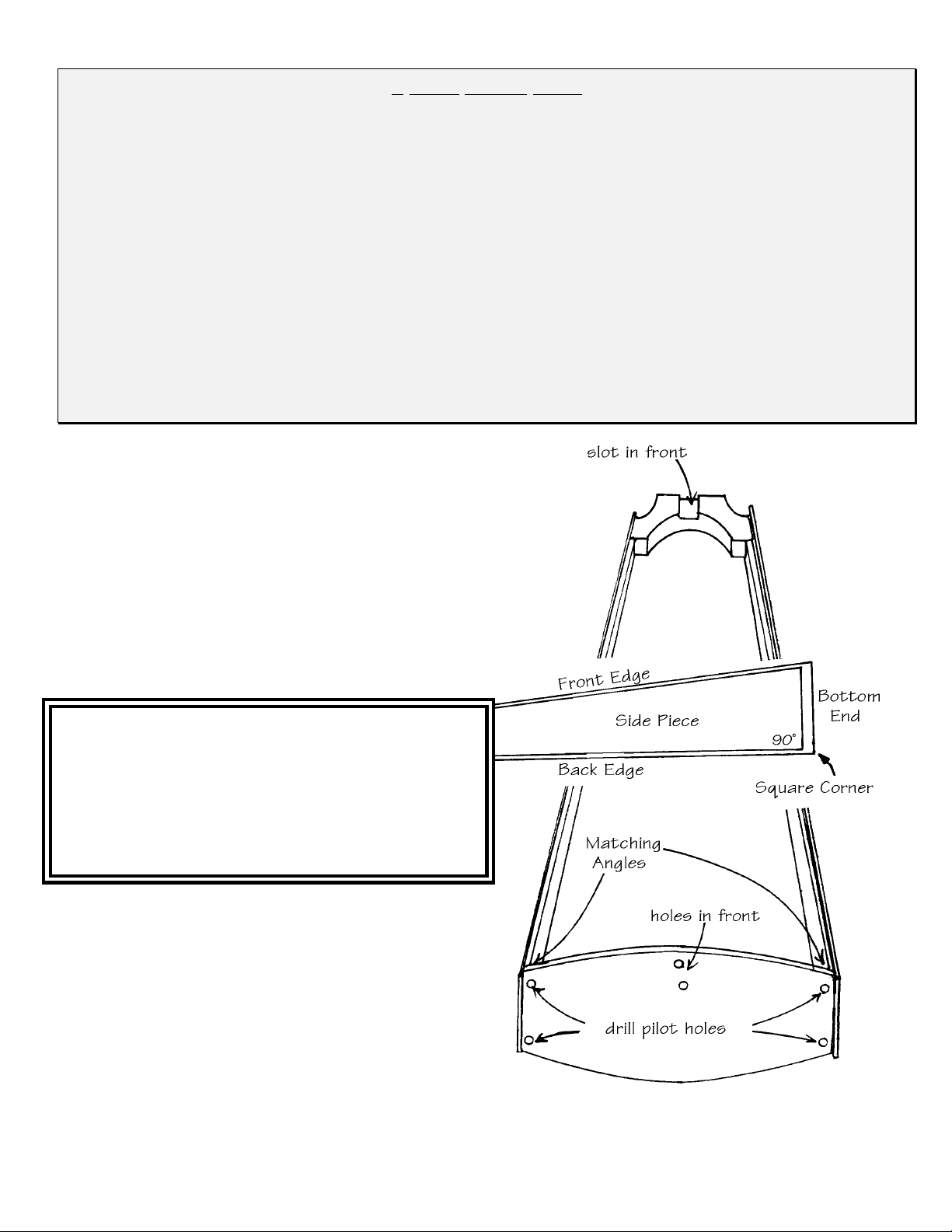

31 STRING GOTHIC HARP KIT

1 set of Assembly Instructions

WOOD PARTS:

1 soundboard, laminated birch

1 back panel, thin plywood

2 sides, solid hardwood

1 curved neck, laminated hardwood

1 pillar, laminated hardwood

1 shoulder, laminated hardwood

2 feet, solid hardwood

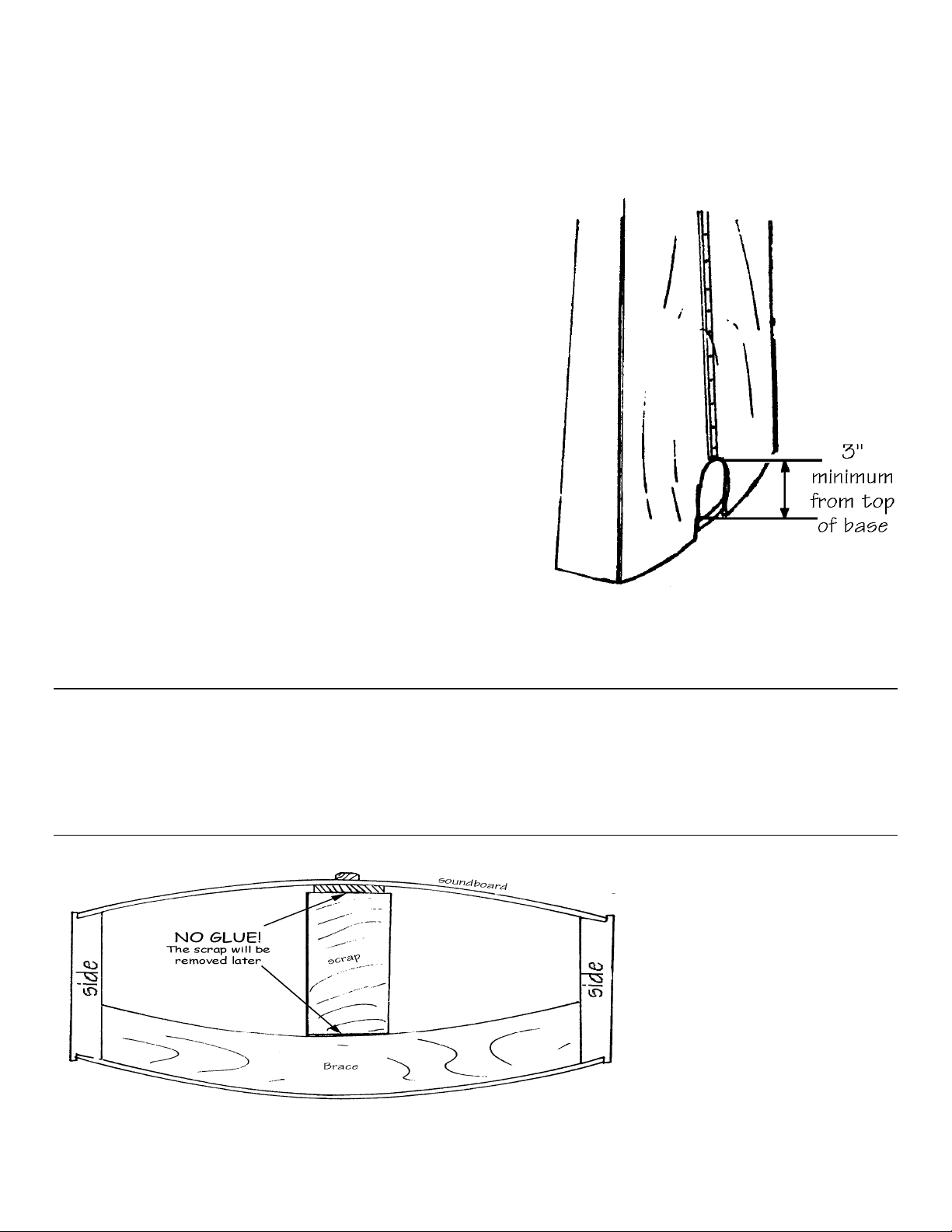

3 internal braces, hardwood

1 base, laminated hardwood

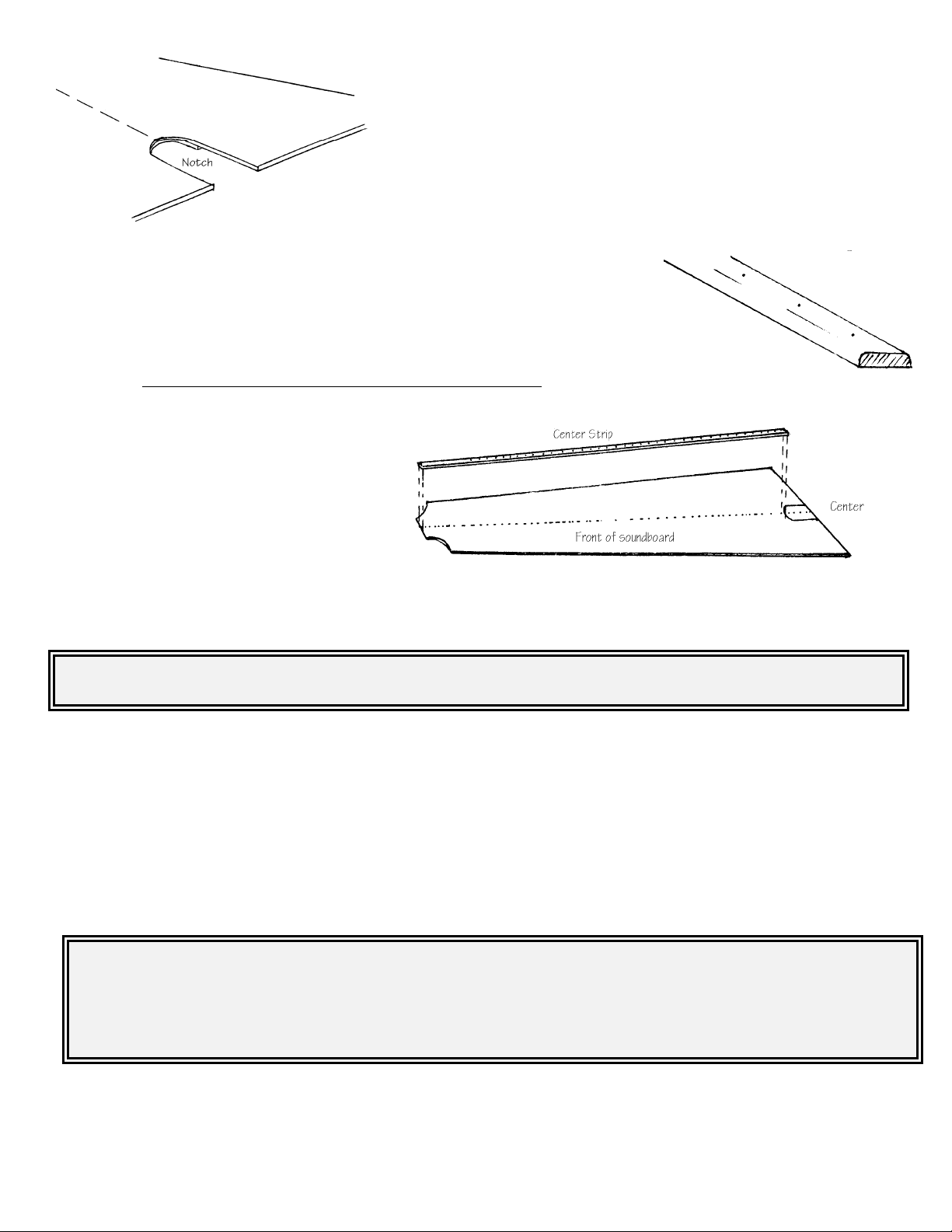

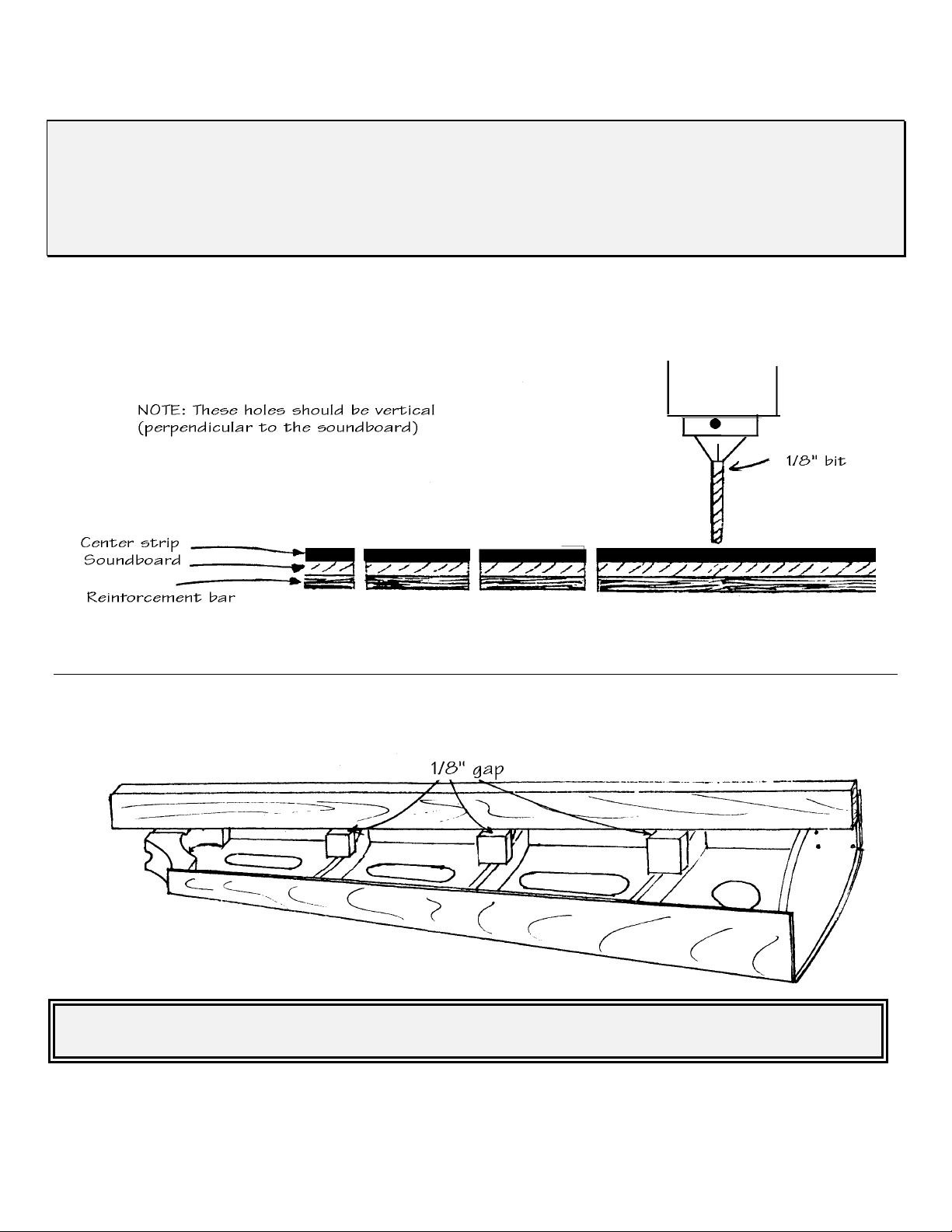

1 ctr strip for soundboard, hardwood

1 reinforcement bar, hardwood

1 hardwood dowel, 1" dia, 3-1/4" long

2 oval wood overlay pieces, hardwood

1 bottom trim strip, hardwood

6 stiffener battens (for back)

HARDWARE:

31 threaded harp pins

31 medium brass eyelets

31 threaded bridge pins

Allen Driver 5/64"

1 brass driver for threaded harp pins

4 wood plugs, 3/8" cherry

1 oz wire nails, 3/4" X 18

2 wood screws, 3" drywall

2 wood screws. 2" drywall

6 wood screws, 1-5/8" drywall

4 wood screws, 1" drywall

Spacing Guide

1 set of 31 harp strings

1 tuning wrench

1 drill bit, 1/8” (for eyelets)

8 ft of decorative inlay banding (Inlay J - 3 strips)

10 ft of iron-on veneer tape, cherry

1 small dowel pin, 1/4 X 2”

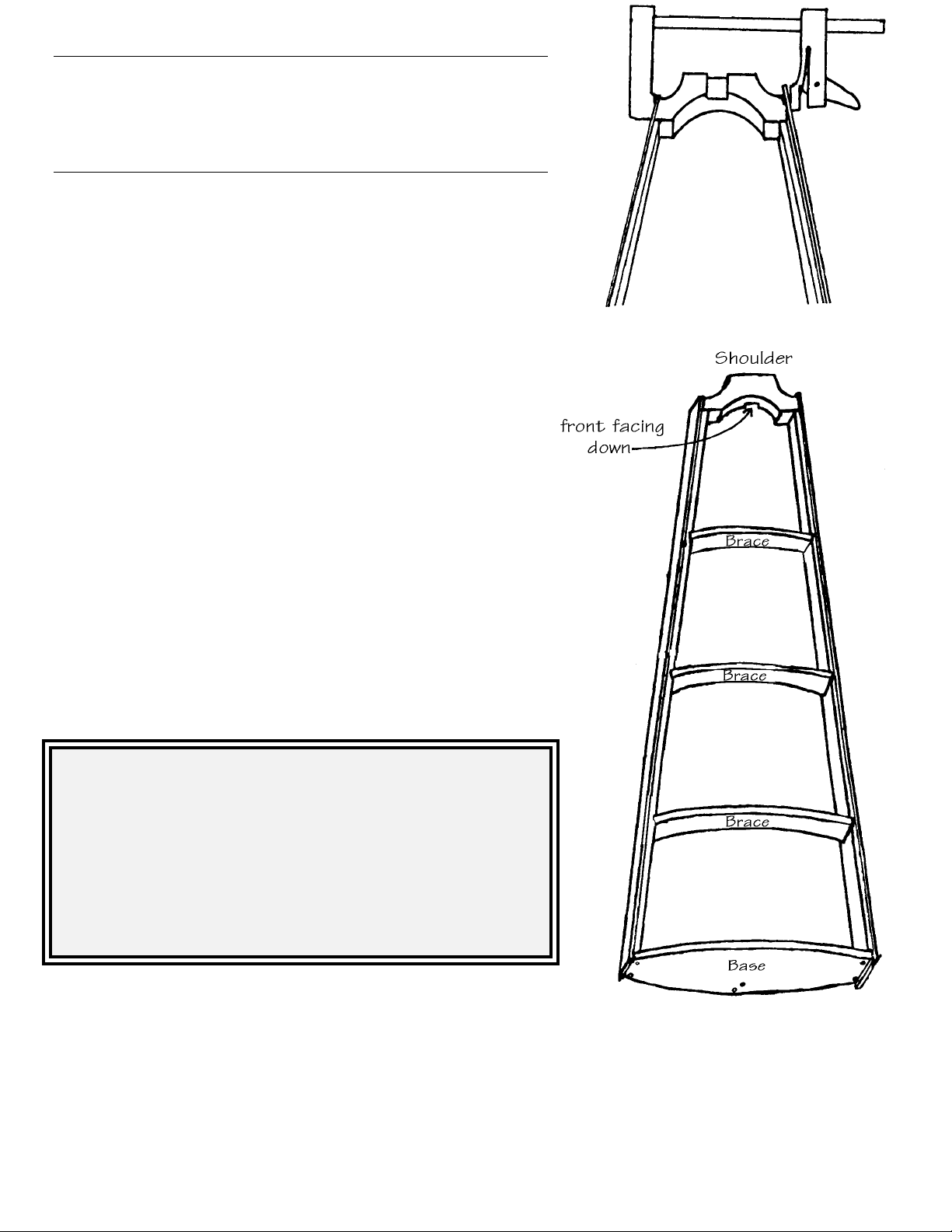

BEFORE YOU BEGIN

Please take the time to check over the parts of your kit now, to make sure everything is

there. If you discover a problem, call us right away so we can rectify it quickly without

causing you much delay in your project. We also suggest skimming through the entire

directions before beginning, just to get an overview of the project. You may decide that you

need to gather more tools or purchase a few optional decorations or accessories to enhance

the finished instrument. Now is a good time to decide so you can avoid delays when you

reach those steps of construction.

If you have any questions about the

assembly process – please visit our

online Builder’s Forum at

www.harpkit.com/forum