10.

FINAL SANDING & FINISHING

_____29. When you are satised with the t of all these parts, unscrew the bolts and screw so you can remove the

NECK and PILLAR for nal sanding and nishing.

Sand the entire harp with 180 grit sandpaper to smooth out all machine marks and remove any glue spots or

smudges on the outside surface. Use a sanding block where it is helpful, but just fold the sandpaper in your hand

for curved areas and inside corners. is is an important step, so take your time to inspect the entire surface care-

fully. Feel the wood surface with your bare hands to make sure it is smooth to the touch.

Don’t forget to sand the two FEET also!

Now you are ready to apply the nish. Here are some recommendations:

STAIN -- STAINS are coloring agents and should only be used if you dislike the natural color of the wood. We

oen like to stain this light-colored wood, but it is certainly not necessary. If you decide to color the wood, it is

easiest to color all the parts the same. It is more dicult to mask o the soundboard, for instance, and just stain

the sides and back of the harp body because the stain tends to “bleed” under the masking tape. If you are a novice

at nishing, or facing a deadline for completion, we recommend skipping the stain altogether.

OIL -- An oil nish (such as Watco Danish Oil) will give your wood a low luster appearance, bringing out the

natural color of the grain, but it tends soak into the wood and appear dry and “thirsty” aer awhile. e principal

advantage of an oil nish is that it can be applied and wiped dry immediately, so you can proceed to installing

hardware (and strings) right away. e disadvantage of oil is that it usually does not give much surface protection

or sheen, if that is important to you.

VARNISH -- Any regular varnish will work ne on this project, but we recommend the wipe-on Gel Topcoat

polyurethane from General Finishes. is is what we supply in our Finishing Kit. e advantages of this nish are

its simple application (no drips or runs), durability, and deep, so luster.

LACQUER -- Many professional instrument makers still use nitro-cellulose lacquer for their nish. e most

readily available lacquer is called De Clear Wood Finish. It is best to purchase a can of liquid to brush on as a

sealer coat rst, and then use an aerosol can of the same product to spray on the nal coats. e advantage of this

nish is its quick drying time, but the disadvantage is the strong odor of the toxic lacquer fumes. CAUTION:

Lacquer nish may smear some painted decorations or blister some types of decorative decals. If you plan to add

such ornamentation to your instrument, it would be better to nish with polyurethane varnish instead of lacquer.

_____30. So choose your weapon and proceed with nishing all the wood parts. Don’t forget the Feet! Plan on

applying at least three coats of nish unless you are using Danish Oil. Be sure to follow the directions on the can.

_____31. Once the nish is dry and you like the results, you are ready to install the FEET on the bottom of the

body and bolt the NECK and PILLAR back in place.

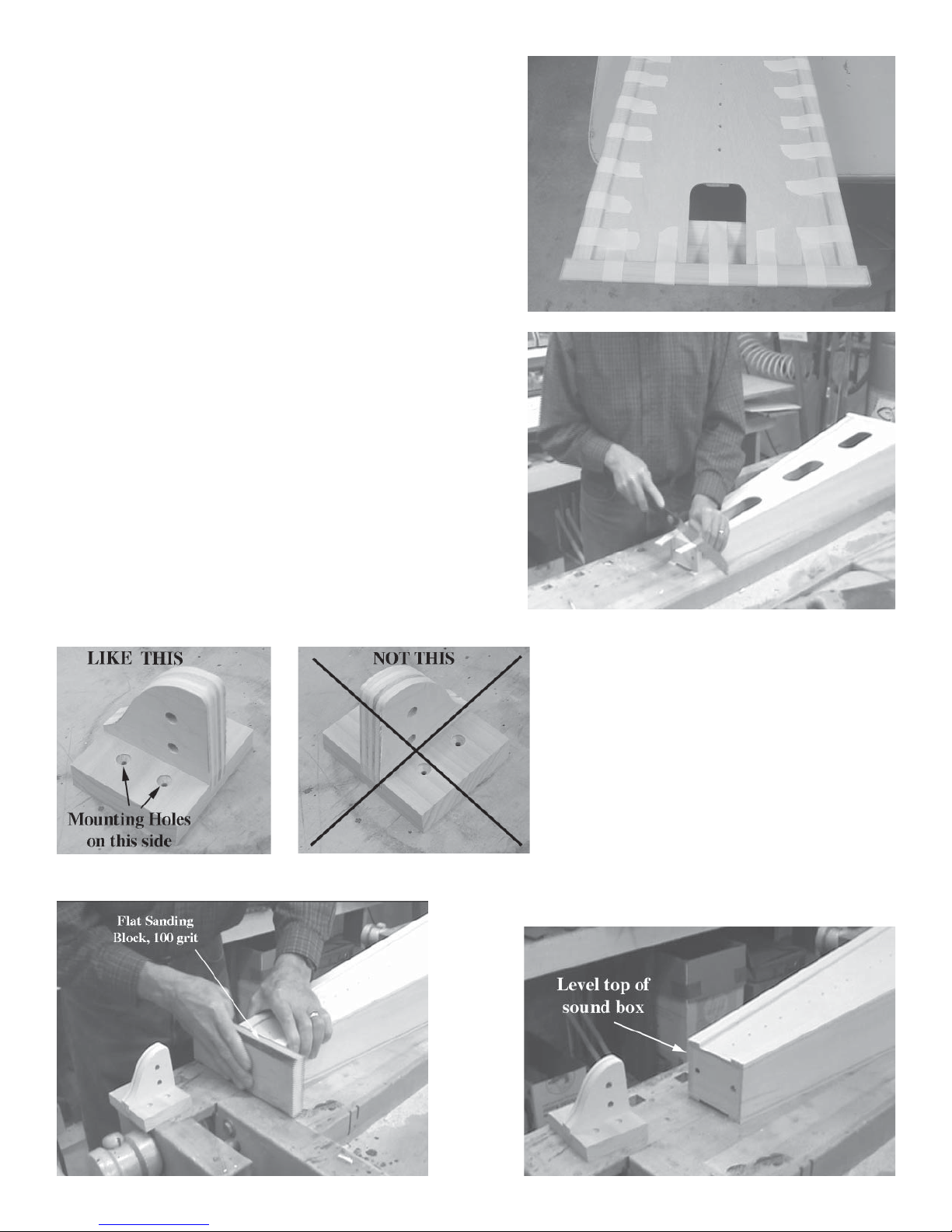

Install the 2 1/2” wood screws in the pre-drilled holes in the

feet so that just the tip is protruding from the BOTTOM.

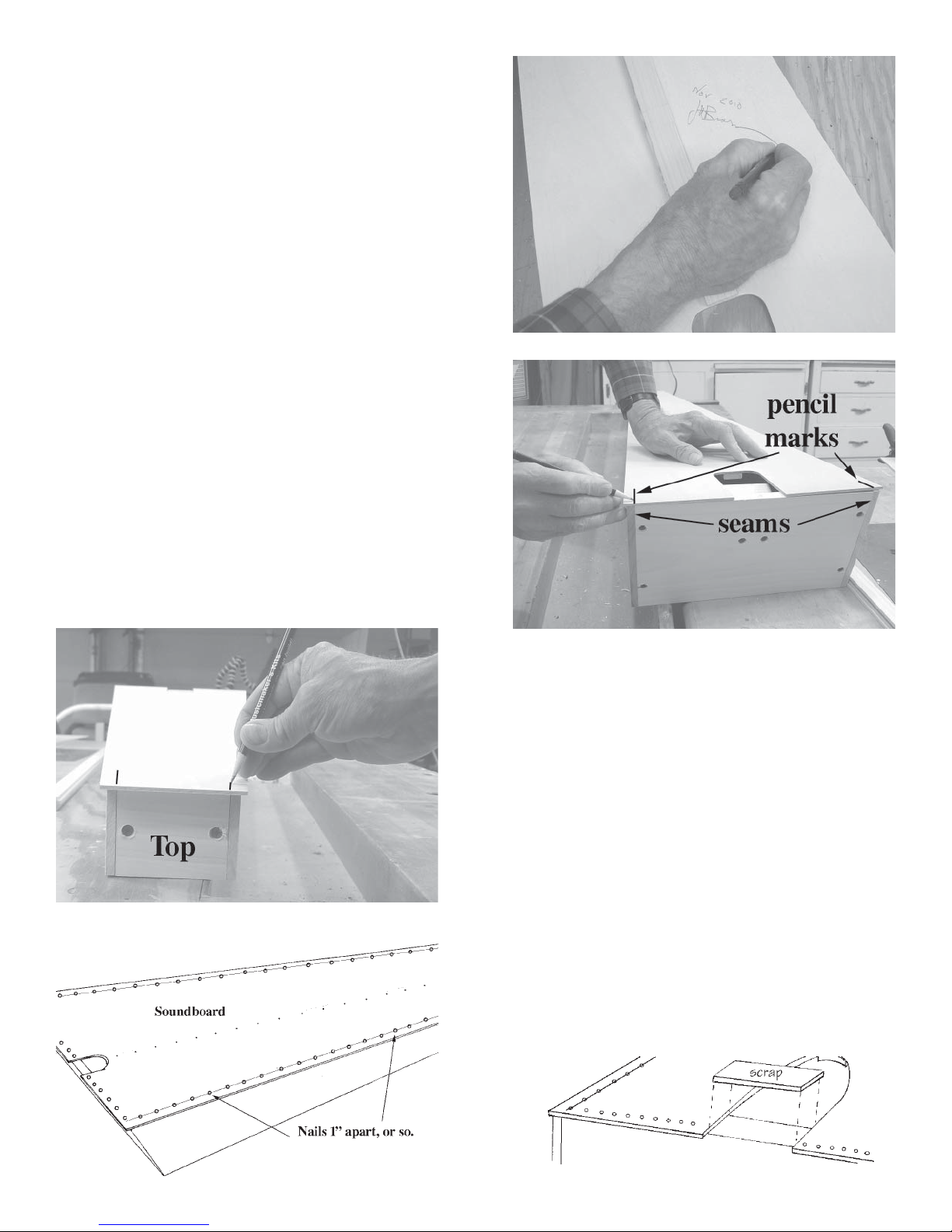

Line the FEET up along the seam between the base of the

harp and the edge as shown in the picture.

ere are 2 surfaces on each foot that will make contact with

the ground. Orient the foot so that the larger contact surface is

coming out the back of the harp.

When the foot is properly aligned - press down rmly enough

for the protruding screws to make punch marks in the BASE.

HINT: It is helpful to pad your work table with an old

towel when you do your sanding. is will prevent adding

scratches and smudges from the table surface as you work.