10/3/2006

7

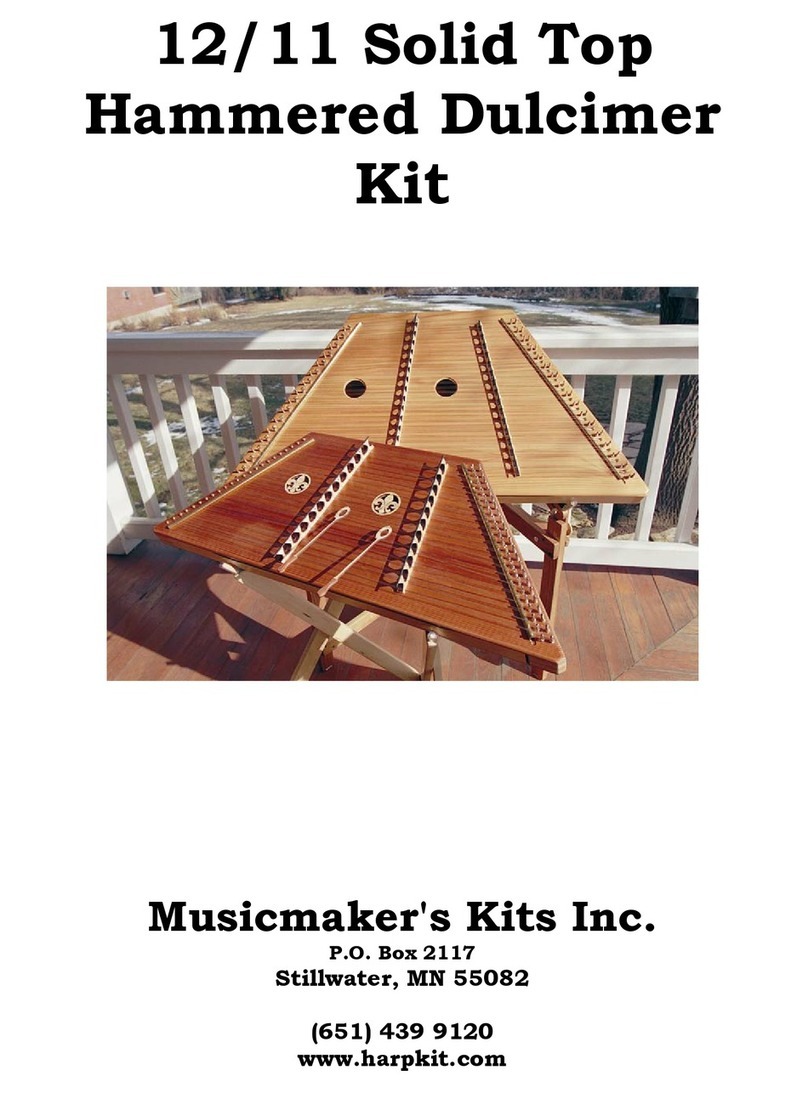

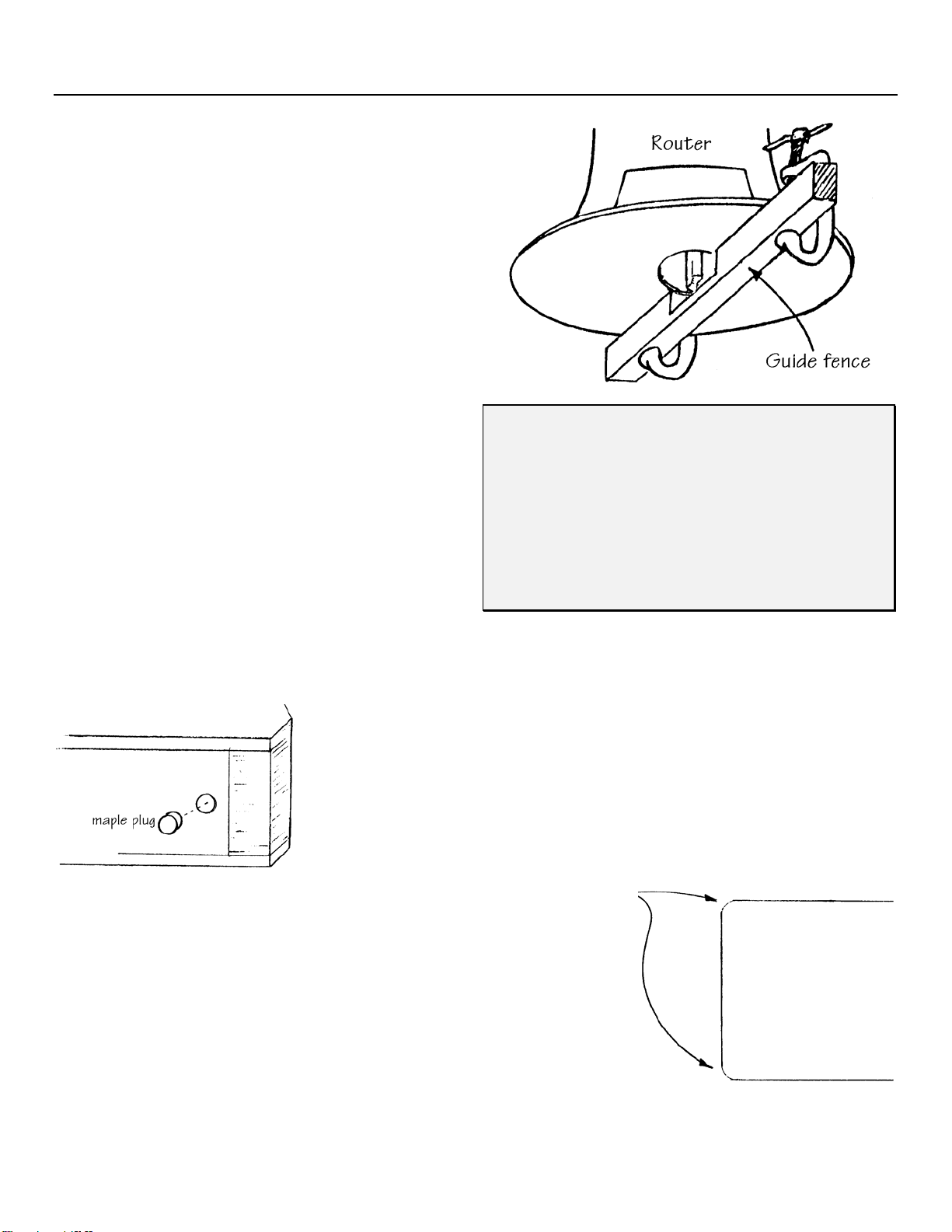

____8. When the soundholes are done, and the dulcimer box is dry, you can test fit

the two together. Please note that the SOUNDBOARD, like the BACK, is cut slightly

oversize, just to make sure it covers the entire frame. Try to position it evenly,

however, because the locations of the tuning pins and hitch pins are already marked

on the wood for you. The goal is to have equal overhang all around the frame.

Check for dried glue blobs or uneven surfaces that might interfere with a good fit of

the SOUNDBOARD on the dulcimer frame. When satisfied with the fit, glue the

SOUNDBOARD to the frame and the TONE BAR, using plenty of clamps and/or weights to

ensure complete contact all the way around the instrument. Look for glue squeezing out as a

sign of good contact.

Pad the jaws of your clamps with wood

blocks to prevent damage to the soft

cedar top. If you are a little short on

clamps, lay long pieces of stiff wood

around the perimeter of the box and

fasten your clamps down against them to

distribute the pressure.

CUSTOM SOUNDHOLES

If you would rather design your own soundholes, this is a good place to be creative,

making your instrument unique. We have tried a number of different sizes and shapes of

holes, and they all work fine.

Draw out your ideas on paper first, then cut them out and try positioning them on the

soundboard to see how they would look. Transfer the design to the wood with carbon paper,

and use a FINE TOOTH jigsaw blade when cutting the wood. Further decoration can be done

with wood overlay of a contrasting color, or with decorative binding around the edges of the

hole, or hand painting, stenciling, heat transfer designs, etc.

Now is a good time to sign

your name to your

instrument. Put your

signature, date, location, and

any message you have for

posterity on the inside of the

back where it can be seen

through one of the

soundholes.

POINT OF INTEREST

Some people ask about finishing the inside of the

soundchamber. We do not recommend trying it. Guitars

and violins are not finished on the inside, so this

instrument need not be sealed on the inside either. We

understand people’s concern about the effects of humidity

on the wood, but even the best varnish or lacquer does not

hermetically seal the wood. It blocks spilled milk from

soaking in, but it does not prevent the wood from

“breathing” moisture vapor from the surrounding air.